Copper etching liquid composition and production method thereof

A composition and etching solution technology, applied in the field of etching solution composition, can solve the problems of environmental pollution, slow speed, poor stability, etc., and achieve the effects of avoiding environmental pollution, reducing production costs, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

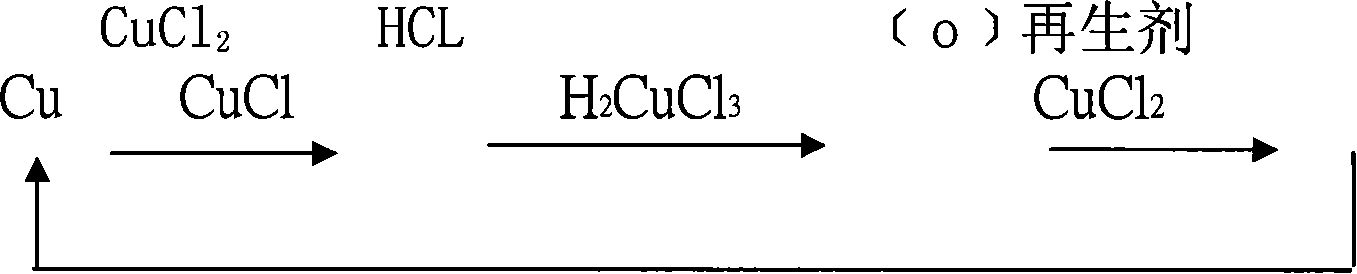

Method used

Image

Examples

Embodiment 1

[0030] 6 kg of ammonium chloride, 0.7 kg of sodium chlorate, 35 kg of hydrochloric acid, and 58.3 kg of water.

Embodiment 2

[0032] 7 kg of ammonium chloride, 0.8 kg of sodium chlorate, 36 kg of hydrochloric acid, and 56.2 kg of water.

Embodiment 3

[0034] 8 kg of ammonium chloride, 0.9 kg of sodium chlorate, 37 kg of hydrochloric acid, and 54.1 kg of water.

[0035] Three. the preparation method of described copper etchant composition:

[0036] At normal temperature and pressure

[0037] 1. Add raw materials ammonium chloride, sodium chlorate, hydrochloric acid and water in sequence in proportion to the production tank;

[0038] 2. Stir until completely dissolved.

[0039] Four. the mode of operation in production of described copper etchant composition:

[0040] Controls can be added manually or automatically, preferably using automatic control.

[0041] (1). Automatically add control production line:

[0042] 1. Clean the etching machine first, and add the copper etching solution into the stock solution tank;

[0043] 2. Perform controller setting (regenerative system setting)

[0044] Its specific gravity is 1.20-1.25, HCl is 2.60-2.70, close the H 2 o 2 , the temperature is 48℃~52℃;

[0045] 3. Etching opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com