Method for transferring disc type Micro-LED array on silicon substrate

A disk-shaped, silicon substrate technology, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of LED chip damage, low transfer efficiency, complex process, etc., and achieve improved transfer efficiency and low material cost. The effect of low cost and simple transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Neither the endpoints nor any values of the ranges disclosed herein are limited to such precise ranges or values, and these ranges or values are understood to include values approaching these ranges or values. For numerical ranges, between the endpoints of each range, between the endpoints of each range and individual point values, and between individual point values can be combined with each other to obtain one or more new numerical ranges, these values Ranges should be considered as specifically disclosed herein.

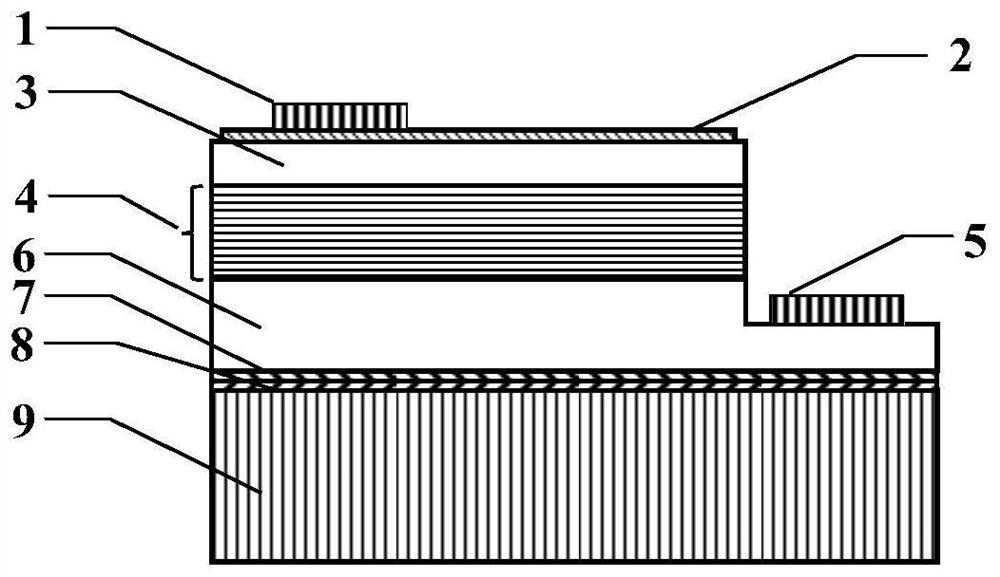

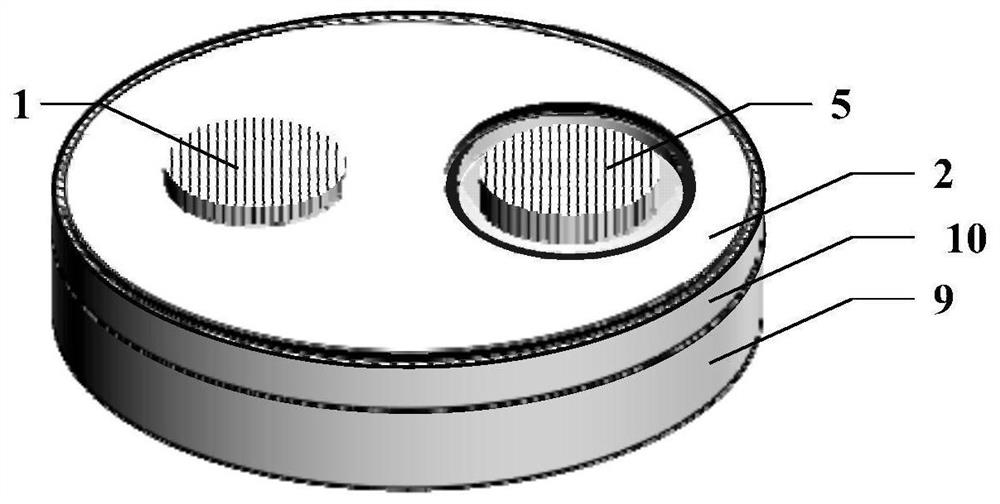

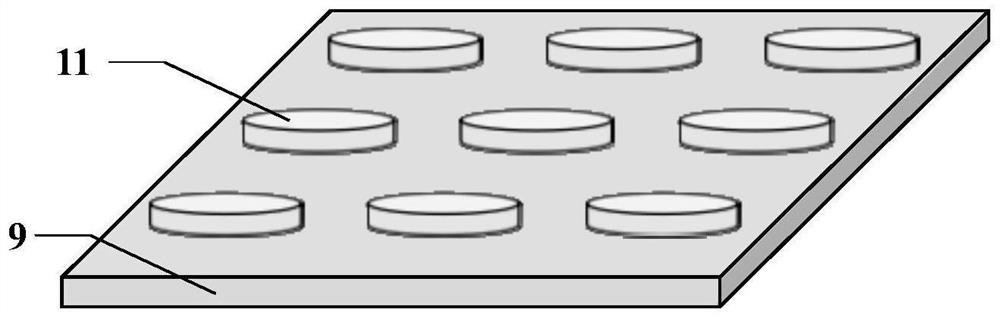

[0031] The present invention provides a method for transferring a disk-type Micro-LED array on a silicon substrate, which is characterized in that it includes the following steps:

[0032] (1) Protect the disk-shaped Micro-LED array on the silicon substrate by photolithography to obtain a Micro-LED array covered with photoresist;

[0033] (2) dry-etching the Micro-LED array covered with photoresist to obtain a suspended disk-type Micro-LED array su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com