Preparation method of electrochemical sensor

A sensor and electrochemical technology, applied in the field of micromachining, can solve the problems of low pollution and low-cost mass production of electrochemical sensors that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

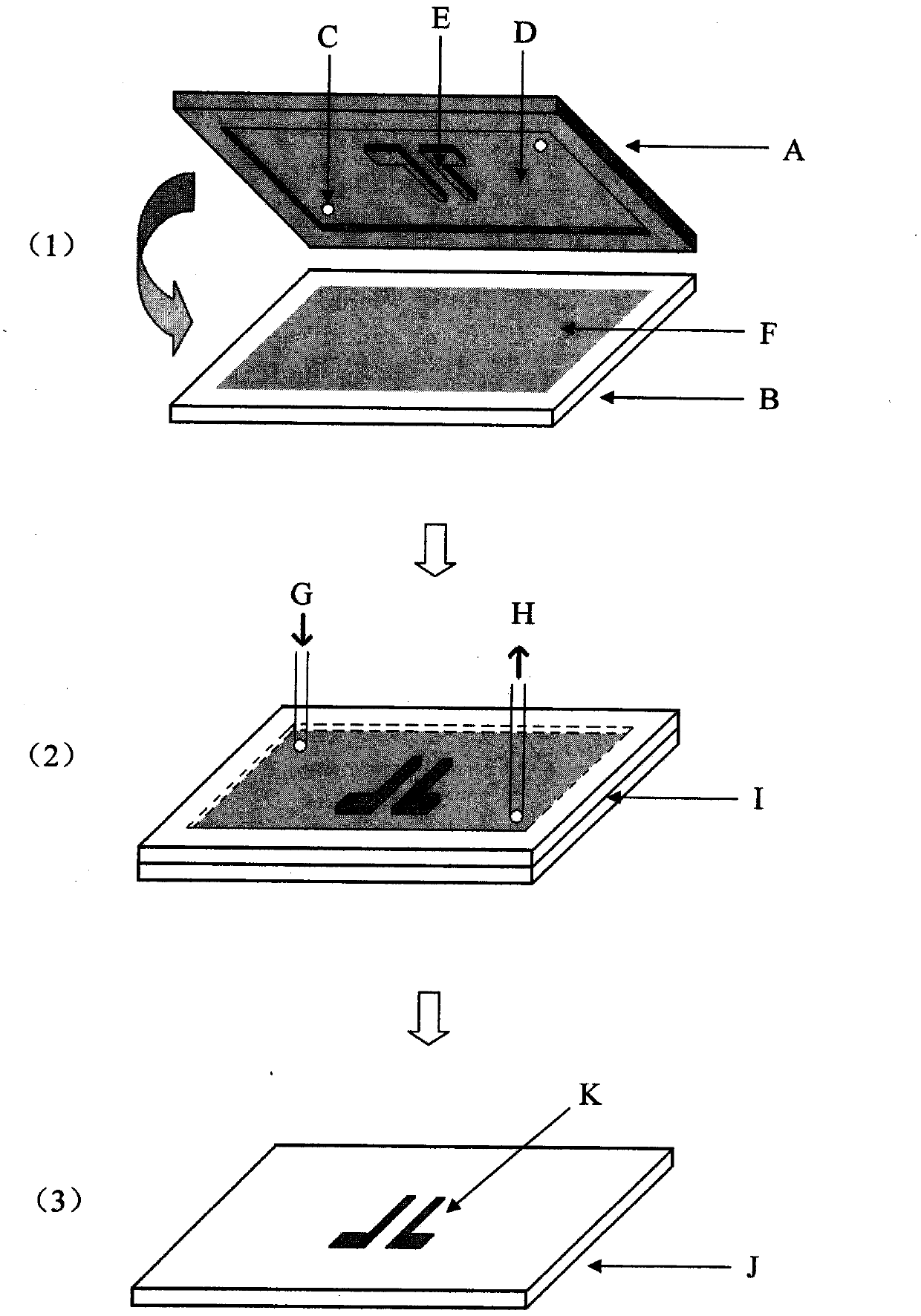

[0018] figure 1 It is a schematic diagram of the preparation process of a two-electrode electrochemical sensor. The specific preparation process of a dual-electrode Au electrode is as follows: (1) Firstly, the fluid inlet and outlet C, the microcavity structure D and the double The electrode protection structure E with completely consistent electrode patterns, and then the microfluidic chip and the surface of the glass substrate B with the Au film F on the surface to be processed are reversibly bonded using a fixture; (2) use an external pump system to pump aqua regia (HF: HNO 3 :H 2 (2=1:1:5, volume ratio) the solution G is continuously introduced into the microfluidic chip along a polytetrafluoroethylene hose, and the etching waste liquid H flows out from another outlet; (3) finally, the polytetrafluoroethylene The microfluidic chip was peeled off from the surface of the glass substrate to obtain an Au double-electrode electrochemical sensor.

