Wet etching method for nitride materials

A wet etching and nitride technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of slow etching speed, device damage, and no wet etching of GaN, etc. The effect of fast corrosion rate and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

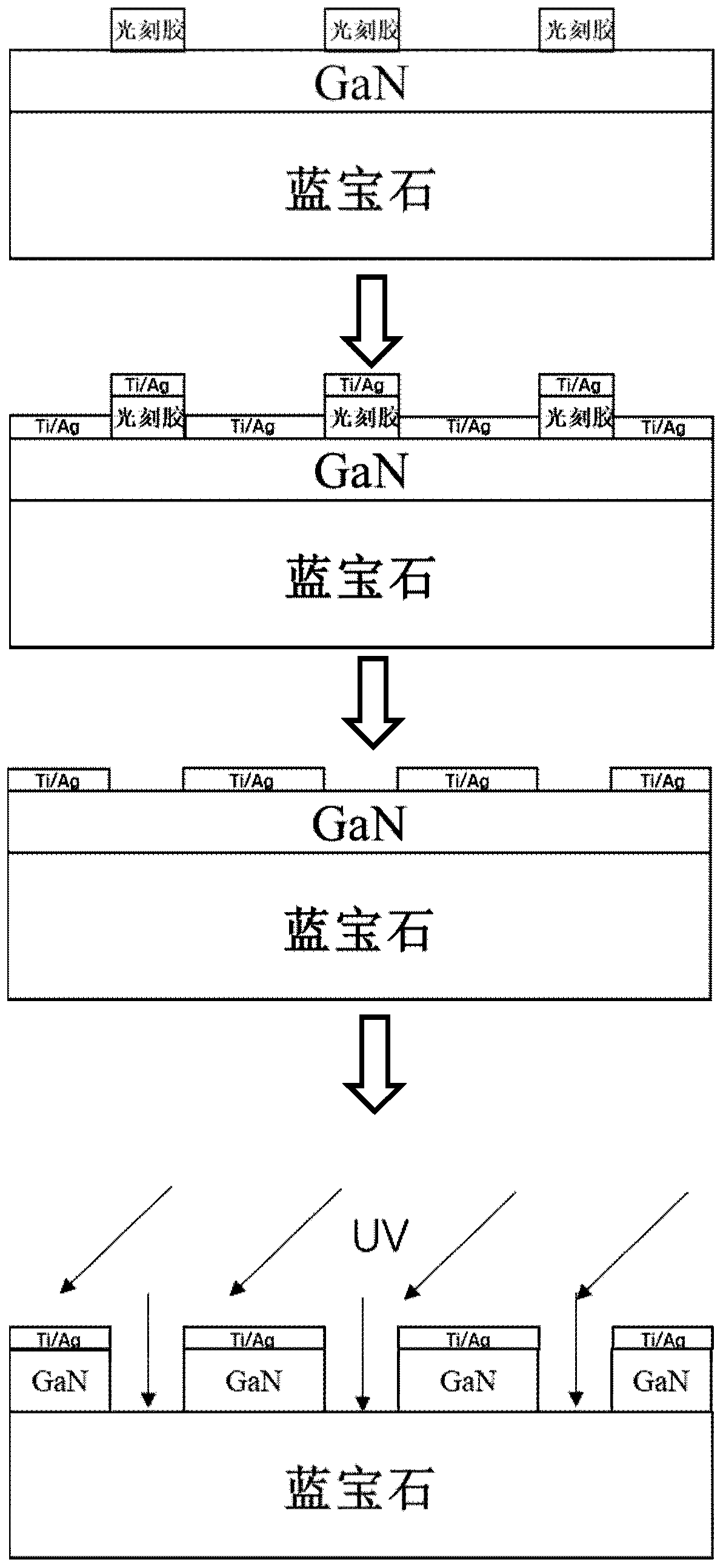

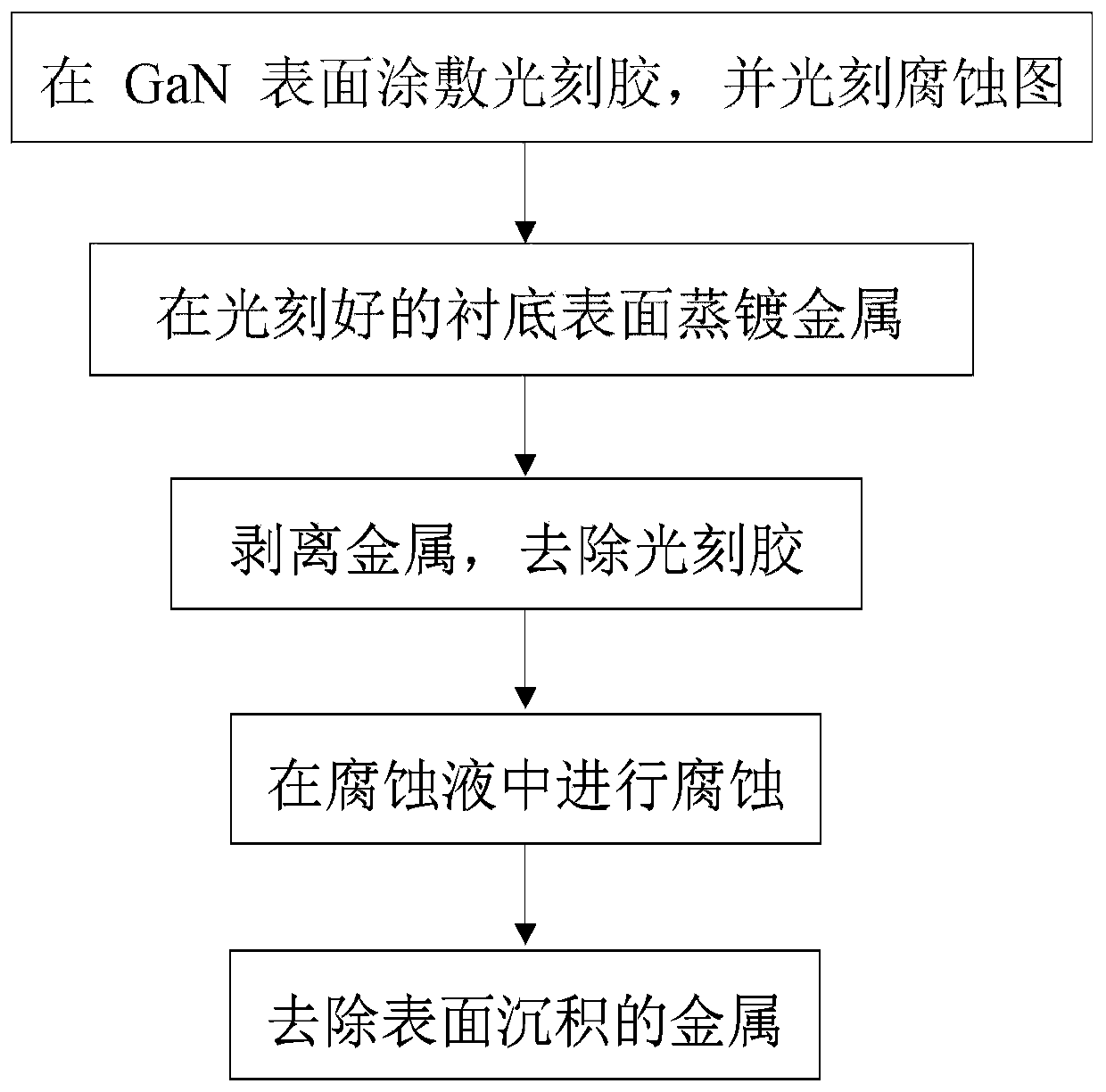

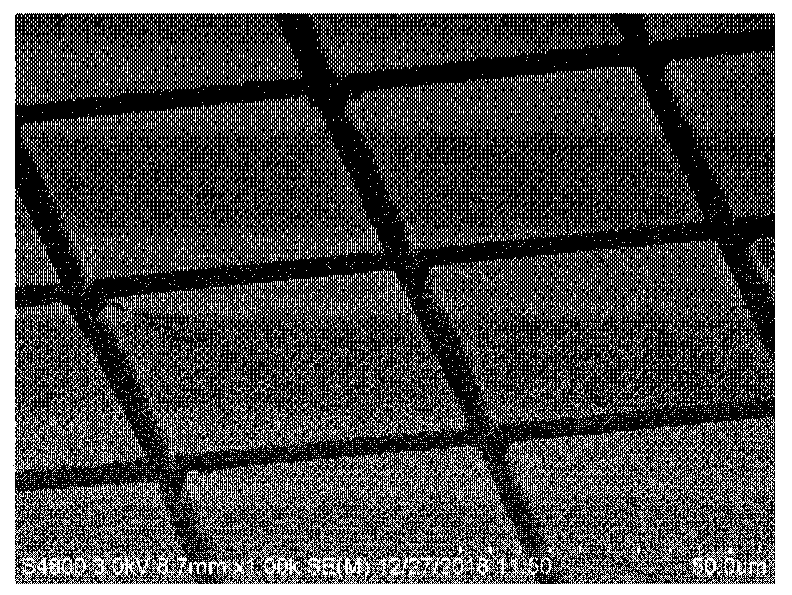

[0042] see figure 2 , and see in conjunction with figure 1 As shown, the substrate used in this embodiment is a sapphire substrate, which was cleaned by the RCA standard cleaning method, and the GaN layer obtained by epitaxy on the sapphire substrate, with a thickness of 6 μm, was cleaned by the RCA standard cleaning method. The GaN substrate was subjected to negative resist photolithography to obtain a square array with a width of 50 μm and a pitch of 5 μm, and then electron beam evaporation was used to vapor-deposit metal Ti / Ag with a thickness of 100 nm and 300 nm on the square array obtained after photolithography, and then Carry out the stripping of the metal with the blue film, expose the part to be corroded, and clean the stripped substrate, remove the photoresist on the surface of the substrate, and then clean it with deionized water. Configure CuSO 4 and HF mixed solution as corrosion solution, CuSO 4 The concentration of the solution is set to 0.015mol / L, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com