Manufacturing method of micro-fluid channel

A microfluidic channel and microchannel technology, applied in the field of microfabrication, can solve the problems of easily polluting the environment, cumbersome, high cost, and achieve the effects of fast and simple preparation process, improved etching efficiency, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

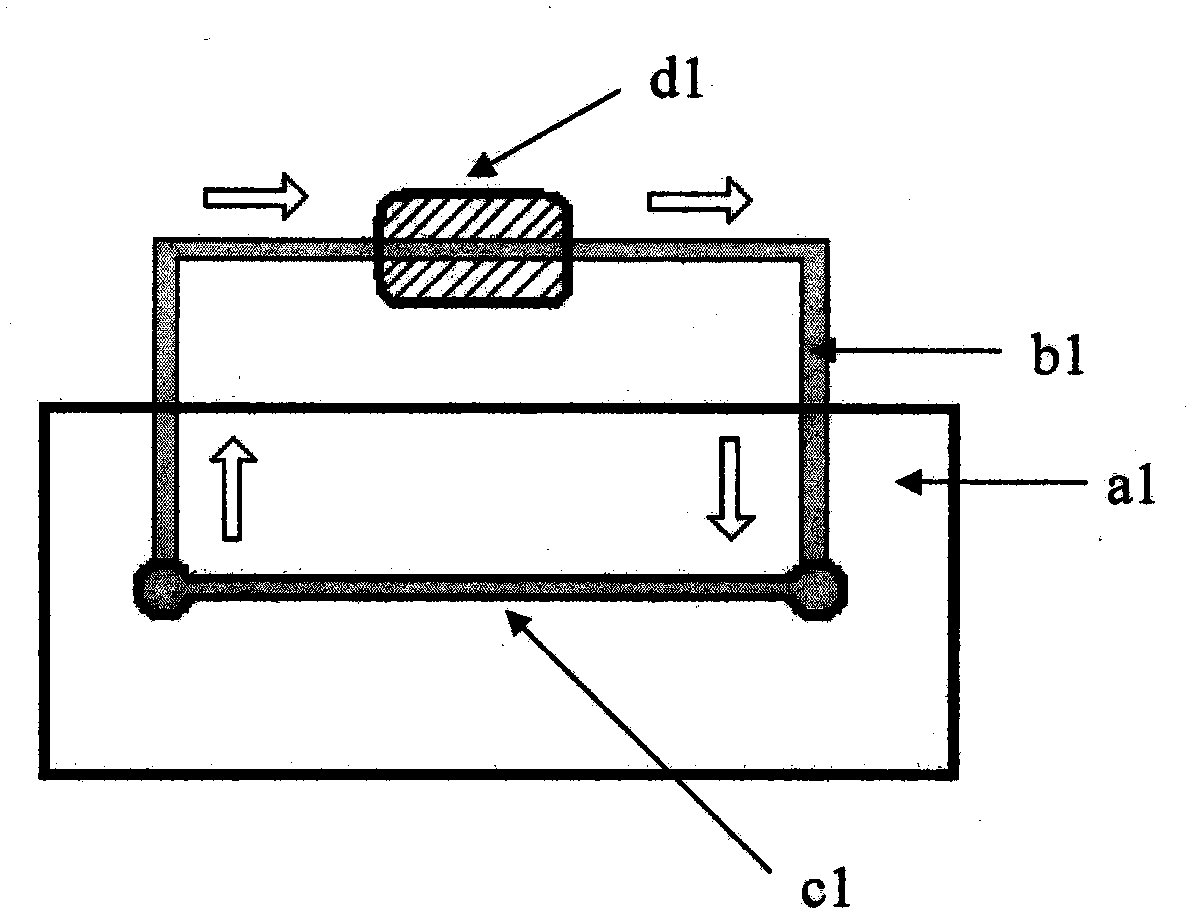

[0023] Embodiment 1 Preparation of a linear glass microchannel

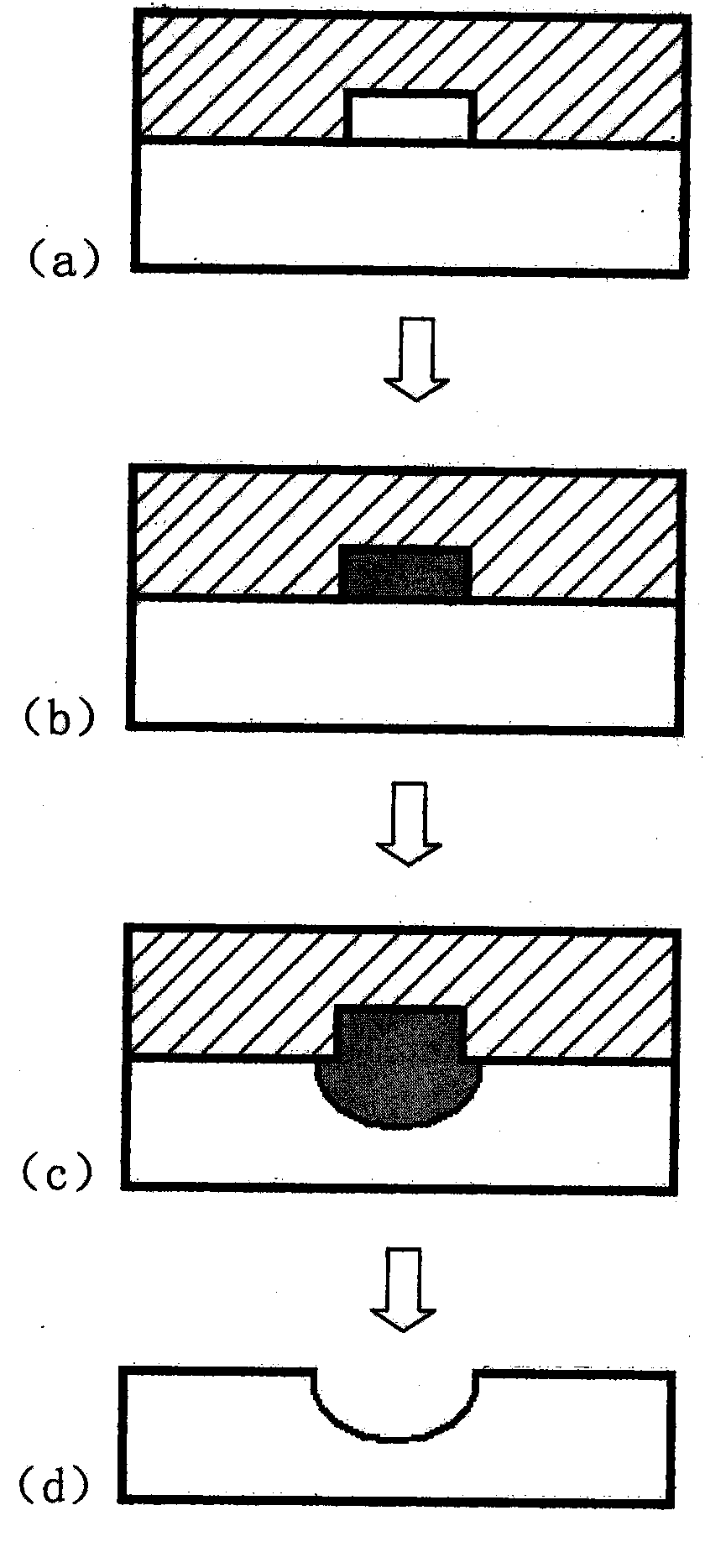

[0024] figure 1 It is a schematic diagram of the processing process of a microchannel provided by the present invention. The specific preparation process is as follows: firstly, a microchannel structure is processed on a smooth and flat polytetrafluoroethylene substrate using precision numerical control CNC engraving technology, and then the substrate and the surface of the flat glass to be processed are reversibly bonded ( figure 1 a); Then use the external peristaltic pump system to continuously introduce the hydrofluoric acid etching solution into the microchannel along a polytetrafluoroethylene hose ( figure 1 b); Hydrofluoric acid etchant etches the area where the microchannel is located on the glass substrate to the desired depth ( figure 1 c); Finally, the polytetrafluoroethylene substrate is peeled off from the surface of the glass substrate to obtain a glass microchannel.

[0025] More specifically, t...

