Driving tool

A work tool and work technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of transmission, difficult to drive the wheel, etc., and achieve the effect of improving the striking force and improving the power transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

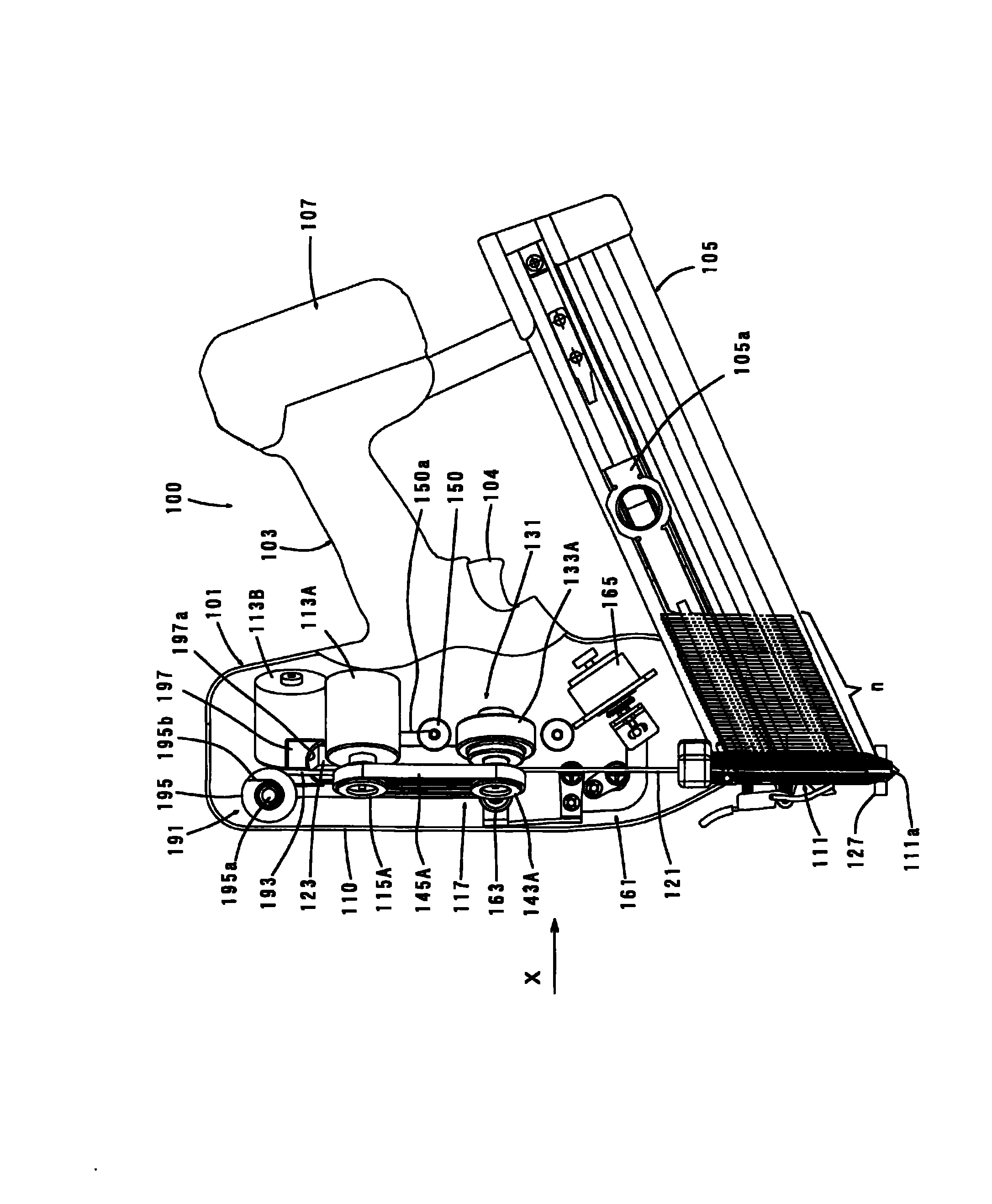

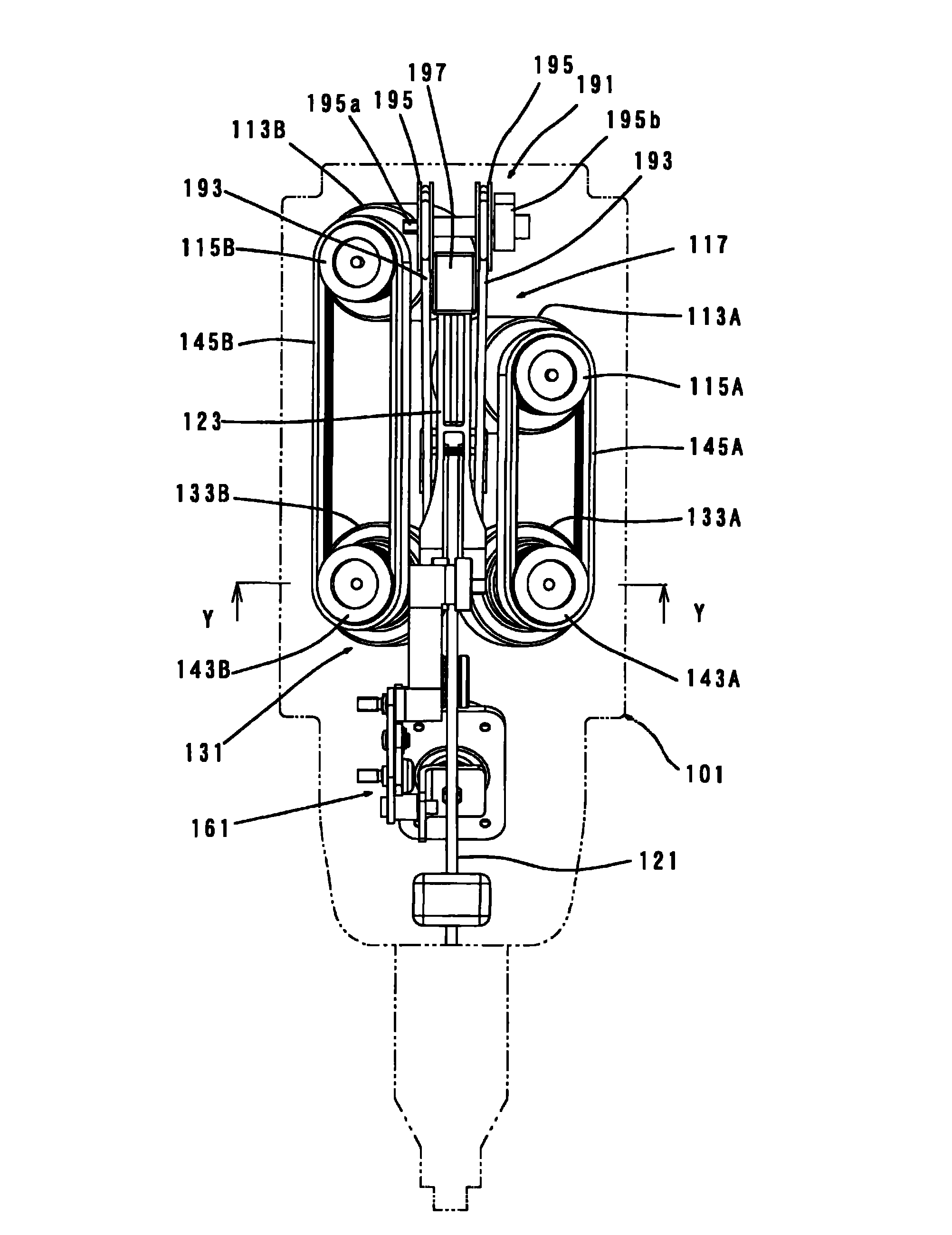

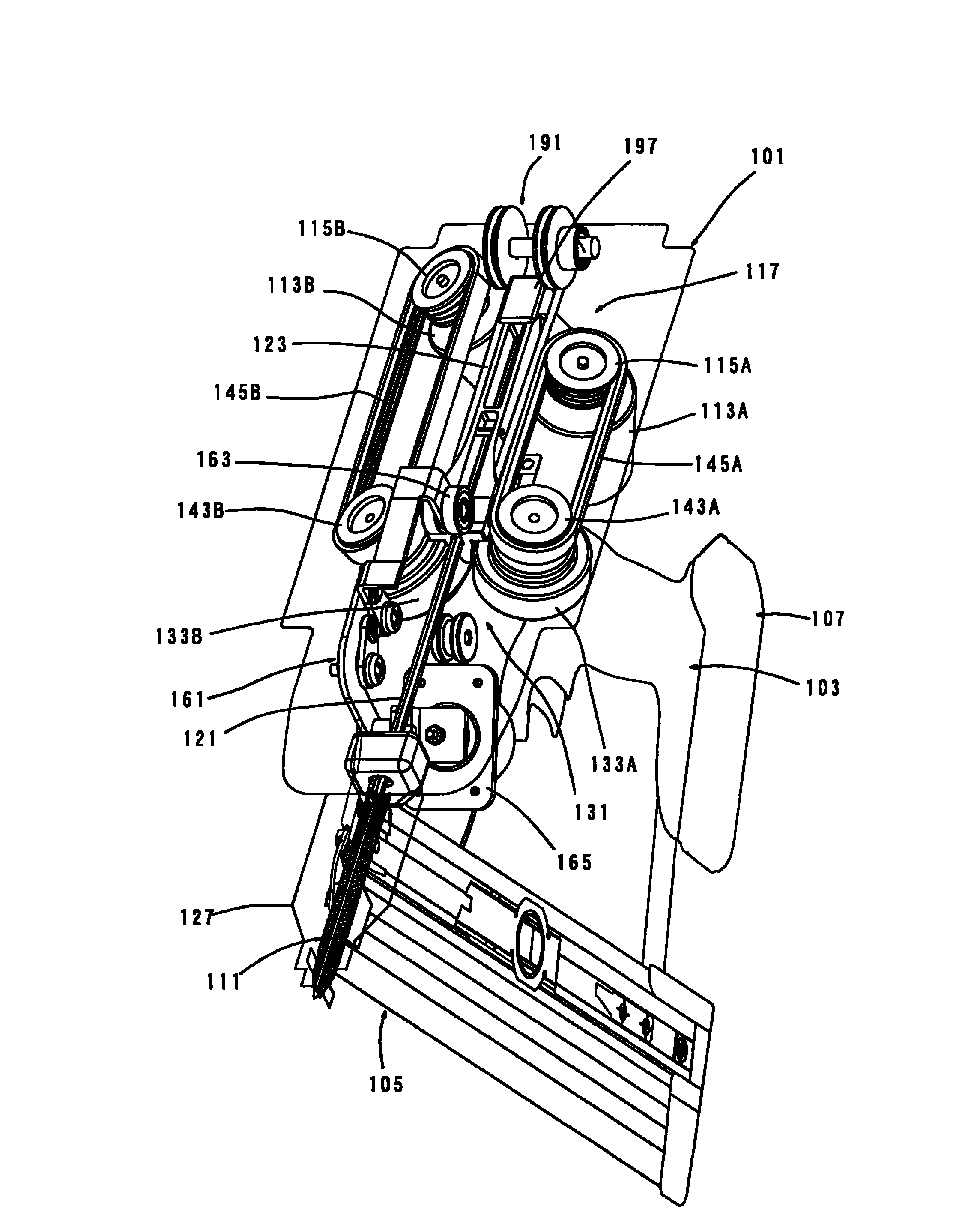

[0040] refer to Figure 1 to Figure 6 The first embodiment of the present invention will be described in detail. This embodiment will be described using a battery-operated nail driver as an example of a driving tool. exist figure 1 The whole of the nailing machine according to this embodiment is shown in . exist figure 2 China and Israel figure 1 The X-direction view shows the main parts of the nailing