Processing method of K9 ultrathin glass

A technology of ultra-thin glass and processing methods, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of difficult control of chemically etched surfaces, unfavorable mass production, and long processing time, so as to avoid appearance defects , Conducive to popularization and application, speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

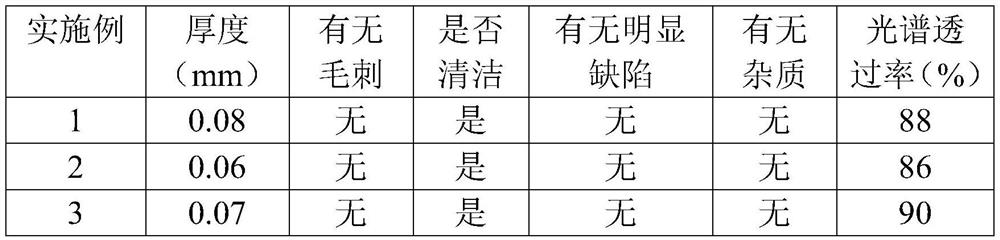

specific Embodiment 1

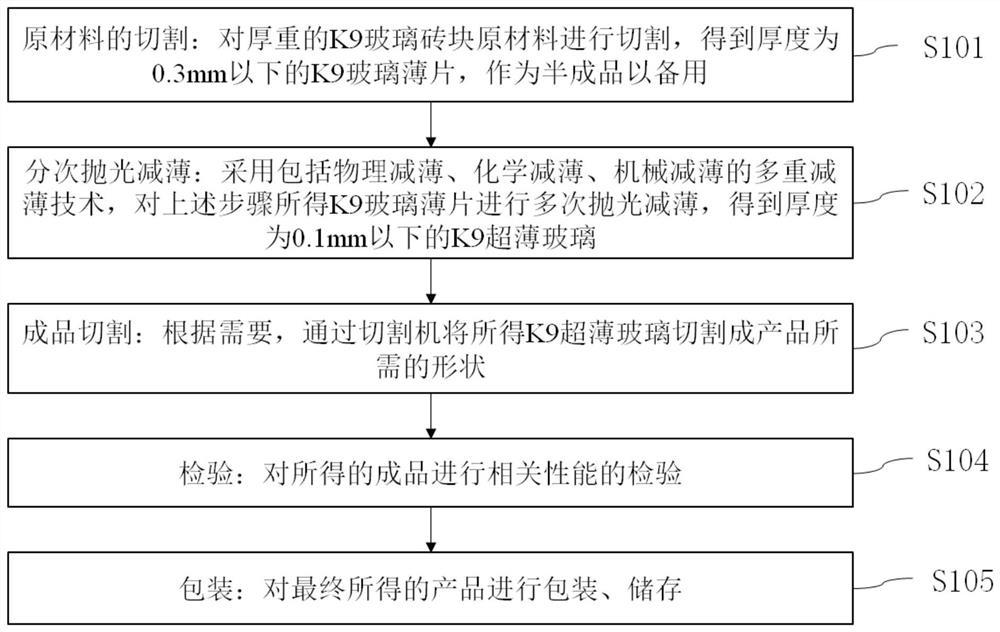

[0035] A processing method of K9 ultra-thin glass, comprising the following steps:

[0036] Step S101: cutting of raw materials: using wire cutting technology to cut thick K9 glass block raw materials to obtain K9 glass flakes with a thickness of 0.28 mm, which are used as semi-finished products for future use;

