Method and device for panel etching process

A panel and etching technology, applied in the field of panel etching process, can solve problems such as difficult etching results, uneven etching, rough surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

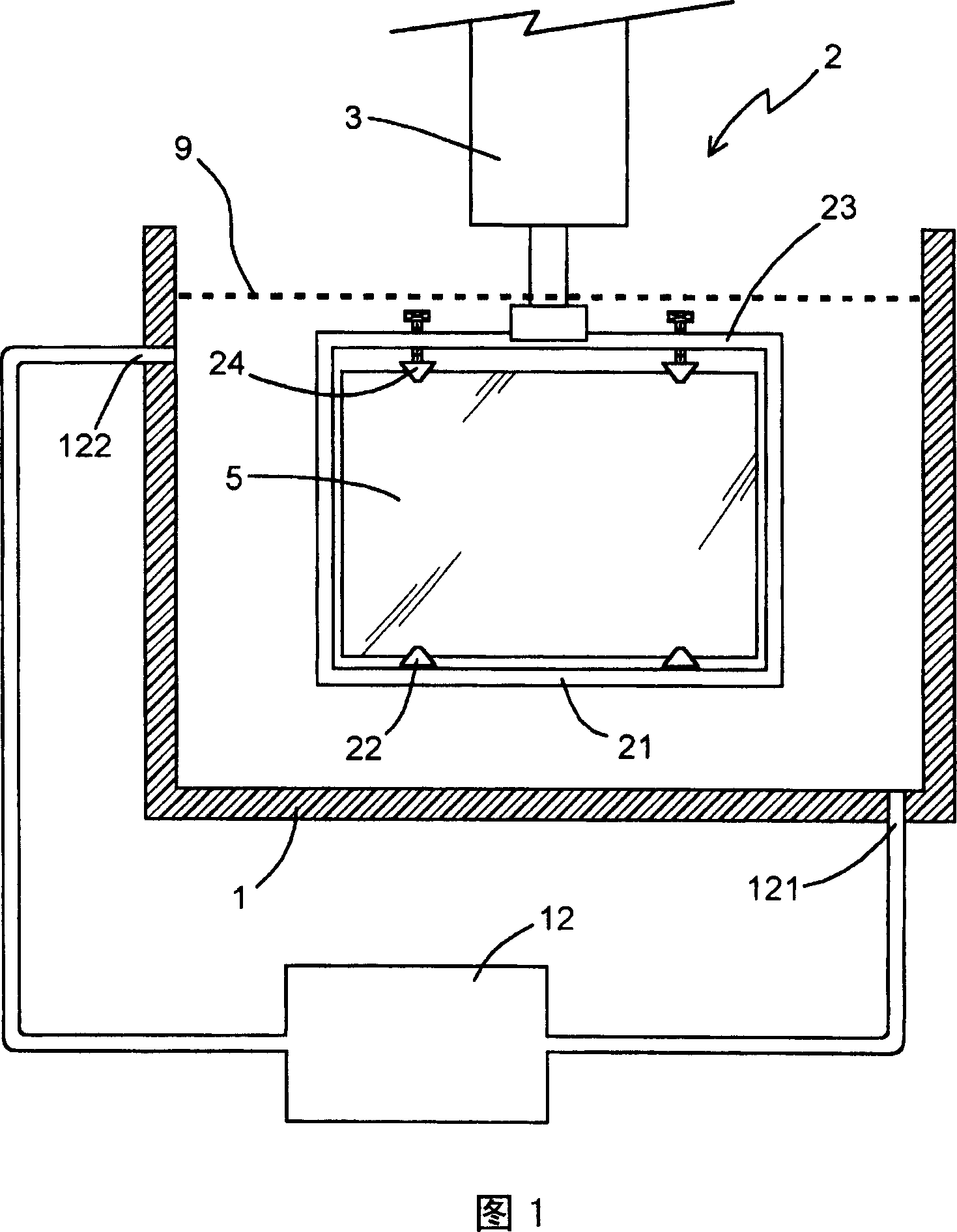

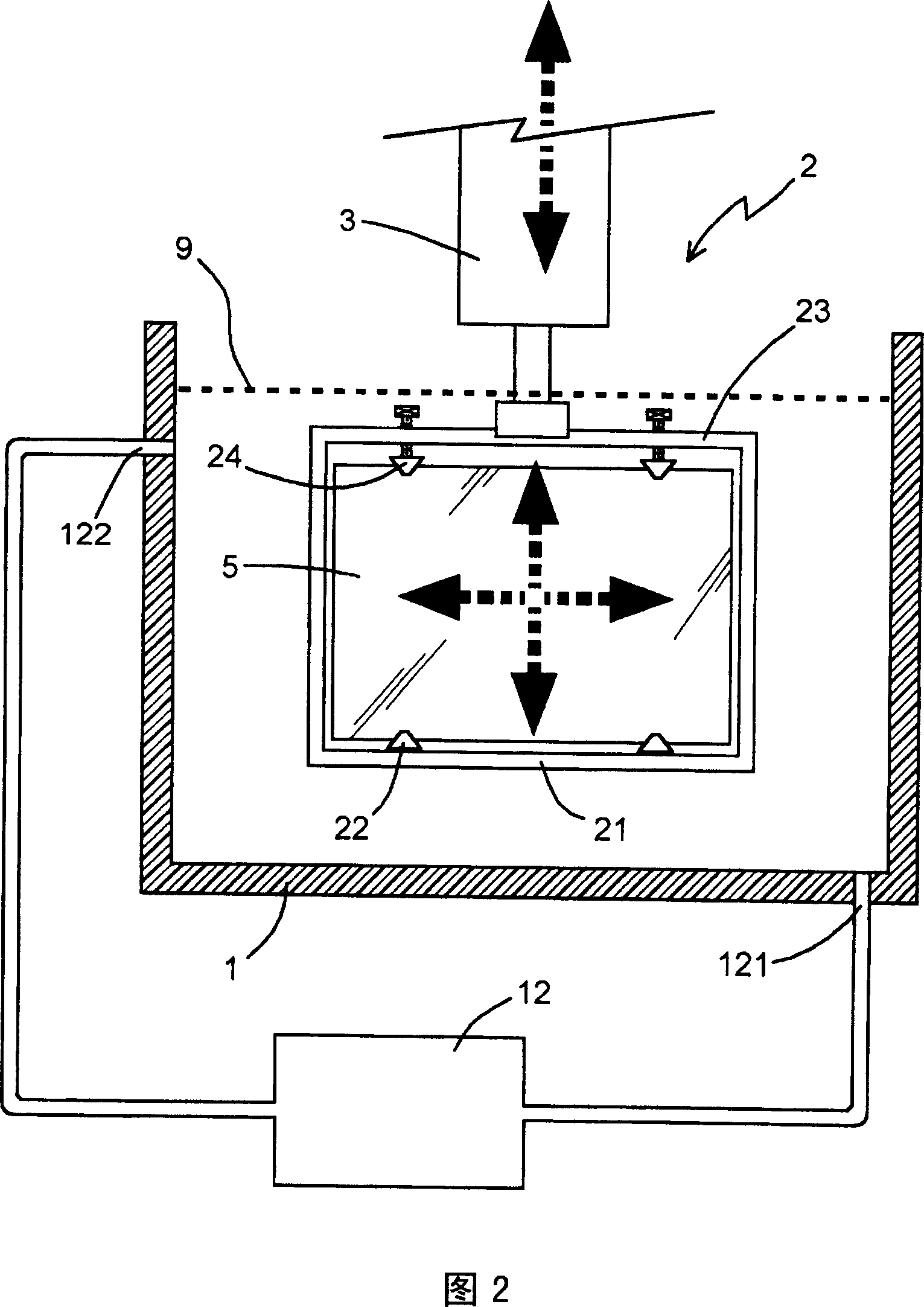

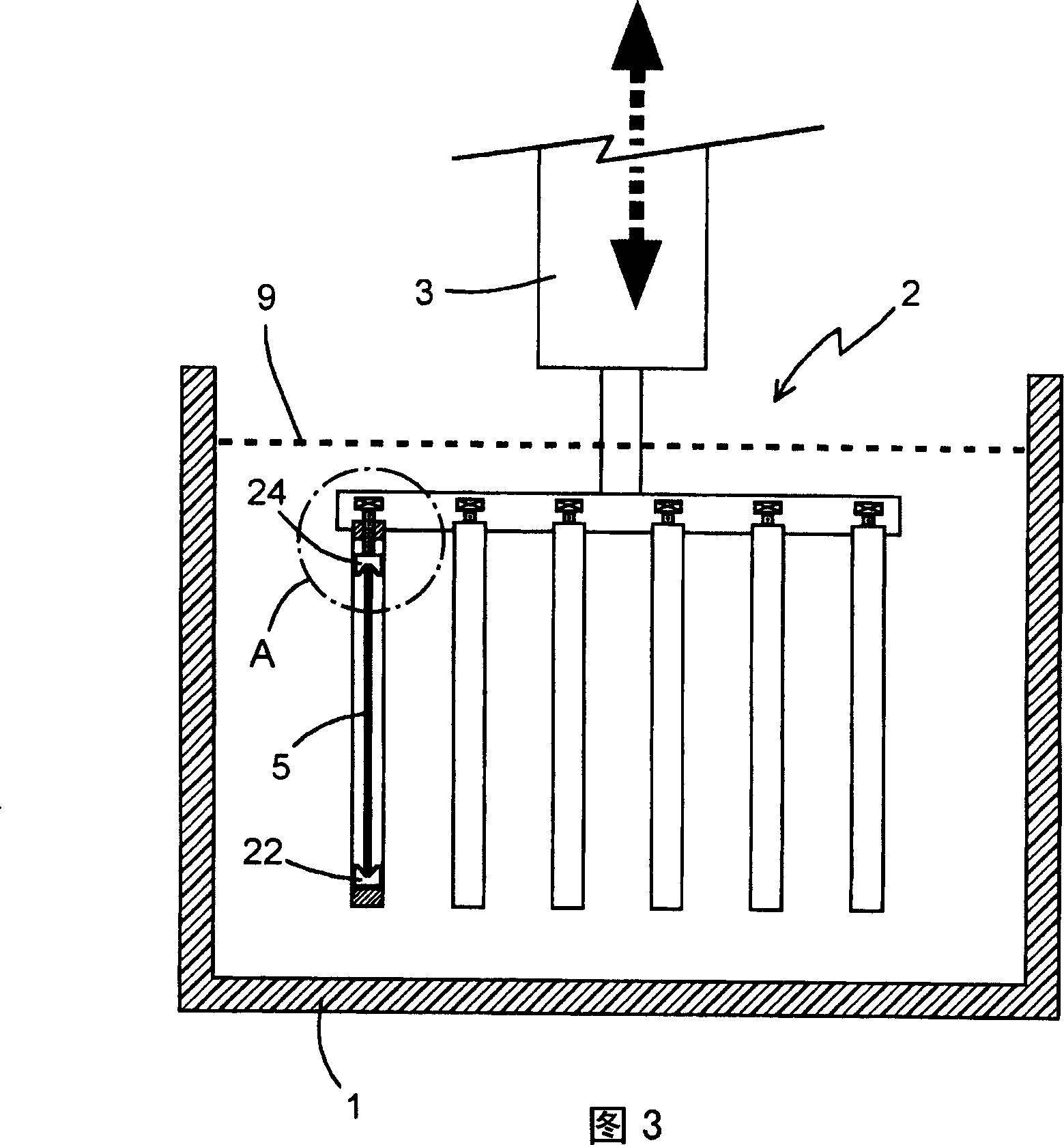

[0031] The preferred embodiment listed below is to carry out the thinning process to the glass substrate of the liquid crystal display panel; As shown in Figure 1, it is a front reference view of the etching device structure of the present invention, showing that an etching solution is installed on the machine platform The working tank 1, and the capacity of the etching solution 9 contained in the tank should be kept at a specific liquid level during the etching process, and the height must at least allow the panel 5 to be etched to be completely immersed In the solution; in addition, the working tank 1 also has a circulation filter 12, and the etching solution in the working tank can be continuously introduced into the circulation through the discharge pipe 121 arranged on the bottom wall of the tank during the etching process. Filtration treatment is carried out in the filter, and then the treated etching solution is discharged into the working tank again through the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com