Rotating member fixing structure

一种旋转构件、构造的技术,应用在旋转构件的固定构造领域,能够解决应力集中等问题,达到简易结构、抑制局部应力集中的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

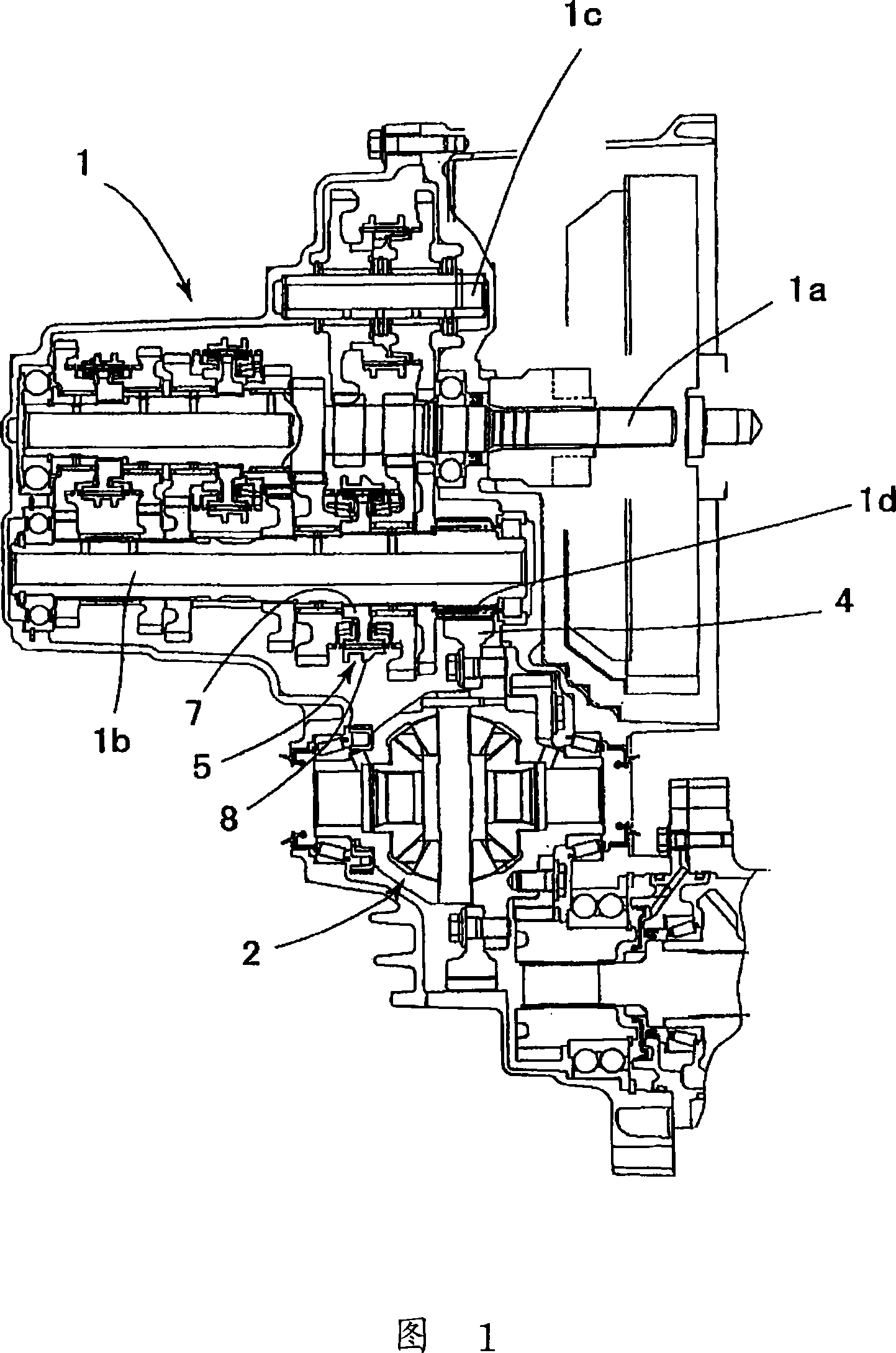

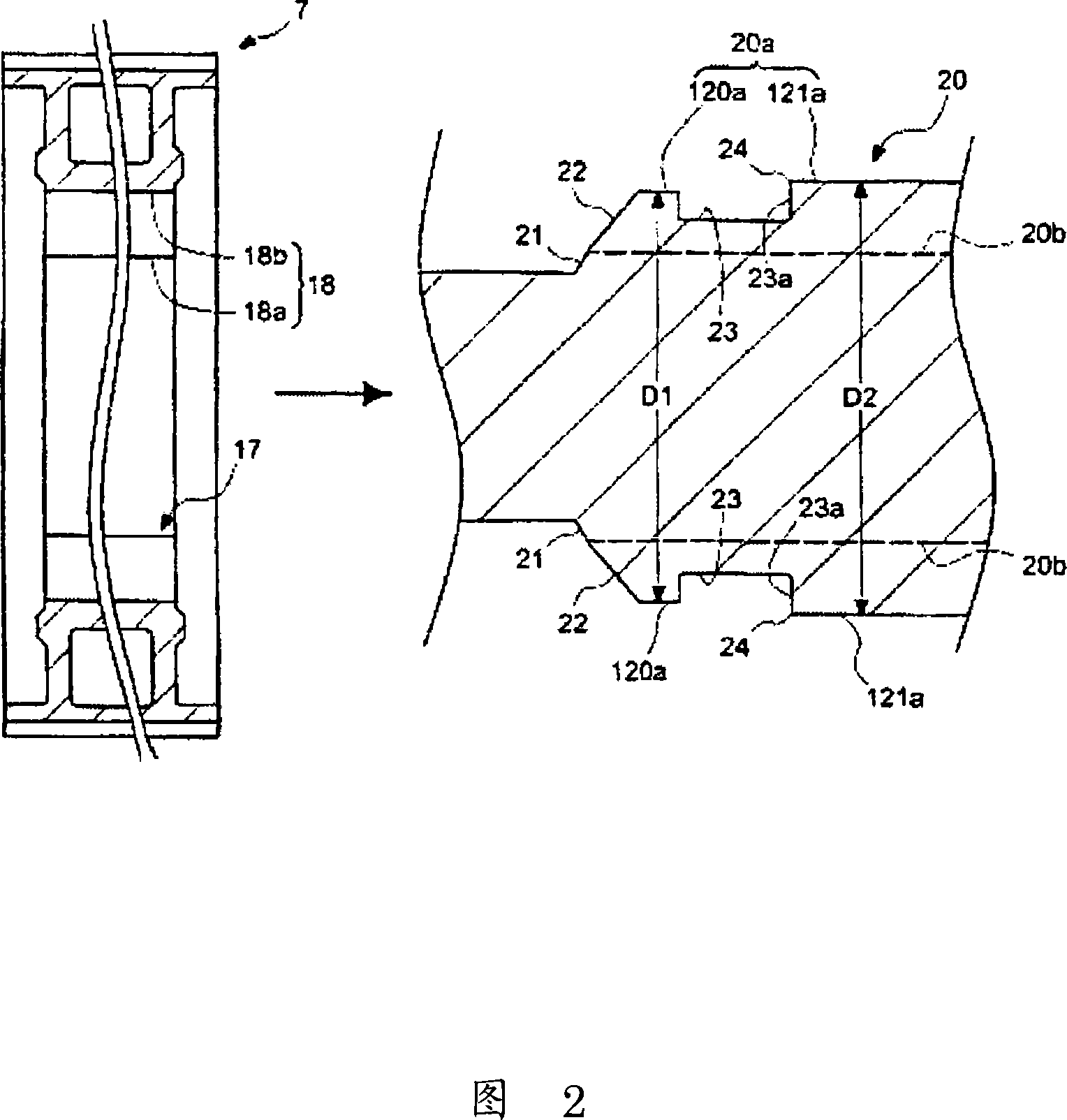

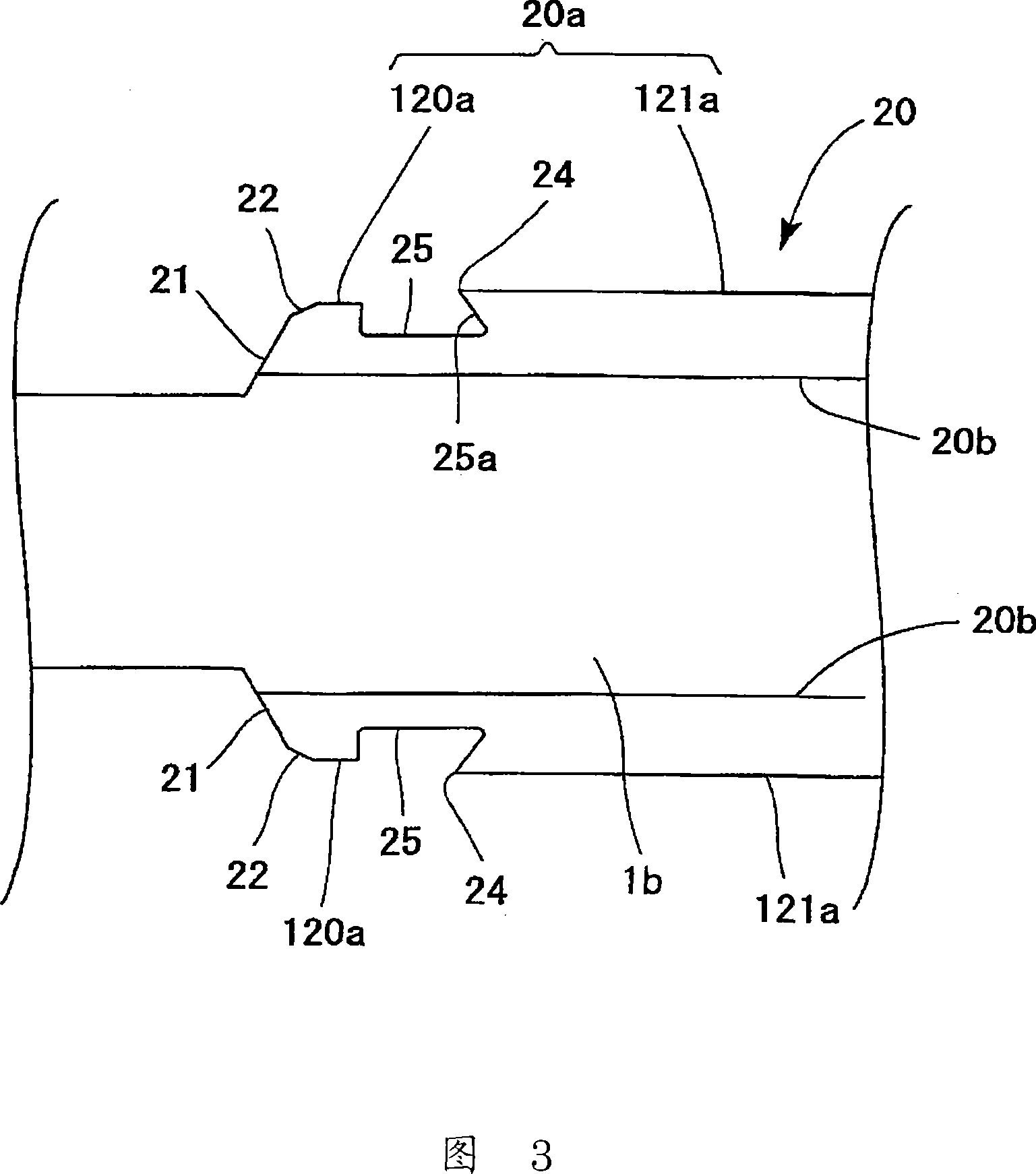

Method used

Image

Examples

Embodiment 2

[0064] Next, in the second embodiment shown in FIG. 6, the cylindrical rotating member 30 is press-fitted and fixed on the shaft member 40 with a circular cross section, as shown in the enlarged cross section in FIG. 7, for example. In the shaft hole 31 of the rotating member 30, a first shaft hole 31a with an inner diameter of d1 and a second shaft hole 31b with an inner diameter d2 smaller than the first shaft hole 31a are formed. An annular groove 32 with a relatively large inner diameter is formed between the two shaft holes 31b. The side of the annular groove 32 close to the second shaft hole 31b is a vertical surface 32a perpendicular to the axial direction. The inner end of the vertical surface 32a is connected to the second A right-angled corner portion 33 is formed at the starting end of the press-fitting direction of the shaft hole 31b.

[0065] The rotation member 30 is formed in such a structure that the rotation member 30 is gradually pressed into the shaft member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com