Circumferential pressure equalization loading device for brittle soft rock, soft rock sampling device and sampling method

A loading device and soft rock technology, applied in the direction of sampling device, applying stable tension/pressure to test material strength, etc., can solve problems such as damage, drilling sample breakage, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

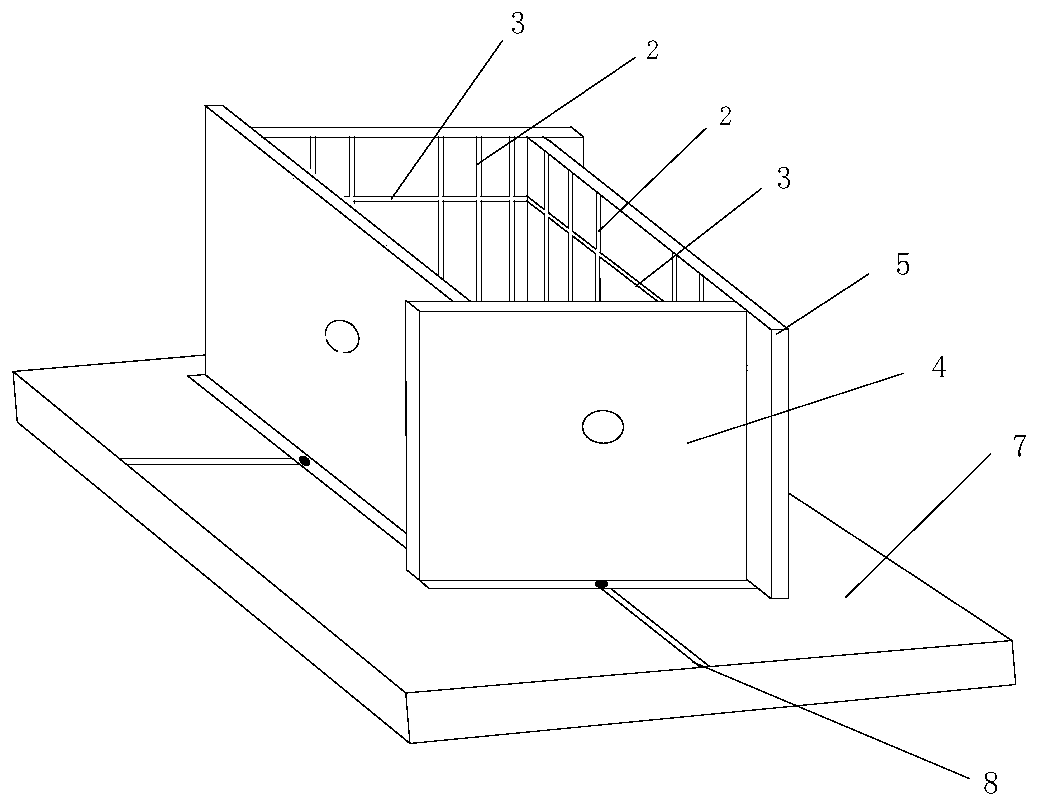

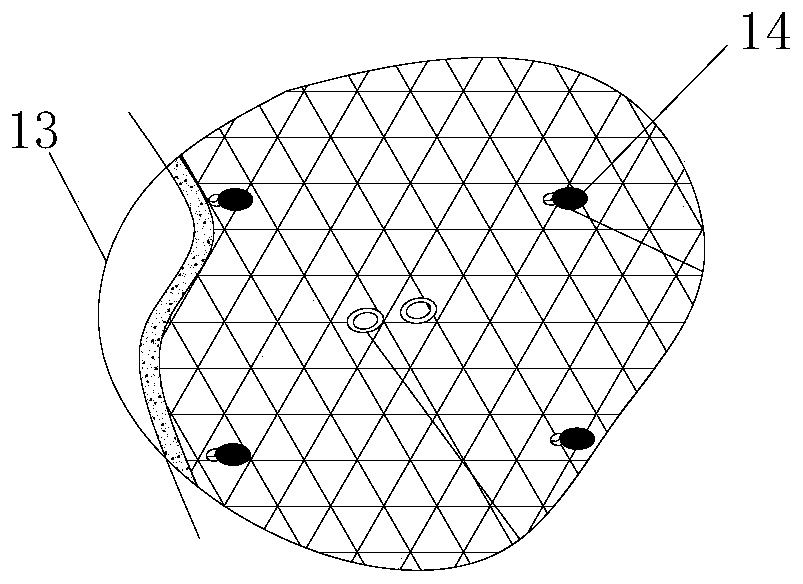

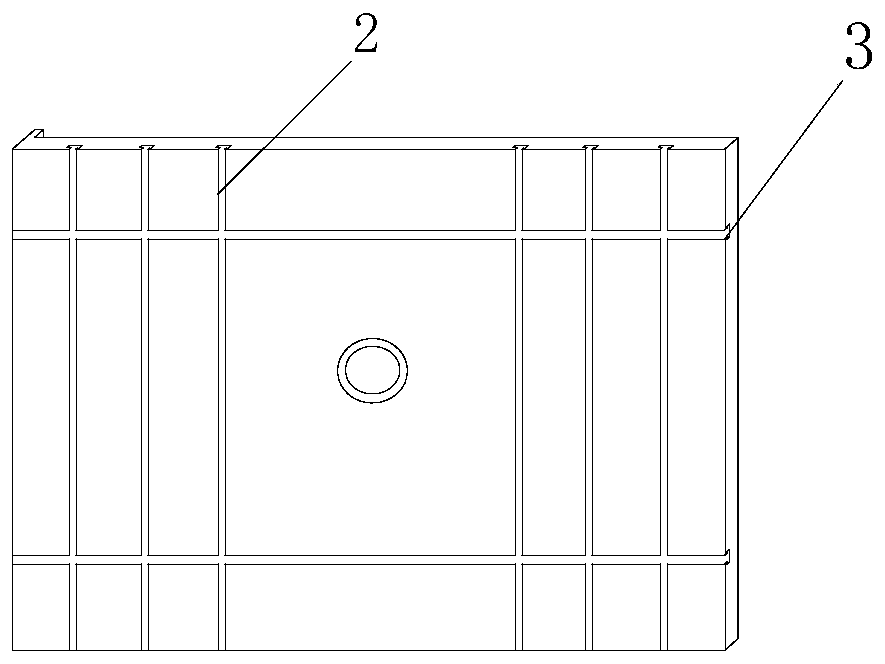

[0032] Participate in figure 1 , 2 , 3, 4, a kind of brittle soft rock circumferential pressure equalizing loading device, described loading device comprises base plate (7), longitudinal partition (5), transverse partition (4), elastic loading soft bag (13), loading power ( 9); the longitudinal baffle (5) and the transverse baffle (4) are 2 pieces and are vertically connected to form a quadrilateral cavity, and the quadrilateral cavity is installed on the base plate (7); in each An elastic-loaded soft bag (13) is installed on the longitudinal partition (5) and the transverse partition (4), and each elastic-loaded soft bag (13) is connected to the loading power (9) through a pipeline;

[0033]The bottom plate (7) is provided with a vertically intersecting positioning chute (8), the cross section of the positioning chute (8) is an inverted "T" shape, and the first bolt (8) is clamped in the positioning chute (8). 11), the second bolt (6), the bottom of the longitudinal partiti...

Embodiment 2

[0040] Participate in Figure 5 , a brittle soft rock circumferential pressure equalization loading sampling device, the sampling device comprises the brittle soft rock circumferential pressure equalization loading device of embodiment 1, a drilling rig (1), and the brittle soft rock circumferential pressure equalization loading device is placed on the drilling rig (1) to work on stage.

Embodiment 3

[0042] See attached figure 1 , 2 , 3, 4, 5, a sampling method for brittle soft rock under uniform pressure in the circumferential direction. The brittle soft rock test piece is soft coal; The block strength is 13Mp, and in this embodiment, the control load is 3Mp.

[0043] Sampling involves the following steps:

[0044] Step 1: Place the brittle soft rock circumferential pressure equalizing device on the drilling rig (1) workbench, adjust the relative positions of the longitudinal partition (5) and the transverse partition (4) and "T" according to the size of the brittle soft rock The position of the shaped positioning column in the longitudinal chute (2) and the transverse chute (3) makes the four elastic-loaded soft capsules (13) arranged on the longitudinal partition (5) and the transverse partition (4) encircle and form a Compartment for brittle soft rock;

[0045] Step 2: Place the brittle soft rock test block in the chamber, place a flexible rubber pad between the br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com