A replenishing liquid capable of improving the service life of hydrogen peroxide-based etching liquid

The technology of hydrogen peroxide and etching solution is applied in the field of replenishing solution that can improve the service life of hydrogen peroxide-based etching solution, can solve the problems such as insufficient utilization of hydrogen peroxide and other components, and achieves saving etching cost, The effect of saving usage and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

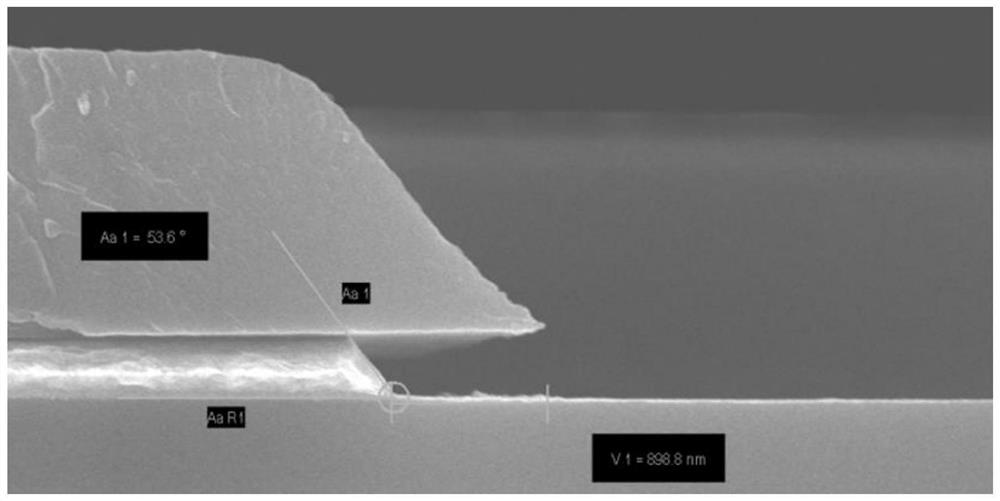

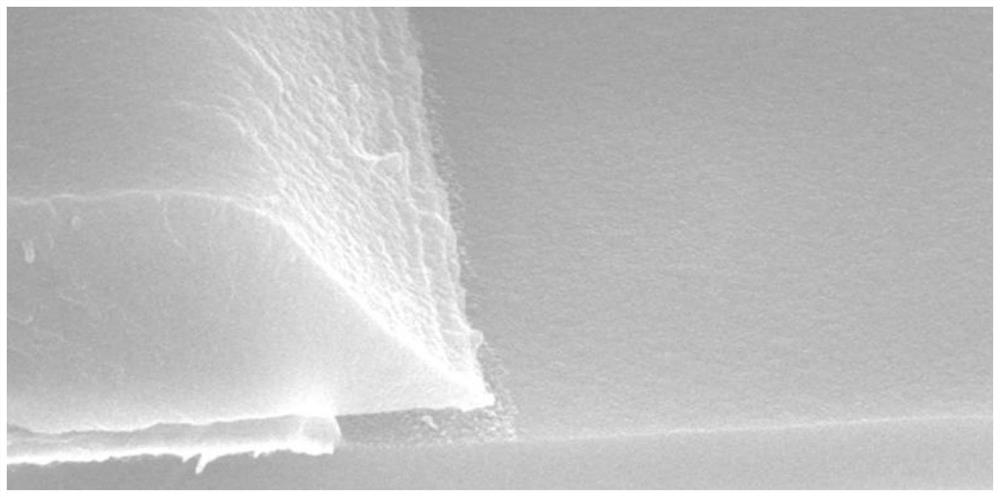

Image

Examples

Embodiment Construction

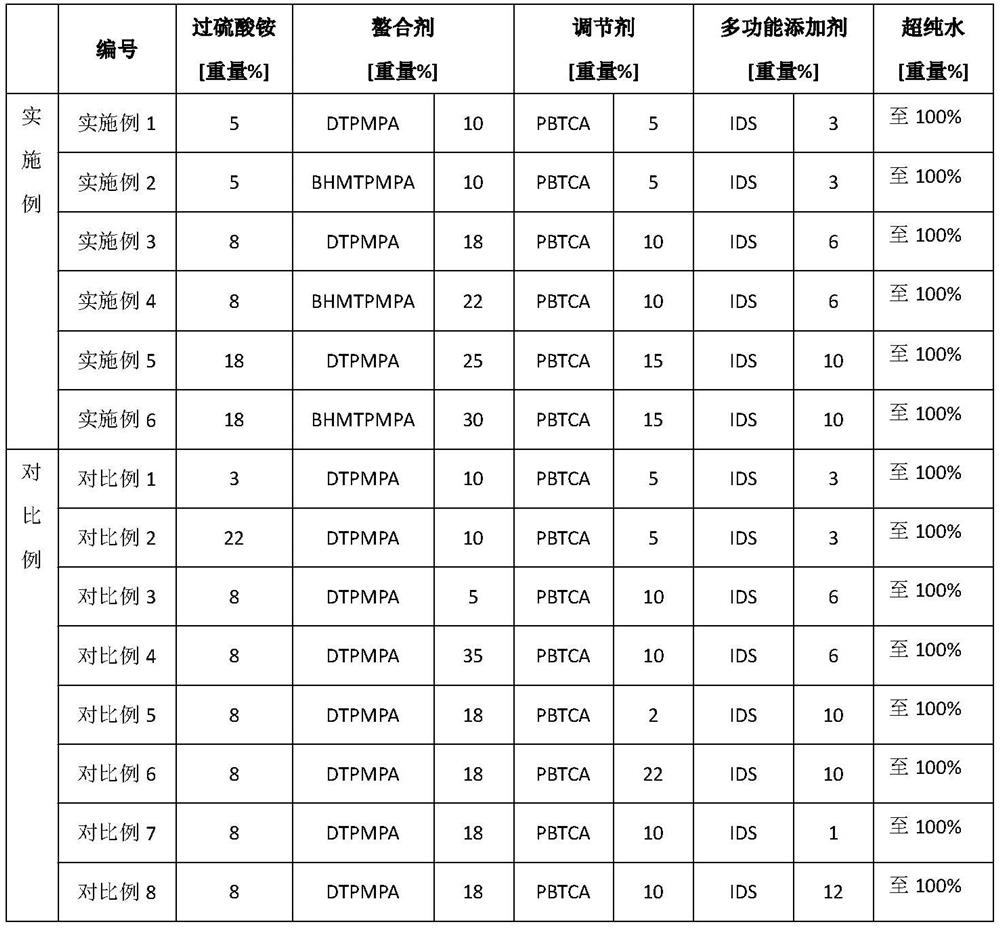

[0027] Below, the applicant will describe the technical solutions and technical effects of the present invention in detail in conjunction with specific embodiments. It should be understood that the following examples are only examples, and the present invention is not limited to these examples.

[0028]The raw materials used in the following examples and comparative examples are all commercially available products with a purity of analytical grade or above, such as ultrapure water with a conductivity of <5 μS / cm.

[0029] According to the types and ratios of raw materials shown in the following table 1, a kind of replenishing liquid that can improve the service life of the hydrogen peroxide-based etching solution of Examples 1-6 and the replenishing liquid of Comparative Examples 1-8 were prepared;

[0030] The preparation method is as follows: firstly, ammonium persulfate is added into ultrapure water, stirred until it is completely dissolved, and then a chelating agent, a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com