machine, in image 3 The main parts of the nailing machine are shown in perspective view. In addition, in Figure 4 shown in the figure 2 The cross-sectional structure of the Y-Y line. Furthermore, in Figure 5 Shows the pressing mechanism that presses the driver supporting platform on the flywheel, in Figure 6 The driver support table and driver are shown in .

[0041] Such as figure 1 As shown, the nailing machine 100, generally speaking, the main body structure includes: the main body 101 forming the shell of the nailing machine 100; the handle 103 held by the ...

no. 2 approach

[0119] Then refer to Figure 15 ~ Figure 17 A second embodiment of the present invention will be described. Figure 15 It is a side view showing the whole of the nailing machine, Figure 16 is a cross-sectional view illustrating a first arrangement example related to a V-shaped arrangement of a flywheel and a motor, Figure 17 is a cross-sectional view showing a second arrangement example related to the V-shaped arrangement of the flywheel and the motor.

[0120] In the second embodiment, a direct coupling method in which the pair of flywheels 133A, 133B are directly driven by the drive motors 113A, 113B without using a power transmission member is adopted. The rest of the configuration is substantially the same as that of the above-mentioned first embodiment. Therefore, descriptions of parts other than the direct coupling of the flywheel and the motor and the structures associated therewith will be omitted. In addition, the same symbols as those used in the description of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com