Patents

Literature

54results about How to "Small side erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical etching solution for titanium and titanium alloy

A chemical etching solution used in Ti and Ti alloys characterizes that it is composed of H2F2, HNO3 and water, their volume percentage is: H2F2 5-15% HNO3 8-35%, water 50-85%, which can be used under normal temperature having the advantages of quick corrosion, small side corrosion, long life time of the solution and low process cost.

Owner:OCEAN UNIV OF CHINA

Etching liquid for copper nickel multilayer film

The invention relates to etching liquid capable of selectively etching a copper nickel multilayer film in a semiconductor device with an oxide semiconductor layer and the copper nickel multilayer film. The etching liquid contains hydrogen peroxide, an etching inhibitor, a chelating agent, organic acid, a hydrogen peroxide stabilizer, a pH modifier and a water medium; according to total weight of the etching liquid, hydrogen peroxide is 5-30%; according to total weight of the etching liquid, the etching inhibitor is 0.01-5%; according to total weight of the etching liquid, the chelating agent is 0.1-5%; according to total weight of the etching liquid, the organic acid is 1-10%; according to total weight of the etching liquid, the hydrogen peroxide stabilizer is 0.01-0.1%; the content of the pH modifier enables the pH value of the etching liquid to be 3-5; and the balance is the water medium. After etching by the etching liquid, the wiring section shape is excellent, and the undercutting phenomenon can be effectively prevented.

Owner:惠州达诚微电子材料有限公司

Method for etching cutting of glass substrate

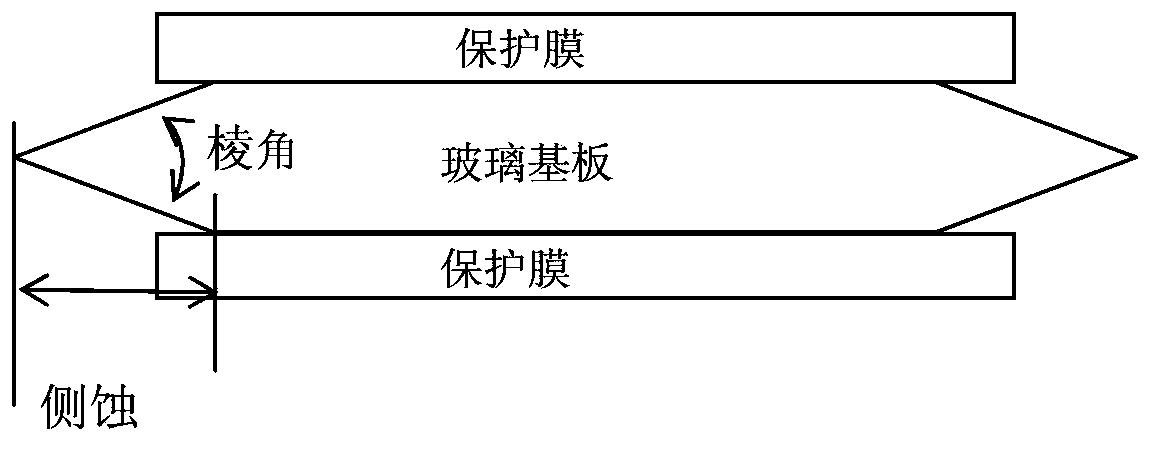

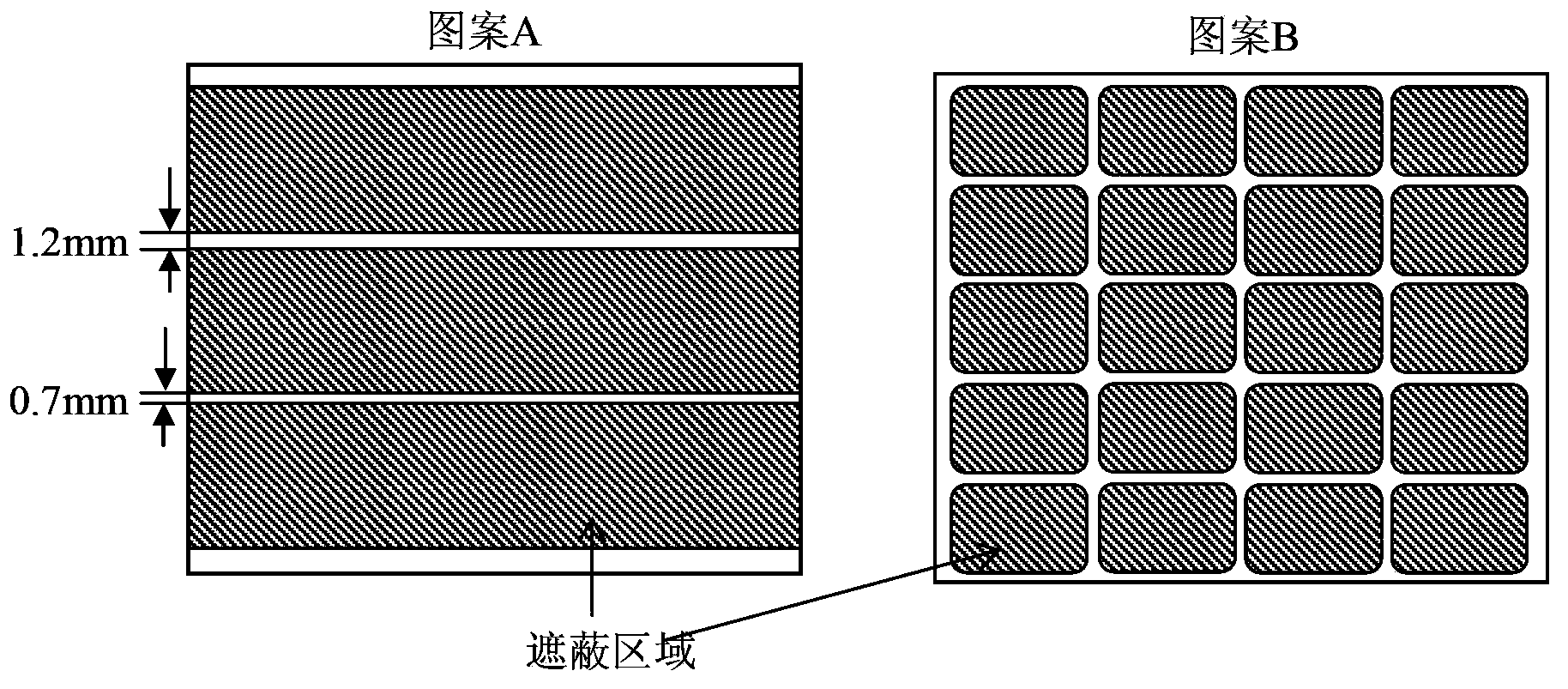

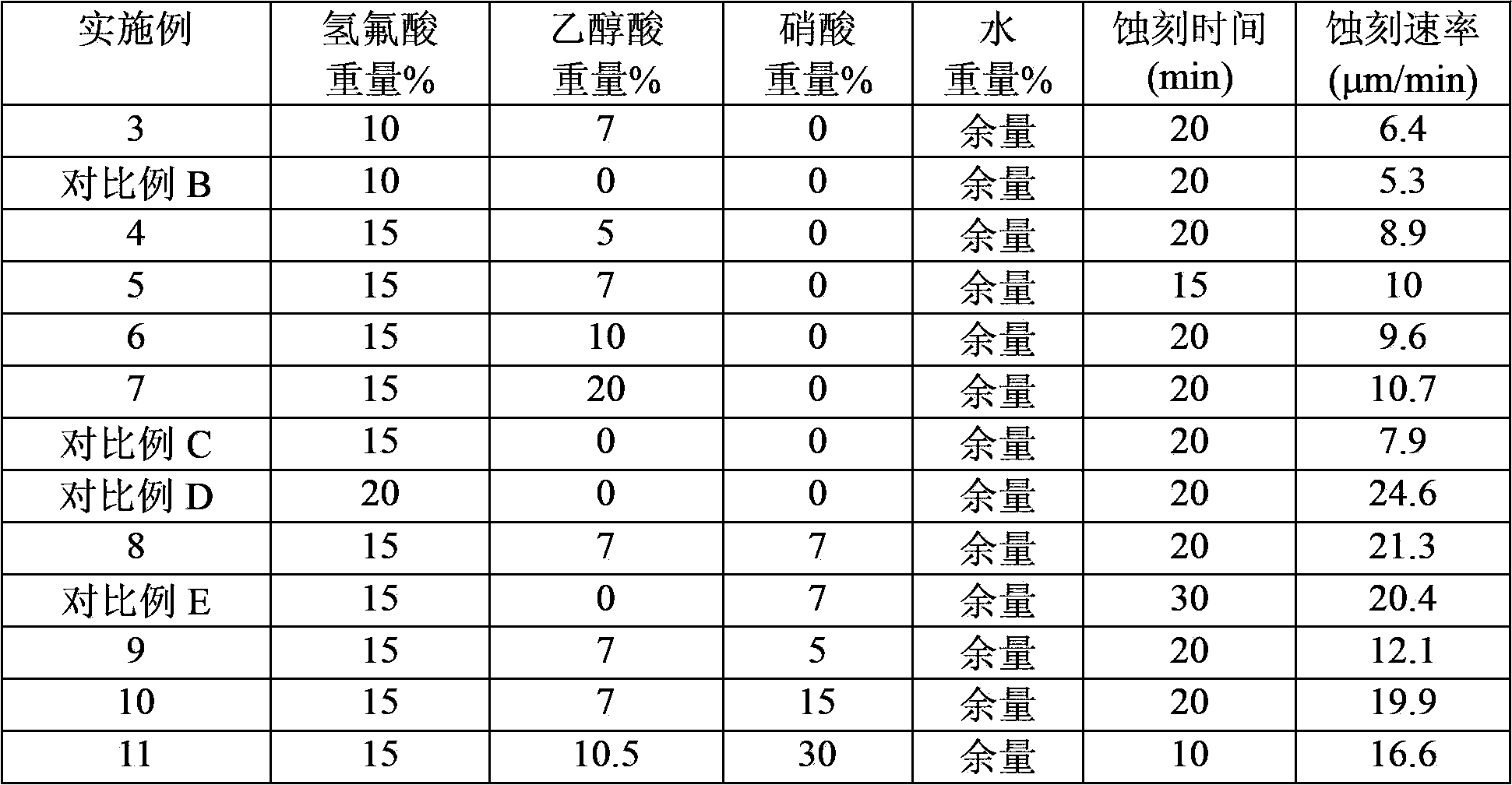

PendingCN103693855ASmall side erosionBig cornersGlass severing apparatusGlass productionHydrofluoric acidCutting glass

The invention relates to a method for the etching cutting of a glass substrate. An etching cutting solution used by the method includes about 10.1-20wt% of hydrofluoric acid, about 5-20wt% of glycollic acid, about 0-30wt% of nitric acid and about 30-84.9wt% of water, the weight percentage content of each of the above components is based on the total weight of the etching cutting solution, and the etching cutting solution basically contains no ammonium fluoride. The invention also relates to a glass substrate. The glass substrate is obtained through the method. Compared with glass substrates obtained after the etching cutting through a solution only containing hydrofluoric acid, the cut glass substrate in the invention has the advantages of less lateral etching and large corner angle.

