Patents

Literature

52results about How to "Prevent heat deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

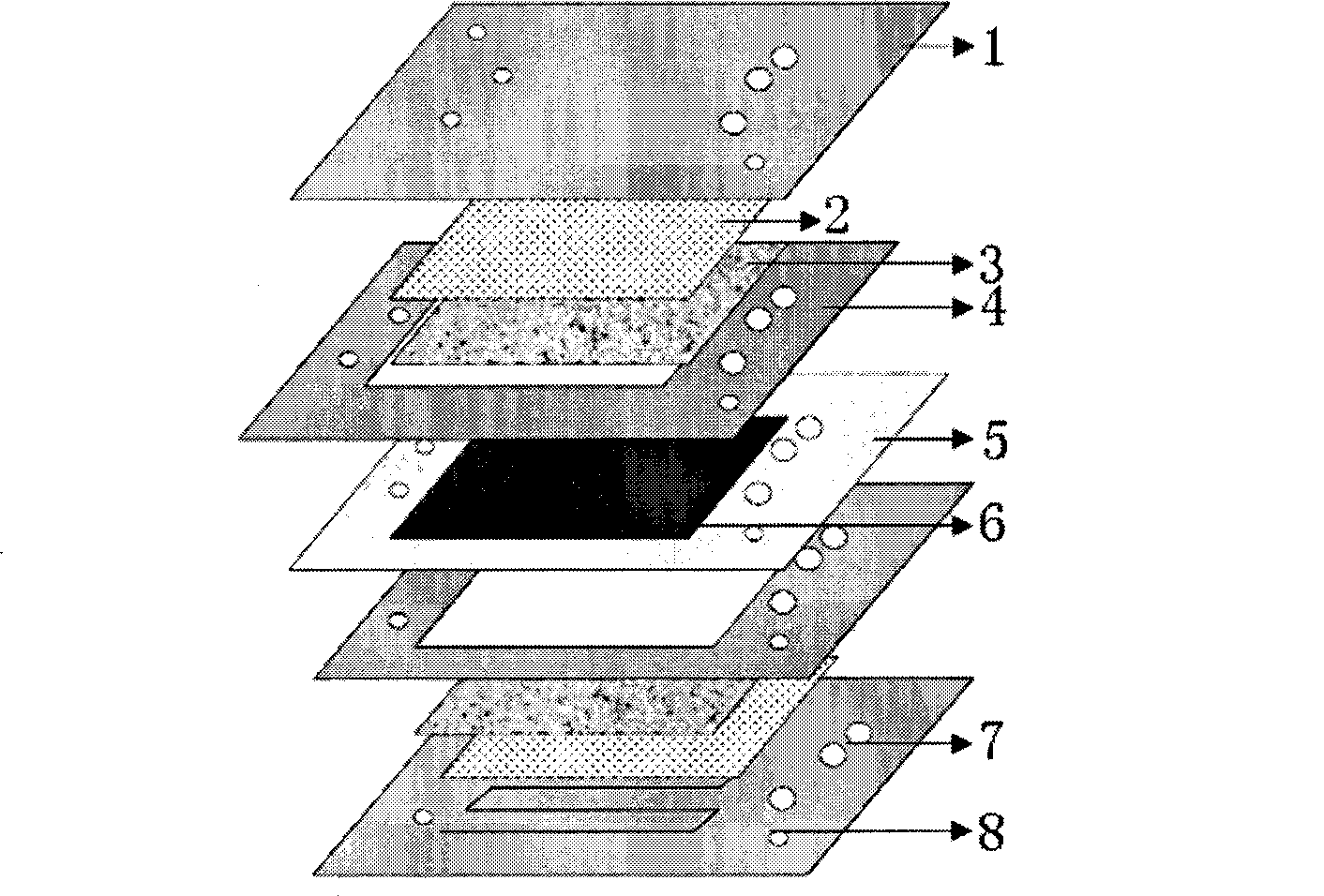

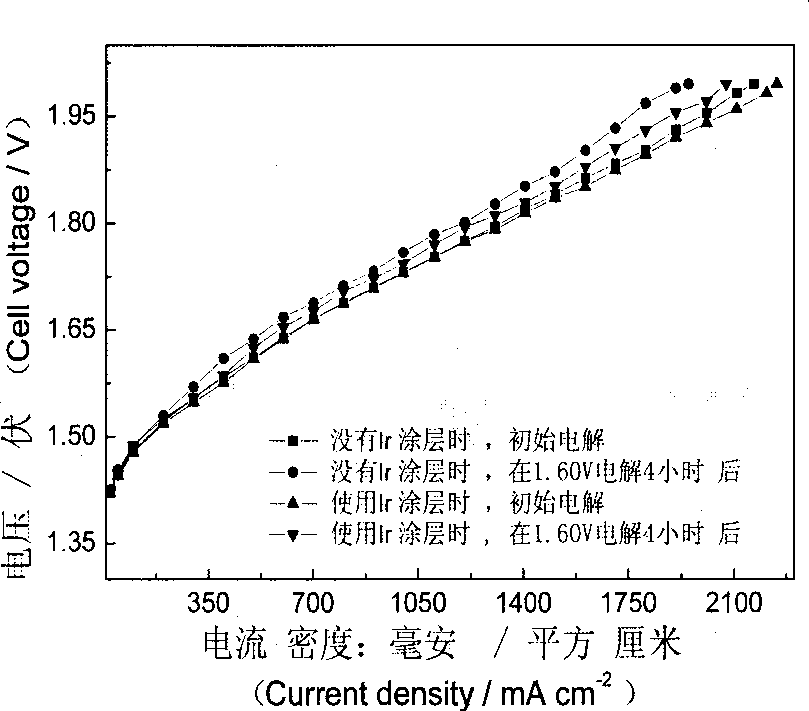

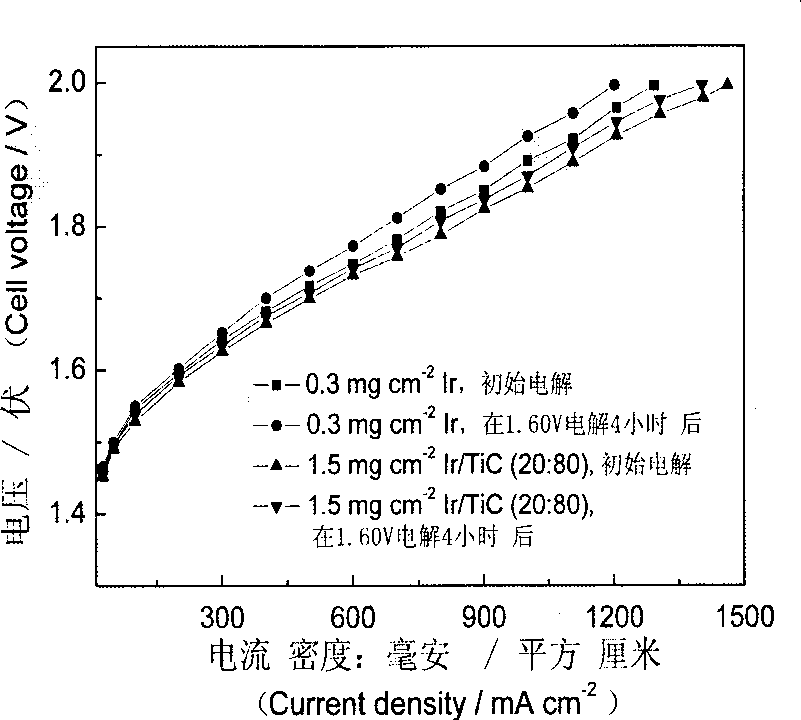

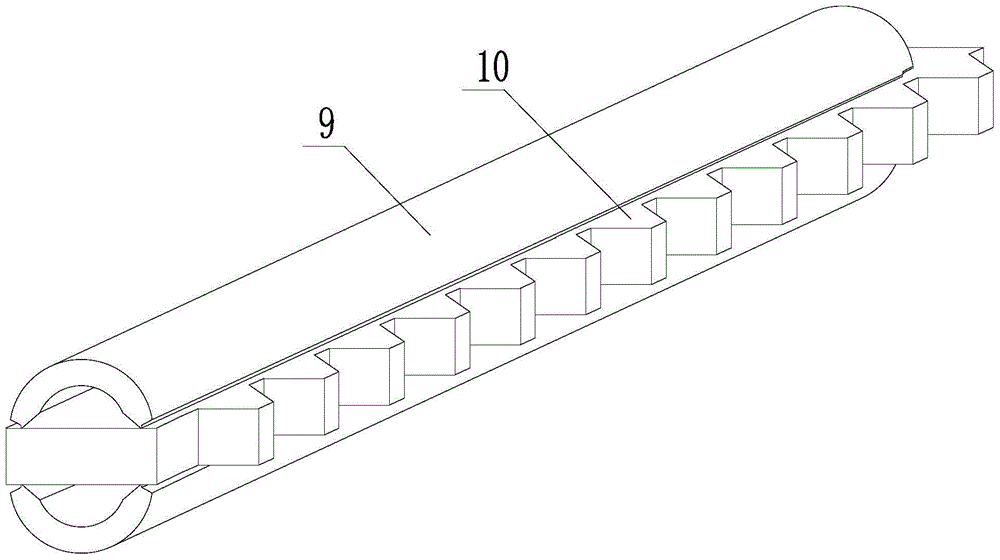

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

Method for manufacturing medium and high-voltage anode aluminum foil for aluminum electrolytic capacitor

InactiveCN101950688AReduce feverPrevent heat deformationElectrolytic capacitorsConversion coatingSulphate Ion

The invention discloses a method for manufacturing a medium and high-voltage anode aluminum foil for an aluminum electrolytic capacitor, which sequentially comprises the following steps of: 1) pretreating an optical foil; 2) putting the optical foil into acid solution in a ratio of chloride ion to sulfate ion of 5-15:1, then applying an alternating current with the current density of 60 to 100mA / cm<2> to the optical foil for primary corroding and hole forming, then putting the optical foil into acid solution in the ratio of the chloride ion to the sulfate ion of 1:9.5-16, and then applying a direct current with the current density of 250 to 300mA / cm<2> to the optical foil for primary corroding and hole forming; 3) after primary cleaning, performing secondary corroding and reaming on the optical foil in the acid solution; 4) after secondary cleaning, drying the optical foil by using a drying furnace to obtain the corroded foil finished product; and 5) performing conversion coating on the corroded foil finished product to obtain the medium and high-voltage anode aluminum foil finished product. In the method for manufacturing the medium and high-voltage anode aluminum foil for the aluminum electrolytic capacitor provided by the invention, the surface dislocation and defect parts of the optical foil are subjected to pitting by the alternating current, and then the optical foil is subjected to primary corroding and hole forming by the direct current, so that heating is reduced, the deformation of the aluminum foil because of heating is prevented, the surface expansion rate of the aluminum foil is increased, and specific volume is improved greatly.

