Titanium seed etching liquid for wafer level package

A technology of wafer-level packaging and etching solution, applied in the field of semiconductor wafer-level packaging, can solve the problems of high cost, instability, and line falling off, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Component A: hydrogen peroxide with a mass fraction of hydrogen peroxide between 30% and 35%;

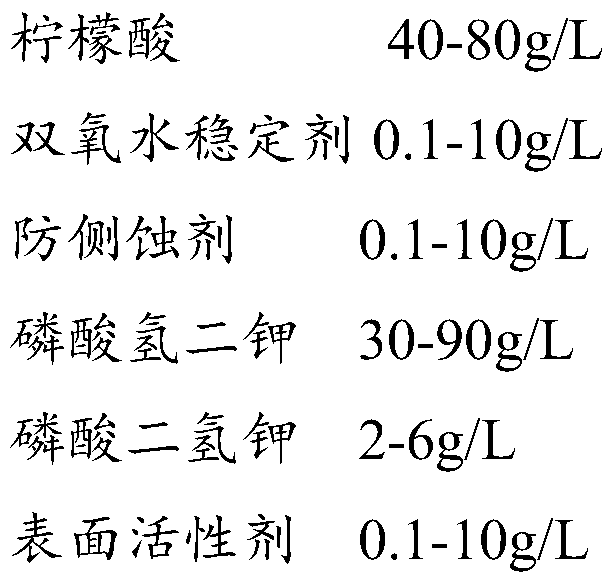

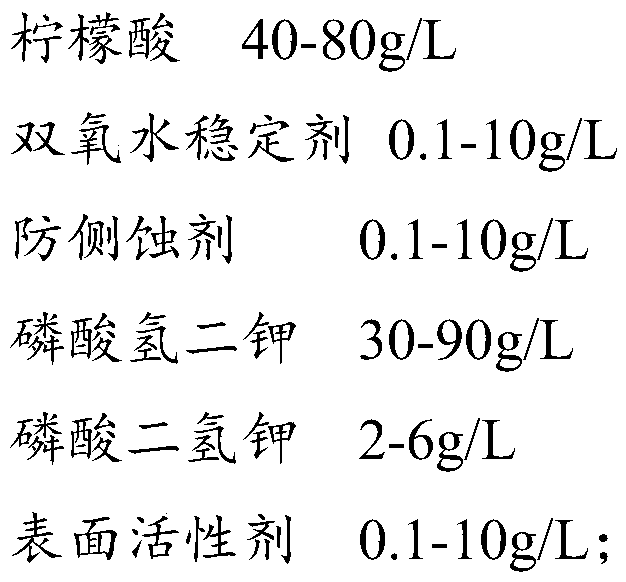

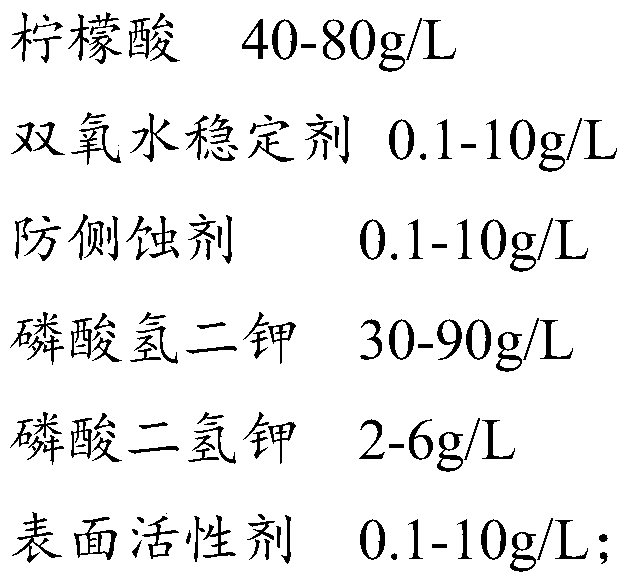

[0032] Component B: citric acid 60g / L, polyacrylic acid amine 1g / L, benzotriazole 0.5g / L, dipotassium hydrogen phosphate 75g / L, potassium dihydrogen phosphate 5g / L, pentaerythritol 1g / L and the balance is Water mix well.

[0033] Mix the above two components at 1:1, add pH buffer to adjust the pH to 8.0, heat to 30°C, test the time required for etching the titanium seed layer of the wafer, and the corrosion of copper and aluminum, and observe the side by FIB section Eclipse situation.

Embodiment 2-4

[0035] Examples 2-4 are based on Example 1, the difference is that the implementation temperature is 40°C, 50°C, and 60°C respectively to test the time required for etching the titanium seed layer of the wafer, as well as the corrosion of copper and aluminum, and observe the side erosion through FIB slices Condition.

Embodiment 5-8

[0037] Embodiments 5-8 are based on Embodiment 1, the difference is that the pH of the etching solution is adjusted to 8.5 by adding a pH buffer solution, and the temperatures are respectively 30°C, 40°C, 50°C, and 60°C to test the time required for etching the titanium seed layer of the wafer, and Corrosion of copper and aluminum, and observation of side corrosion through FIB slices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com