Owner:THE CHEMOURS CO FC LLC

Etching method and etching polishing liquid

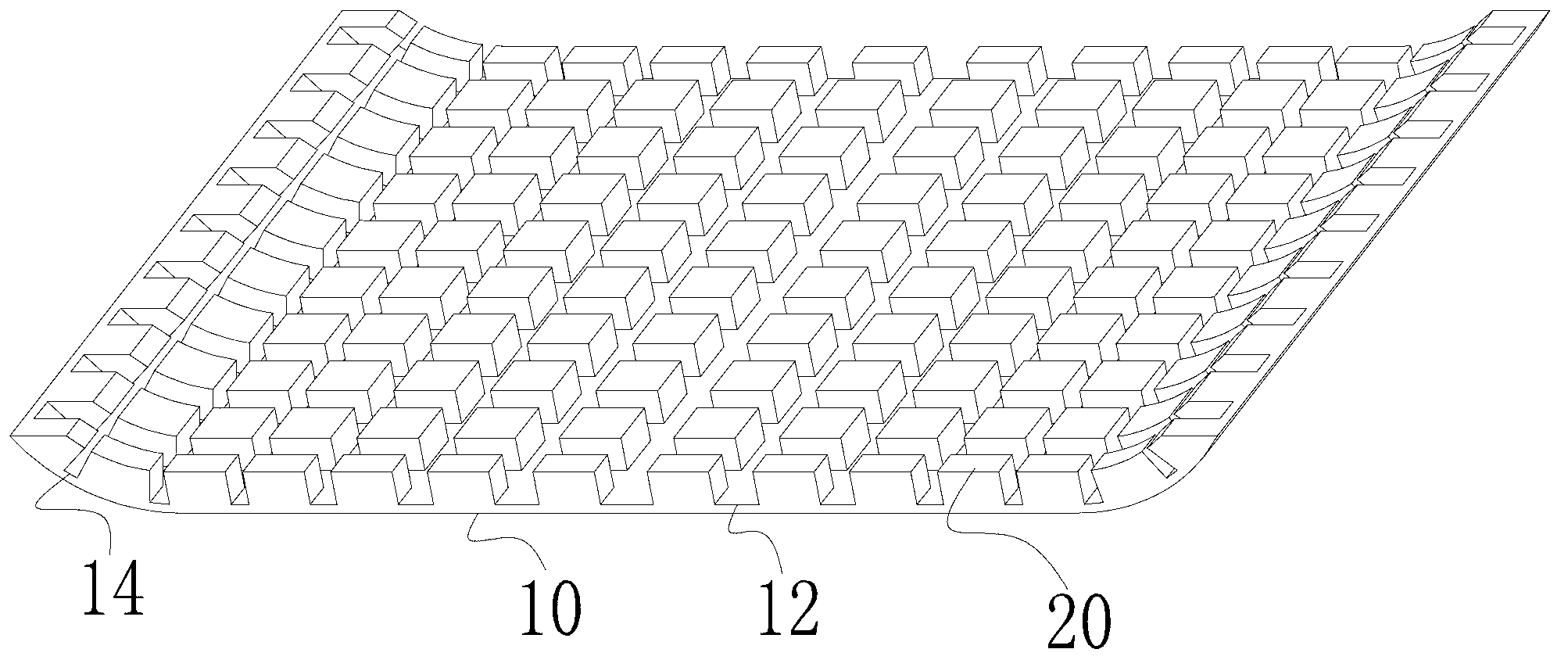

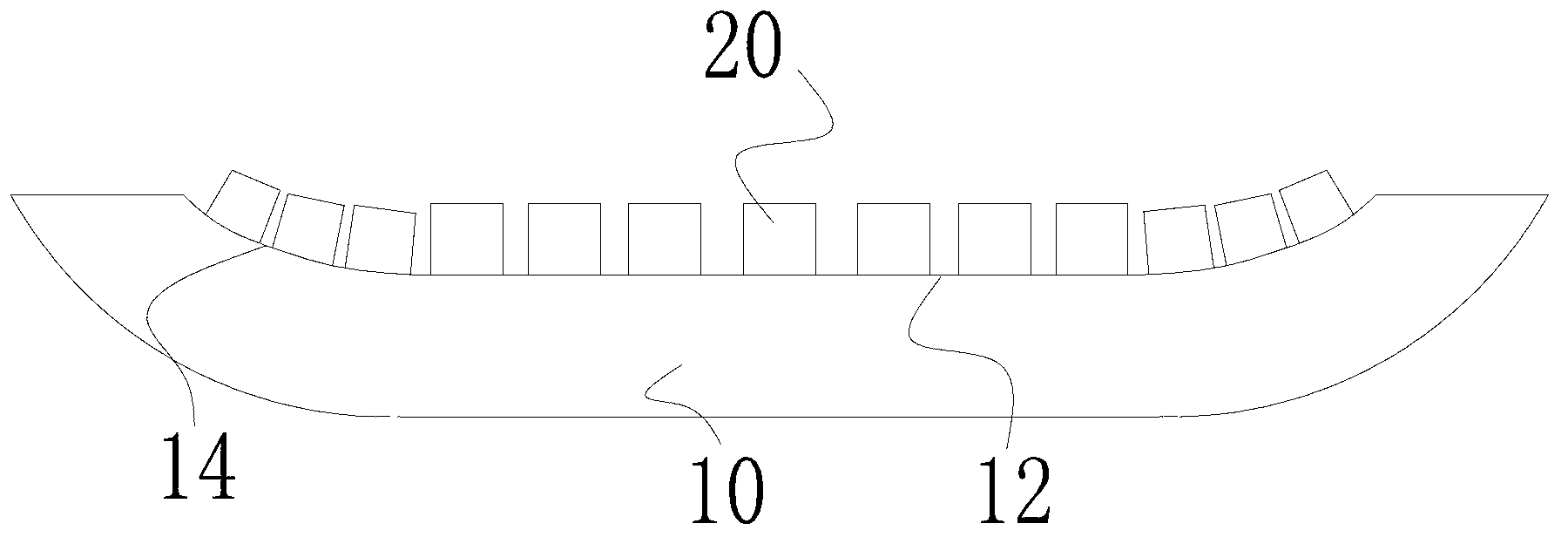

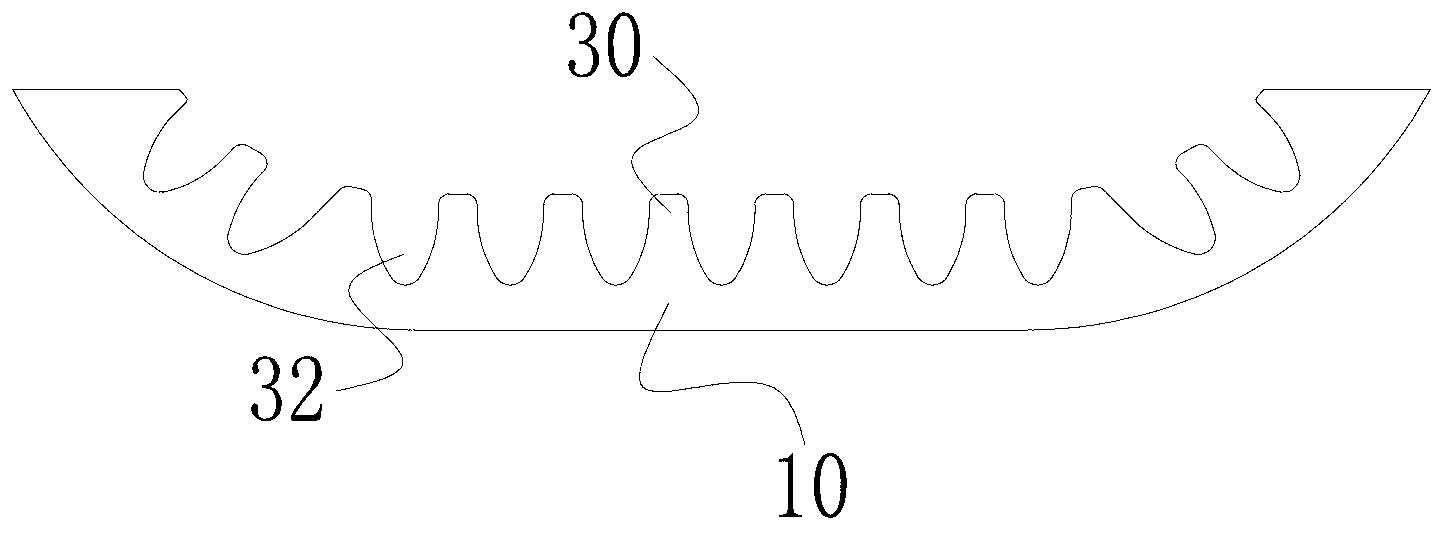

The invention discloses a method for etching a flat surface of a metal product and a curved surface connected with the flat surface. According to the method, a concavo-convex continuous microstructure is formed in the surface of the metal product by controlling the size of mask blocks and mask gap on the flat surface and the curved surface of the metal product and controlling related process parameters such as etching time, etching pressure and the like in an etching process; the depth of each pit is gradually reduced from the center of the flat surface to the edge of the curved surface; the section of the pit is shaped like a trough arc of sine wave; each projection does not have an obvious edge; the adaption part of the projection is in smooth transition; the section of the projection is similar to a quadrangular shape; the whole structure is in gentle transition; the microstructure takes on gradual transition connection of from existence to null and has good visual and tactile effects; and the requirements on higher anti-skid performance and attractive appearance can be met.

Owner:GUANGDONG UNIV OF TECH

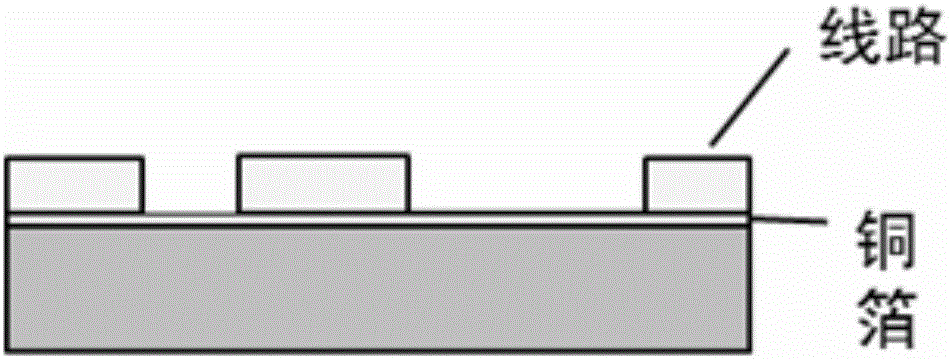

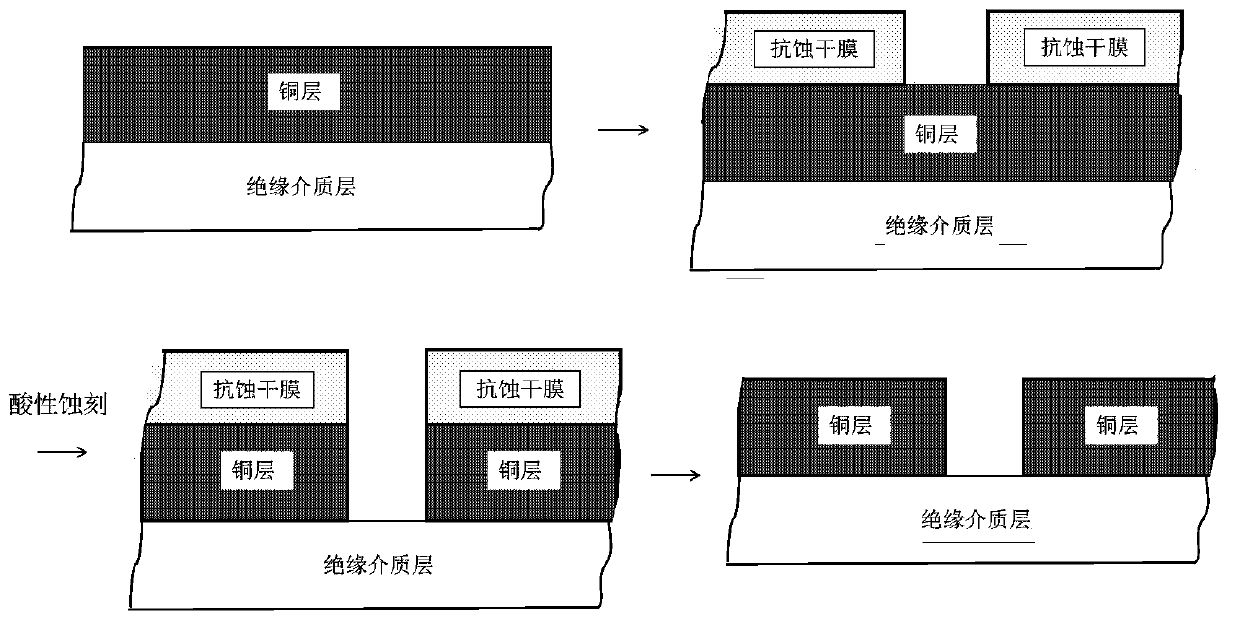

Method for etching PCB outer layer circuit of fine circuit

InactiveCN103327746AAvoid thin linesQuick responseConductive material chemical/electrolytical removalWire widthEtching

The invention discloses a method for etching a PCB outer layer circuit of a fine circuit. According to the method, when a circuit board outer layer figure with wire width smaller than or equal to 0.10mm and with a wire gap smaller than or equal to 0.10mm is etched, the face with dense circuits is arranged downwards, spraying etching is carried out under the condition that the spraying pressure is controlled within 0.3-0.7Kg / cm<2>, and the sprayed etching liquid is reacted with the copper exposed area on the bottom of grooves among the circuits. Due to the fact that the etching liquid in the middle on the bottom of each groove flows fast, the reaction speed is high, the etching effect is good and the problem of unclean etching can be effectively avoided. Due to the fact that the etching liquid on the two sides of the bottom of each groove flows slowly, reacted flowing etching liquid and the etching liquid which is sprayed at present are offset, the etching process on the two side faces on the bottom of each groove is slowed down, the purpose of reducing side etching is achieved, and the problem that the circuits are too thin is avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

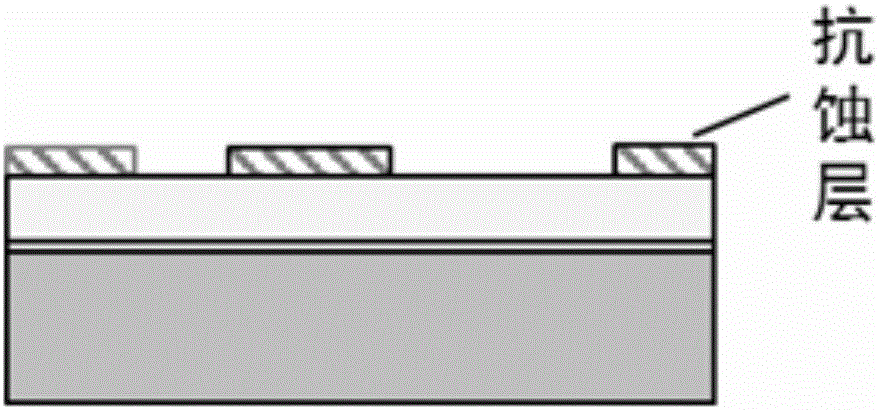

Manufacturing method of fine circuit board free of corrosion resistant layer

InactiveCN106852003AAvoid the impact of side erosionImprove manufacturing qualityConductive pattern formationCopper foilElectroplating

The invention discloses a manufacturing method of a fine circuit board free of a corrosion resistant layer. The method comprises the processes of laminating, base copper reduction, drilling, depositing copper preplating, pattern electroplating, stripping and flash rusting and subsequent processes. According to the manufacturing method, the fine circuit board is manufactured by combining a thin copper foil with a flash rusting technology; the manufacturing method can be used for manufacturing an ultrafine circuit; and the manufacturing accuracy of the circuit is improved.

