a kind of sb 2 te 3 Thermoelectric material film wet etching method

A material thin film, wet etching technology, used in the manufacture/processing of thermoelectric devices, circuits, electrical components, etc., to achieve the effects of high etching accuracy, controllable etching rate, and clear appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

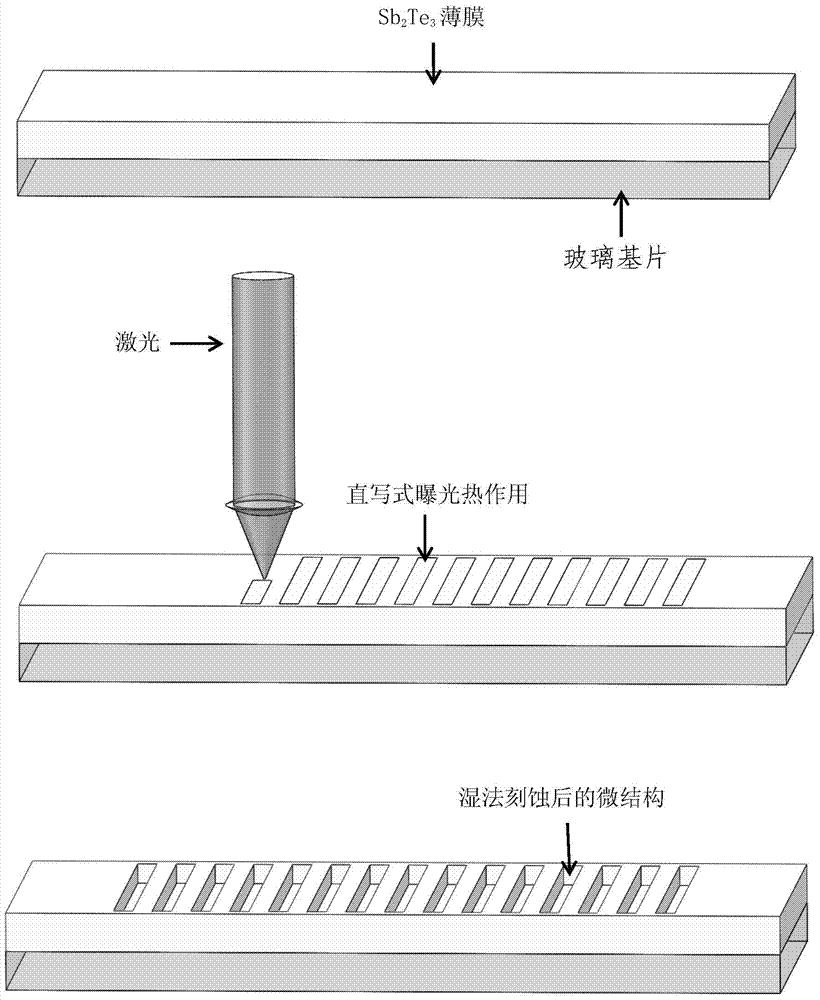

[0019] Such as figure 1 As shown, a Sb 2 Te 3 The method for wet etching of a thermoelectric material thin film comprises steps:

[0020] (a), a layer of Sb was coated on the glass substrate by magnetron sputtering. 2 Te 3 Thin films of thermoelectric materials with a film thickness of 80nm;

