Method for recovering copper from alkaline etching waste liquid and recycling alkaline etching liquid

A technology of etching waste liquid and a recovery method, which is applied in the field of recycling copper from alkaline etching waste liquid and alkaline etching liquid, can solve the problems of low efficiency, and achieve the effects of reducing use cost, reducing cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

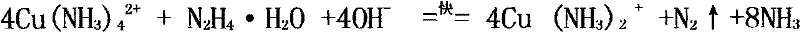

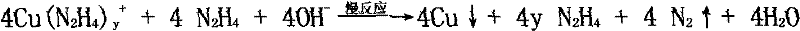

Method used

Image

Examples

Embodiment 1

[0031] 1. Put 1 liter of waste alkaline etching solution in a reaction vessel, heat to 100°C, add 175 ml of 40% hydrazine hydrate dropwise, add 1.0 ml of palladium chloride solution containing 1 mg / mL palladium metal, and keep the reaction The temperature was 100°C, and the reaction time was 35 minutes.

[0032] 2. Quickly filter after the reaction to obtain the precipitate and filtrate. The precipitate is copper powder precipitation with a purity of 99.2%. The obtained filtrate has a copper content of 40 g / L and a pH of 8.5, and the filtrate can be reused to prepare a new etching solution.

Embodiment 1-1

[0034] 1. Put 1 liter of waste alkaline etching solution in a reaction vessel, heat to 100°C, add 175 ml of 40% hydrazine hydrate dropwise, add 1.0 ml of palladium chloride solution containing 1 mg / mL palladium metal, and keep the reaction The temperature was 100°C, and the reaction time was 35 minutes.

[0035] 2. Quickly filter after the reaction to obtain the precipitate and filtrate. The precipitate was washed twice with a small amount of 200g / L ammonium chloride solution to obtain the copper powder precipitate and washing liquid, and the filtrate and washing liquid were combined to obtain filtrate A.

[0036] 3. The precipitated copper powder was washed with 2% dilute sulfuric acid and water, and dried at 105° C. to obtain 115 g of copper powder and filtrate B at the same time. Hydrazine hydrate consumption (calculated per gram of copper powder): 1.52ml / g

[0037] 4. The obtained filtrate A has a copper content of 40g / L, a pH of 8.0, and an oxidation-reduction potential...

Embodiment 2

[0039] 1. Put 1 liter of waste alkaline etching solution in a reaction vessel, heat to 100°C, add 175 ml of 40% hydrazine hydrate dropwise, add 10.0 ml of palladium chloride solution containing 1 mg / mL palladium metal, and keep the reaction The temperature was 100°C, and the reaction time was 35 minutes.

[0040] 2. Quickly filter after the reaction to obtain the precipitate and filtrate. The precipitate was washed twice with a small amount of 200g / L ammonium chloride solution to obtain the copper powder precipitate and washing liquid, and the filtrate and washing liquid were combined to obtain filtrate A.

[0041] 3. The precipitated copper powder was washed with 2% dilute sulfuric acid and water, and dried at 105° C. to obtain 118 g of copper powder and filtrate B at the same time. Hydrazine hydrate consumption (calculated per gram of copper powder) is: 1.48ml / g.

[0042] 4. The obtained filtrate A has a copper content of 39g / L, a pH of 8.0, and an oxidation-reduction pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com