Etching liquid and method for manufacturing printed circuit board

A printed circuit board and printed circuit board technology, applied in the field of etching solution, can solve the problems of high content of organic additives, insufficient ability to inhibit side erosion, and difficulty in wastewater treatment, and achieve the effect of low content of organic additives and reduction of side erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

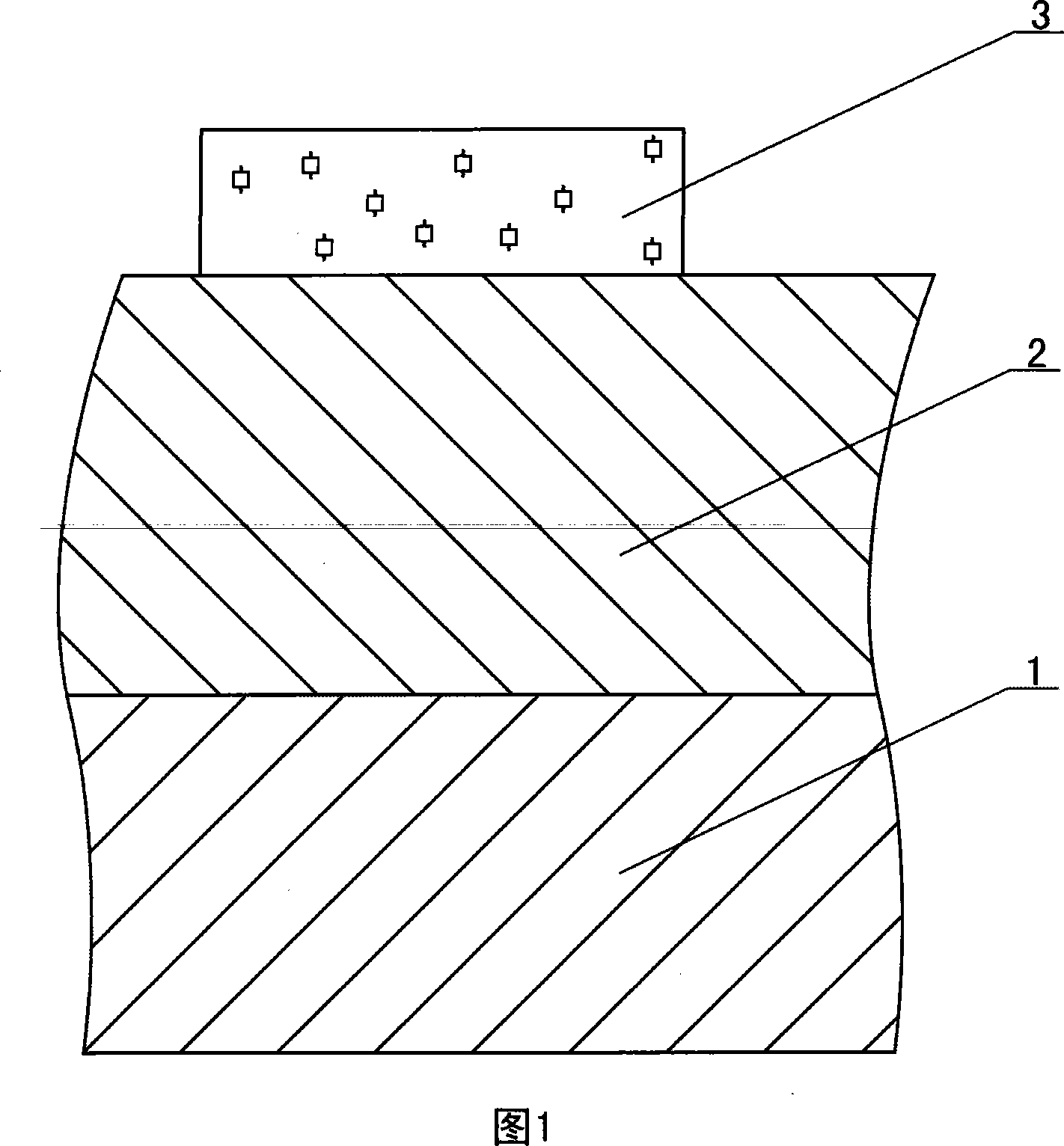

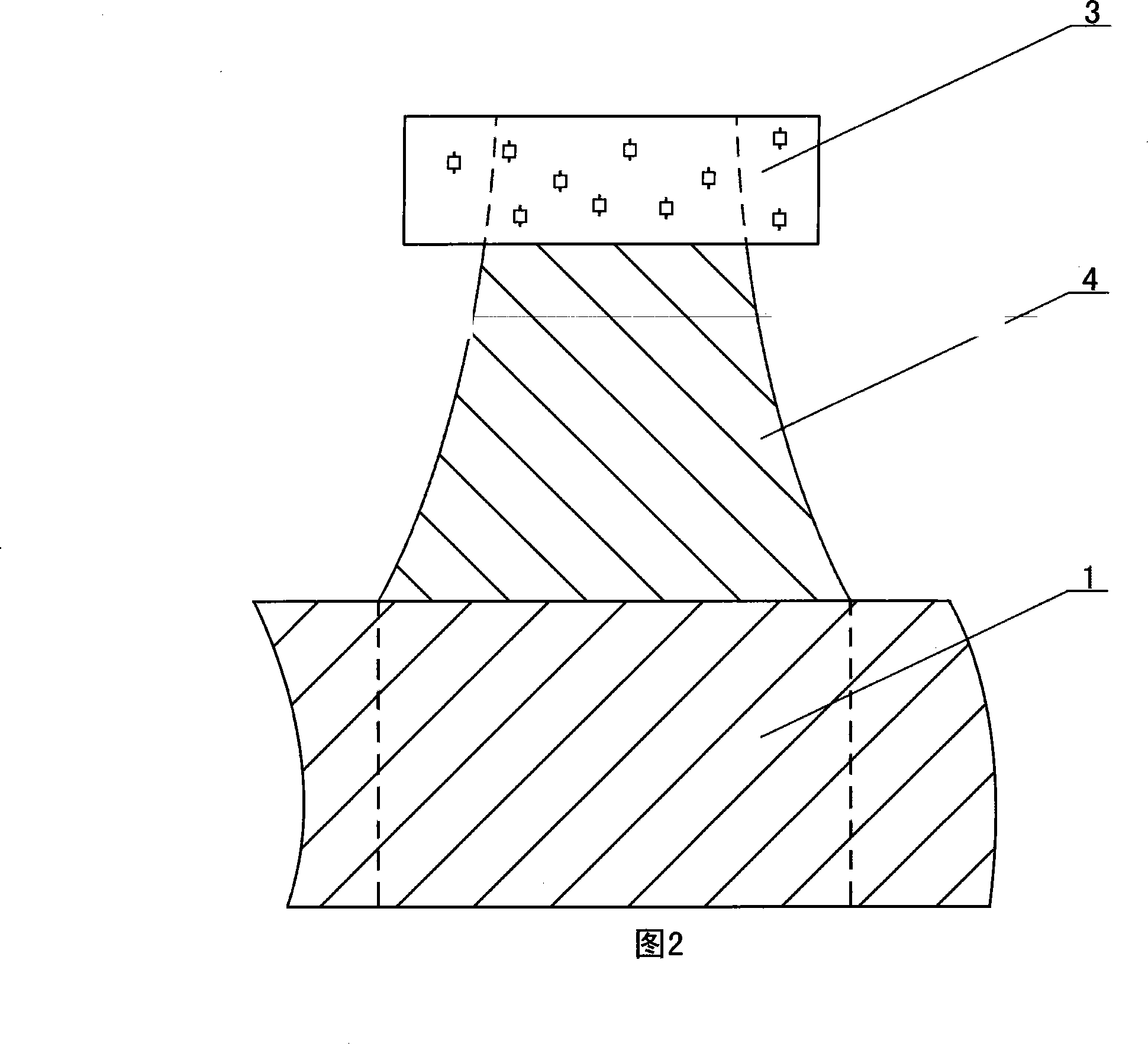

[0025] As shown in Fig. 1, 2, 3 embodiments form the method for printed circuit board circuit pattern by etching copper and copper alloy as follows:

[0026] As shown in FIG. 1 , a copper foil 2 is coated with an anti-etching layer 3 with a circuit pattern, and an etching solution is used to remove the part of the copper foil not covered by the anti-etching layer 3 .

[0027] The etchant is sprayed on the surface of the copper foil 3 using a conventional horizontal spray etching device, and the copper foil portion 2A not covered by the anti-etching layer 3 is etched away ( FIG. 2 ).

[0028] The solution temperature of the etching solution is 20-55° C., preferably 40-50° C., the spray pressure is 0.1-0.3 MPa, and the etching time is set according to the copper thickness.

[0029] After copper is etched, the cuprous ions produced in the etching solution will lose the etching ability. In order to restore the etching ability of the etching solution, air can be passed into the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com