Owner:YIXING SILICON VALLEY ELECTRONICS TECH

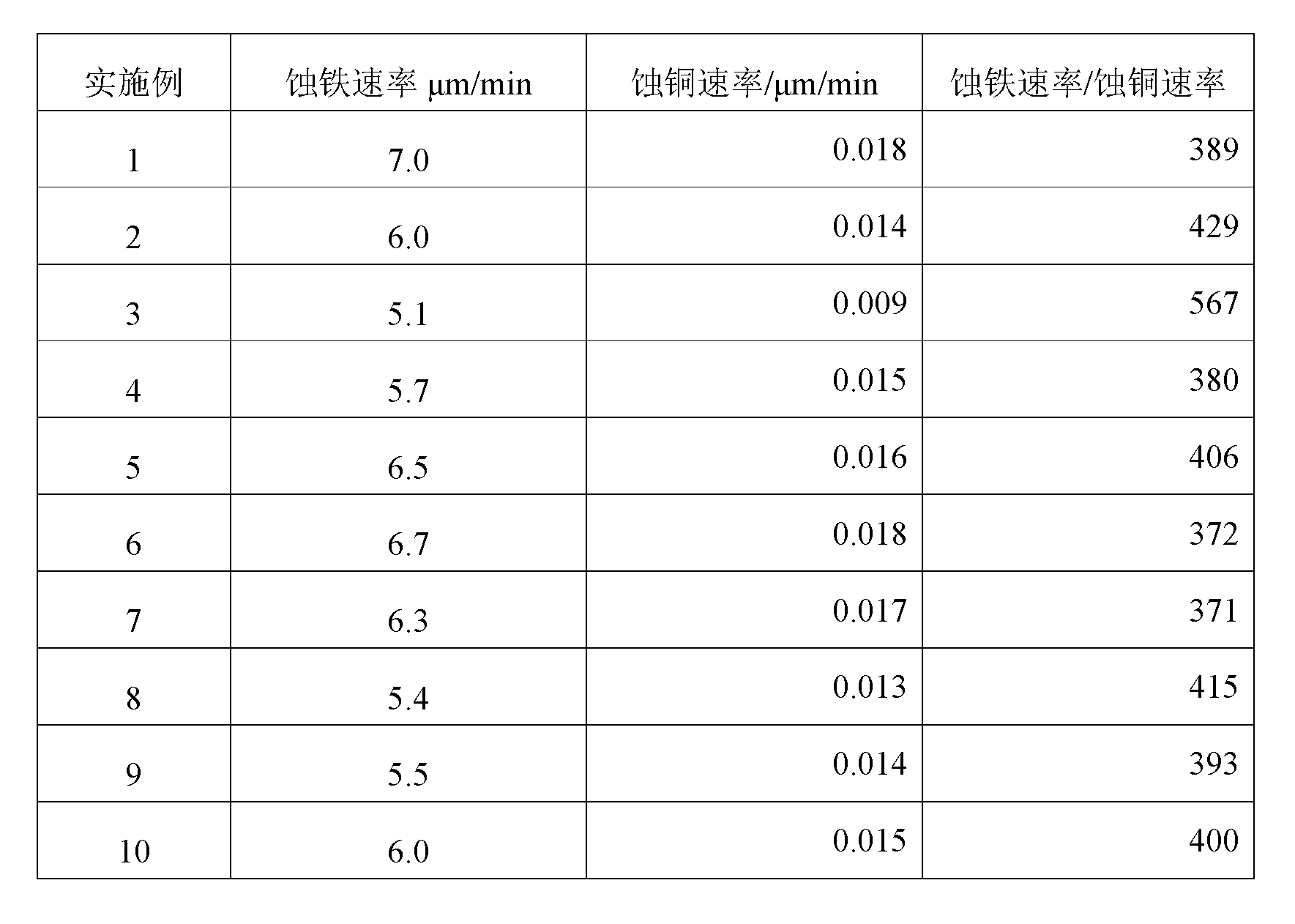

Selective iron etching solution and etching method

The invention discloses selective iron etching solution, comprising 4-250g / L of a water-soluble aromatic nitro-compound, 2-10mol / L of inorganic acid, 0.1-2g / L of a corrosion inhibitor and the balance of deionized water. A novel selective etching system is adopted; the etching method is fast in iron etching speed, stable in etching speed, even in etched surface, small in side corrosion, regular in side boundary and small in copper etching speed; the iron etching speed and the copper etching speed are greater than or equal to 200; the etching solution does not contain the materials with large volatility, such as hydracids or nitric acid; the etching solution is greener and more environment-friendly; and the etching solution is suitable for selective etching of the surface of a copper base material, and is also suitable for refined processing of carbon steel or low-alloy steel and members thereof.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

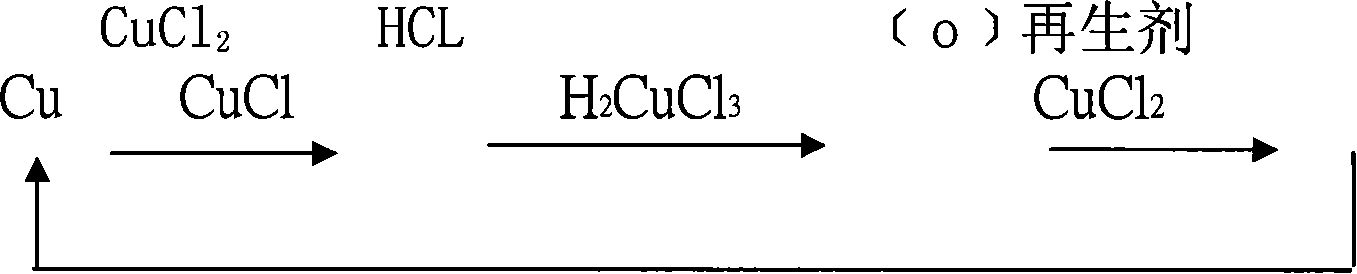

Etching liquor and circular use method thereof

The invention discloses etching liquor and a circular use method thereof. The etching liquor comprises copper chloride, organic amine, an oxidizing agent, an additive agent and deionized water. In each liter of etching liquor, 10 to 150 g of copper chloride, 10 to 200 g of organic amine, 1 to 100 g of the oxidizing agent, 1 to 100 g of the additive agent and the balance deionized water are included; in the use process of the etching liquor, the solution is alkaline, and the requirement for a device is not high, the use cost is low, operation is safe and environment-friendly, and a detection control system is simple; low etching is achieved, the etching speed is high, and stability is high. A membrane separation technology and a deposition reduction technology are combined, circular recycling of the etching liquor can be well achieved, a product after the reaction is nitrogen and water, other impurities are not brought in, and filter liquor obtained after copper filter and depositing can be recycled to be used for preparing new etching liquor.

Owner:长沙利洁环保科技有限公司

Copper etching liquid composition and production method thereof

The invention discloses an acidic copper-eroding fluid combination for eroding copper or copper alloy on surfaces of printed circuit boards and a production method for the fluid combination. The fluid combination comprises by weight the following: ammonium chloride 6-8%, sodium chloride 0.7-0.9%, sulfuric acid 35-37%, and the remainder water. The method for producing the copper-eroding fluid combination comprises: (1) adding by proportion in sequence the raw materials ammonium chloride, sodium chloride, sulfuric acid and water in a production tank, (2) agitating to completely solve, then inspecting. The copper-eroding fluid is a standalone fluid, can be used without changing prior production system, is of high steadiness, low erosion on the sides of base boards and high eroding speed, can reduce production cost and avoid environmental pollution.

Owner:珠海顺泽科技股份有限公司

Two-liquid acid etching liquid oxidant

InactiveCN101760199AHigh amount of dissolved copperImprove stabilitySurface treatment compositionsAcid etchingSodium chlorate

The invention relates to a two-liquid acid etching liquid oxidant used for all kinds of copper chloride etching systems. The two-liquid acid etching liquid oxidant contains the following components by weight percent: 35-37 percent of sodium chlorate, 6-8 percent of sodium chloride, 0.15-0.25 percent of additive and 55-58 percent of water. The invention has the advantages that the amount of dissolved copper is large, the side etching is small, no sediment is produced during use and the stability is high.

Owner:广东奥美特集团有限公司

Etching liquid and method for manufacturing printed circuit board

The invention relates to an etchant used for manufacturing a printing circuit board, is characterized in that the etchant contains bivalent copper ions, hydrochloric, poly-guanidine and water. The invention still relates to an etching method for a printing circuit board and includes the following steps: firstly, the etchant is used for contacting the surface of copper or the copper alloy of the printing circuit board; and secondly, the surface is covered by an organic coating. Compared with the prior art, the invention has the advantages that the organic addition agent of the etchant has a low content, therefore, the side etching can be reduced effectively and a fine circuit diagram can be formed as well.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

Acid etching liquid and preparation method thereof

The invention discloses an acid etching liquid. The acid etching liquid comprises the following components: sodium chlorate, refined salt, ammonium chloride, hydrochloric acid and an additive agent, wherein the additive agent is one or several of ureas. The acid etching liquid provided by the invention has the benefits as follows: the corrosion to the equipment is little due to the medium-low acidconcentration during the using process, the using cost is low, the operation is safe and environment-friendly, the detection and control system is simple, peroxides are not contained, the operation is safe and reliable, the lateral erosion is little, the production of compact and fine circuit boards is facilitated, the etching speed is higher and automatically controlled, and the stability is good.