Owner:南通华冠电子科技有限公司

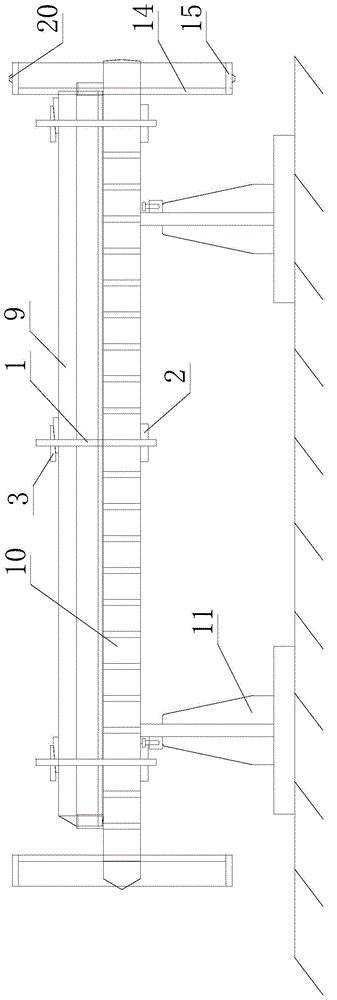

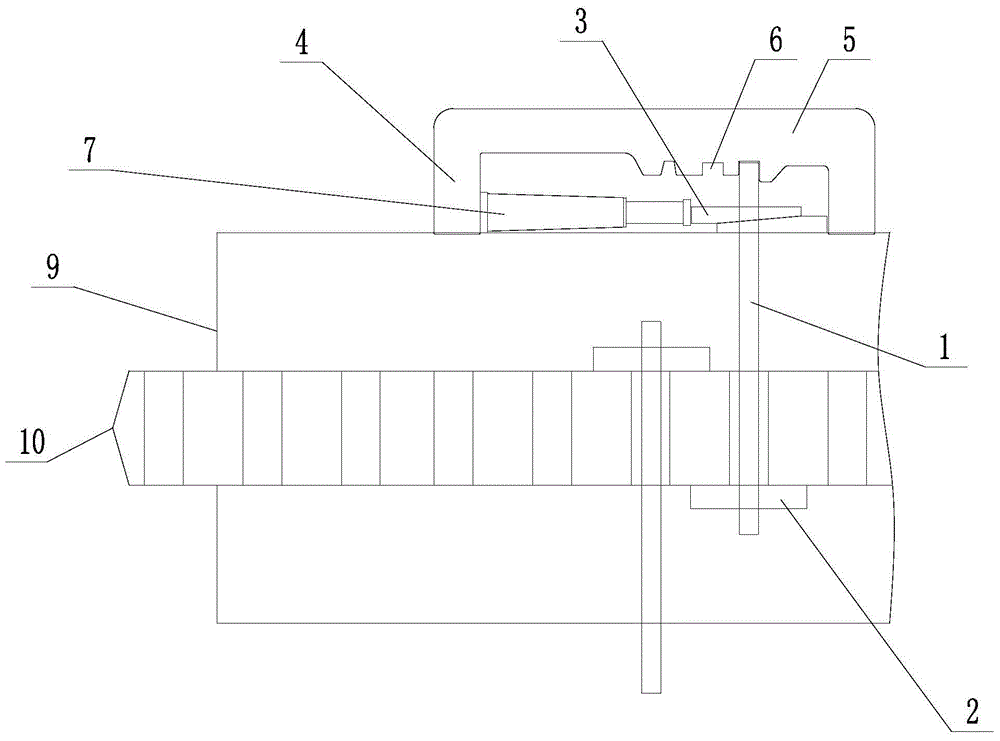

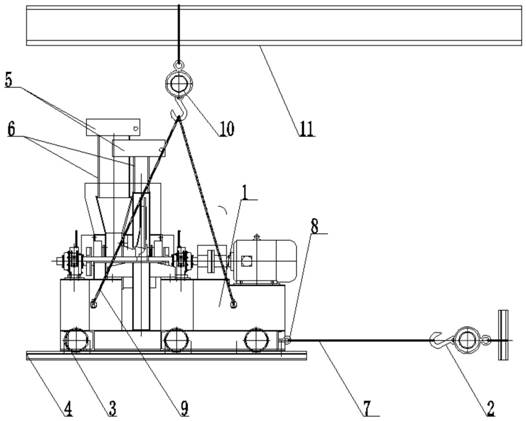

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

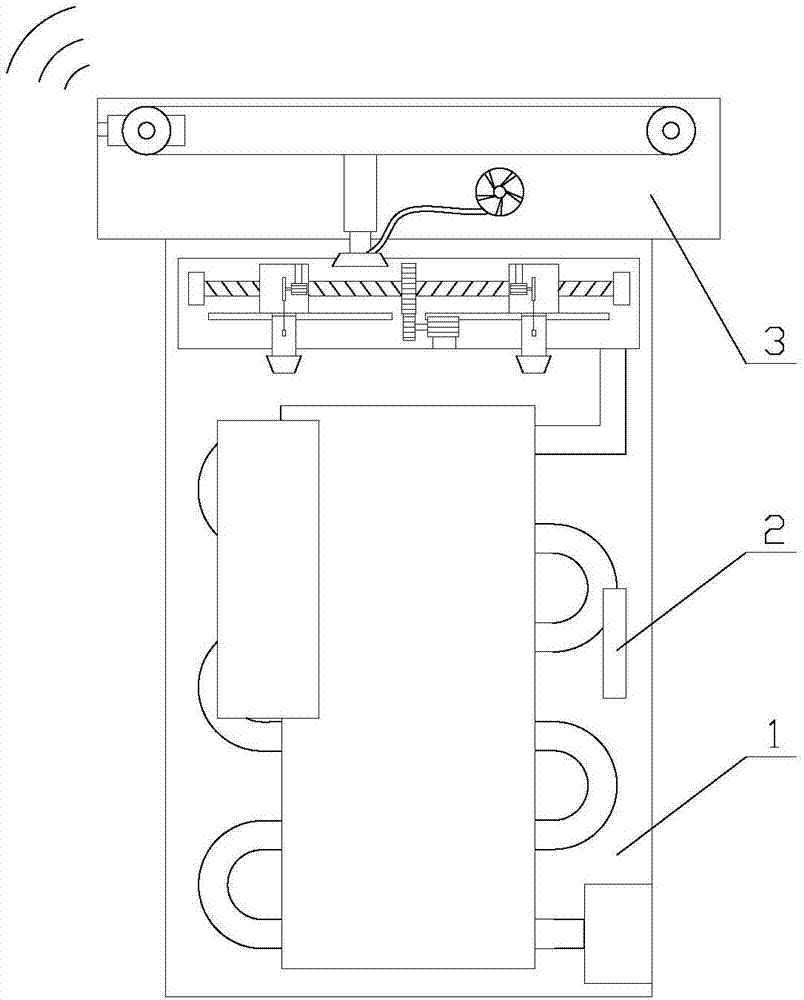

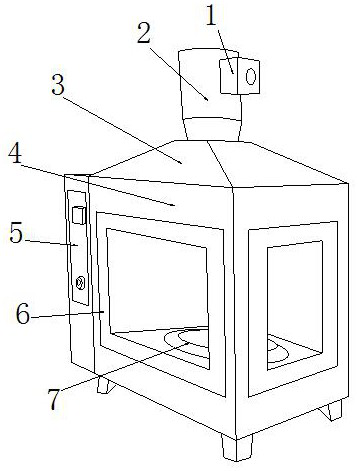

Fireproof door based on Internet of Things and having extinguishing and smoke removing functions

ActiveCN107882491AImprove practicalityImprove reliabilityFireproof doorsFire rescueEngineeringInternet of Things

The invention relates to a fireproof door based on Internet of Things and having extinguishing and smoke removing functions. The fireproof door includes a main body and a handle and further includes an extinguishing mechanism, a casing and a smoke absorbing mechanism. The extinguishing mechanism includes a heat absorption assembly and a spraying assembly. The heat absorption assembly includes a water pump, a heat absorption plate, a heat absorption pipe and a stabilizing assembly. The spraying assembly includes a driving chamber, a driving unit and a spraying unit. The smoke absorbing mechanism includes a rotating assembly and a smoke absorbing assembly. In the fireproof door based on Internet of Things and having the extinguishing and smoke removing functions, through the extinguishing mechanism, a main body is effectively prevented from being heated and deforming; omnidirectional uniform spraying for extinguishing is performed through a spray head, and fire spreading is effectively retarded, to achieve the protective effect. Smoke can be absorbed through the smoke absorbing mechanism, to prevent the smoke from spreading, people's life safety is ensured as far as possible, and through these, the practicality and reliability of the fireproof door are greatly improved.

