Solar cell panel electrode removing device and method

A solar cell and electrode technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of no recycling, waste of resources, increased production costs, etc., to avoid uneven removal of electrodes, avoid The problem of inscribed corners, the effect of improving electrode removal efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] The present invention also provides a solar cell spray electrode removal method based on the above-mentioned solar cell electrode removal device, one embodiment of which includes the following steps:

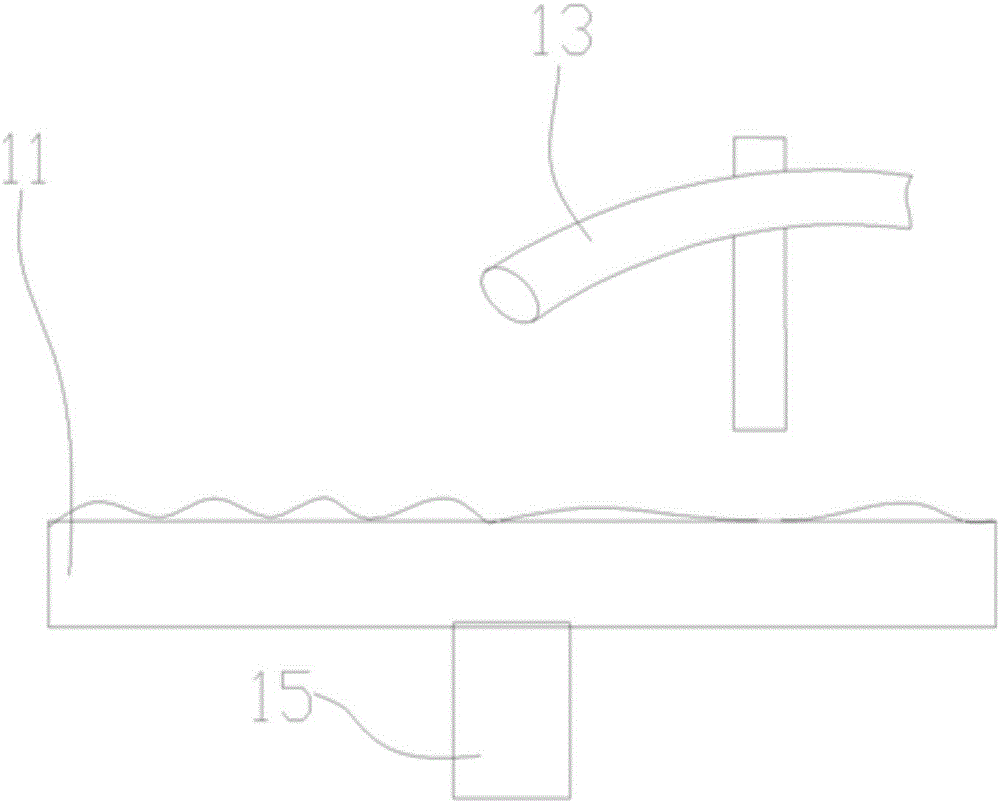

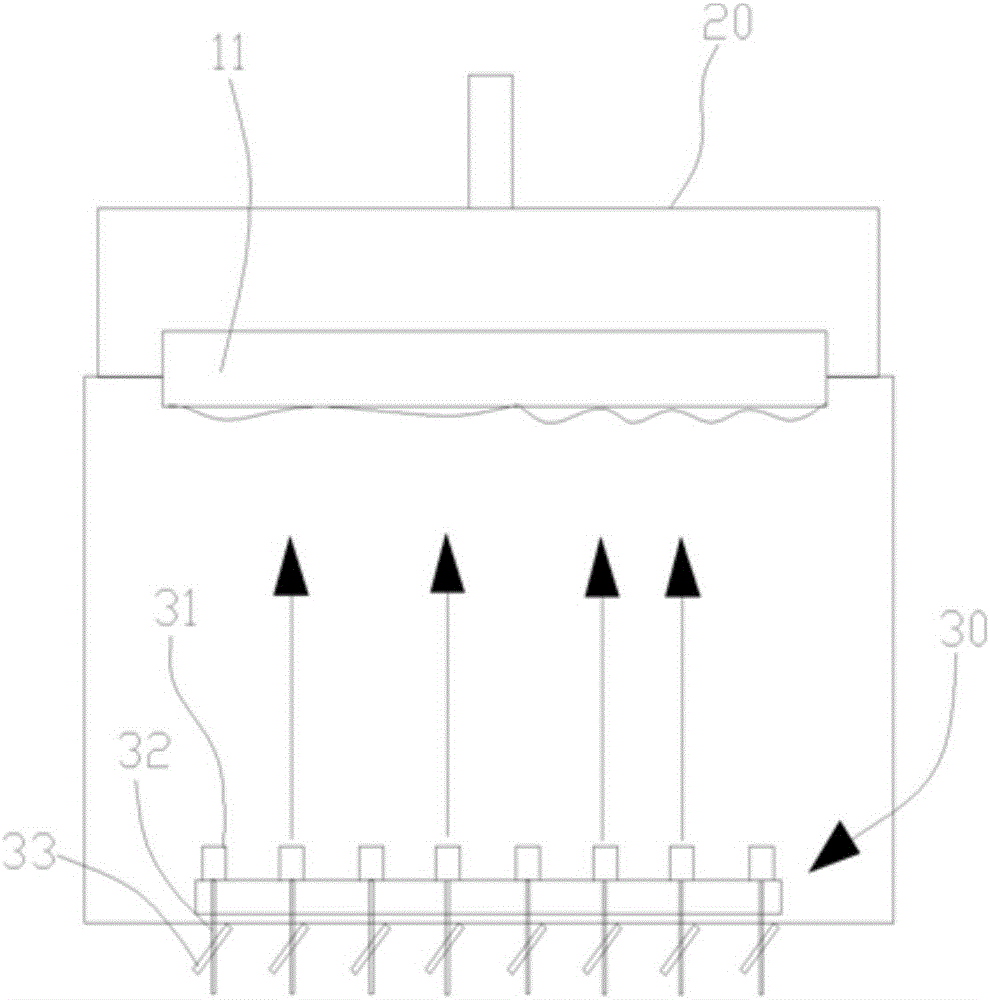

[0028] Step S1 : fix the solar cell 11 with the surface to be removed facing downward on the suction cup 20 , and control the rotation of the solar cell 11 through the suction cup 20 .

