Organic light-emitting display apparatus and preparation method thereof

A technology of light-emitting display and organic light-emitting layer, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc. It can solve the problems of easily scalding the pixel area of OLED, high requirements on laser precision, and affecting production capacity. The effect of low etching cost, high etching precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

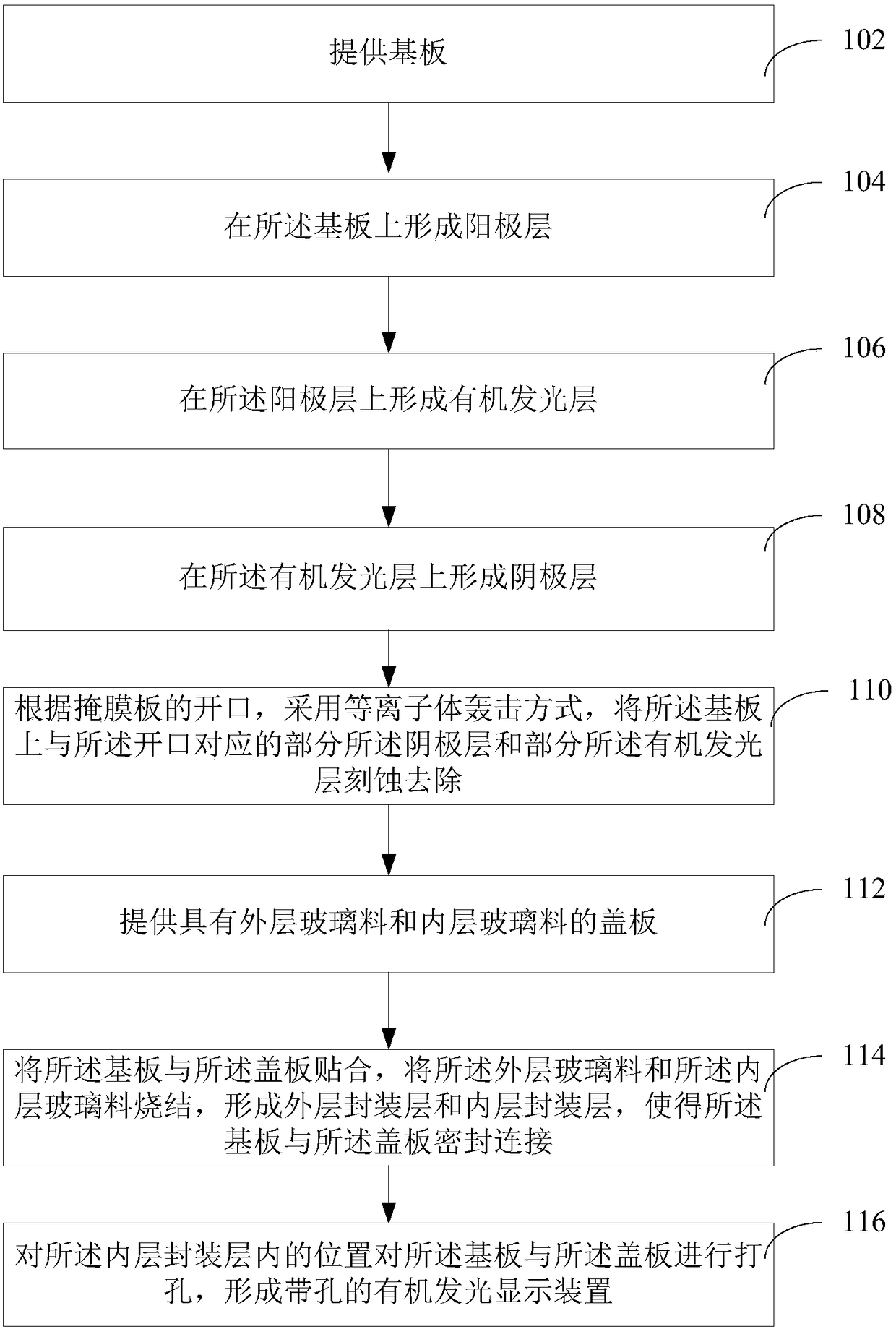

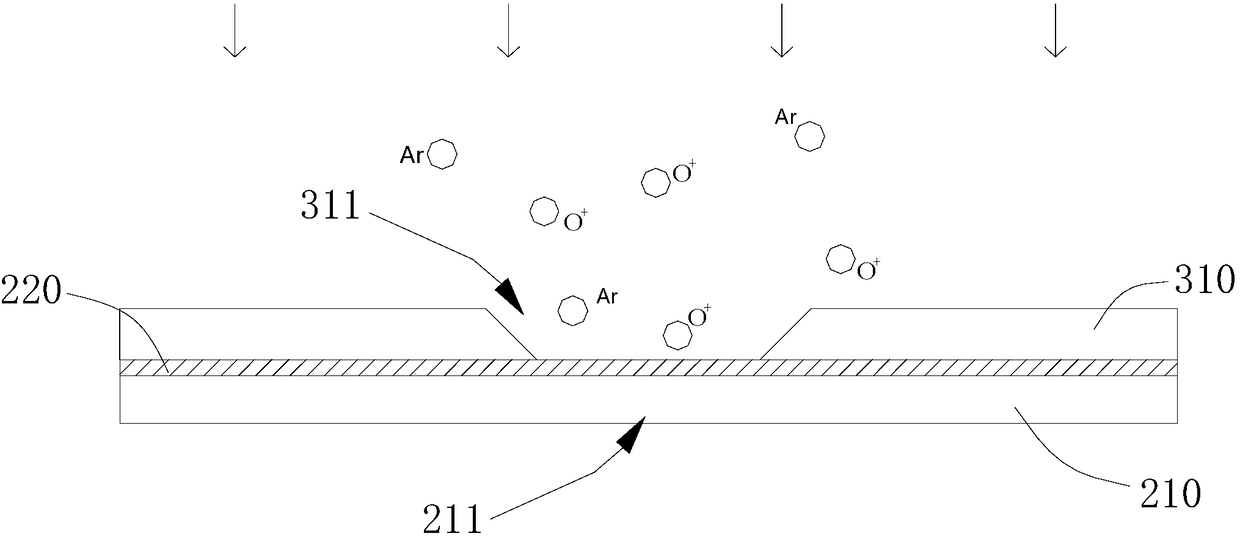

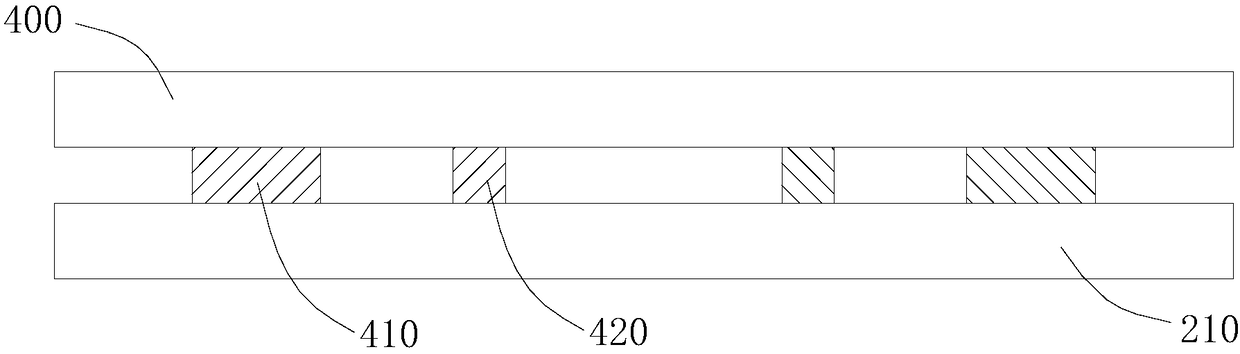

[0039] For example, a method for manufacturing an organic light-emitting display device includes: providing a substrate; forming an anode layer on the substrate; forming an organic light-emitting layer on the anode layer; forming a cathode layer on the organic light-emitting layer; For the opening of the film plate, the part of the cathode layer and the part of the organic light-emitting layer corresponding to the opening on the substrate are etched and removed by plasma bombardment; Cover plate: bonding the substrate to the cover plate, sintering the outer glass frit and the inner glass frit to form an outer encapsulation layer and an inner encapsulation layer, so that the substrate and the cover The plates are sealed and connected; the base plate and the cover plate are perforated at positions in the inner encapsulation layer to form an organic light-emitting display device with holes.

[0040] In the above embodiment, compared with traditional laser etching, the plasma bomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com