Metal bonding method of three-dimensional chip structure and bonding structure

A three-dimensional chip and metal bonding technology, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of low reliability, complex process and high cost, achieve high reliability, simplify the process low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached picture The principles and features of the present invention are described, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

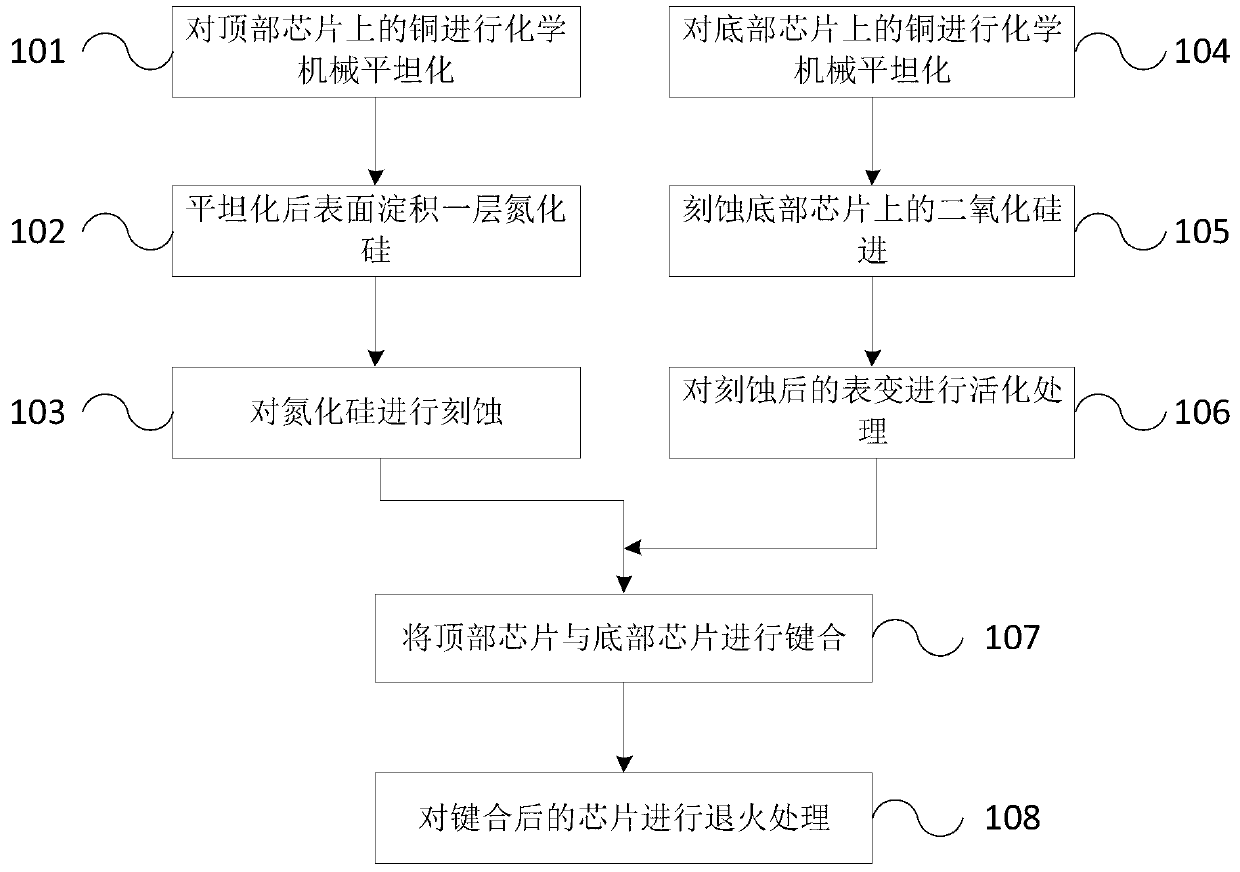

[0038] Such as figure 1 Shown, is the flow process of the inventive method picture , including the following steps:

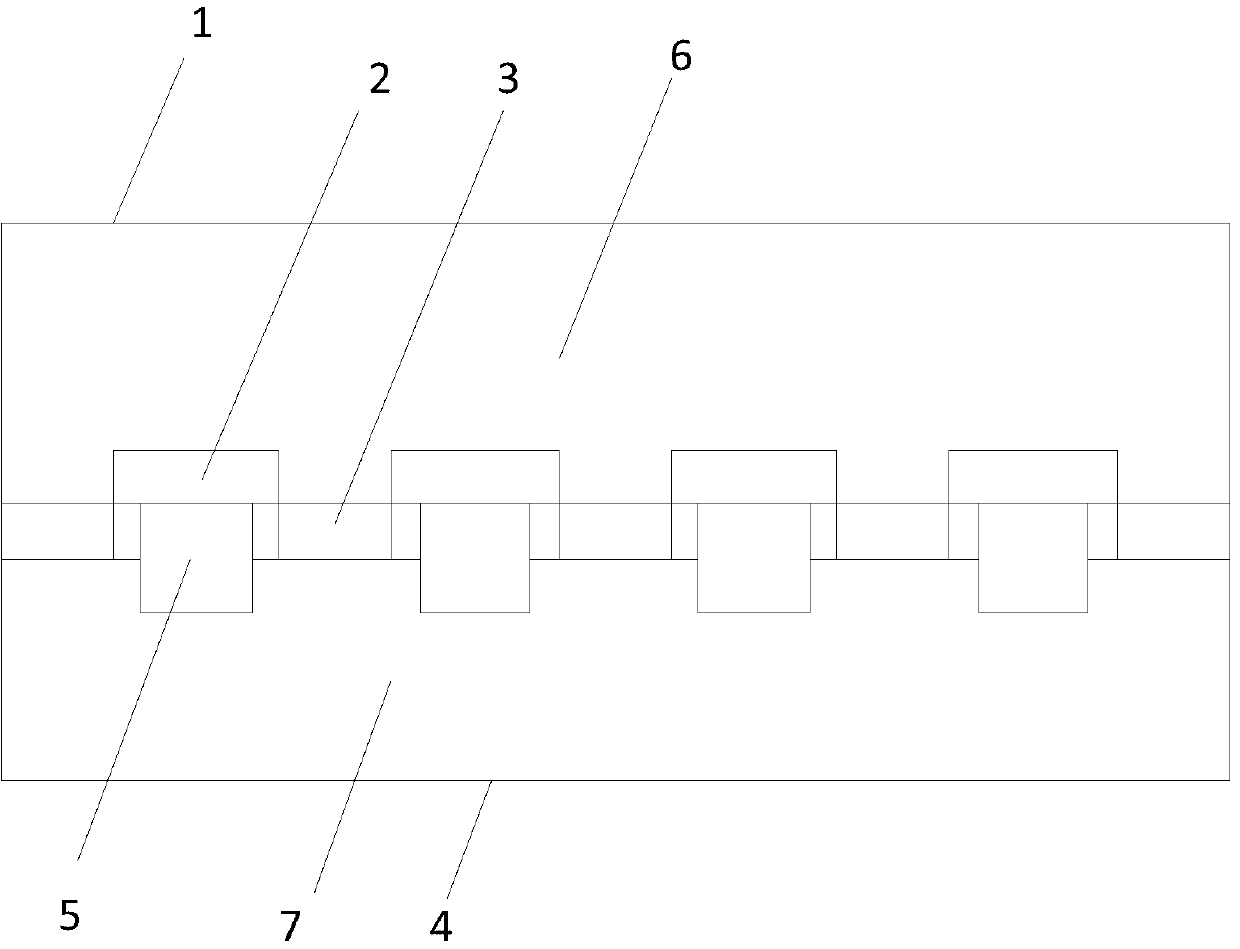

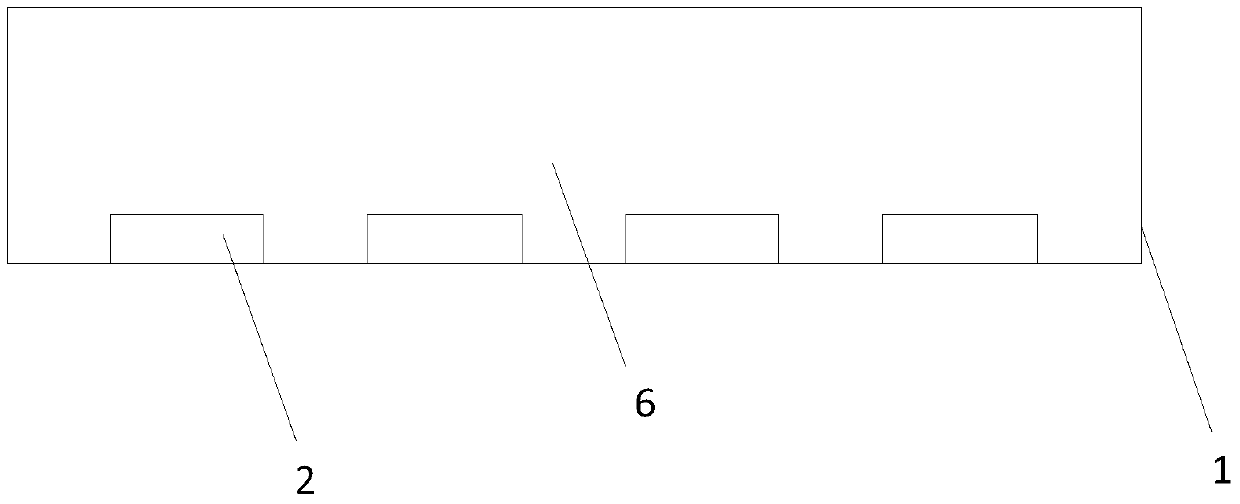

[0039] Step 101, the top chip 1 of the three-dimensional chip is provided with a top chip groove, and copper is deposited in the top chip groove and on the surface of the top chip 1, and the surface of the top chip 1 deposited with copper is chemically mechanically planarizing until the top silicon dioxide layer 6 is exposed, and the copper in the top chip trench is the top chip copper 2;

[0040] Step 102, depositing a silicon nitride layer 3 on the surface of the top chip 1 after chemical mechanical planarization;

[0041] Step 103, etching the silicon nitride layer 3 attached to the top chip copper 2 to form a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com