Production line and production process of printed circuit board for new energy automobile

A technology for new energy vehicles and printed circuit boards. It is applied in the fields of printed circuit, printed circuit manufacturing, and removal of conductive materials by chemical/electrolytic methods. It can solve problems such as reducing product quality, reducing leveling efficiency, and wasting etching solution. , to achieve the effect of saving etching cost, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

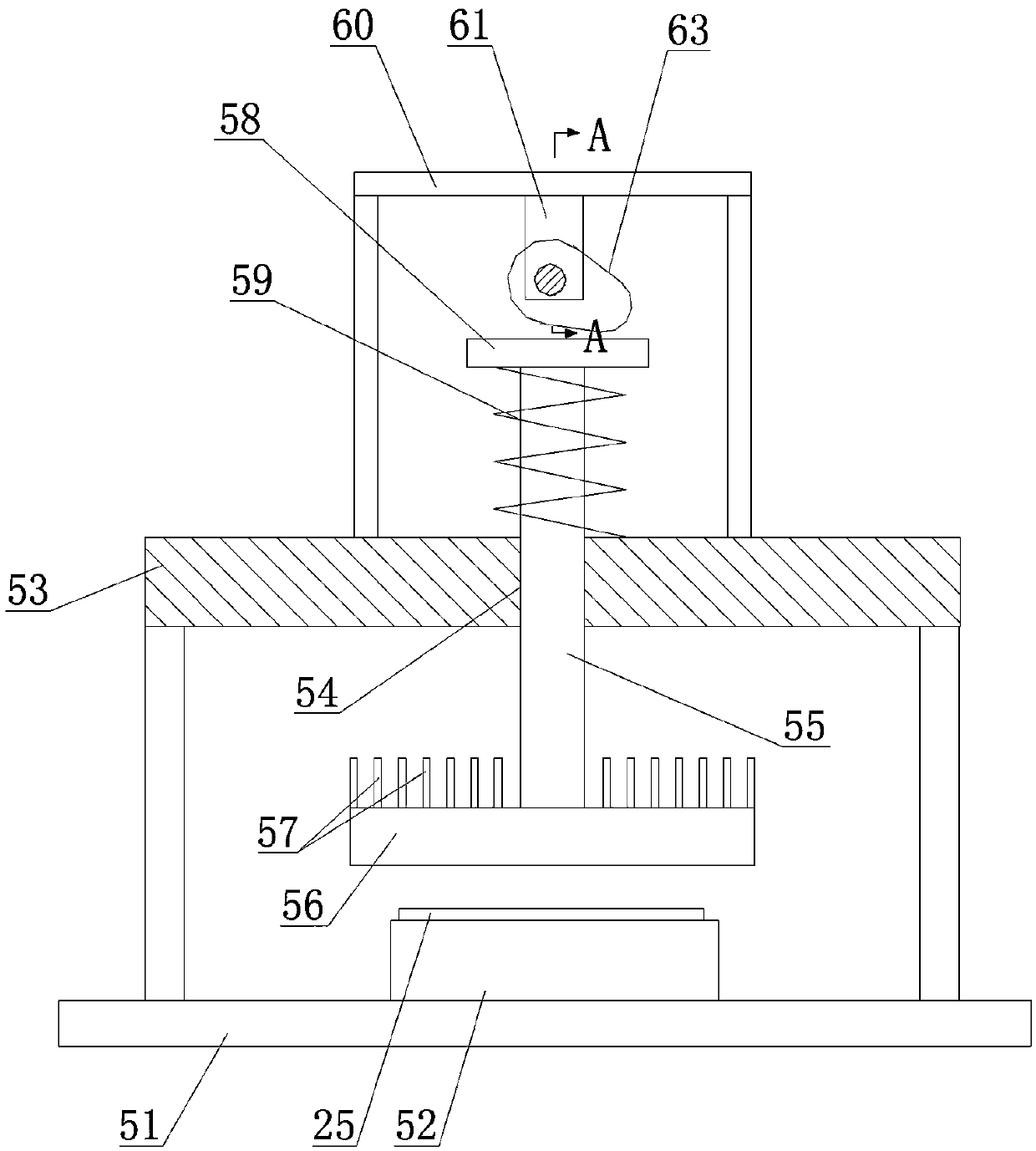

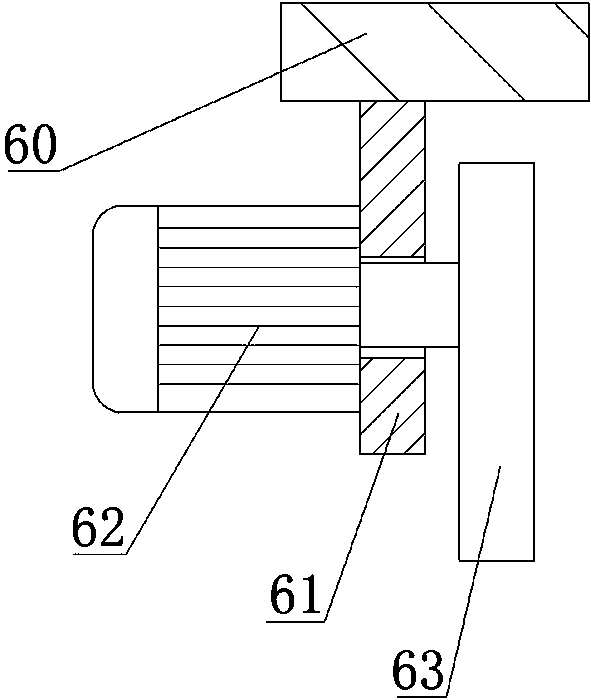

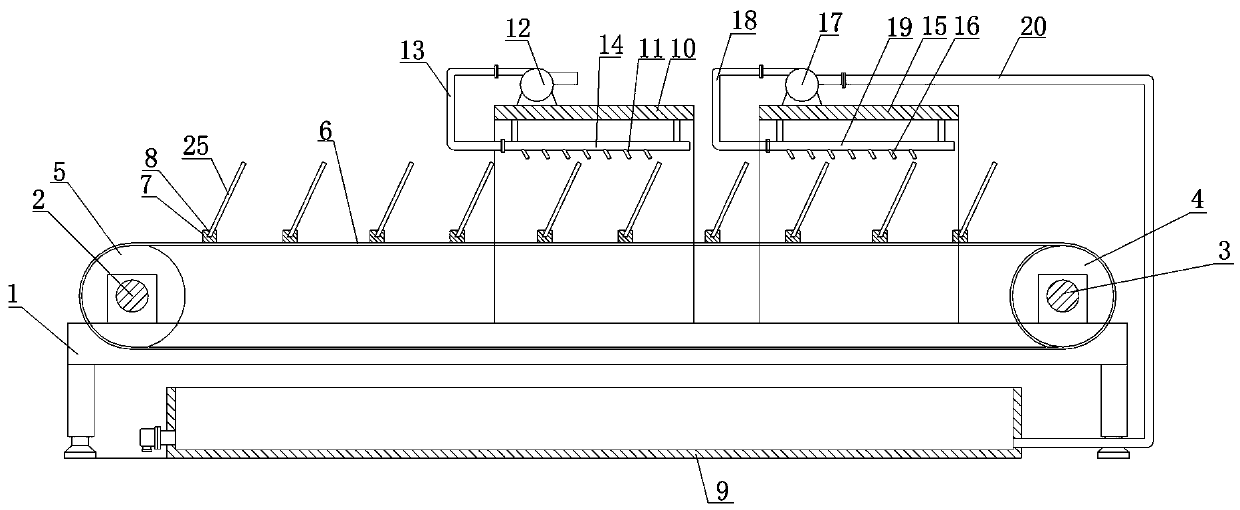

[0028] Such as Figure 3~4 As shown, the production line of printed circuit boards for new energy vehicles includes an etching device and a leveling device, and the etching device includes a frame 1, a power unit, a purging device and a spray device arranged on the frame 1, On the said frame 1, a driven shaft 2 and a driving shaft 3 are respectively rotated at its left and right ends, and two belt transmissions are arranged between the driving shaft 3 and the driven shaft 2, and the belt transmission comprises a driving pulley 4, a slave The driving pulley 5 and the flat belt 6, the driving pulley 4 and the driven pulley 5 are installed on the driving shaft 3 and the driven shaft 2 respectively, a flat belt 6 is installed between the driving pulley 4 and the driven pulley 5, and the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com