Semiconductor wafer liquid-spraying etching system and method

A semiconductor and wafer technology, applied in the field of semiconductor wafer spray etching system, can solve the problems of poor etching uniformity, inability to adjust, affecting the quality of chip processing, etc. The effect of etching efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] refer to Figure 7 , the present invention also provides a semiconductor wafer liquid spray etching method based on the above-mentioned semiconductor wafer liquid spray etching system, one embodiment of which includes the following steps:

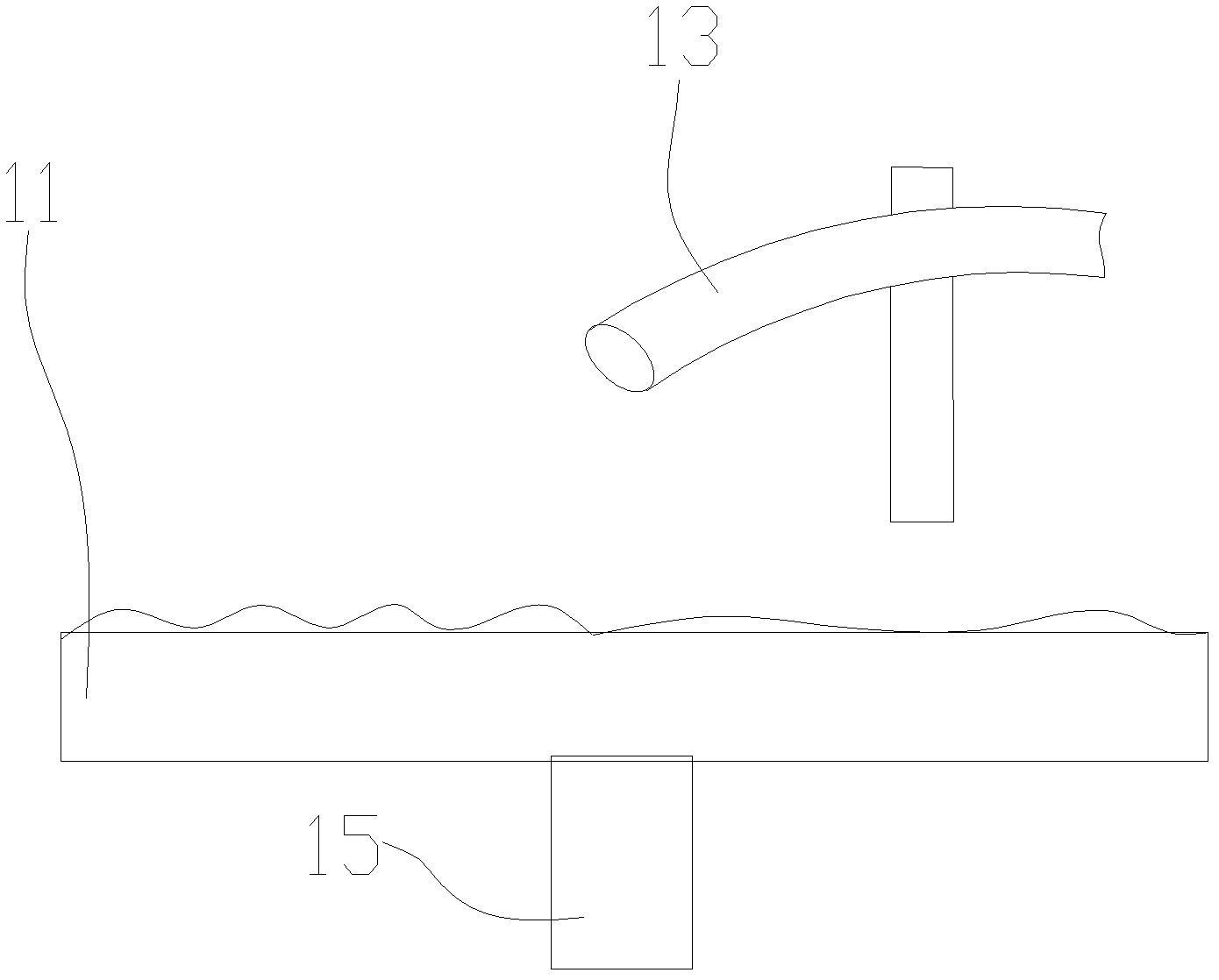

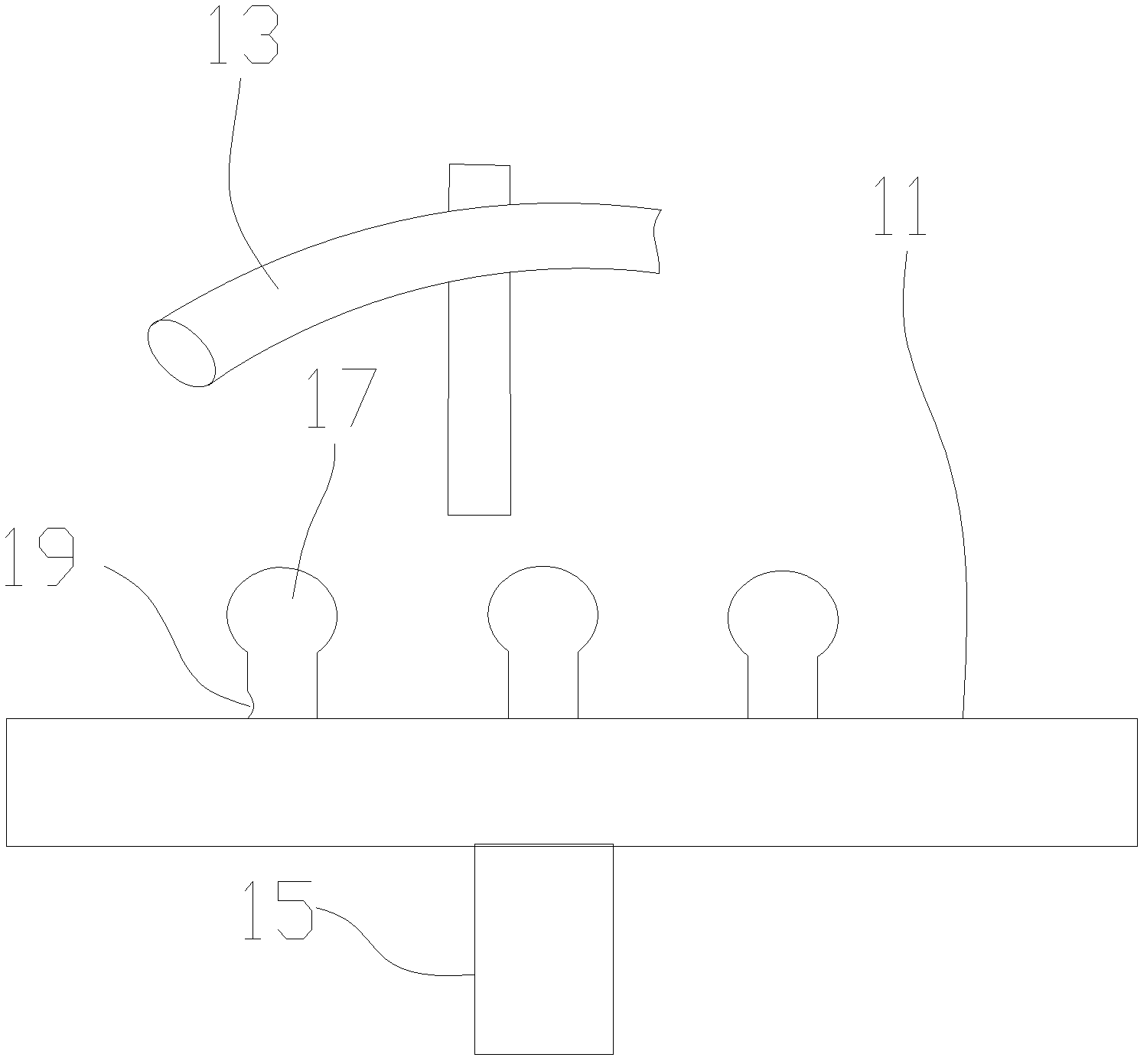

[0029] Step S1 : Fix the semiconductor wafer 11 with its surface to be etched facing down on the stage device 20 , and control the rotation of the semiconductor wafer 11 through the stage device 20 .

