Manufacturing method of fine circuit board free of corrosion resistant layer

A manufacturing method and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as difficulties and inapplicability to fine circuits, and achieve the effect of avoiding side erosion of circuits and good quality of circuit manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

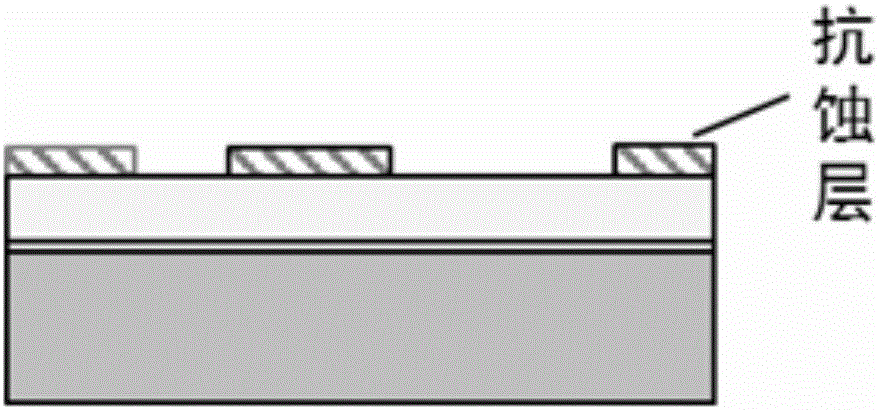

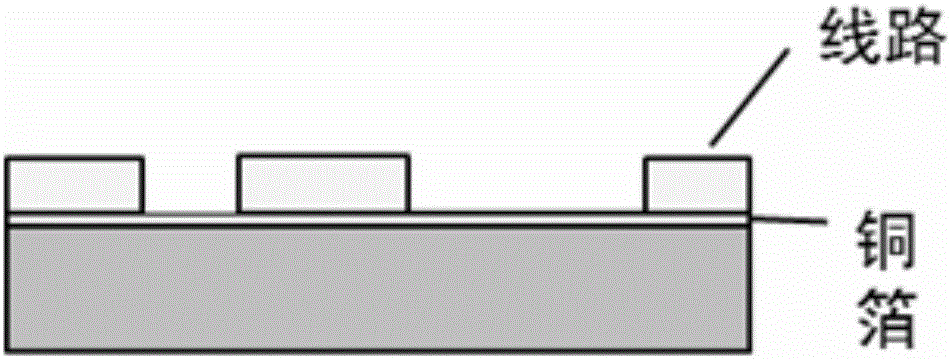

[0030] The method for manufacturing a fine circuit board without a resist layer provided in this embodiment includes the following processes: lamination-thinning of base copper-drilling-drilling-copper pre-plating-pattern electroplating-film fading flash etching-subsequent process, wherein :

[0031] (1) In this embodiment, a thin copper foil with a copper thickness ≤ 12 μm is selected for lamination during the production process of the circuit board;

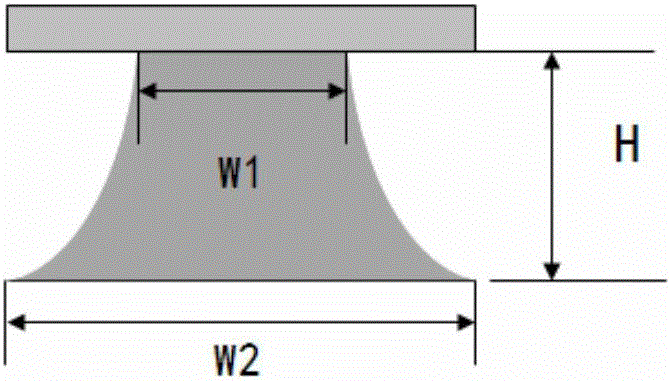

[0032] (2) Thinning the base copper process on the copper surface on the plate so that the thickness of the copper surface is uniformly reduced to 5-7μm. The potion used in the base copper thinning process is a mixed system of copper thinning agent, sulfuric acid, and hydrogen peroxide;

[0033] Control the thinned copper thickness. When there are through holes in the plate structure, the copper thickness of the thinned copper is controlled at 5 μm; when there are blind holes and through holes in the plate, the copper thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Copper thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com