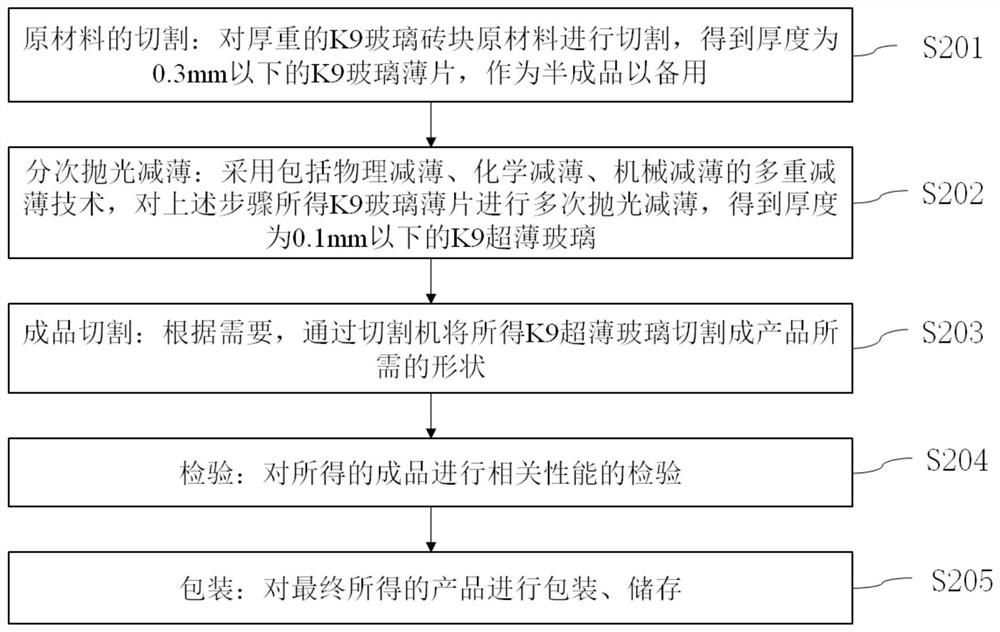

[0037] Step S102: Gradual polishing and thinning: using multiple thinning techniques including physical thinning, chemical thinning, and mechanical thinning to perform multiple polishing and thinning on the K9 glass sheet obtained in the above steps, specifically including the following steps:

[0038] Step S201: physical thinning: by means of automatic grinding and polishing, the K9 glass sheet obtained in the above steps is subjected to double-sided grinding, polishing and thinning, and cleaned;

[0039] Step S202: Bonding and fixing: bonding the physically thinned glass sheet to a special carrier plate with glue for fixing;

[0040] Step S203: Chemical thinning: a...

specific Embodiment 2

[0048] A processing method of K9 ultra-thin glass, comprising the following steps:

[0049] Step S101: Cutting of raw materials: using wire cutting technology to cut thick K9 glass block raw materials to obtain K9 glass flakes with a thickness of 0.26mm, which are used as semi-finished products for future use;

[0050]Step S102: Gradual polishing and thinning: using multiple thinning techniques including physical thinning, chemical thinning, and mechanical thinning to perform multiple polishing and thinning on the K9 glass sheet obtained in the above steps, specifically including the following steps:

[0051] Step S201: physical thinning: by manual grinding and polishing, the K9 glass sheet obtained in the above steps is double-sided grinding, polishing and thinning, and cleaned;

[0052] Step S202: Bonding and fixing: bonding the physically thinned glass sheet to a special carrier plate with glue for fixing;

[0053] Step S203: Chemical thinning: add a treatment liquid at 35...

specific Embodiment 3

[0061] A processing method for K9 ultra-thin glass, comprising the following steps:

[0062] Step S101: cutting of raw materials: using wire cutting technology to cut thick K9 glass block raw materials to obtain K9 glass flakes with a thickness of 0.28 mm, which are used as semi-finished products for future use;

[0063] Step S102: Gradual polishing and thinning: using multiple thinning techniques including physical thinning, chemical thinning, and mechanical thinning to perform multiple polishing and thinning on the K9 glass sheet obtained in the above steps, specifically including the following steps:

[0064] Step S201: physical thinning: by means of automatic grinding and polishing, the K9 glass sheet obtained in the above steps is subjected to double-sided grinding, polishing and thinning, and cleaned;

[0065] Step S202: Bonding and fixing: bonding the physically thinned glass sheet to a special carrier plate with glue for fixing;

[0066] Step S203: Chemical thinning: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com