Owner:佛山市华希盛化工有限公司

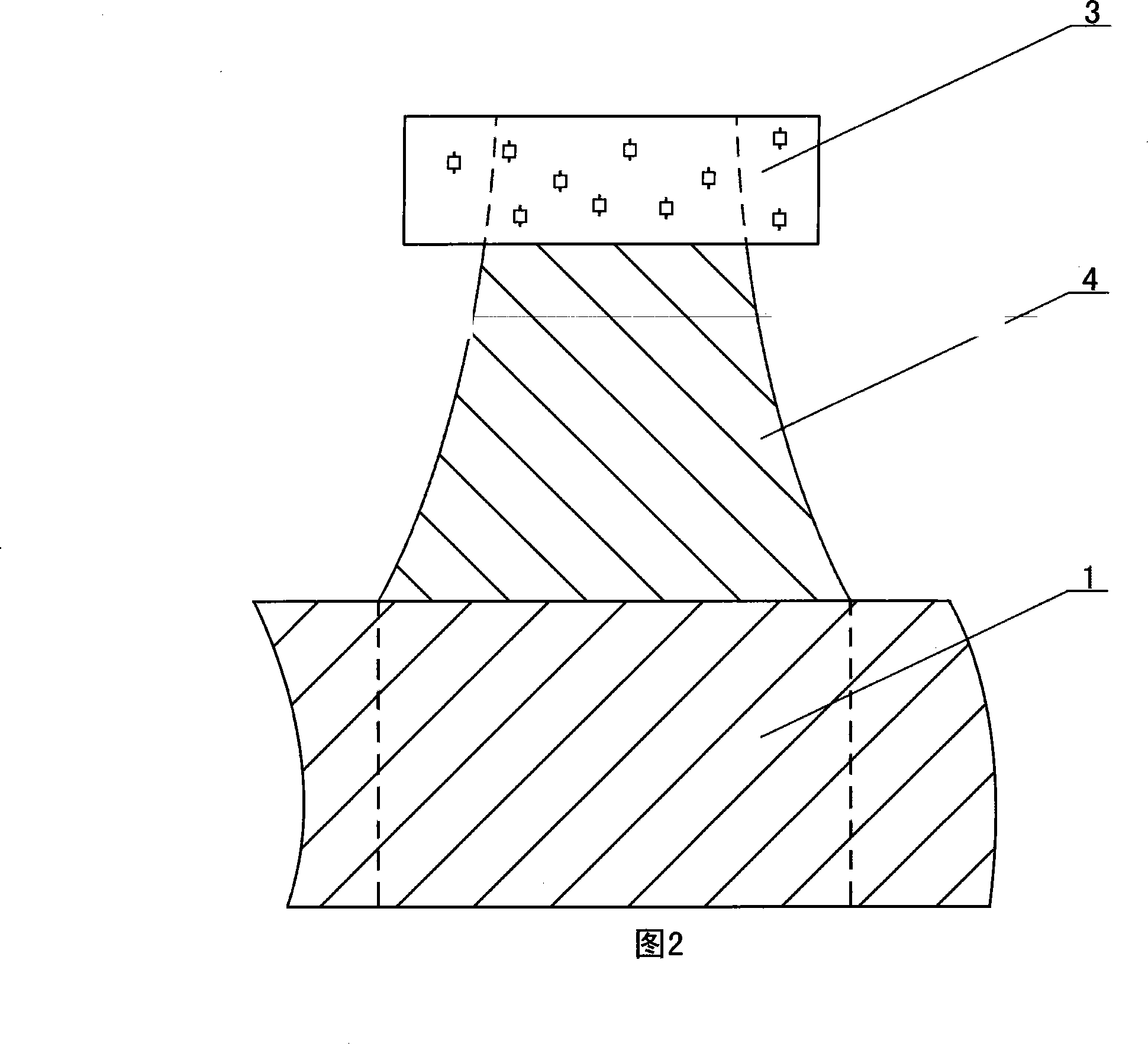

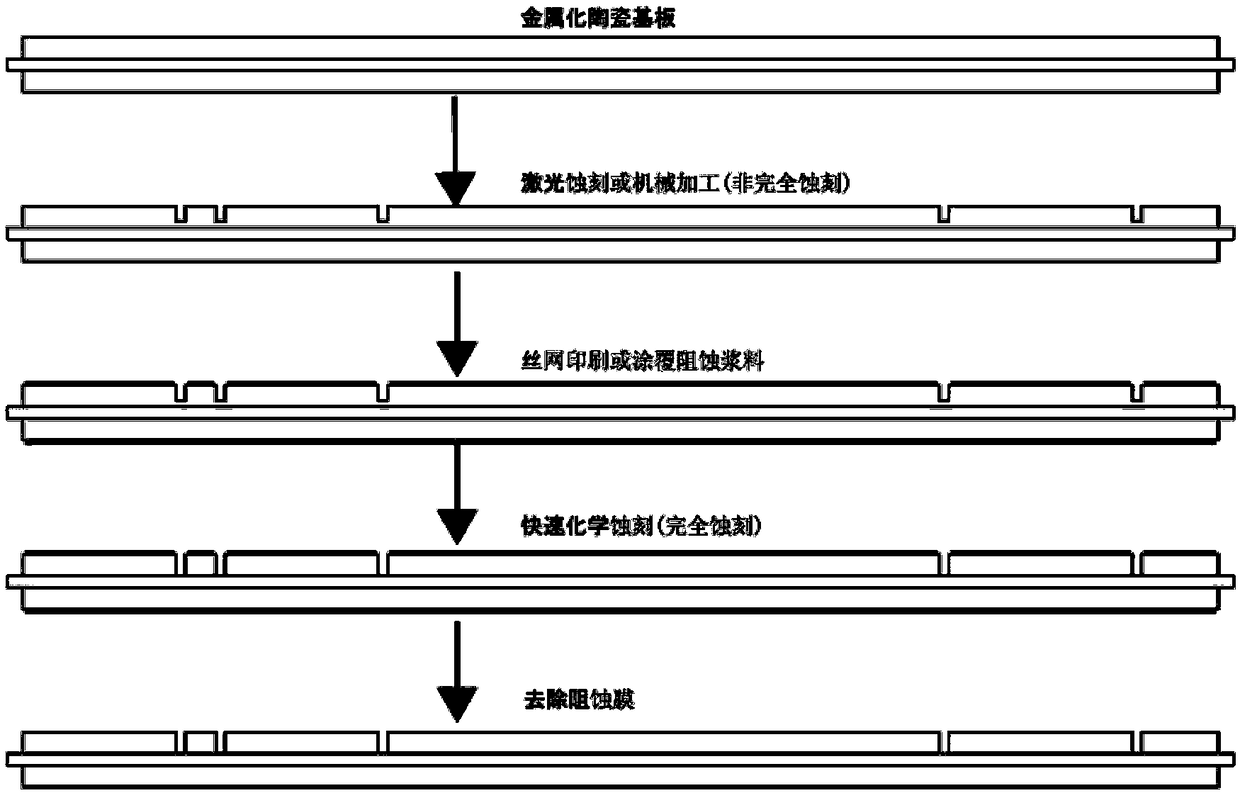

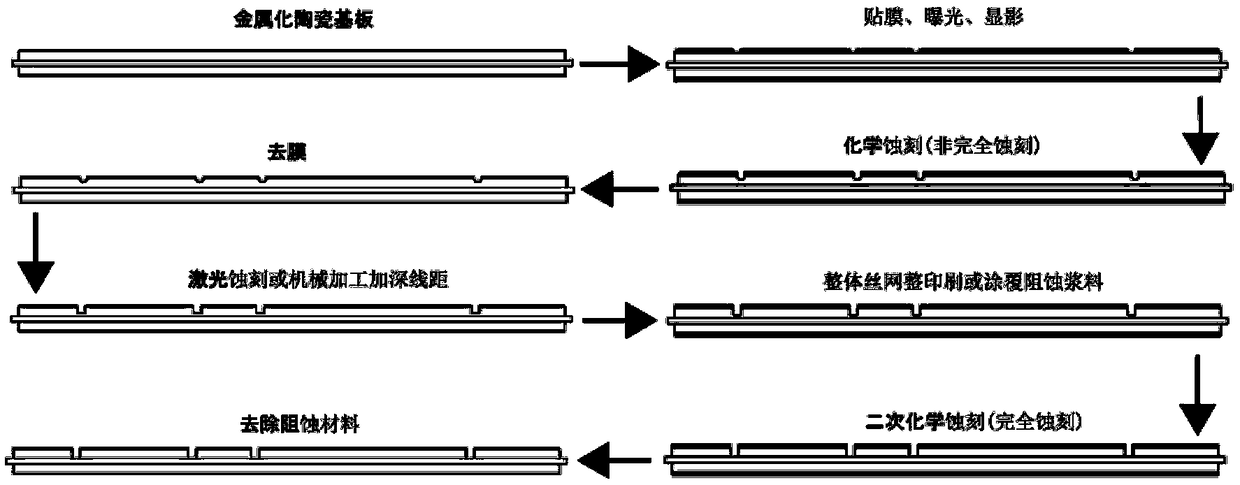

A Method for Making Ultra-narrow Line Width and Line Distance Pattern of Metallized Ceramic Substrate

InactiveCN109195340AFast processingImprove efficiencyConductive material mechanical removalConductive material chemical/electrolytical removalFine lineLower limit

The invention discloses a method for manufacturing ultra-narrow line width and line distance pattern of a metallized ceramic substrate, belonging to the field of power electronic device packaging. Inthe normal production process of metallized ceramic substrate, because the circuit pattern needs to be processed on the ceramic substrate, there will inevitably be an etching process. When the thickness of copper reaches more than 300 [mu]m m, the line width and the line distance of the pattern are guaranteed to be more than 500 [mu]m m. However, in the high-end electronic packaging field, the linewidth is required to be less than 100 [mu]m m, which limits the application of metallized ceramic substrate in these high-end electronic packaging fields. As to the phenomenon, the invention providea circuit pattern ultra-narrow linewidth for fabricating a metallized ceramic substrate, In the scheme, the metallization layer is etched by laser etching and chemical etching, so that the fine line width and line distance are etched, the lower limit value and precision of line width and line distance are greatly improved, and the application field of metallization ceramic substrate is widened.

Owner:桑尼维尔新材料科技(南京)有限公司

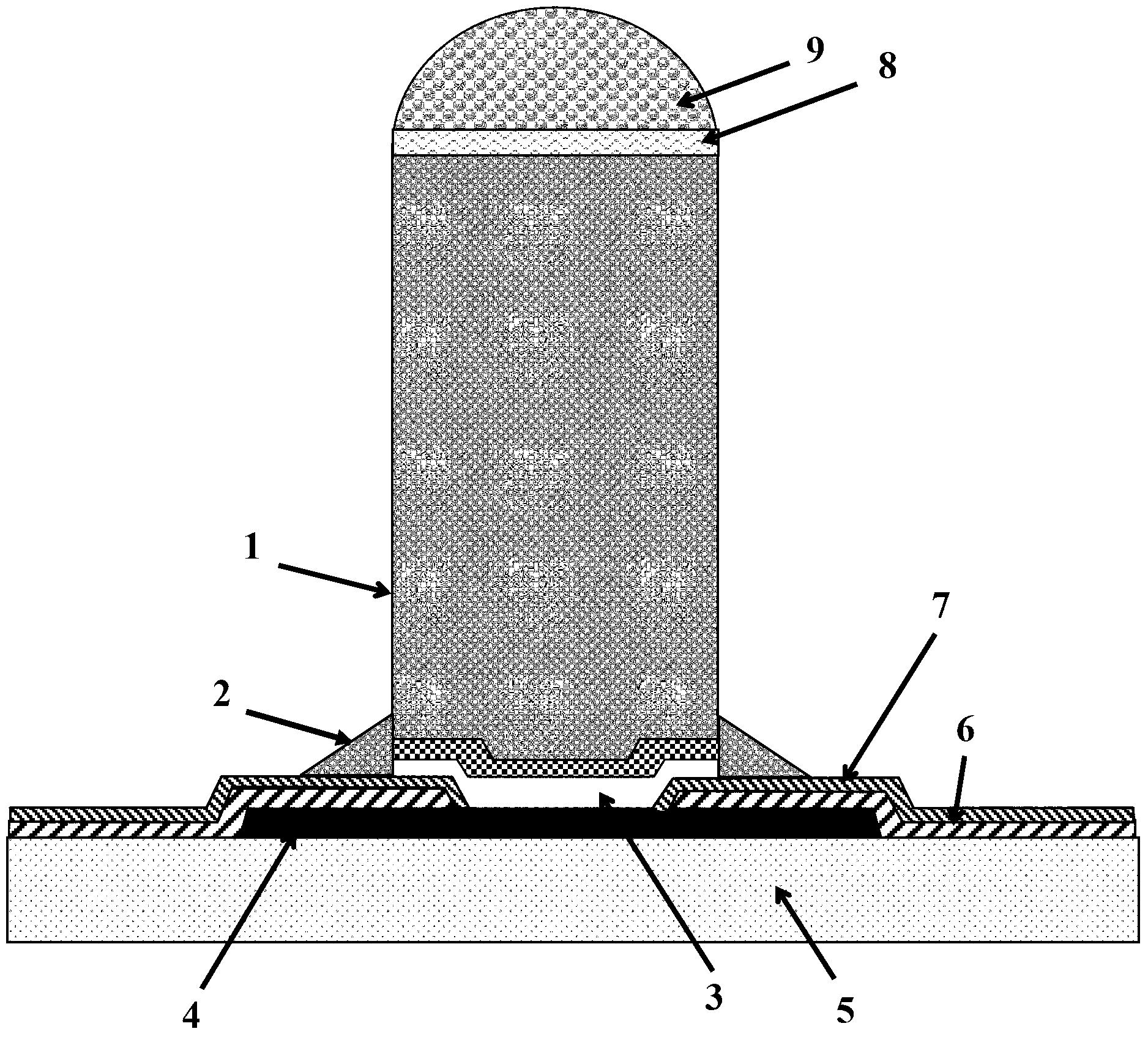

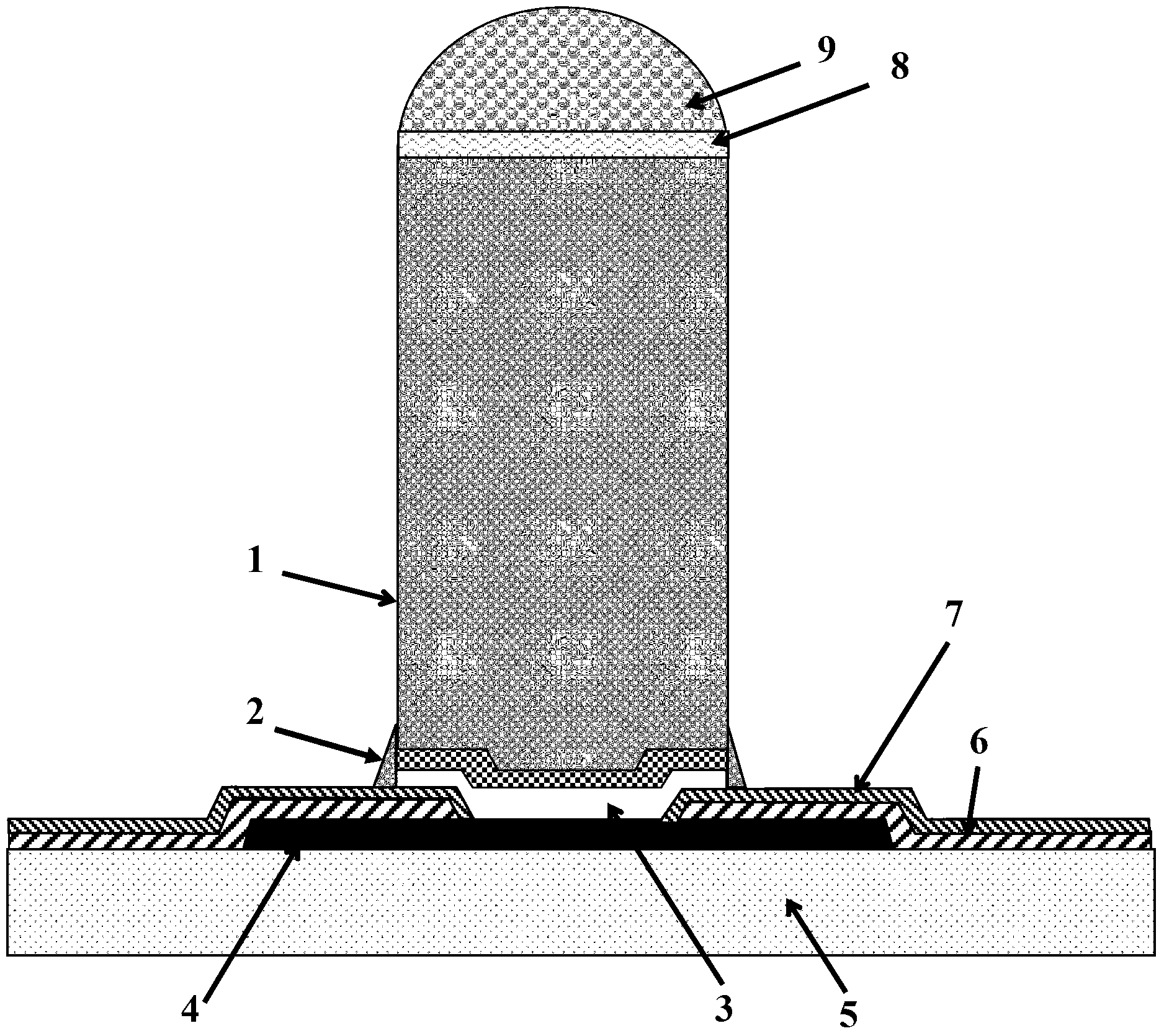

Salient point bottom protection structure

ActiveCN103219305AAct as compensationSmall side erosionSemiconductor/solid-state device detailsSolid-state devicesEtchingErosion

The invention discloses a salient point bottom protection structure which comprises a salient point. Protruding objects are arranged on the periphery of the bottom portion of the salient point, and the materials of the protruding objects are identical to the materials of the salient point. A salient point lower metal layer is arranged on the bottom portion of the salient point, an aluminum layer is arranged on the lower portion of the salient point lower metal layer, and a silicon wafer is arranged on the lower portion of the aluminum layer. Due to the fact that the protruding objects are arranged on the bottom portion of the salient point, the protruding objects have the function of compensation in a wet etching process, the probability of occurrence of lateral erosion is reduced, and therefore a reliable salient point packaging structure is formed.

