Three grade cyclic absorption treatment method and equipment in acid etching production lines

A technology of acid etching and treatment method, which is applied in the field of three-stage cyclic absorption treatment method and equipment, which can solve the problems of adjusting absorption efficiency and increasing construction costs, and achieve the effects of reducing etching costs, avoiding heat supplementation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

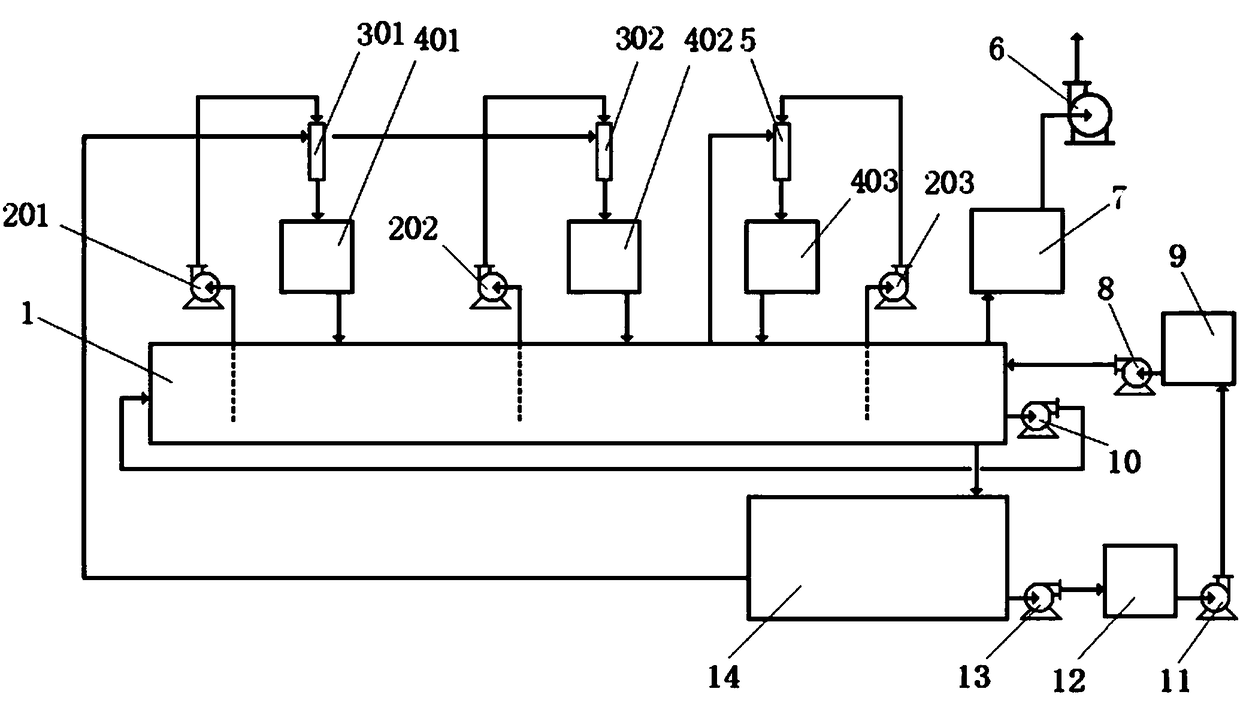

[0035] A treatment method using three-stage cyclic absorption in an acid etching production line, comprising the steps of:

[0036] (1) Electrolysis and regeneration solution circulation: The waste etching solution produced in the acid etching production line is sent to the electrolytic tank for electrolysis, metal copper is recovered, and the regeneration etching solution after removing copper ions is sent back to the acid etching production line for use; The waste etching solution mainly contains HCl, NaCl and Cu + 、Cu 2+ and other components; preferably, the regenerated etching solution after removing copper ions is transported to the liquid storage tank through the regenerated liquid delivery pump, and then lifted and pumped to the regenerated liquid supply tank through the regenerated liquid, according to the control index of the acid etching production line, through The regeneration liquid supply pump is automatically sent back to the acid etching production line for us...

Embodiment 2

[0042] On the basis of embodiment 1, the following preferred technical features are added:

[0043] In the step (2), the chlorine gas absorption cycle is a two-stage cycle, and two sets of independent systems work at the same time, and each stage includes an absorption cycle pump, a chlorine gas absorber and an absorption cycle tank; The inlet of the circulating pump is more than 2m apart and continuously flows into the acid etching production line.

[0044] While recirculating in the step (3), according to the ORP value of etching solution, determine the frequency conversion operation status of the absorption circulation pump corresponding to the chlorine absorber, to ensure the efficient and stable progress of the acid etching production line;

[0045] The negative pressure value of the electrolytic cell is controlled between 2-6Kpa, and the ORP value of the etching solution is controlled to be 480-600mV through chlorine gas absorption. The number of cycles of etching solut...

Embodiment 3

[0047] Send the etching solution of the acid etching production line to the electrolytic tank for electrolysis, and the negative pressure value of the electrolytic tank is controlled at 2KPa; the etching solution absorbs the chlorine gas from the electrolytic tank through the absorption circulation pump and the chlorine gas absorber, and controls the etching of each absorption circulation tank The number of liquid circulation is 1 time / h. Absorb Cl in the chlorine absorber 2 The gas-liquid ratio is controlled at 1:1, and the ORP value of the etching solution is controlled at 500mV; the absorbed waste gas is sent to the tail gas treatment tank; the absorbed etching solution is returned to the acid etching production line for use.

[0048] The result of the chlorine gas absorbed by the etching solution was: the absorption rate was 86.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com