Indirect regeneration for waste etching solution and recovery processing system for copper

A technology for recycling waste etching solution, which is applied in the recycling field of waste etching solution, which can solve the problems of large consumption of reagents, poor production stability, and low purity, and achieve the effects of increasing by-product income, stable etching effect, and high etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

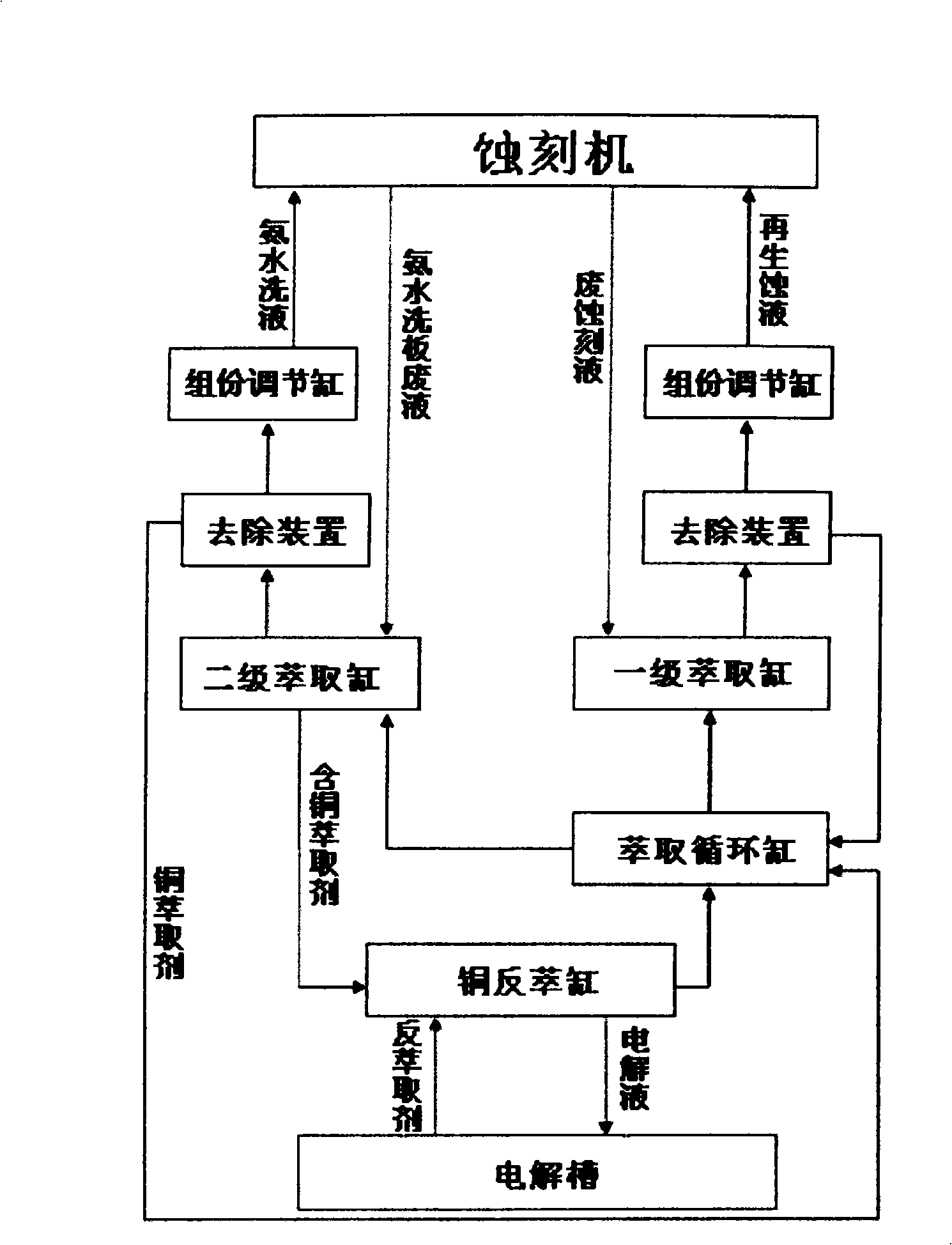

[0012] From figure 1 It can be seen that the waste etching solution recycling and copper recovery treatment system is composed of a waste etching solution extraction system, an etching solution recycling system and an electrolysis system. The waste etching solution extraction system includes a primary extraction cylinder, a secondary extraction cylinder, an extraction agent and an extraction agent circulation cylinder, the etching waste liquid inlet, extraction agent inlet and regeneration liquid outlet are respectively arranged on the first-level extraction cylinder and the second-level extraction cylinder, and the extraction agent circulation cylinder is respectively connected with the first-level extraction cylinder and the second-level extraction cylinder The extraction cylinder is connected; the etching solution circulation regeneration system includes a removal device and a component adjustment cylinder, the first-stage extraction cylinder and the second-stage extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com