An etching device and a single-side etching method of a wafer

An etching device and wafer technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of scrapping wafers, adding protective layers, and increasing the production cost of semiconductor chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] As mentioned in the background, when the wafer is etched by wet method in the prior art, the efficiency is low and the cost is high.

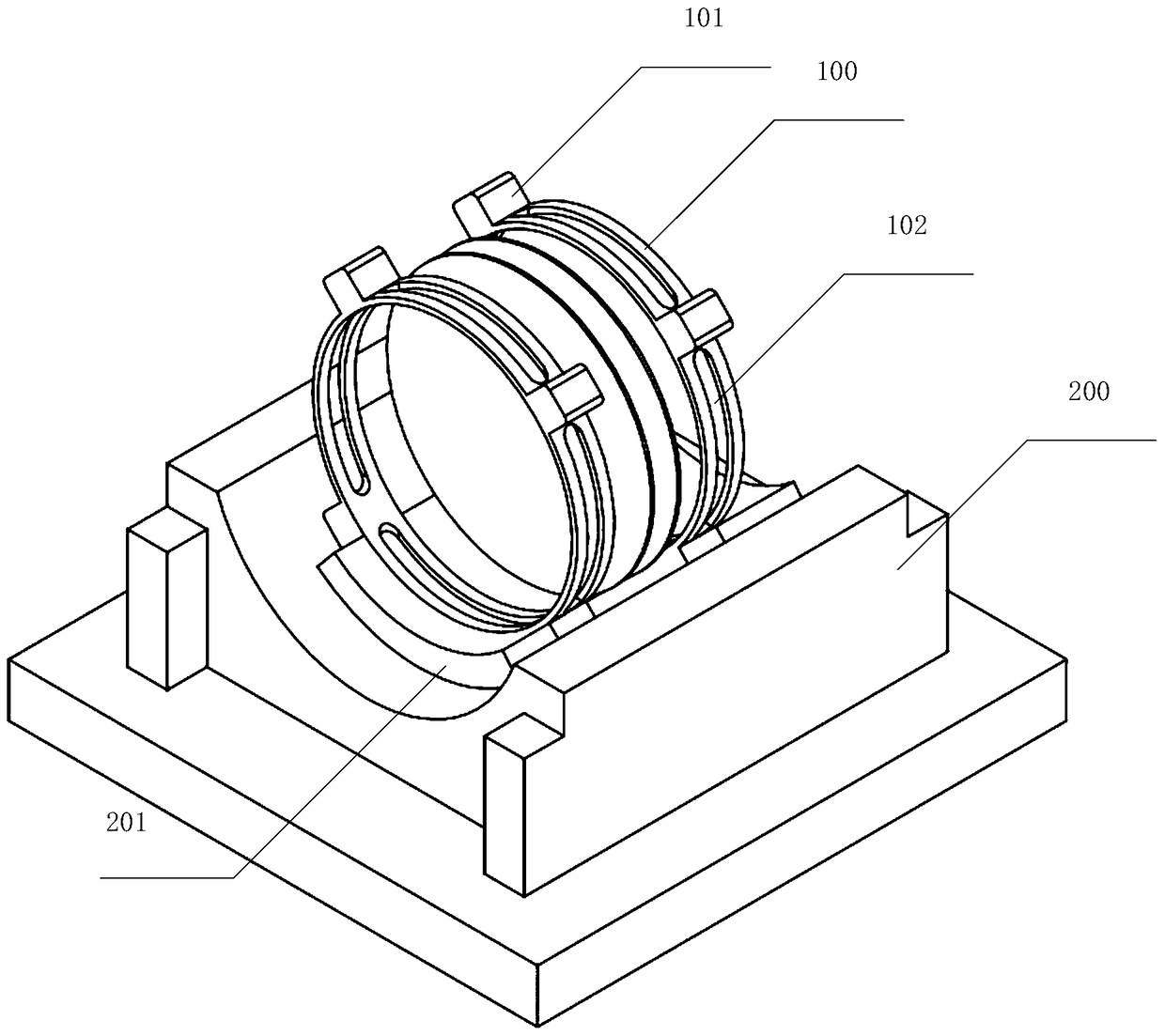

[0042] In view of this, an embodiment of the present invention provides an etching device, which is applied to wafer wet etching, including:

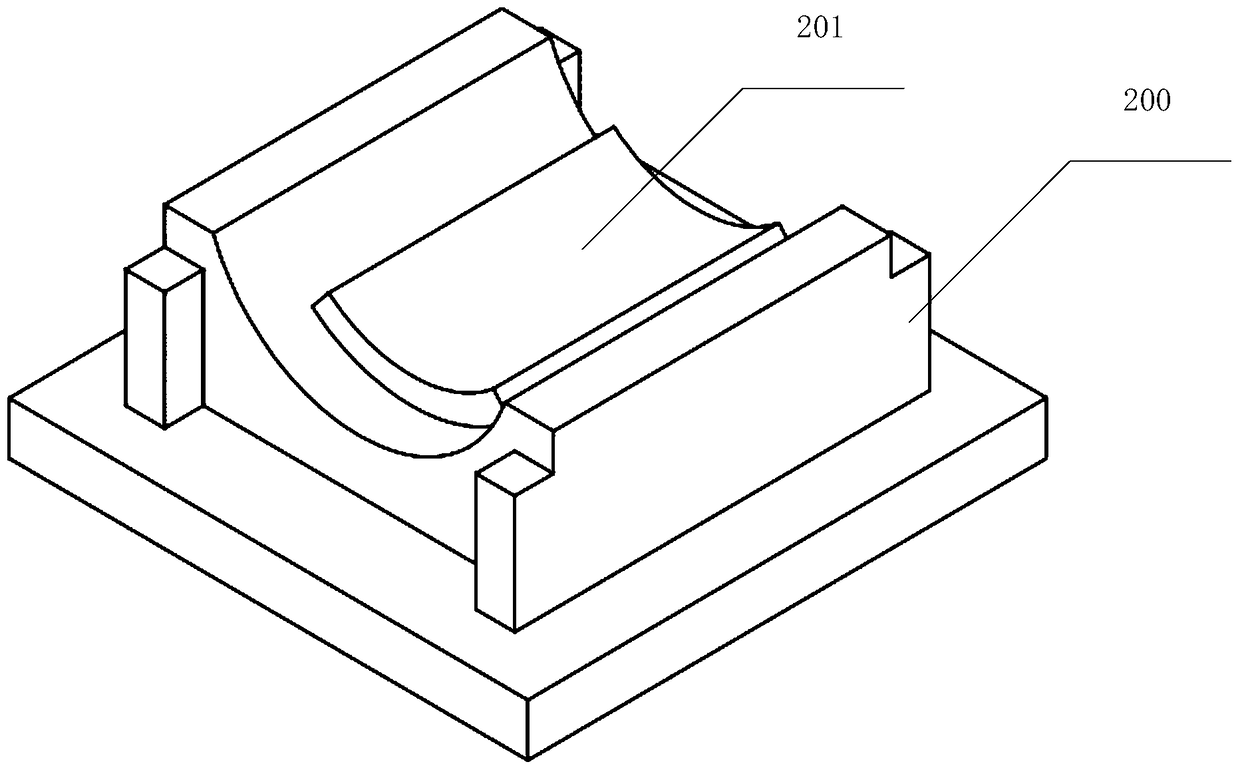

[0043] base;