Owner:NANTONG FUJITSU MICROELECTRONICS

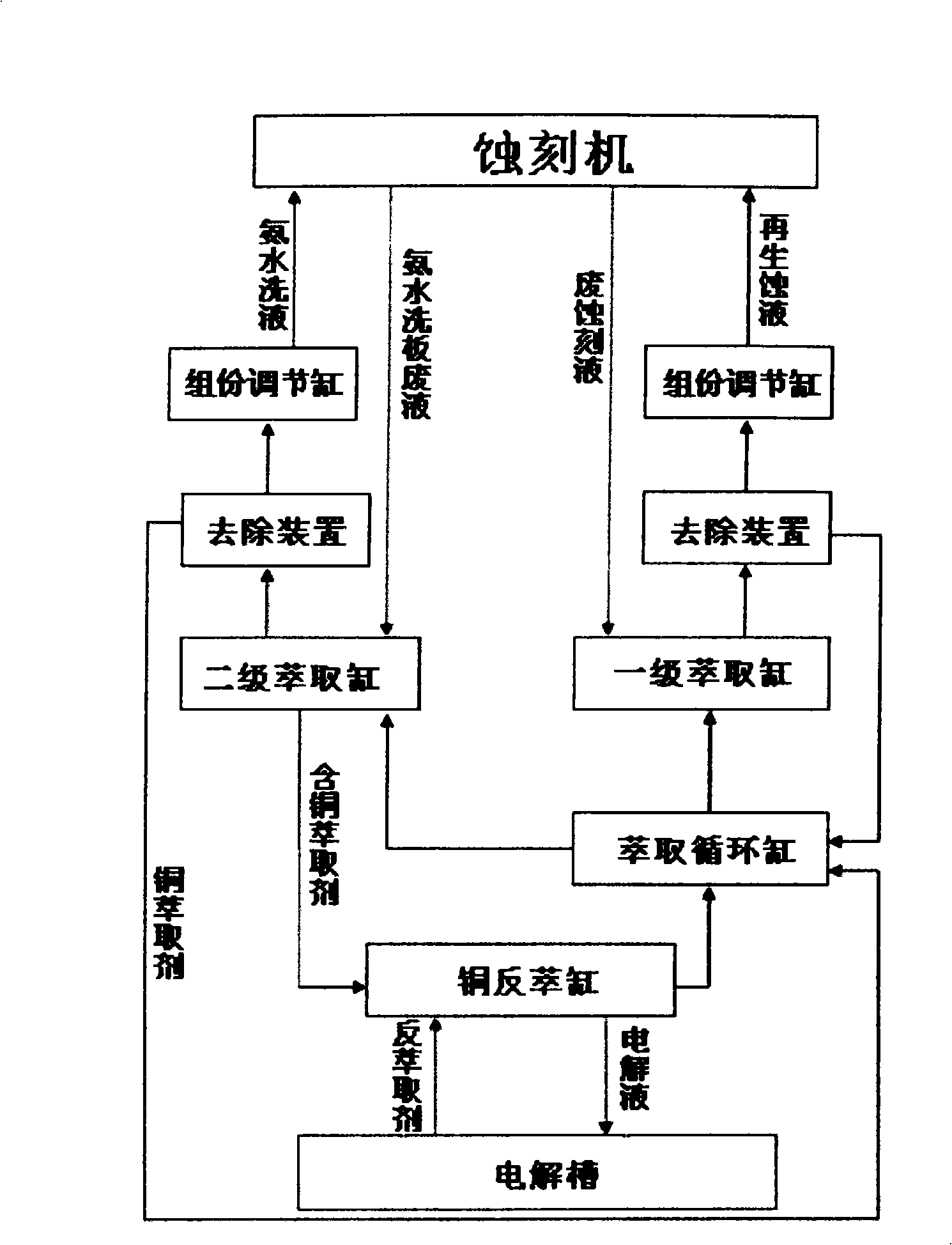

Indirect regeneration for waste etching solution and recovery processing system for copper

InactiveCN101285195AIncrease incomeEtching effect is stableProcess efficiency improvementLiquid wasteEtching

The invention relates to a cyclic regeneration technology for etching waste solution, in particular to a system for cyclic regeneration of the etching waste solution and recovery processing of copper. The etching waste solution generated by an etching machine and ammonia board-washing waste solution pass through an etching waste solution inlet in the system and respectively enter into a primary extraction cylinder and a secondary extraction cylinder; extracting agent in an extracting agent circulation cylinder passes through an extracting agent inlet and enters into the primary extraction cylinder and the secondary extraction cylinder; copper ions in the etching waste solution are extracted and separated by the extracting agent; the etching waste solution becomes regenerated etching solution and ammonia wash solution, passes through a regenerated solution outlet and enters into the etching solution regeneration system for respective composition preparation, and then an etching procedure and an ammonia board-washing procedure are performed. During the whole process of the system, closed cycle is realized; no waste water and waste gas are exhausted; the copper, the regenerated etching solution and the ammonia wash solution can be recovered high efficiently; the sewage discharge rate of the etching procedure is greatly reduced; the environmental protection pressure is reduced; moreover, the processing and running cost is reduced because three circulating systems can be operated continuously.

Owner:徐毅

Alkaline etching solution and preparation method thereof

The invention discloses an alkaline etching solution. The alkaline etching solution is characterized by comprising, ammonium chloride, ammonium bicarbonate, aqua ammonia and an additive, wherein the additive is of the urea type. In the use process of the alkaline etching solution, the etching solution is alkaline, and the requirement for equipment is low; the use cost is low, operation is safe andenvironmentally friendly, and a detection control system is simple; side etching is low, the alkaline etching solution is suitable for production of dense and thin circuit boards, and the etching speed can be automatically controlled, the etching speed is high, and the stability is rapid.

Owner:佛山市华希盛化工有限公司

Addition process manufacturing process of fine circuit board

InactiveCN112867274AIncrease roughnessImprove bindingInsulating layers/substrates workingCarbon layerEtching

The invention discloses an addition process manufacturing process of a fine circuit board, which comprises the following steps of immersing a base material into a micro-etching solution, and carrying out micro-etching treatment on the base material under the assistance of ultrasonic oscillation, placing the base material in a chemical copper plating solution for chemical copper plating, and acquiring a copper-clad base material, drilling a via hole in the copper-clad base material, depositing a conductive carbon layer on the via hole of the copper-clad base material, pasting a photosensitive dry film on the copper-clad base material, performing exposure and development treatment on the photosensitive dry film to obtain a groove of a fine circuit, forming a copper layer in the groove in an electroplating mode, and removing the dry film, and placing the copper-clad base material in a flash etching solution to be subjected to flash etching treatment. According to the process, the conductive carbon layer is adopted to realize the conduction between the conducting hole and the circuit, the copper circuit is directly formed by matching the pattern electroplating process with the flash etching process, the process is simple, the production cost is low, the production efficiency is high, the binding force between the copper circuit of the manufactured circuit board and the base material is high, and the product yield is high.

Owner:悦虎晶芯电路(苏州)股份有限公司

Method for electroplating silver on surface of printed circuit board through pulse current

The invention discloses a method for electroplating silver on the surface of a printed circuit board through pulse current. The method is low in cost, simple in process and controllable. The method comprises the steps of (1) preparing electroplate liquid containing silver salt and (2) carrying out the silver plating process. In the step (1), silver cyanide, sodium cyanide and sodium hydroxide are used as main salt, dimethylamine-borane and thiourea serve as supporting electrolytes, and an inorganic molten salt plating solution system is prepared. In the step (2), the silver plating process comprises the steps of grinding of the surface of the printed circuit board, chemical oil removal, water flushing, brush polishing, etching activation, pulse silver plating, washing and drying, wherein the pulse silver plating process is that electroplating is carried out at the temperature of 50-60 DEG C, and reverse pulse electroplating is adopted; pulse parameters are that forward current is 5-15 A, reverse current is 15 A, forward pulse time is 18-108 ms, reverse pulse time is 2 ms, and electroplating time is 60 min. The method can be applied to the field of metal materials.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

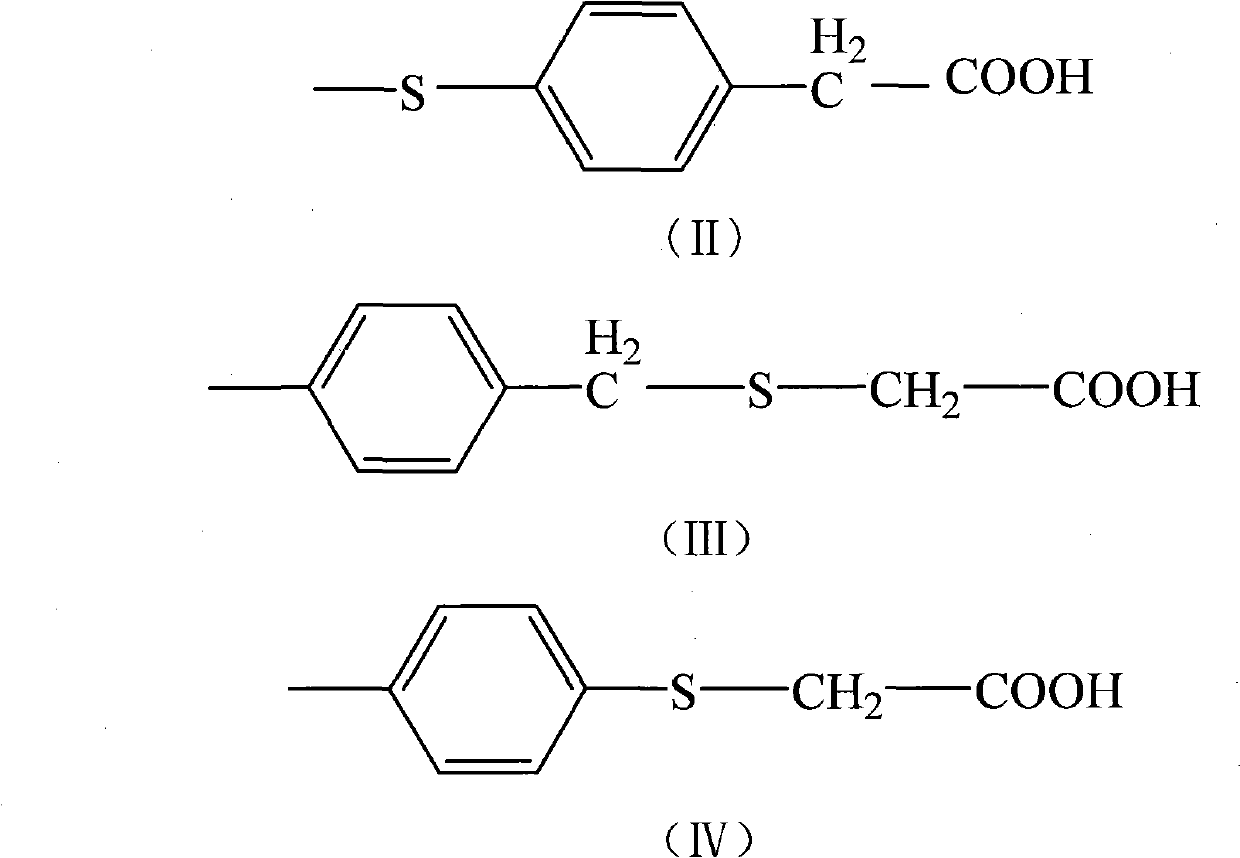

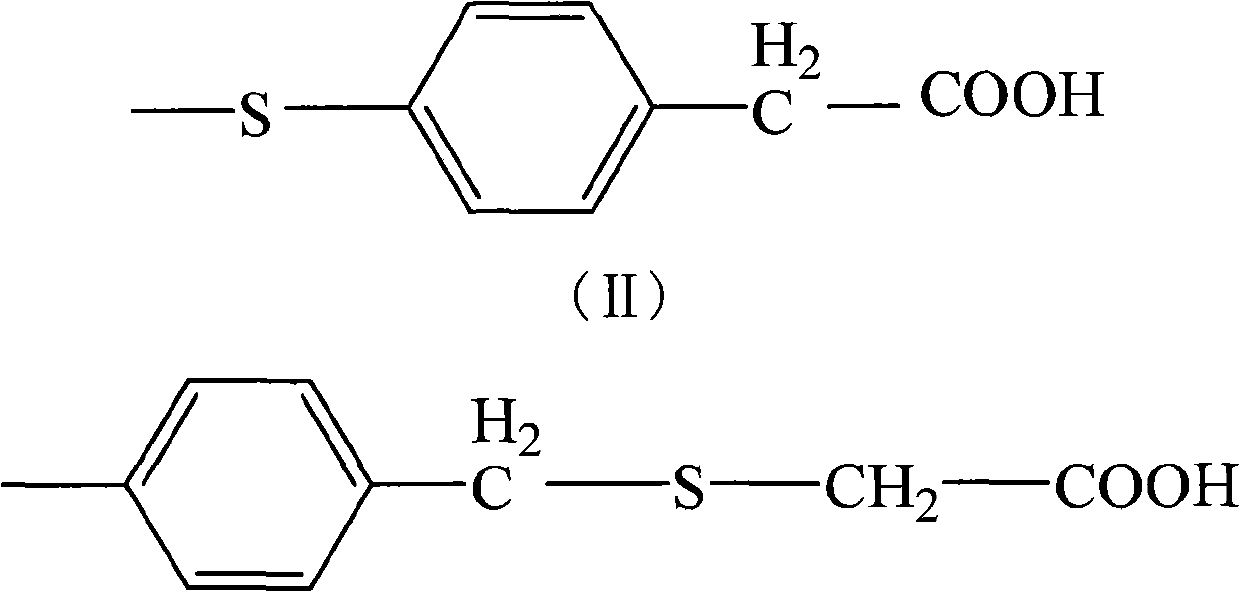

Light-cured colorized composition for color filter

InactiveCN102789129ANeat edgesReduce light leakagePhotosensitive materials for photomechanical apparatusHydrogenColor gel

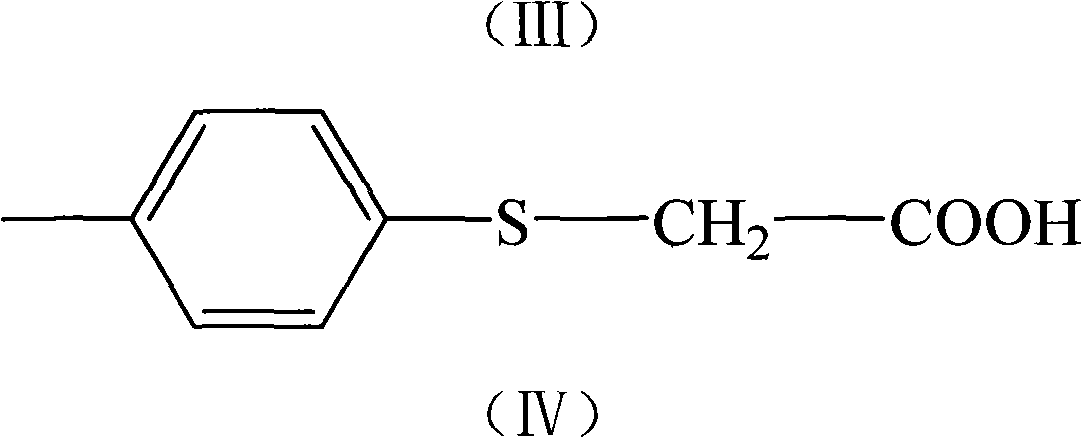

The invention provides a light-cured colorized composition for manufacturing liquid crystal display color filters. The light-cured colorized composition is characterized in that an alkali-soluble side group contained in alkali-soluble resin is at least one of the following (I), (II), (III), and (IV), wherein R is a non-aromatic group. In addition, at least one hydrogen abstracting photoinitiator is contained. -R-S-CH2-COOH (I).

