Photoinitiator composition, photosensitive solder resist composition containing same, and printed circuit board

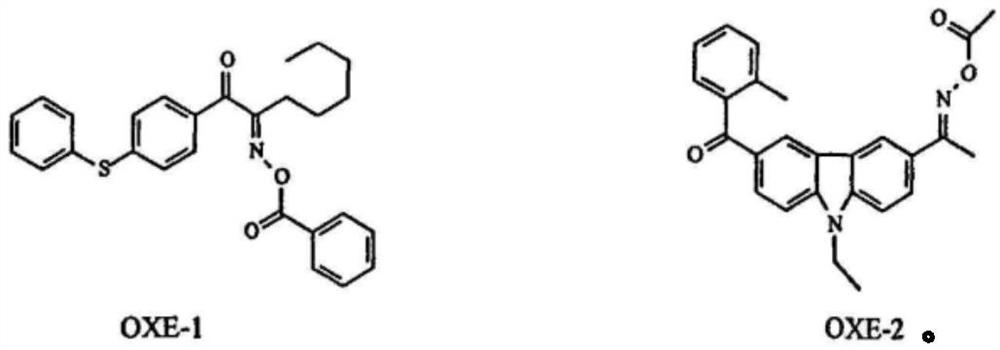

A photoinitiator, photosensitive solder resist technology, applied in printed circuits, printed circuit manufacturing, printed circuit secondary processing, etc., can solve the problems of high reactivity, easy ink reaction, and reduced ink storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative Embodiment 1-4

[0123] Main ingredient: mix the photosensitive resin A prepared above with other components according to the main ingredient formula shown in Table 1, disperse for 20 minutes with a high-speed disperser (Qinkai U400\80-220, the same below), and then use A three-roll mill (Chile S-65 three-roll mill, the same below) grinds to a particle size of less than 10 μm (detected by a scraper fineness meter (Jinfulun QXP-100ISO, the same below)) to obtain the ink main agent.

[0124] Curing agent: The curing agent formula shown in the following table 1, mix each component evenly, disperse at high speed with a disperser for 10 minutes, and then grind with a three-roll mill until the particle size is less than 10 μm (detected by a scraper fineness meter ), to obtain the ink curing agent component.

[0125] Mix the main ingredient with the curing agent before use, stir evenly before use.

[0126] Table 1

[0127]

[0128] Note 1: Pigment, phthalocyanine green L9361 purchased from BASF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com