Method for etching cutting of glass substrate

A glass substrate and etching technology, applied in glass production, glass cutting devices, glass manufacturing equipment, etc., can solve problems such as unfavorable glass manufacturing, reducing process controllability, increasing heat release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All publications, patent applications, patents, and other references mentioned herein are hereby expressly incorporated by reference in their entirety, unless indicated to the contrary, as if fully disclosed herein.

[0025] Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. In case of conflict, the definitions in this specification shall prevail.

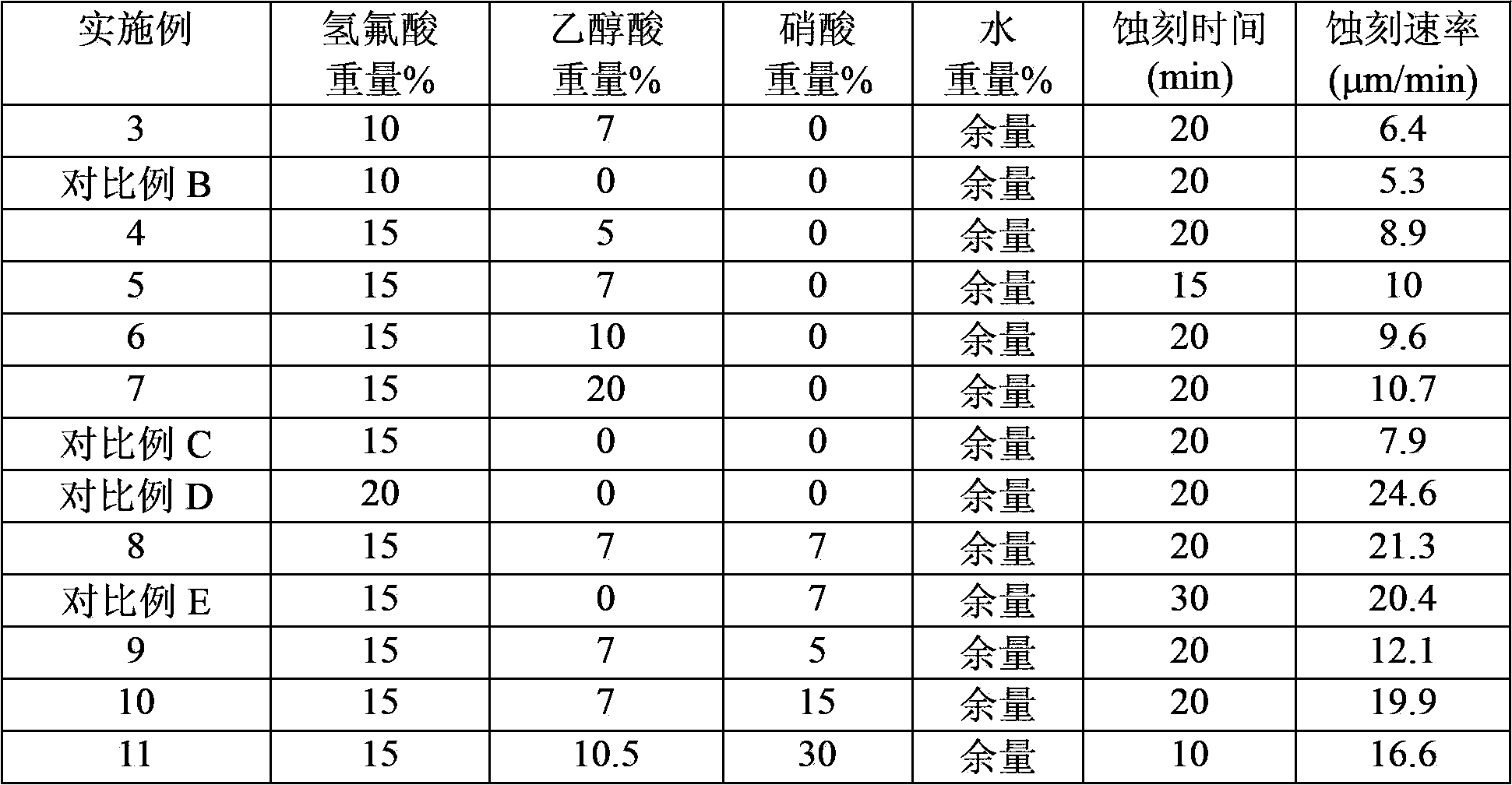

[0026] All percentages, parts, ratios, etc., are by weight unless otherwise indicated.

[0027] As used herein, the term "prepared from" is synonymous with "comprising". As used herein, the terms "comprises," "including," "has," "containing," or any other variation thereof, are intended to cover a non-exclusive inclusion. For example, a composition, step, method, article, or device comprising listed elements is not necessarily limited to those elements, but may include other elements not e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com