Owner:张海清

Etching method based on nickel-phosphorus alloy buried resistance copper foil

InactiveCN108684153ASmall side erosionImprove qualityConductive material chemical/electrolytical removalAcid etchingCopper foil

The invention discloses an etching method based on a nickel-phosphorus alloy buried resistance copper foil, comprising the steps of: providing a nickel-phosphorus alloy buried resistance plate, laminating a film on the nickel-phosphorus alloy buried resistance plate, and forming a circuit pattern by exposure and development; etching away a copper layer and a nickel-phosphorus alloy buried resistance layer on the non-circuit pattern portion of the nickel-phosphorus alloy buried resistance plate by an acid etching process, and forming a circuit by retreating the film, wherein the time for etching the nickel-phosphorus alloy buried resistance layer is twice to three times the time for etching copper foil of the same thickness; according to the amount of side etching of the first board, compensating the circuit pattern and then executing mass production; applying a film to the nickel-phosphorus alloy buried resistance plate, and opening a window in the circuit at a joint corresponding to the nickel-phosphorus alloy buried resistance layer; etching away the copper layer at the window by an alkaline etching process, and then retreating the film. The method of the invention simplifies thecorresponding production process, improves the production efficiency, and prevents the copper layer in the circuit pattern from being seriously laterally eroded.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

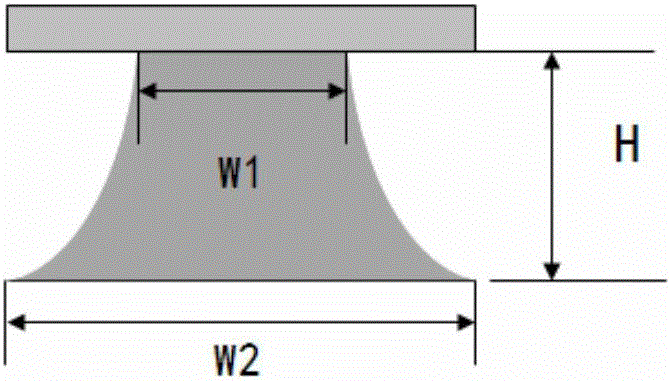

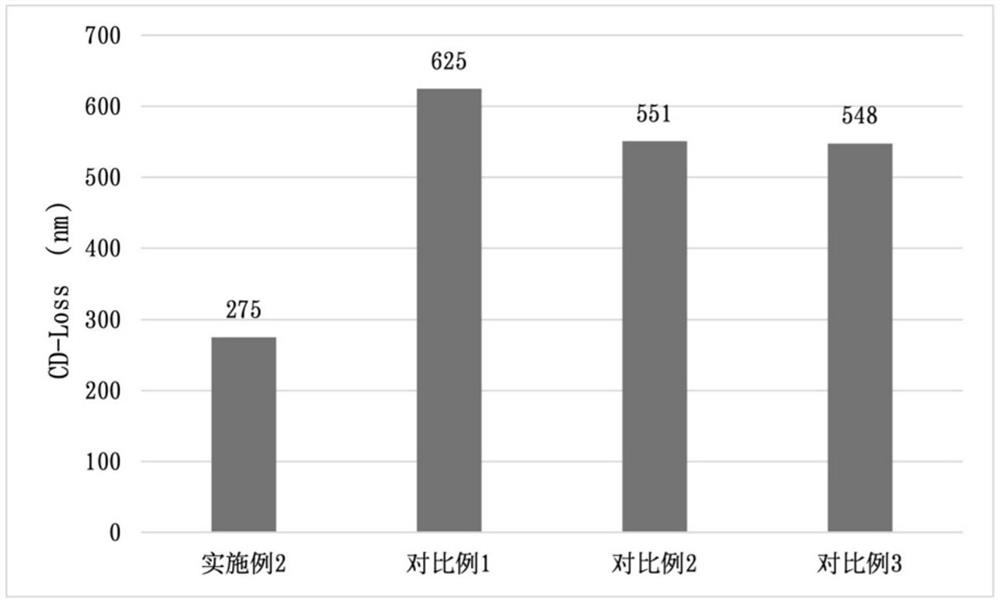

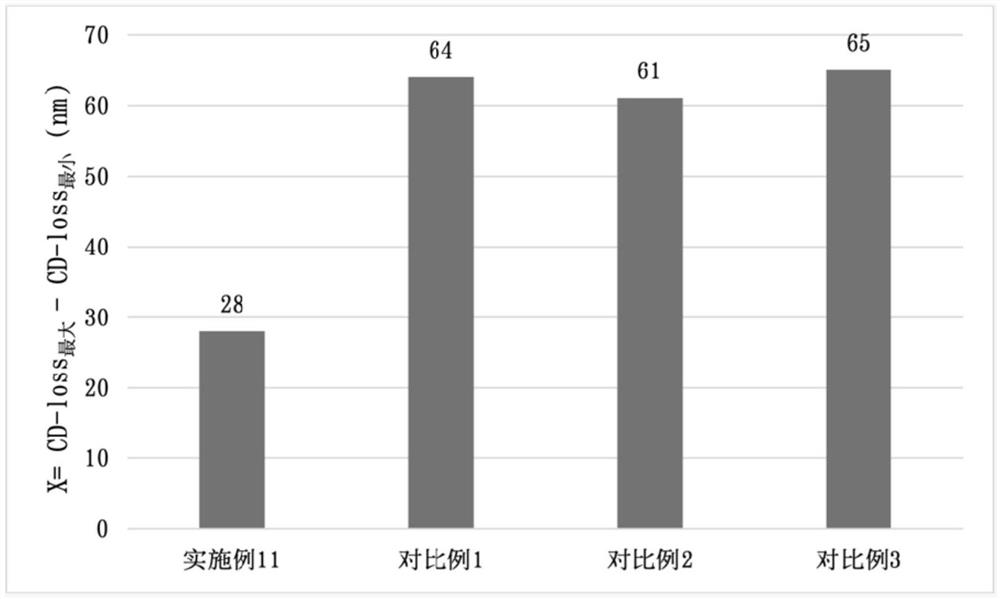

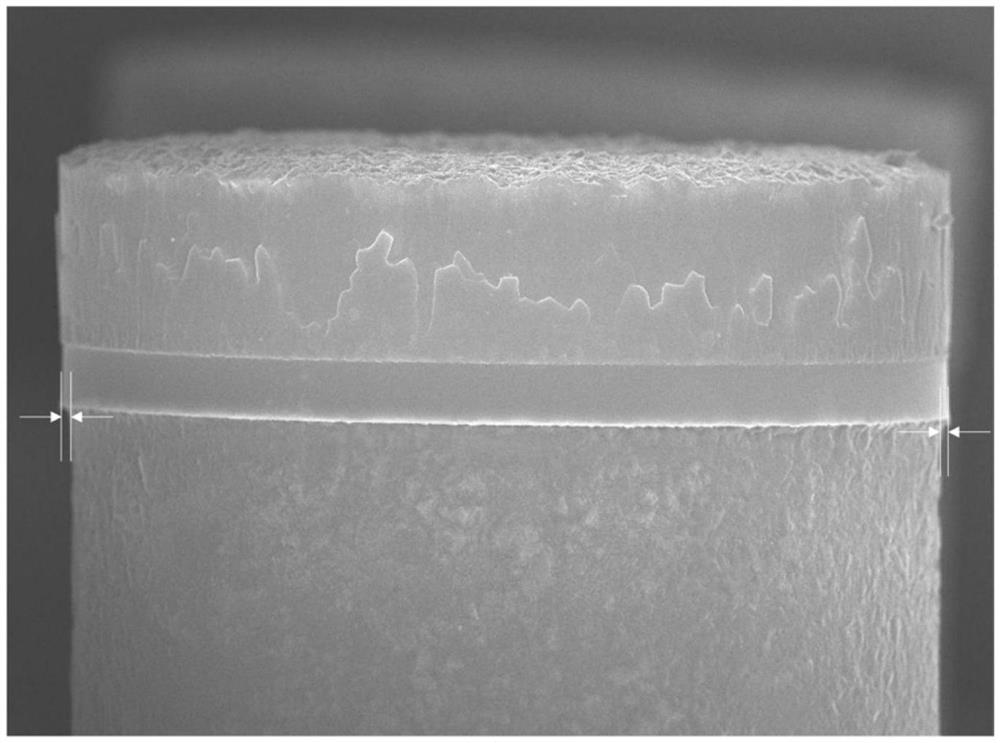

Copper etching solution and application thereof in wafer level packaging

ActiveCN113718256AEfficient removalReduce corrosionSemiconductor/solid-state device manufacturingOrganic acidActive agent

The invention discloses a copper etching solution. The copper etching solution comprises the following components in parts by weight: 1.0-8.0 parts of organic acid; 0.1 to 4.0 parts of an amine compound containing a carboxylic acid group; 0.001 to 1.0 part of an amide type surface active agent; 0.3 to 3.0 parts of an organic phosphine compound; 1-10 parts of hydrogen peroxide; and 70.0 to 99.0 parts of water. In a certain concentration range, the copper layer on the wafer can be effectively removed by compounding the organic acid, the amine compound containing the carboxylic acid group, the amide type surface active agent, the organic phosphine compound, the hydrogen peroxide and the water. In especial, due to the introduction of the amine compound containing the carboxylic acid group and the amide type surface active agent, the synergistic effect of the amine compound containing the carboxylic acid group and the amide type surface active agent not only reduces the corrosion of metal, but also reduces lateral erosion and controls CD-loss within 300nm, so that effective technical support is provided for manufacturing wafer-level packaging narrow-pitch bumps and fine lines.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

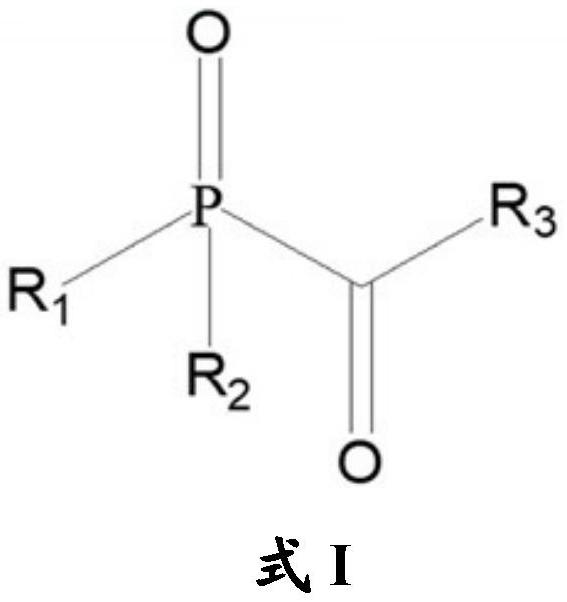

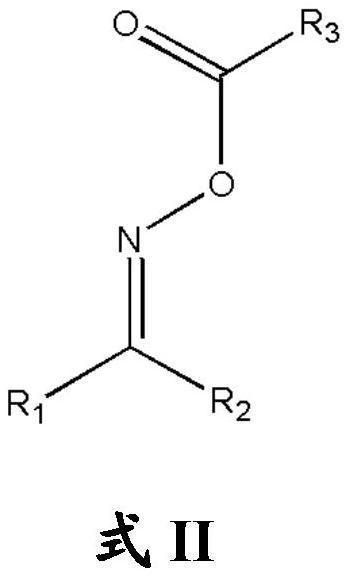

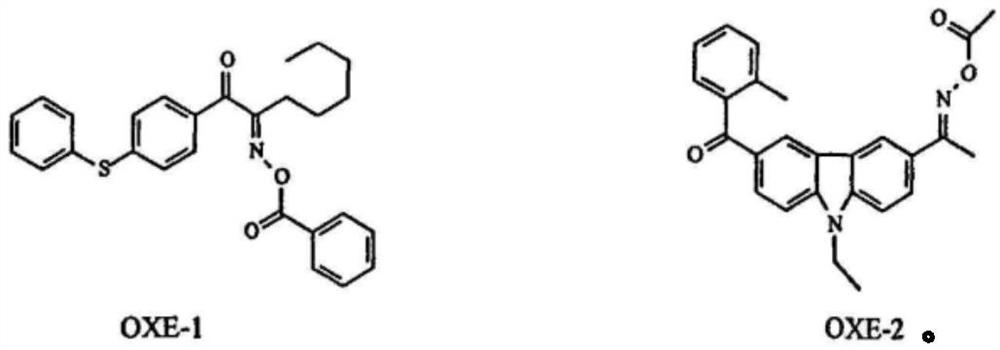

Photoinitiator composition, photosensitive solder resist composition containing same, and printed circuit board

InactiveCN112625149AImprove chemical resistance gold watermark performanceNo significant increase in costPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationPolymer sciencePhotoinitiator

The present invention relates to a photoinitiator composition comprising: an acylphosphine oxide-based photoinitiator and an oxime ester-based photoinitiator, in which the weight ratio of the acylphosphine oxide-based photoinitiator to the oxime ester-based photoinitiator is 0.5-150: 1, preferably 1-120: 1, more preferably 5-100: 1, most preferably 10-90: 1. The invention also relates to a photosensitive solder resist composition containing the photoinitiator composition and application of the photosensitive solder resist composition. In addition, the invention also provides a circuit board comprising the cured film formed by the photosensitive solder resist composition.

