Preparation method of cubic boron nitride micro-powder scanning electron microscopy sample

A technology of boron nitride micropowder and scanning electron microscopy, which is applied in the preparation of test samples, etc., can solve the problems of not being able to see the specific shape of a single particle, not being able to clearly locate the particle size, and not being able to determine the existence of impurities, etc., to achieve a simple dispersant Easy to obtain, easy to observe and locate, and the effect of clear single particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

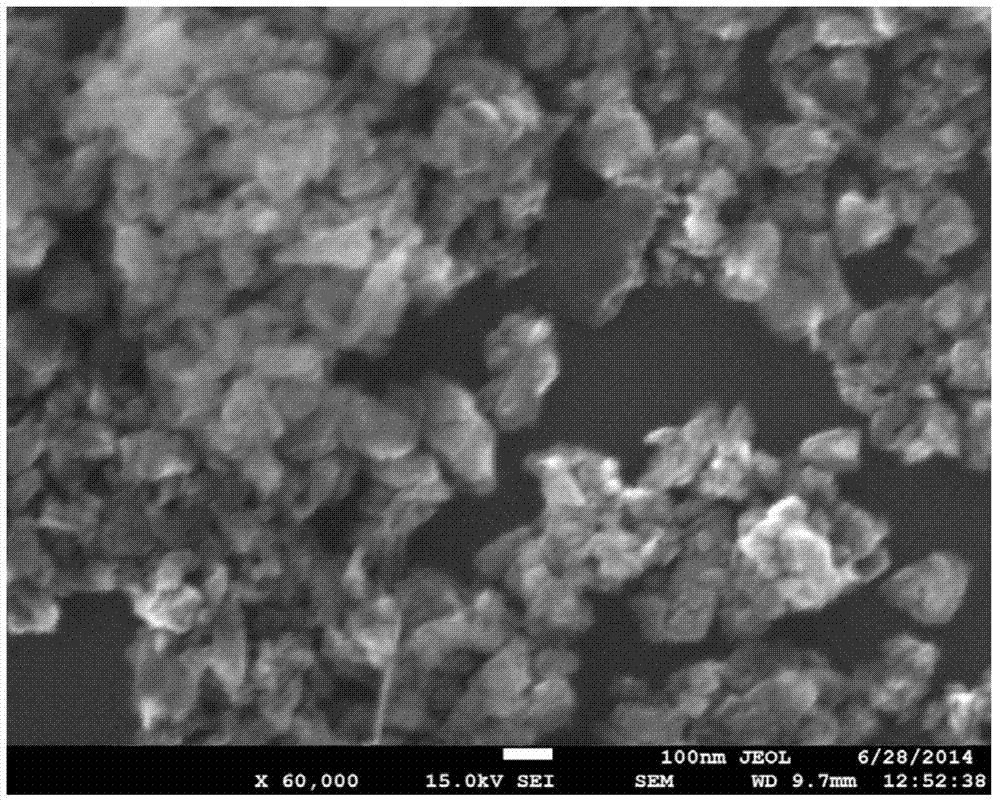

[0025] The preparation method of the cubic boron nitride micropowder SEM sample of the present embodiment comprises the following steps:

[0026] 1) Crush the agglomerated ultrafine powder with a hard object to obtain cubic boron nitride powder, with a single particle size ≤ 300nm;

[0027] 2) Place the cubic boron nitride micropowder obtained in step 1) in a test tube, and add absolute ethanol at the same time, the mass ratio of the cubic boron nitride micropowder and absolute ethanol is 1:10000; the test tube is placed in an ultrasonic device, and at F =Under the condition of 100KHz, ultrasonically oscillate for 5 minutes, shake the test tube constantly to shake the sample evenly, to obtain a suspension; the pH of the obtained suspension is 9.

[0028] 3) Take the suspension obtained in step 2) with a rubber dropper, drop 1 drop on the conductive adhesive, and after it is completely dried naturally, the scanning electron microscope sample of the cubic boron nitride micropowd...