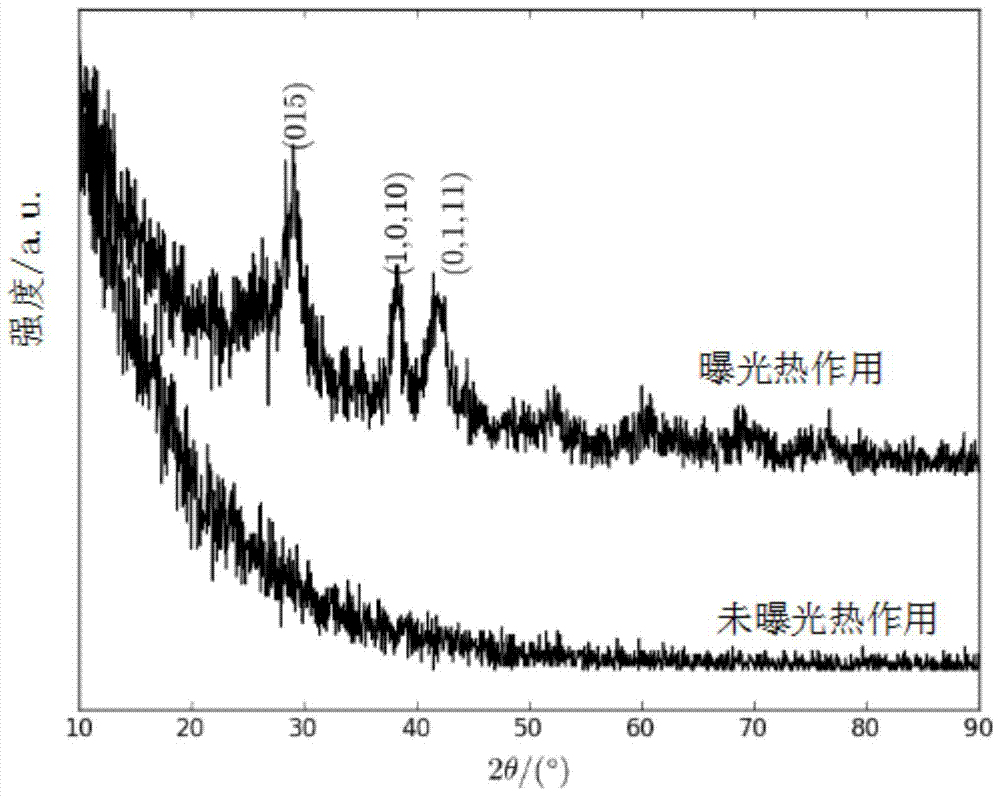

[0021] (b), using a laser with a wavelength of 405nm to the Sb 2 Te 3 Direct-write exposure thermal action of thermoelectric material thin film, Sb before and after laser exposure thermal action 2 Te 3 The XRD pattern of the film is as figure 2 As shown in the figure, we can know that the area after laser direct writing exposure heat has undergone a transformation from amorphous state to crystalline state;

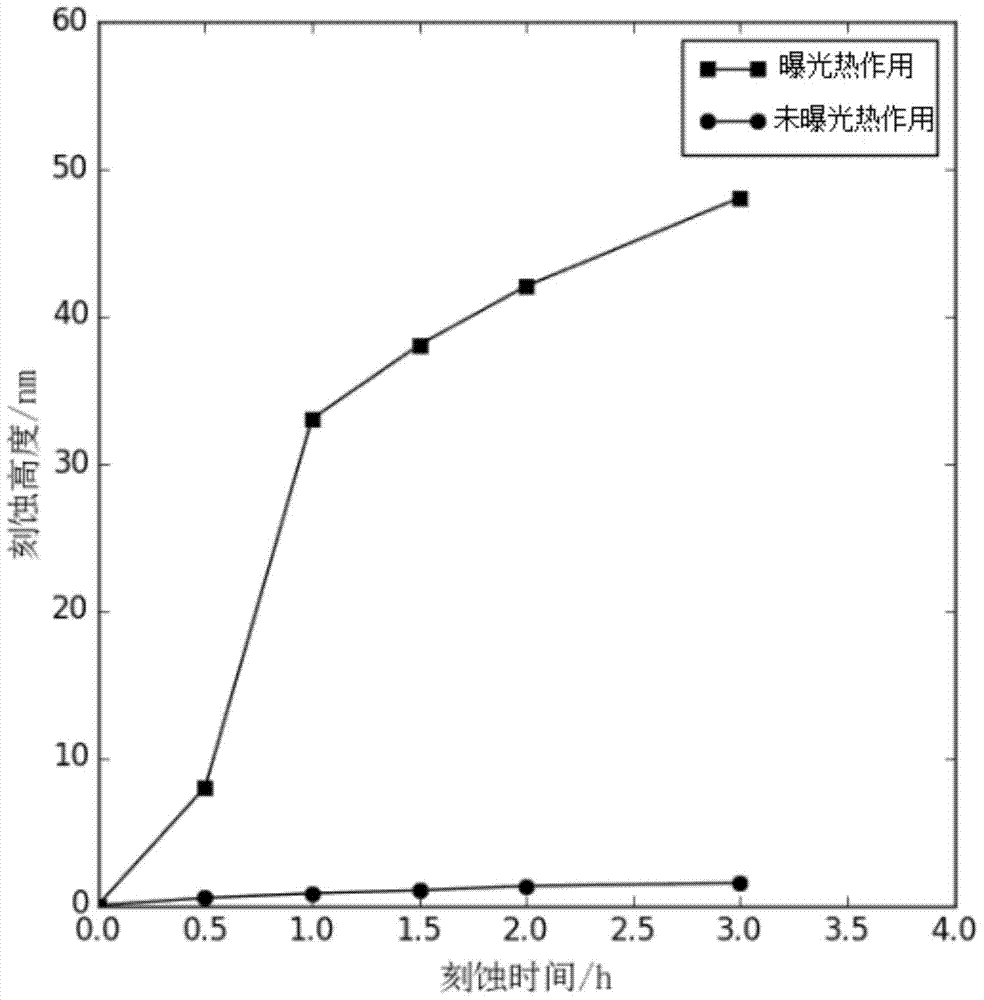

[0022] (c), using NaOH solution with a molar concentration of 0.1mol / L to treat Sb after laser exposure heat 2 Te 3 The film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com