Copper etching solution and application thereof in wafer level packaging

A technology of copper etching and etching solution, which is applied in the field of etching solution, can solve the problems of lack of in-depth research and improvement on the uniformity of etching of large-sized wafers, and achieve the effect of reducing side etching and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In terms of parts by mass, weigh the following components in parts by mass: 1 part of citric acid, 0.5 part of ammonium chloride, 0.1 part of 3,4,5-tricarboxylic aniline, 0.001 part of potassium lauroyl glycinate, 0.001 part of poly Ether modified silicone defoamer, 0.3 parts of hydroxyethylidene diphosphonic acid, 1 part of hydrogen peroxide, 99 parts

[0064] Deionized water, pH 2.72.

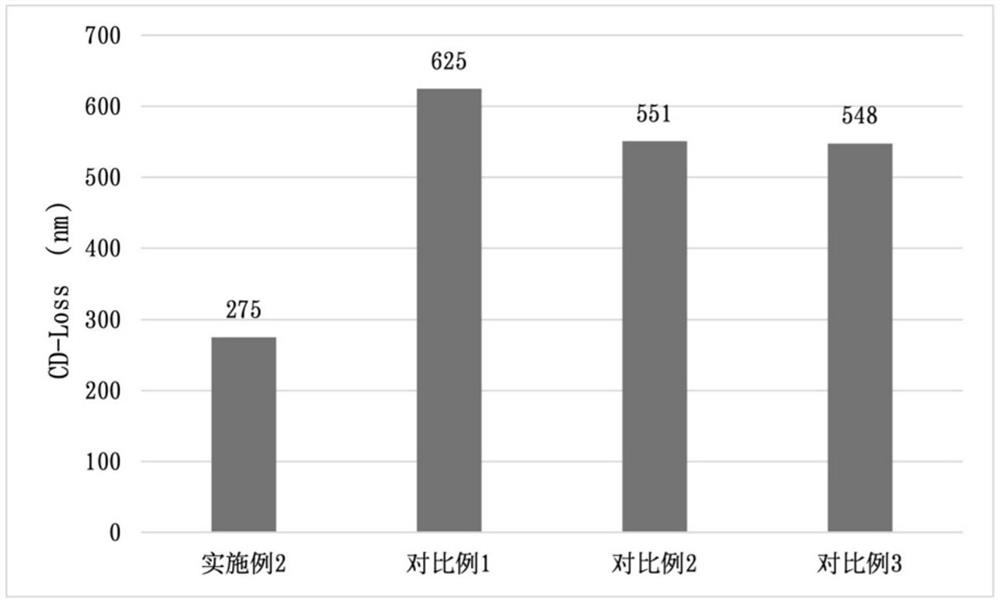

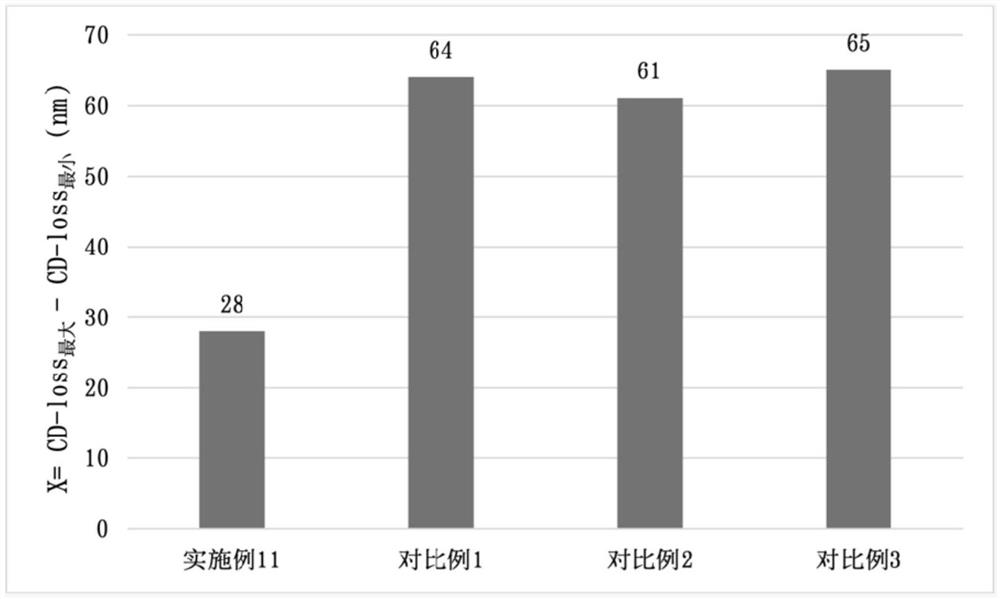

Embodiment 2-23

[0066] The formula of polyether modified silicone defoamer is shown in Table 1.

[0067] In embodiment 2-4, organic acid is citric acid (1.0-8.0 part), ammonium chloride (0.1-5.0 part), amine carboxyl compound is L-acridine-2-carboxylic acid (0.1-4.0 part), amide The surfactant is potassium lauroyl glycinate (0.001-1.0 parts), the organic phosphine compound is hydroxyethylidene diphosphonic acid (0.3-3.0 parts), hydrogen peroxide (1.0-10.0 parts) and water (70.0-99.0 parts ).

[0068] In embodiment 5-8, based on embodiment 1, difference is that organic acid is malic acid, tartaric acid, succinic acid, ferulic acid.

[0069] In Examples 9-12, based on Example 2, the difference is that the amine carboxyl compound is trans-1,2-cyclohexanediaminetetraacetic acid, (S)-(-)-N-(1-phenylethyl ) o-carboxybenzamide, 1-aminocyclopropanecarboxylic acid, 5-aminosalicylic acid.

[0070] In Examples 13-16, based on Example 3, the difference is that the amide surfactants are sodium lauroyl ...

Embodiment 2

[0072] In embodiment 21-22, based on embodiment 2, difference is the content of ammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com