Embodiment 2

[0019] Embodiment 2 Preparation of a three-electrode type Ag electrode

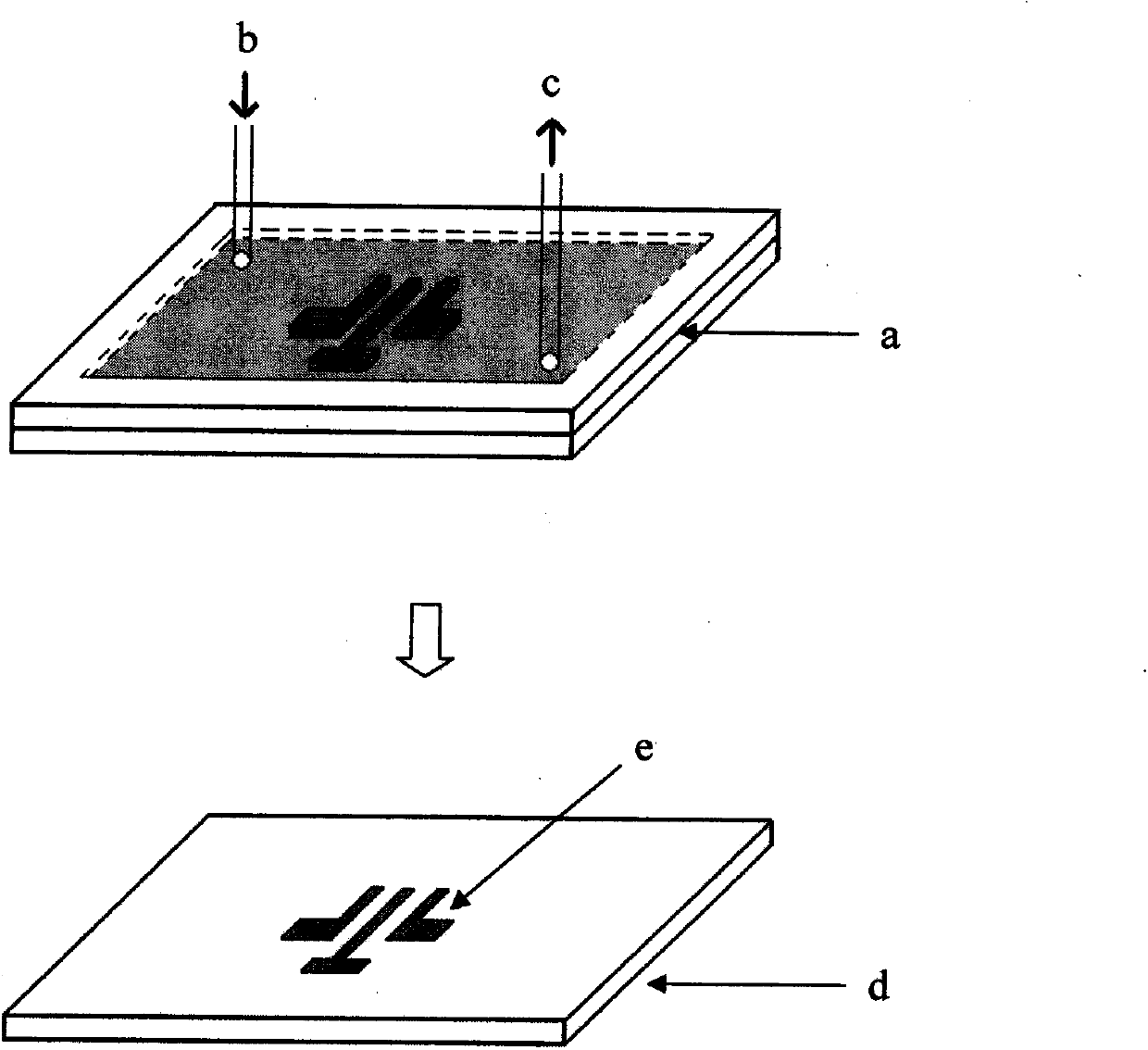

[0020] figure 2 It is a schematic diagram of the preparation process of a three-electrode electrochemical sensor. A specific preparation process of a three-electrode Ag electrode in this embodiment is as follows: first, a polydimethylsiloxane (PDMS) chip is prepared by pouring and polymerizing a photoresist mold, and the chip has a fluid inlet and outlet, a microcavity structure and The electrode protection structure of the three electrode patterns is completely consistent, and then the microfluidic chip and the surface of the polymethyl methacrylate (PMMA) substrate d with Ag film on the surface to be processed are reversibly bonded or chip a is obtained; then use The external pump system continuously introduces the ferric chloride solution b into the microfluidic chip a along a polytetrafluoroethylene hose, and the etching waste liquid c flows out from another outlet; finally, the PDMS microfluidic ch...

Embodiment 3

[0021] Embodiment 3 Preparation of a kind of ITO electrochemical sensor

[0022] A specific preparation process of two-electrode type and three-electrode type ITO electrochemistry can be found in figure 1 and figure 2 The details are as follows: firstly, the PDMS microfluidic chip is prepared by pouring and polymerizing the photoresist mold. The surface of the glass substrate with ITO film on the surface to be processed is reversibly bonded; then the HCl solution is continuously introduced into the microfluidic chip along a polytetrafluoroethylene hose by using an external pump system, and the HCl etching solution is used for ITO. For regionalized etching, the etching waste liquid flows out from another outlet of the microfluidic chip; finally, the PDMS microfluidic chip is peeled off from the surface of the glass substrate to obtain an ITO electrochemical sensor.

[0023] Using the preparation method of the electrochemical sensor provided by the present invention, the etch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com