Laser processing method and system assisted by water jet and gas jet

An auxiliary laser and water jet technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of ineffective removal of laser etching debris and cooling, affecting laser etching efficiency and processing quality, and inability to use Larger thickness plate cutting and other problems, to achieve the effect of improving efficiency and processing quality, eliminating thermal influence, and obvious superiority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Method embodiment of water jet and airflow composite assisted laser processing

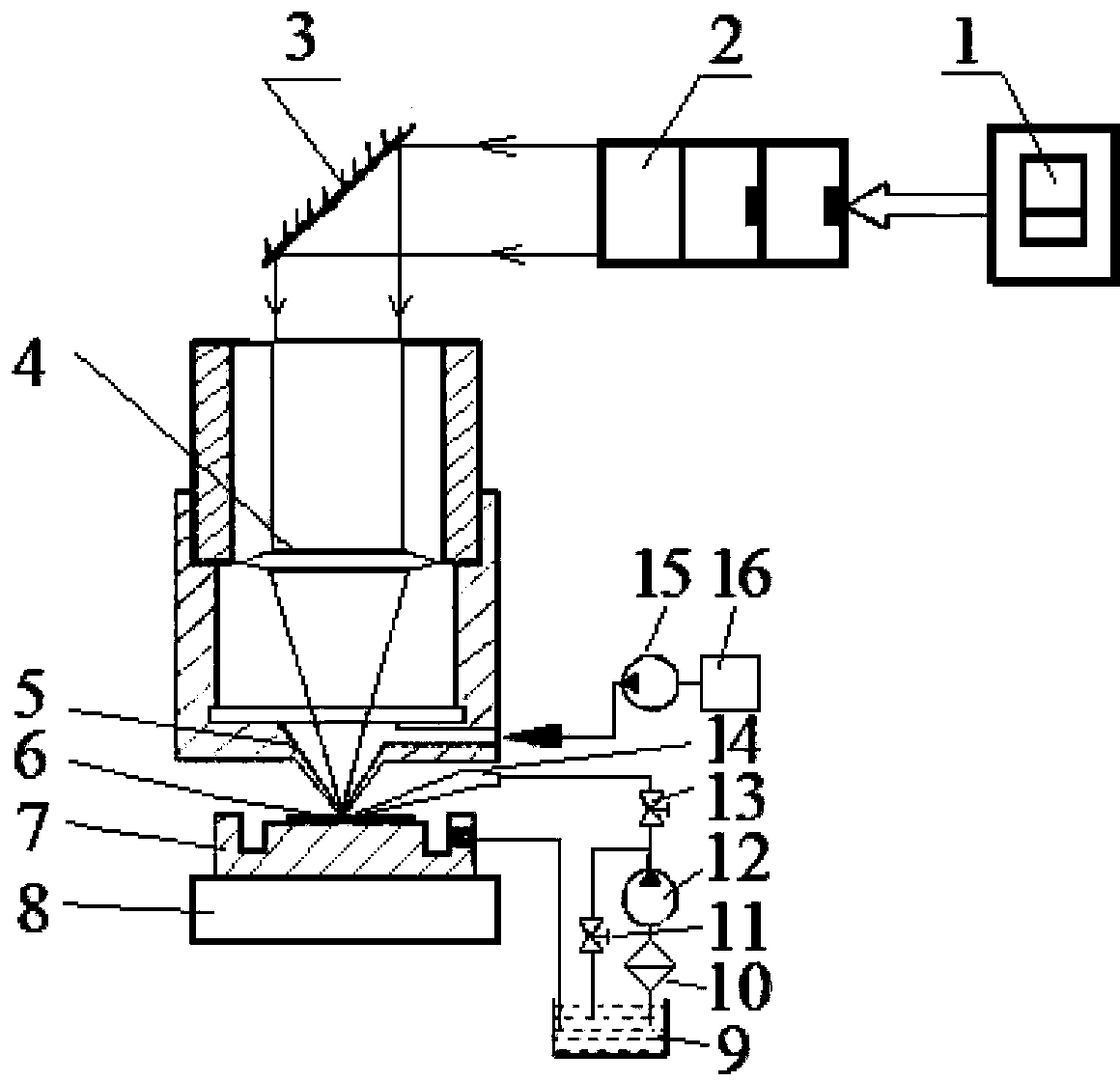

[0028] The principle diagram of the embodiment of the method of water jet and airflow composite assisted laser processing is as follows figure 1 as shown,

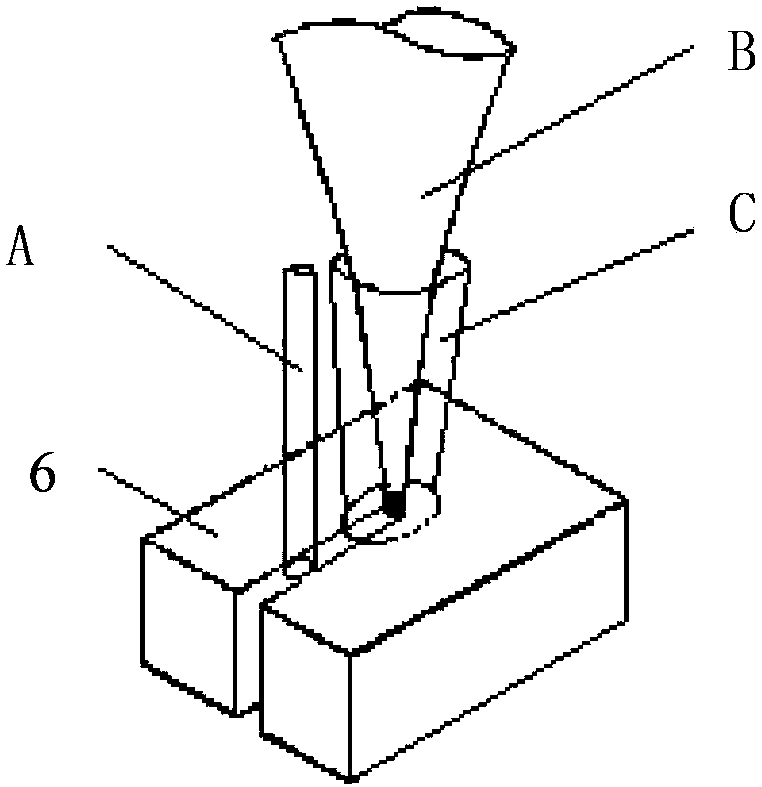

[0029] The laser beam B is focused on the surface of the workpiece, the air beam C is coaxial with the laser beam B, and both are perpendicular to the surface of the workpiece, the diameter of the air beam C is larger than the diameter of the focus point of the laser beam B, and there is a water jet A behind the air beam C, and the water jet The beam A is also perpendicular to the surface of the workpiece and enters the kerf of the laser processed workpiece 6 .

[0030] The water of the water jet in this example is deionized water, distilled water can also be used.

[0031] In this example, the distance between the intersection point of the center line of the water jet beam and the surface of the workpiece and the center of the focal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com