Owner:深圳市容大感光科技股份有限公司 +1

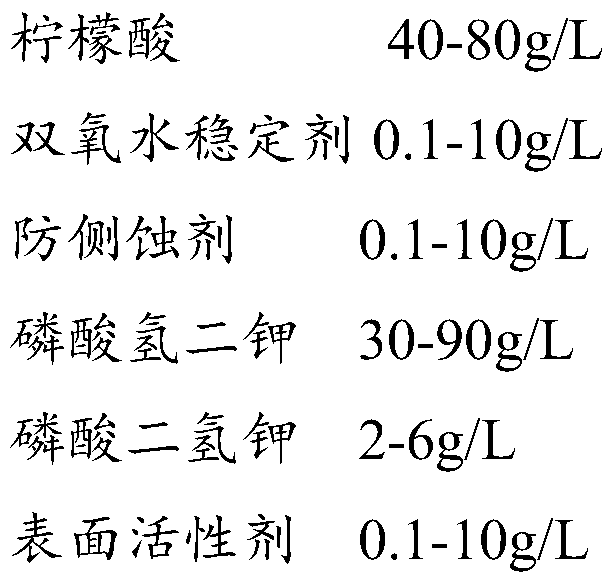

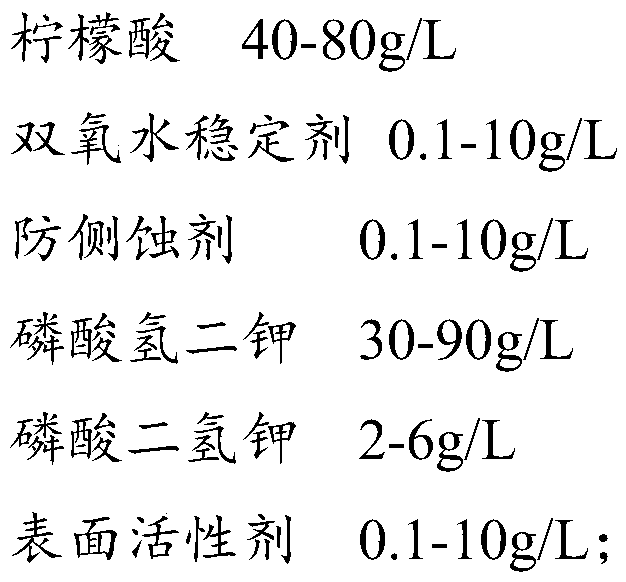

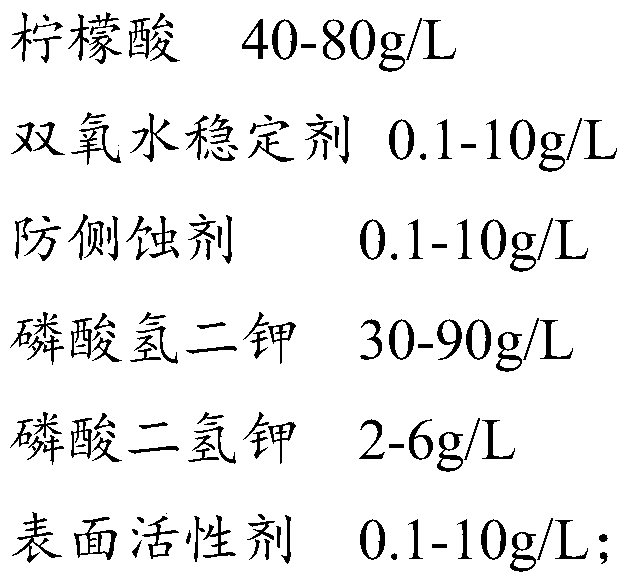

Titanium seed etching liquid for wafer level package

PendingCN110438505AImprove performanceImprove reliabilityDipotassium phosphateMonopotassium phosphate

The invention discloses titanium seed etching liquid for wafer level package. The etching liquid is formed by mixing a component A and a component B according to the size proportion before use. The proportion of the component A and the component B is (0.8-1):1. The component A is hydrogen peroxide. The component B comprises, by concentration, 40-80 g / L of citric acid, 0.1-10 g / L of hydrogen peroxide stabilizer, 0.1-10 g / L of lateral erosion preventing agent, 30-90 g / L of dipotassium phosphate, 2-6 g / L of monopotassium phosphate and 0.1-10 g / L of surface activator. After being prepared according to the component proportion, the component B is mixed with the component A uniformly according to the proportion. After the component A and the component B are mixed uniformly, pH buffering liquid is added according to needs to adjust the pH value to be controlled within 8-9, and thus the titanium seed etching liquid is formed. The titanium seed etching liquid needs to be used when the temperature is between 30 DEG C and 60 DEG C. The titanium seed etching liquid has the characteristics of being stable in performance, suitable for super-thin line, and small in lateral erosion, and nearly having no corrosion to copper and aluminum.

Owner:成功环保科技(南通)有限公司

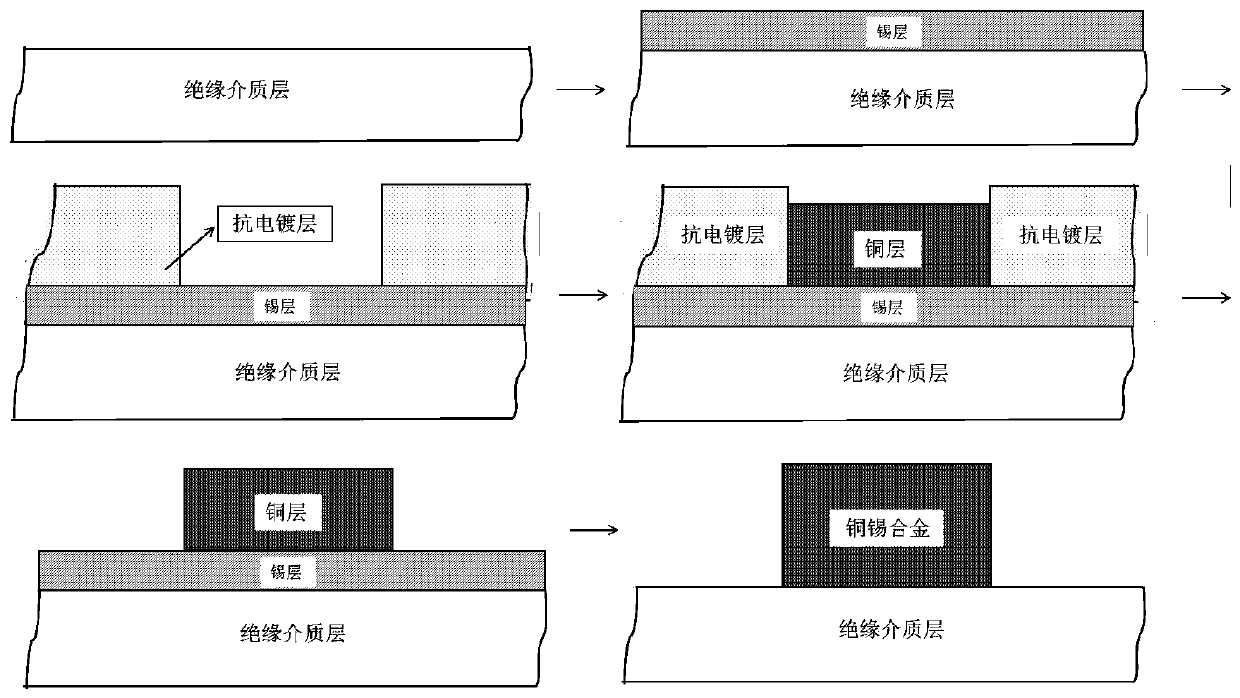

Manufacturing method of printed circuit conductive circuit

PendingCN111405771AAvoid over etchingAvoid poor thermal stabilityConductive material chemical/electrolytical removalElectrically conductiveEtching

The invention discloses a manufacturing method of a printed circuit conductive circuit, and relates to the technical field of printed circuit board manufacturing. The method comprises the following steps: (1) growing a tin seed layer on the surface of a printed circuit insulating substrate; (2) covering the tin seed layer with a patterned dry film; (3) electroplating copper to form a copper conductive circuit; (4) removing the dry film; (5) carrying out heat treatment on the substrate obtained after the treatment in the previous step, so that the copper conductive circuit and the tin seed layer are co-melted into a whole; and 6) etching the tin seed layer to obtain a printed circuit conductive circuit. According to the method, the tin layer etching speed is high, the precision is high, thecircuit is complete and free of side etching, and manufacturing of a high-precision circuit board is facilitated; meanwhile, the copper and the tin are eutectic to form a uniform alloy layer, so thatthe stress between the metals is released, the local defect caused by inconsistent etching speeds of the tin seed layer and the copper conductive wire is prevented, the binding force of the conductive circuit and a bottom layer insulating medium is ensured, and the circuit pattern is good in heat resistance, high in stability and high in reliability.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Etching solution for processing N-type silicon microchannel array by photon-assisted electrochemical etching method

InactiveCN101792106AEasy to controlReduce side erosionSemi-permeable membranesFixed microstructural devicesHydrofluoric acidPhenyl Ethers

The invention relates to an etching solution for processing an N-type silicon microchannel array by a photon-assisted electrochemical etching method, which belongs to the technical field of silicon micro-processing. In the prior art, the etching solution for processing an N-type silicon microchannel array by a photon-assisted electrochemical etching method is made by adding ethanol or p-octyl polyethylene glycol phenyl ether, which is used as a surfacetant, into hydrofluoric acid electrolyte, and the etching solution can result in severe lateral erosion in the etching process. The etching solution of the invention is prepared from hydrofluoric acid and ethanol water solution, wherein the concentration of the hydrofluoric acid is 1-10 wt%, and the concentration of the ethanol is5-10 wt%. In addition, an anionic surfactant is added, and the amount of the anionic surfactant is 0.1-1% of the hydrofluoric acid and ethanol water solution by volume. The invention is used for processing N-type macro-pore silicon microchannel arrays.