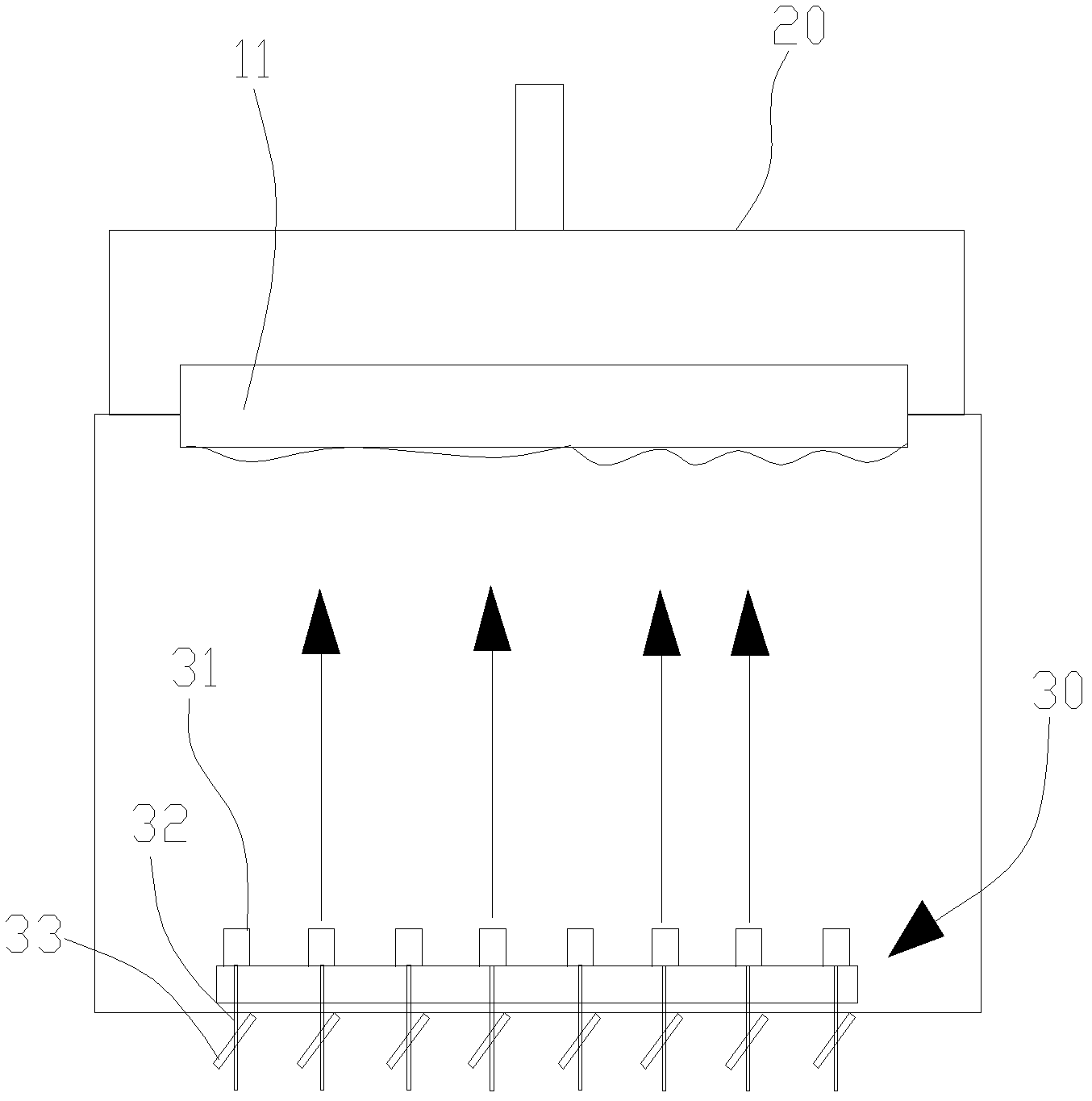

[0030] Step S2: adjust the flow rate of each nozzle 31 on the spraying device 30 through each control member of the spraying device 30, and spray the etching solution upwards to the corresponding position of the surface to be etched of the semiconductor wafer 11 through the above-mentioned multiple nozzles 31.

[0031] Optionally, in step S2, in the semiconductor wafer liquid jet etching method, the flow rate of the nozzles is controlled by operating the solenoid valves 33 provided on the delivery pipes 32 of the nozzles 31 .

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com