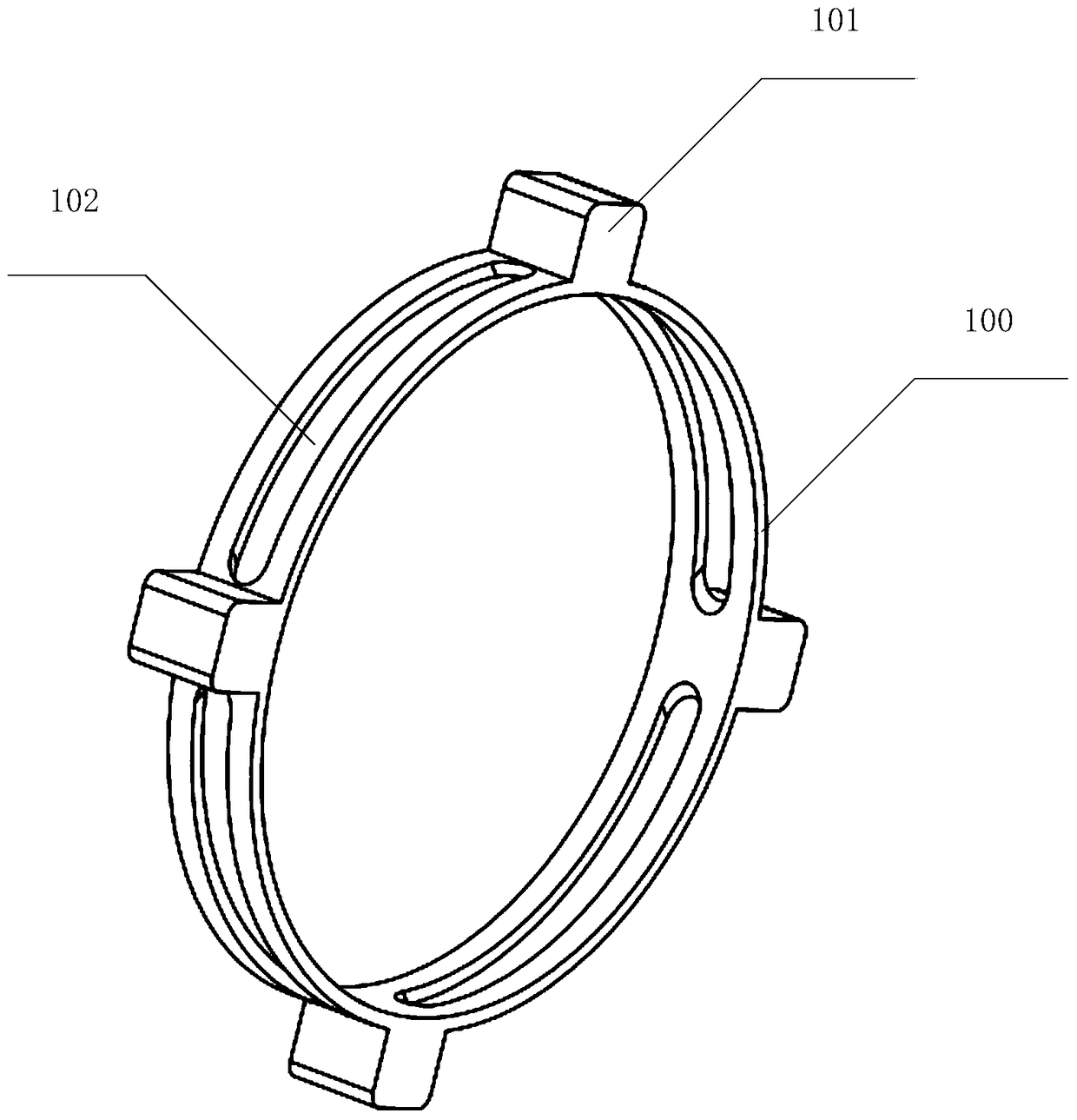

[0044] A plurality of clip rings arranged on the base, at least two wafers are placed between adjacent clip rings, and the surface to be etched of the wafer faces the adjacent clip rings , and the clip ring is circular, and its side wall includes at least one liquid inlet groove;

[0045] A clamping device arranged on the base, the clamping device is used for clamping a plurality of clip rings and a plurality of wafers placed on the base.

[0046] Correspondingly, the embodiment of the present invention also provides a single-side etching method of a wafer, which is applied to the etching device described in the above embodiment, including:

[0047] placing a plurality of said cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com