Plasma etching device and etching method thereof

A plasma and etching device technology, used in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as damage to semiconductor devices, affecting device morphology and performance, and achieve the effect of preventing accumulation and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

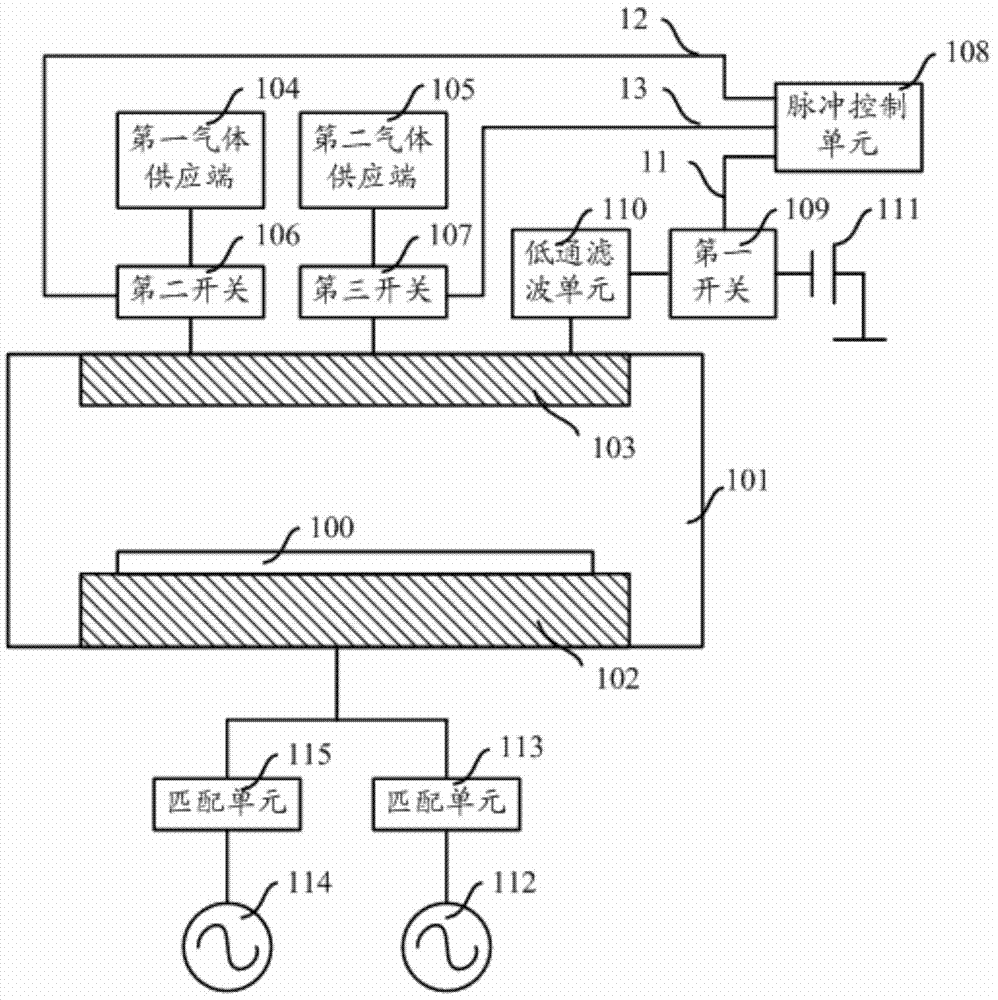

[0045] figure 2 It is a schematic structural diagram of the plasma etching device according to the first embodiment of the present invention.

[0046] refer to figure 2 , the plasma etching device, comprising:

[0047] processing chamber 101;

[0048] The first electrode 102 is located in the processing chamber 101, the first electrode 102 has a platform (not shown) on which the wafer 100 is placed, and the first electrode 102 is electrically connected to at least one radio frequency power supply;

[0049] The second electrode 103 is located in the processing chamber 101 and directly opposite to the first electrode 102, the second electrode 103 is electrically connected to the DC power supply 111, and a first switch 109 is provided between the second electrode 103 and the DC power supply 111;

[0050] The first gas supply end 104 is used to introduce the first gas into the processing chamber 101, and there is a second switch 106 between the first gas supply end 104 and th...

no. 2 example

[0078] Figure 5 It is a schematic structural diagram of a plasma etching device according to the second embodiment of the present invention. It should be noted that, for the functions and related limitations of the same structures in the plasma etching apparatus in the second embodiment as in the first embodiment, please refer to the first embodiment, and details will not be repeated in the second embodiment.

[0079] Please refer to Figure 5 , the plasma etching device, comprising:

[0080] processing chamber 201;

[0081] The first electrode 202 is located in the processing chamber 101, the first electrode 202 has a platform for placing the wafer 200, the first electrode 202 is electrically connected to at least one radio frequency power supply, and the first electrode 202 is electrically connected to the DC power supply 221 , there is a first switch 209 between the first electrode 202 and the DC power supply 221;

[0082] The second electrode 203 is located in the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com