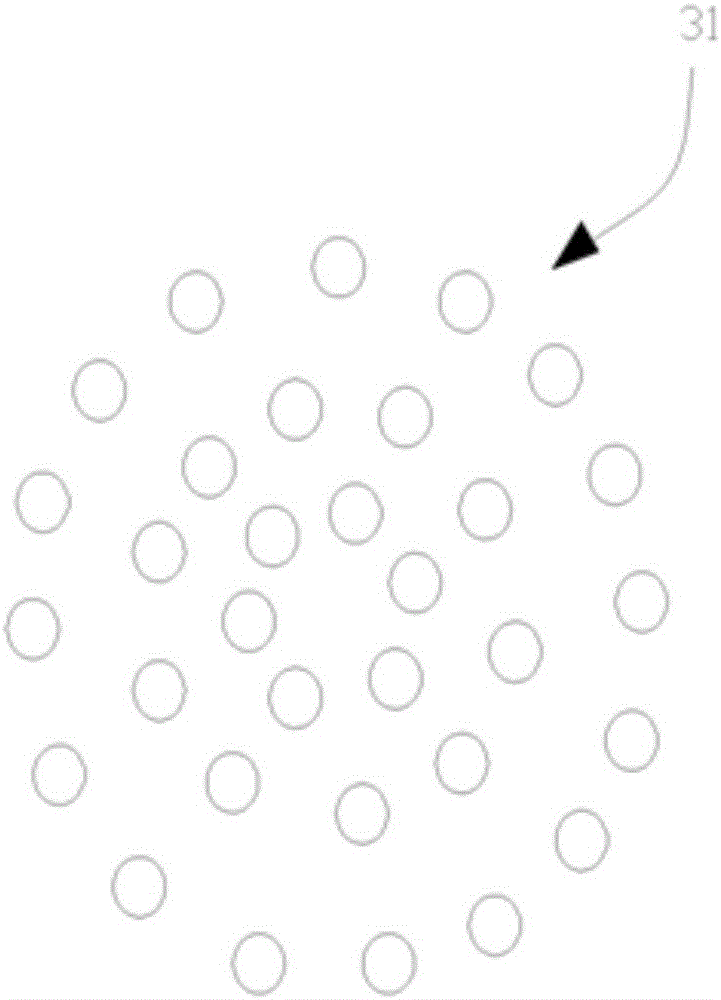

[0029] Step S2: Adjust the flow rate of each nozzle 31 on the liquid spraying device 30 through each valve of the liquid spraying device 30, and spray the electrode corrosion solution upwards to the corresponding position on the surface to be removed of the electrode of the solar cell sheet 11 through the above-mentioned multiple nozzles 31.

[0030] Optionally, in step S2, the method for removing the sprayed electrodes of solar cells controls the flow rate of the nozzles by operating the solenoid valves 33 provided on the delivery pipes 32 of the nozzles 31 .

[0031] In the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com