Method for etching FTO (fluorine-doped tin oxide) conductive thin film

A conductive film and electrolyte technology, applied in electrolysis process, electrolysis components, etc., can solve the problems of low production efficiency and poor accuracy, and achieve the effect of scientific etching method, etching precision and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

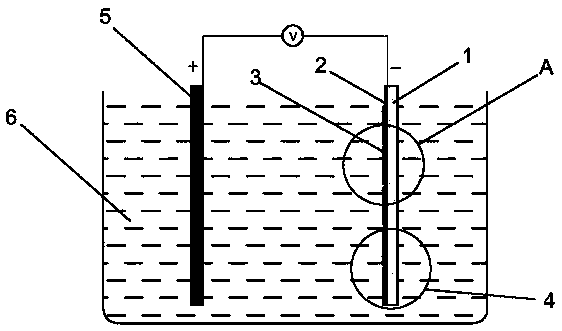

[0026] This embodiment discloses a method for etching a conductive film, such as Figure 1-3 Shown, specifically a kind of etching method of FTO conductive film, comprises the following steps:

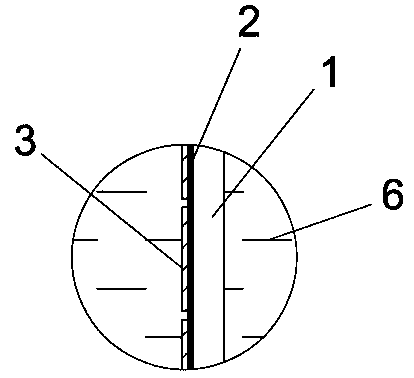

[0027] Step 1: According to the prefabricated pattern, print a layer of acid-resistant ink 3 on one side of the cleaned FTO conductive film 2 (in this embodiment, choose to deposit the FTO conductive film 2 on the glass substrate 1), which is the insulating etchant, and forms Working electrode - cathode 4;

[0028] Step 2: Place the cathode 4 and the anode 5 (graphite electrode) together in a hydrochloric acid solution 8 with a mass fraction of 8%, such as figure 1 and figure 2 shown;

[0029] Step 3: Apply a DC voltage of 2V between the cathode 4 and the anode 5 for 30 minutes;

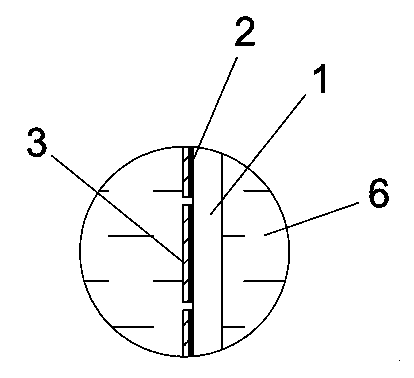

[0030] Step 4: After step 3, the FTO conductive film 2 placed in the hydrochloric acid solution 8 and not covered by the insulating ink 3 is etched and removed, as image 3 shown;

[0031] Step 5: Take...

Embodiment 2

[0033] This embodiment discloses an etching method for a conductive thin film, specifically an etching method for an FTO conductive thin film, comprising the following steps:

[0034] Step 1: According to the prefabricated pattern, print a layer of acid-resistant ink on the side of the cleaned FTO conductive film (in this embodiment, choose to deposit the FTO conductive film on the PET flexible substrate), that is, to form the working electrode-cathode;

[0035] Step 2: Place the cathode and the anode (platinum electrode) together in a hydrochloric acid solution with a mass fraction of 5%;

[0036] Step 3: Apply a DC voltage of 4V between the cathode and the anode for 40 minutes;

[0037] Step 4: After step 3, the FTO conductive film placed in the hydrochloric acid solution and not covered by the insulating ink is etched and removed;

[0038] Step 5: Take the cathode out of the hydrochloric acid solution, wash it with water, put it in 1% sodium hydroxide solution to remove th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com