Embodiment 2

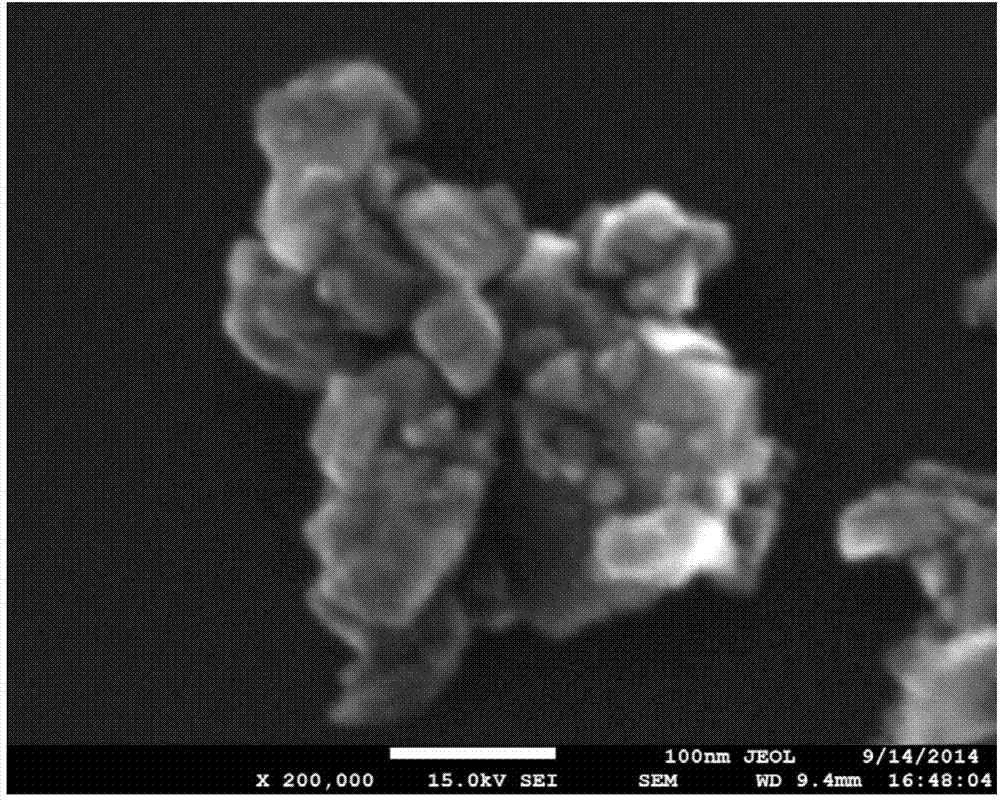

[0031] The preparation method of the cubic boron nitride micropowder SEM sample of the present embodiment comprises the following steps:

[0032] 1) Crush the agglomerated ultrafine powder with a hard object to obtain cubic boron nitride powder, with a single particle size ≤ 300nm;

[0033] 2) Take the cubic boron nitride micropowder obtained in step 1) and place it in a test tube, add sodium hexametaphosphate (LPL) and absolute ethanol at the same time, the volume ratio of sodium hexametaphosphate and absolute alcohol is 1:1000, cubic nitriding The mass ratio of boron micropowder to absolute ethanol is 3:10000; the test tube is placed in an ultrasonic device, and under the condition of F=60KHz, ultrasonic vibration is performed for 20 minutes, and the test tube is constantly shaken to shake the sample to obtain a suspension; the pH of the obtained suspension is 10.

[0034] 3) Take the suspension obtained in step 2) with a rubber dropper, drop 2 drops on the silicon wafer ad...

Embodiment 3

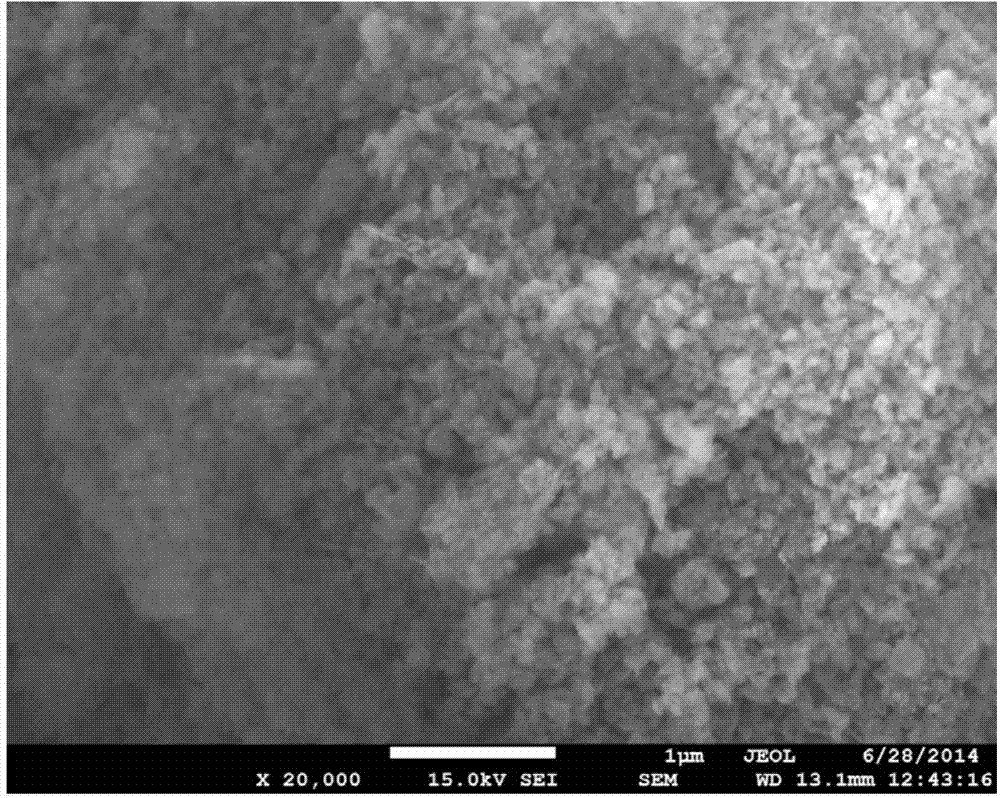

[0037] The preparation method of the cubic boron nitride micropowder SEM sample of the present embodiment comprises the following steps:

[0038] 1) Crush the agglomerated ultrafine powder with a hard object to obtain cubic boron nitride powder, with a single particle size ≤ 300nm;

[0039] 2) Take the cubic boron nitride micropowder obtained in step 1) and place it in a test tube, add polyacrylic acid (PAA) and dehydrated alcohol simultaneously, the volume ratio of polyacrylic acid and dehydrated alcohol is 3:1000, cubic boron nitride micropowder and dehydrated alcohol The mass ratio of water to ethanol is 8:10000; the test tube is placed in an ultrasonic device, under the condition of F=20KHz, ultrasonically oscillates for 30 minutes, and the test tube is shaken continuously to shake the sample to obtain a suspension; the pH of the obtained suspension is 11.

[0040] 3) Take the suspension obtained in step 2) with a rubber dropper, drop 3 drops on the silicon wafer adhered t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com