Graphene sensor, manufacturing method thereof and touch display device

一种石墨烯、石墨烯层的技术,应用在照相制版工艺曝光装置、仪器、感光材料加工等方向,能够解决导电性变差等问题,达到提高良率、减少数量、降低制作成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

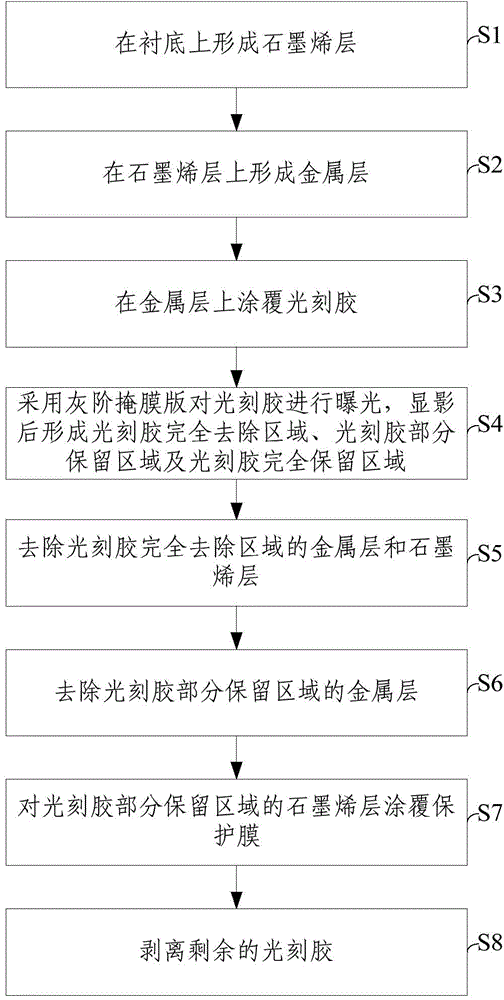

[0056] In order to illustrate the technical solution of the present invention more clearly, Embodiment 1 is illustrated below in conjunction with the schematic cross-sectional view of the device structure formed in each step, as Figure 9 As shown, the manufacturing method of this embodiment may specifically include the following steps:

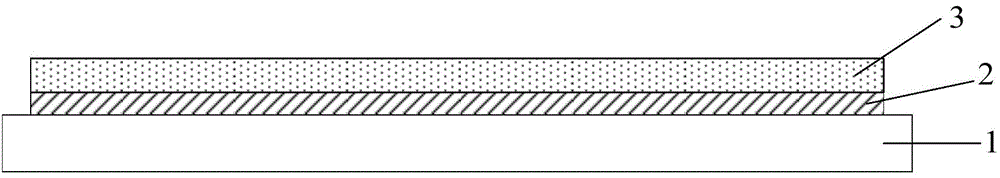

[0057] S10: forming a graphene layer 2 on the substrate 1, and depositing a sputtered metal film on the graphene layer 2 to form a metal layer 3, such as figure 2 shown;

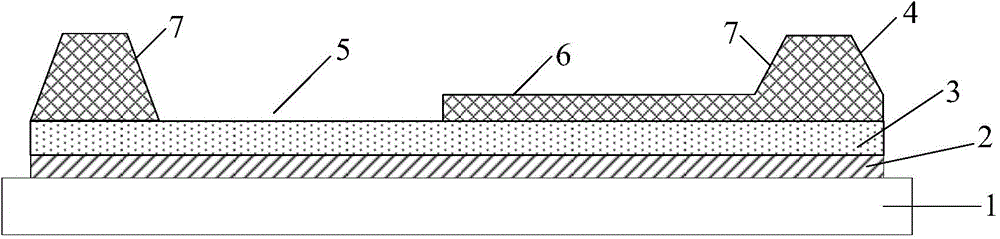

[0058] S20: Coating photoresist 4 on the metal layer 3, exposing and developing the photoresist 4 with a gray scale mask to form photoresist completely removed region 5, photoresist partially retained region 6 and photoresist Glue completely preserves region 7, as image 3 shown;

[0059] S30: using an acidic solution to wet etch the photoresist to completely remove the metal layer 3 in the region 5, such as Figure 4 shown;

[0060] S40: dry etching the photoresist t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com