Embodiment 2

[0026] Embodiment 2 Preparation of a cross-shaped glass microchannel

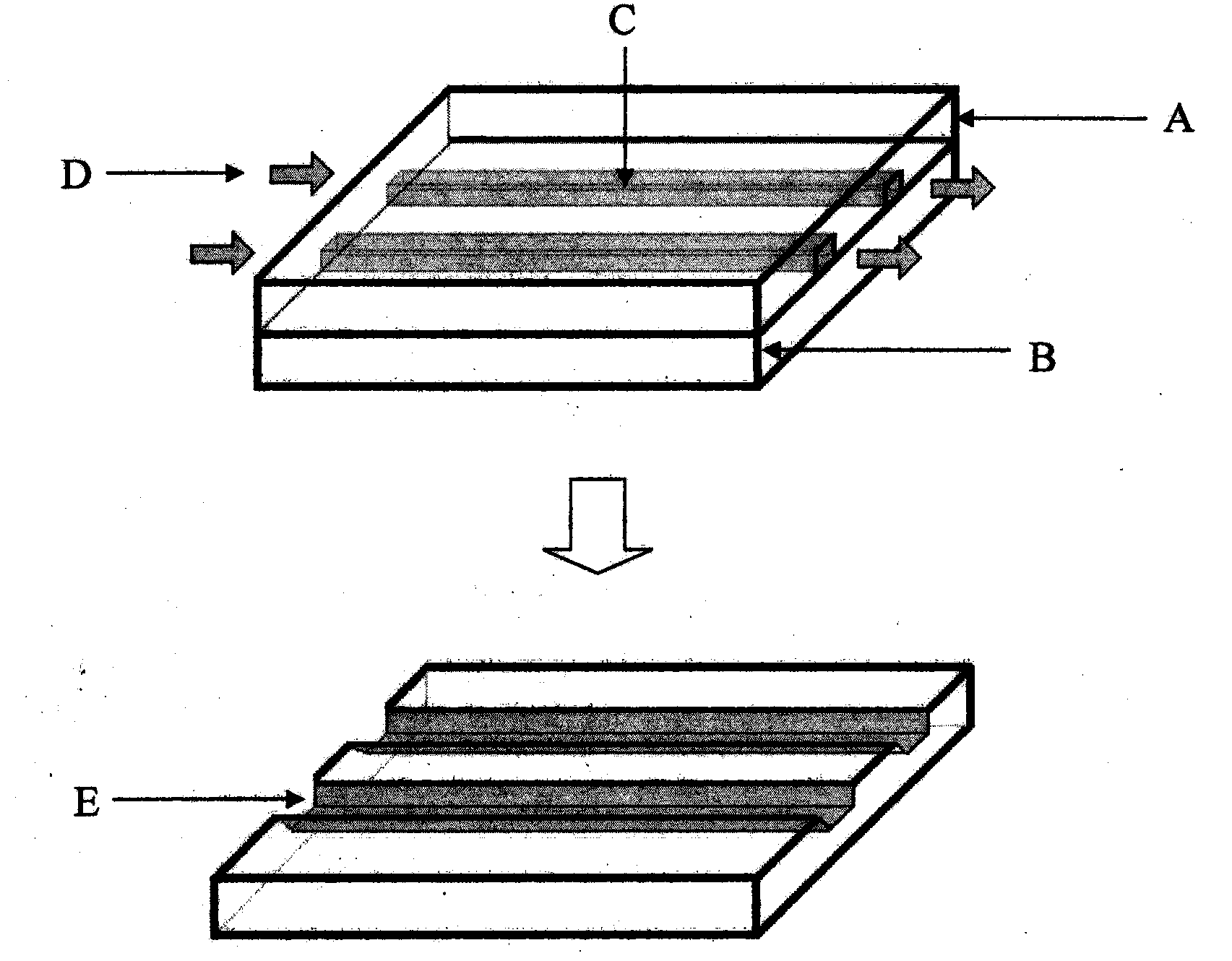

[0027] The structure and preparation method of a kind of criss-cross type glass microchannel are as Figure 4 shown. A PTFE cover sheet with a cross-shaped channel is closely attached to the glass substrate to be processed to form a chip a2 with a closed microchannel c2, and a peristaltic pump d2 is used to pump the hydrofluoric acid etching solution from the storage container e Draw out and inject into the inlet of the chip along the polytetrafluoroethylene hose b2, and the etching waste liquid is exported from the three outlets of the chip to the waste liquid storage container f. After etching for 20-30 minutes, the cover sheet and the base sheet are peeled off, and a cross-shaped microfluidic channel is obtained on the glass substrate. Using this system, the amount of etching solution can be reduced to a few milliliters level. Since the etching solution flows continuously from the surface to be etched,...

Embodiment 3

[0028] Embodiment 3 Preparation of a silicon substrate microchannel

[0029] The fabrication process of microchannels on silicon substrates is as follows: figure 1 As shown, the specific preparation process is as follows: firstly, the microchannel structure is processed on a smooth and flat polytetrafluoroethylene substrate by using precision numerical control CNC engraving technology, and then the substrate and the surface of the polished silicon wafer to be processed are reversibly bonded. combine( figure 1 a); Then use the external peristaltic pump system to continuously introduce the commercially available silicon etching solution into the microchannel along the polytetrafluoroethylene hose ( figure 1 b); the silicon etchant etches the area where the microchannel on the silicon wafer is to the required depth ( figure 1 c); Finally, the polytetrafluoroethylene substrate is peeled off from the surface of the silicon wafer to obtain a silicon substrate microchannel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com