Owner:CHANGCHUN UNIV OF SCI & TECH

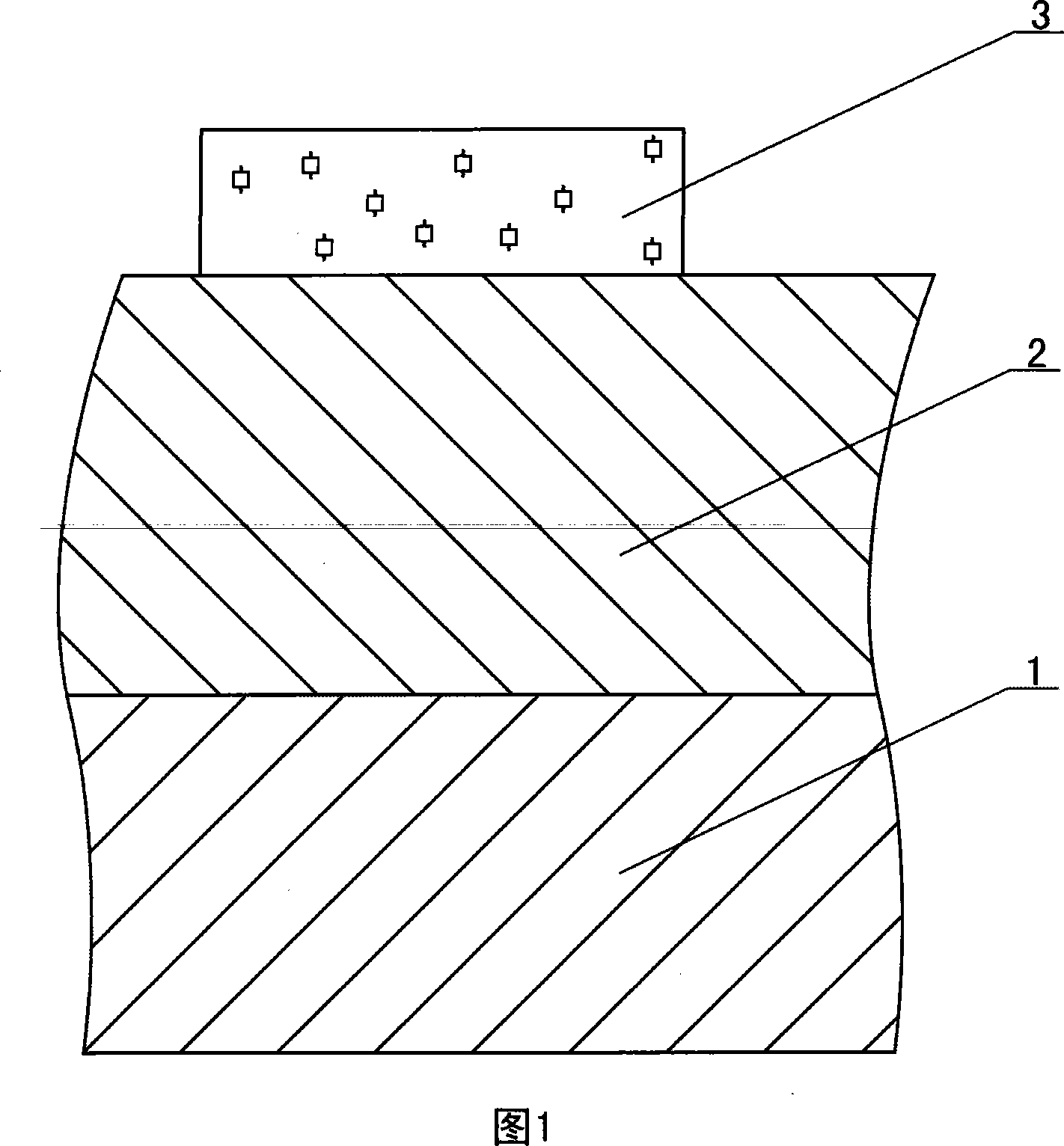

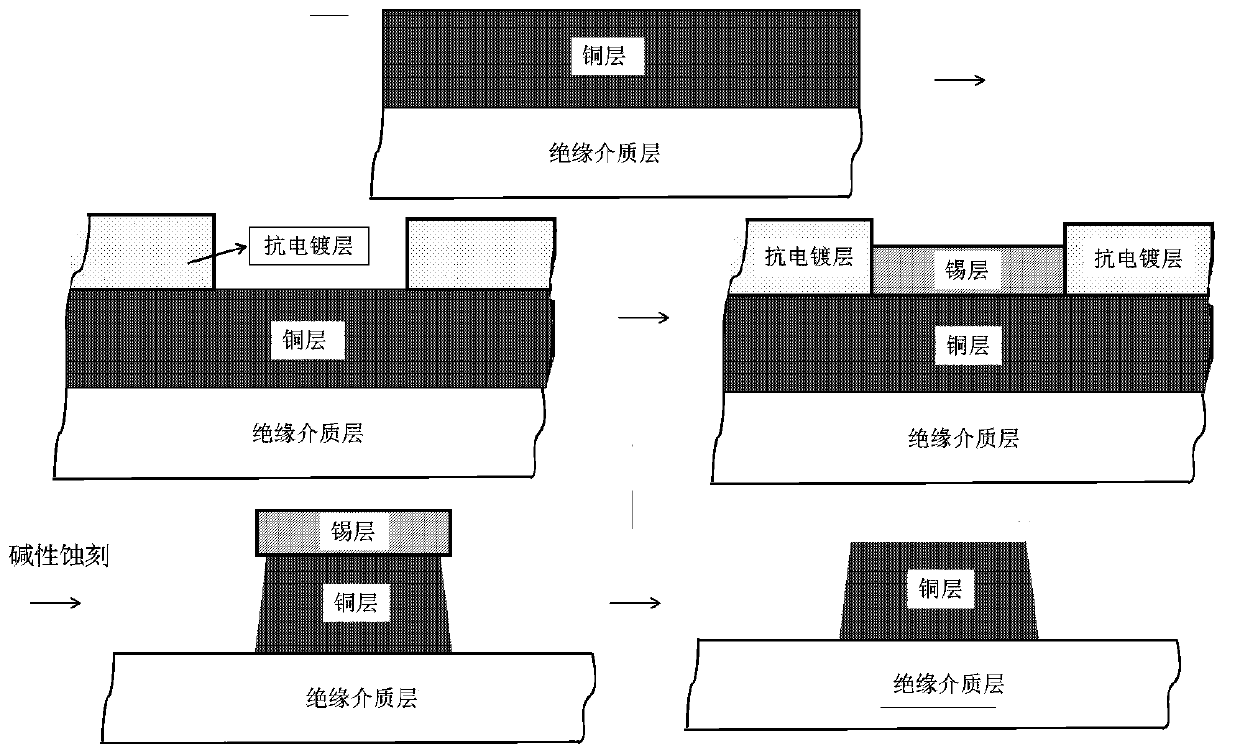

Electrolytic etching and electroplating synchronous manufacturing method for fine circuit of printed circuit board

InactiveCN110636710AImprove regularityImprove qualityConductive pattern formationElectrochemical responseProduction line

The invention provides an electrolytic etching and electroplating synchronous manufacturing method for a fine circuit of a printed circuit board. The method is characterized by comprising the following steps: performing copper reduction treatment on a copper-clad substrate; carrying out surface treatment on the copper-clad substrate through a dry film pretreatment production line; pressing a layerof photoresist dry film on the pre-treated copper-clad substrate; carrying out exposure and development treatment on the copper-clad substrate, and carrying out molding to obtain a circuit board witha size required by an experiment; with an inner-layer circuit board and an outer-layer circuit board which are equal in area being used as an anode plate and a cathode plate respectively, dissolvingaway the exposed copper foil, not covered with the dry film, of the anode plate through electrochemical reaction, and depositing metal copper at the position, not covered with the dry film, of the cathode plate; and carrying out film stripping: removing the photoresist dry film covering the circuit, and carrying out cleaning and drying to obtain the required fine circuit. The prepared fine circuitof the printed circuit board is higher in regularity and good in circuit quality.

Owner:JIANGSU BOMIN ELECTRONICS +1

Application of carbamate compound in magnesium alloy etching additive

The invention provides application of a carbamate compound in a magnesium alloy etching additive. The carbamate compound achieves the effects of uniform corrosion inhibition and reducing of lateral corrosion on the magnesium alloy etching additive. The carbamate compound mainly comprises carbamate, 1,6-hexamethylenedicarbamate, isophorone dicarbamate, phenyl carbamate, toluene dicarbamate, 1,2-hexamethylene dicarbamate, 1,4-hexamethylene dicarbamate, and 4,4-diphenylmethane dicarbamate. The carbamate compound is matched with a corresponding surfactant, a defoaming agent, a solvent, deionized water and the like to form the additive for magnesium alloy etching, and the compound has the advantages that the use amount is small, and an etching process window is wide; meanwhile, the compound contains amino groups and ester groups, the composition of the additive is greatly simplified, the service life of the additive is prolonged, and the compound has obvious social and economic benefits.

Owner:上海镁印科技有限公司

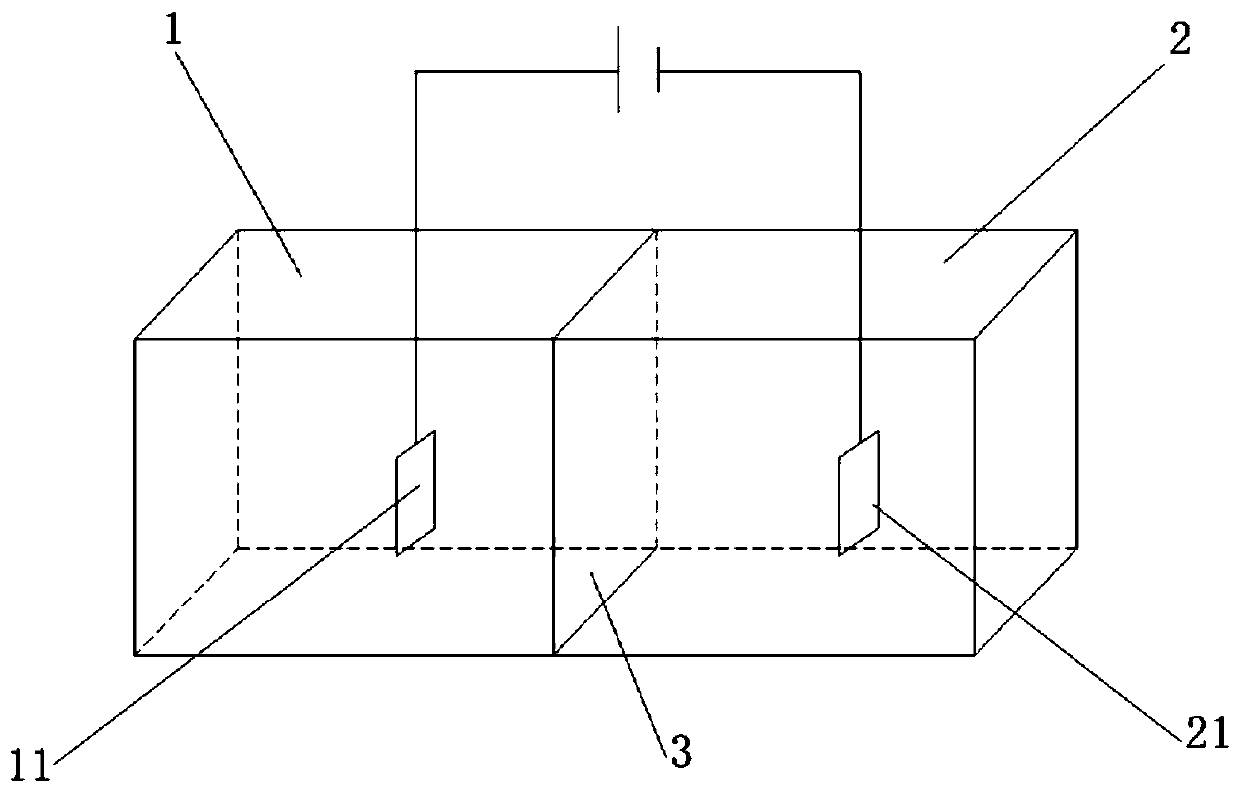

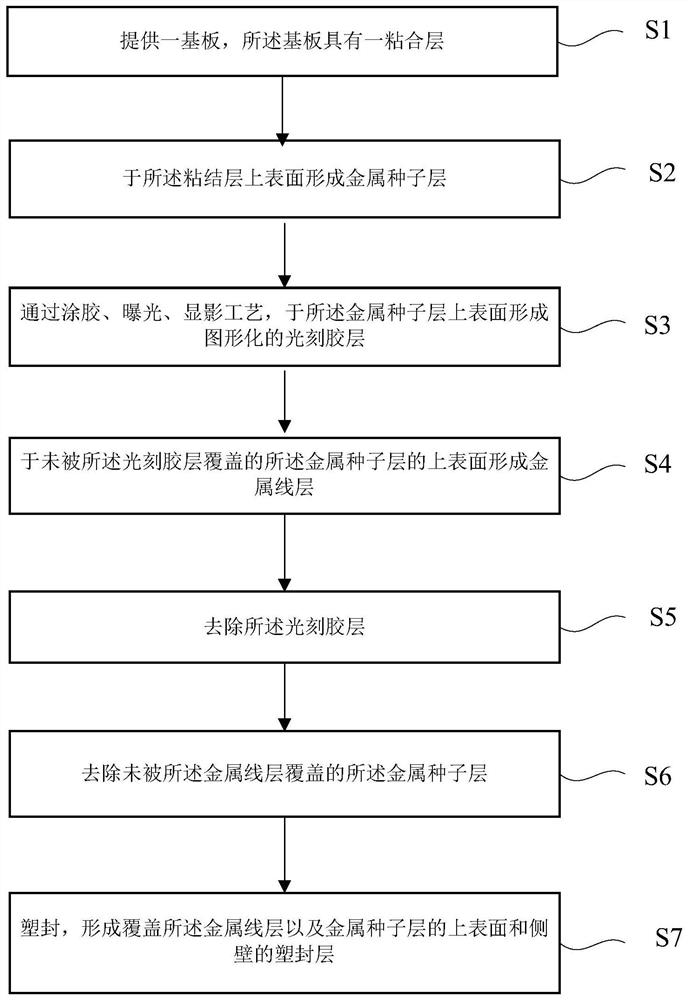

Rewiring layer and preparation method thereof

PendingCN112259465APrevent peelingImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEtchingMetal

The invention provides a rewiring layer and a preparation method thereof. The rewiring layer comprises a metal seed layer, a metal wire layer which is positioned on the upper surface of the metal seedlayer, and a plastic package layer which covers the upper surfaces and the side walls of the metal wire layer and the metal seed layer. The metal seed layer is made of a single material. The metal seed layer made of a single material is adopted to replace a traditional Ti / Cu seed layer, so that side etching caused by a wet etching process is reduced, stripping of the rewiring layer caused by reduction of a connecting surface between the metal wire layer and the substrate is prevented, the etching process is reduced, and the yield of the fine-pitch rewiring layer is improved.

Owner:SJ SEMICON JIANGYIN CORP

Application of a carbamate compound in magnesium alloy etching additive

The invention provides an application of a carbamate compound in a magnesium alloy etching additive, which can uniformly inhibit corrosion and reduce side corrosion in the magnesium alloy etching additive; the carbamate compound mainly includes amino Formate, 1,6‑hexamethylene dicarbamate, isophorone dicarbamate, phenylcarbamate, toluene dicarbamate, 1,2‑cyclohexanedicarbamate esters, 1,4-cyclohexane dicarbamate and 4,4'-diphenylmethane dicarbamate. The carbamate compound is combined with corresponding surfactants, defoamers, solvents and deionized water to form additives for magnesium alloy etching. It has the characteristics of small dosage, wide etching process window, etc., and contains amino and ester at the same time. The base greatly simplifies the composition of the additive, prolongs the service life of the additive, and has obvious social and economic benefits.

Owner:上海镁印科技有限公司

Two-liquid acid etching liquid oxidant

InactiveCN101760199BHigh amount of dissolved copperImprove stabilitySurface treatment compositionsAcid etchingSodium chlorate

The invention relates to a two-liquid acid etching liquid oxidant used for all kinds of copper chloride etching systems. The two-liquid acid etching liquid oxidant contains the following components by weight percent: 35-37 percent of sodium chlorate, 6-8 percent of sodium chloride, 0.15-0.25 percent of additive and 55-58 percent of water. The invention has the advantages that the amount of dissolved copper is large, the side etching is small, no sediment is produced during use and the stability is high.

Owner:广东奥美特集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com