Patterned substrate, light -emitting diode and manufacturing method thereof

A technology for patterning substrates and manufacturing methods, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult p-GaN layer and transparent electrode layer patterning procedures, etc., so as to improve light extraction efficiency and simple process method. , the effect of improving the internal quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

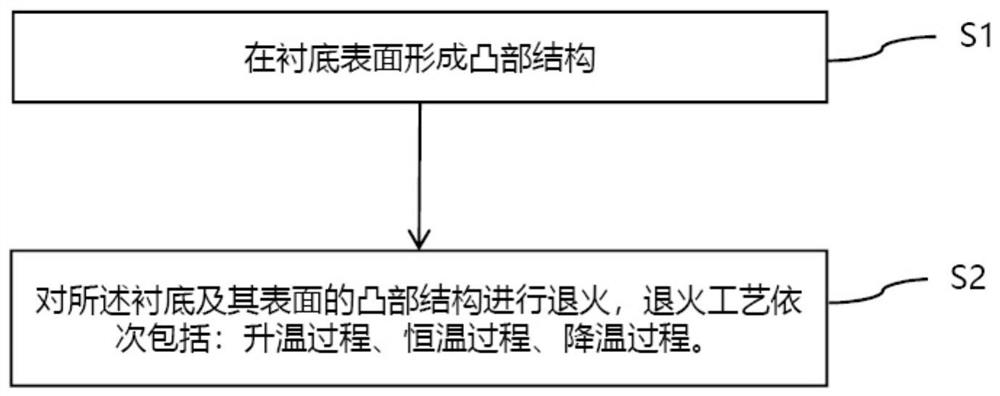

[0052] like figure 1 Shown is the processing method of the patterned substrate provided in this embodiment,

[0053] forming a convex structure on the surface of the substrate;

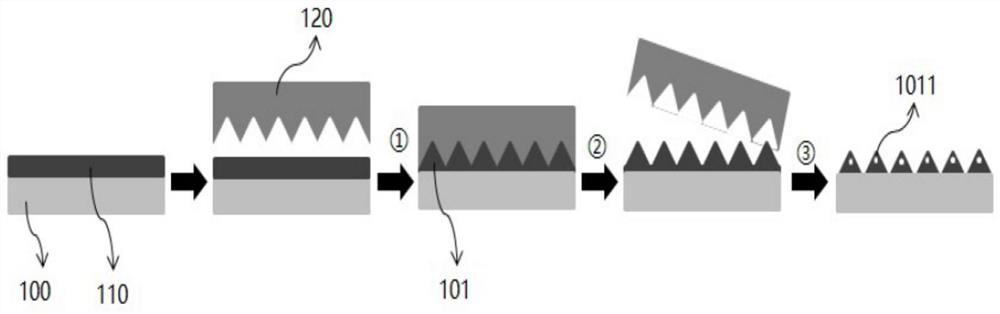

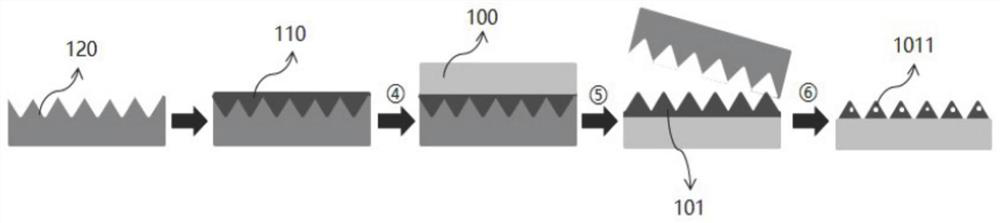

[0054] There are two methods for forming the convex structure. The convex forming method selected in this embodiment is as follows: figure 2 Imprinting method shown. like figure 2 As shown, a layer of solution is applied on the surface of the substrate 100 to form the coating 110; the nano-mold 120 is used to imprint the substrate, and the process ① shown in the figure is imprinting, and the substrate 100 and the nano-mold 120 are separated , the process ② shown in the figure is the stripping process, the substrate 100 and the convex structure 101 are subjected to the process ③ in the figure, that is, ultraviolet light treatment and annealing treatment to form a convex structure with pores 1011 inside.

[0055] The substrate surface coating solution can be selected from any of the following: SiO...

Embodiment 2

[0073] This embodiment discloses a light-emitting diode, which includes the patterned substrate described in Embodiment 1 and an epitaxial layer formed on the surface of the patterned substrate, wherein the epitaxial layer includes a convex structure formed on the patterned substrate in turn. A first semiconductor layer on one side, an active layer, and a second semiconductor layer of the opposite type to the first semiconductor layer. This embodiment also discloses a method for manufacturing a light-emitting diode: forming a convex structure on the surface of the substrate; annealing the substrate and the convex structure on the surface, and the annealing process sequentially includes: a heating process, a constant temperature process, and a cooling process; the Refer to Embodiment 1 for the fabrication method of the patterned substrate, which will not be repeated here. The manufacturing method of the light emitting diode in this embodiment further includes sequentially prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com