Owner:北京城房科技集团有限公司

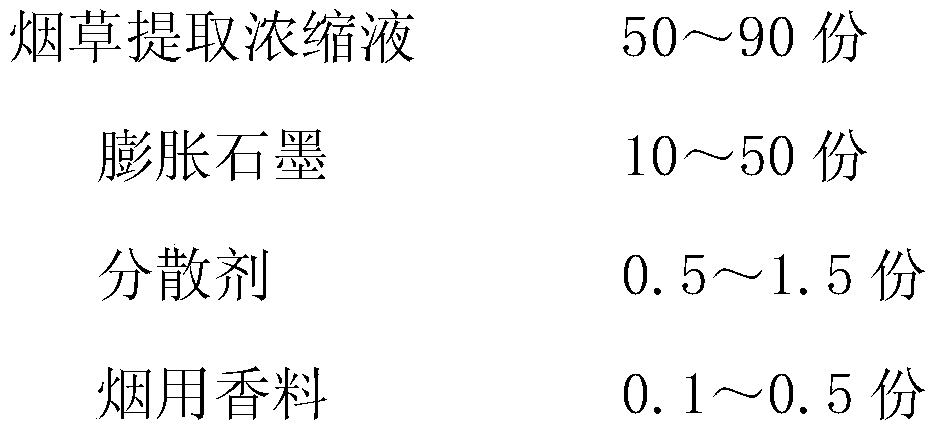

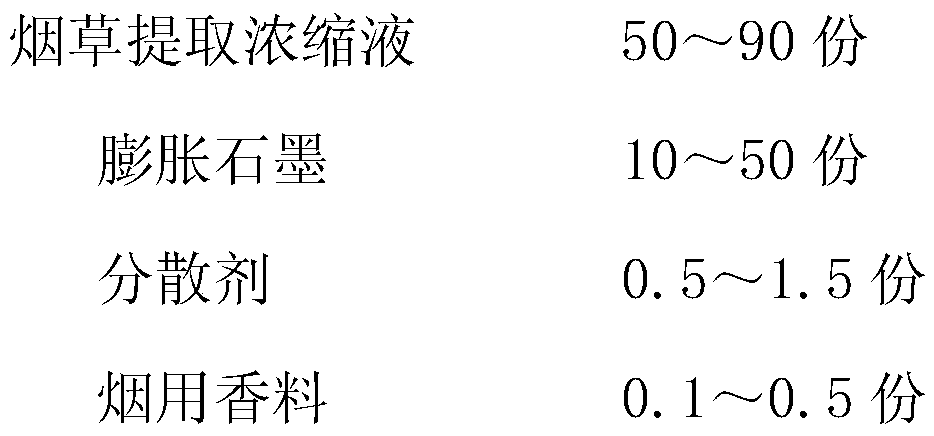

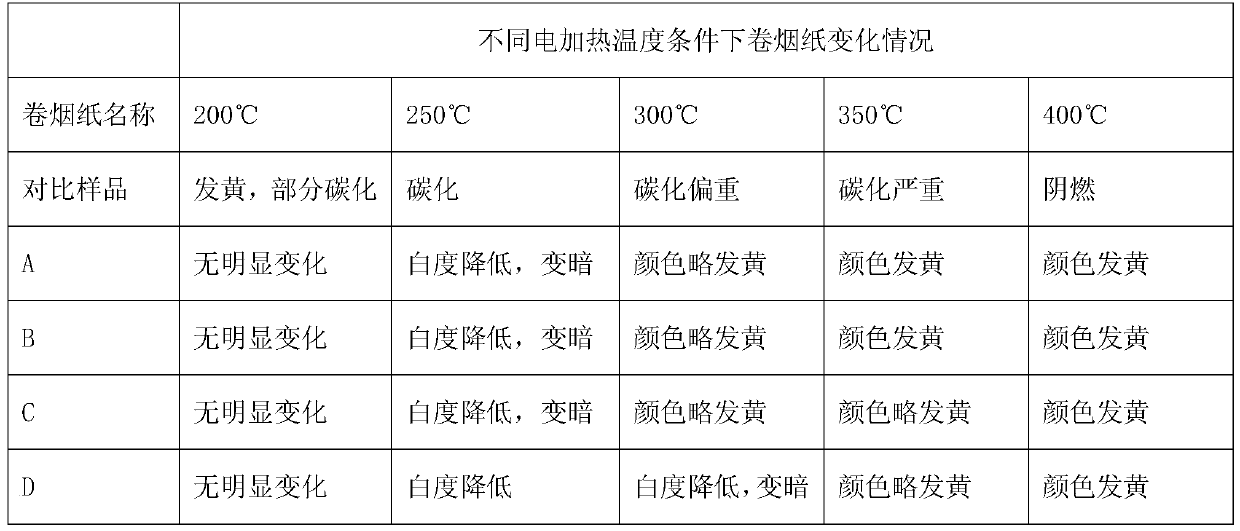

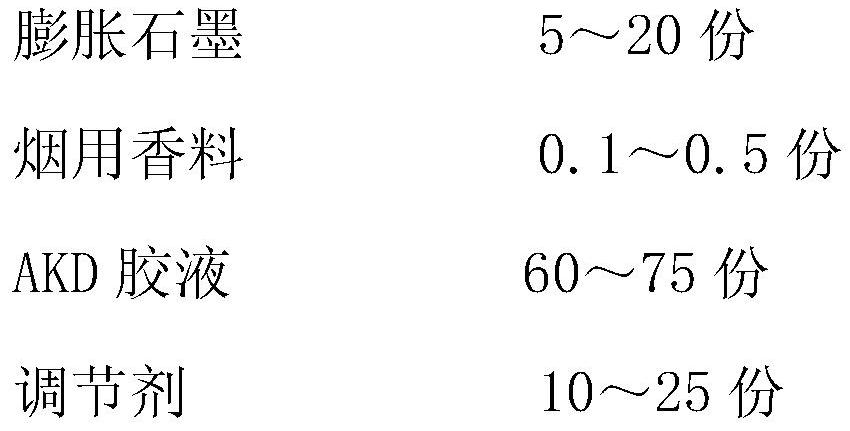

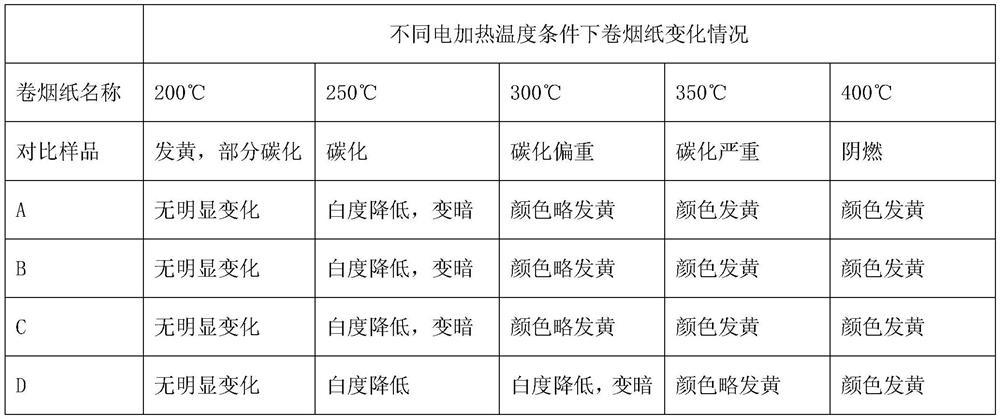

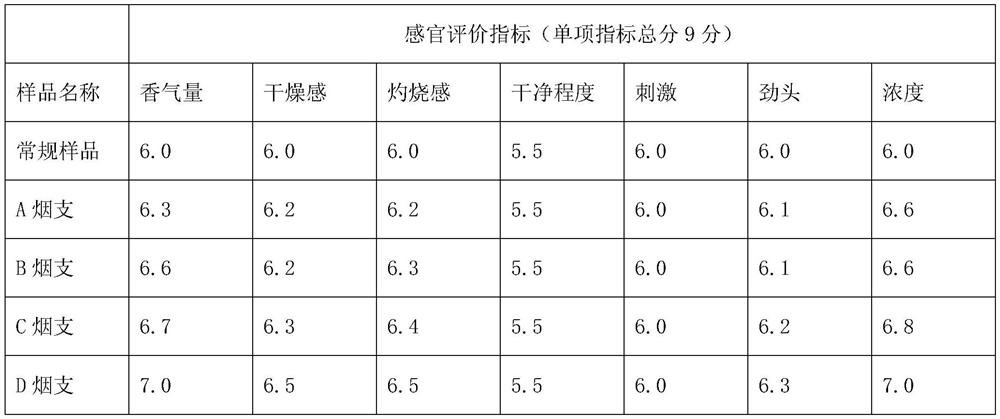

Coating liquid for heating incombustible tobacco product cigarette paper and preparation method and application of coating liquid

ActiveCN109763378APrevent high temperature heat deformationIncrease surface areaNon-fibrous pulp additionCoatings with pigmentsFlavorTobacco product

The invention provides coating liquid for heating incombustible tobacco product cigarette paper and a preparation method and application of the coating liquid. The coating liquid is prepared from thestep that tobacco extracting concentrated solution, expanded graphite particles, a dispersing agent and tobacco flavor are evenly mixed and subjected to ultrasonic dispersion for 7-15 minutes. The expanded graphite particles are prepared from the steps that expanded graphite particles with the particle diameters of 5-15[mu]m are placed in an atomizing agent solution, fully stirred under a negativepressure condition and absorb the atomizing agent solution, and drying at a low temperature of 70-100 DEG C is carried out. The tobacco extracting concentrated solution is prepared from the step thata tobacco extracting concentrated solution is subjected to vacuum concentration to the relative concentration of 1.21-1.28g / cm<3>. One surface of cigarette paper substrate paper is coated with the coating liquid evenly and subjected to drying slicing under the condition of 50-65 DEG C to obtain the cigarette paper, the cigarette paper can resist high temperature (about 300 DEG C), and the smoke releasing quantity during smoking can be improved.

Owner:HUBEI CHINA TOBACCO IND

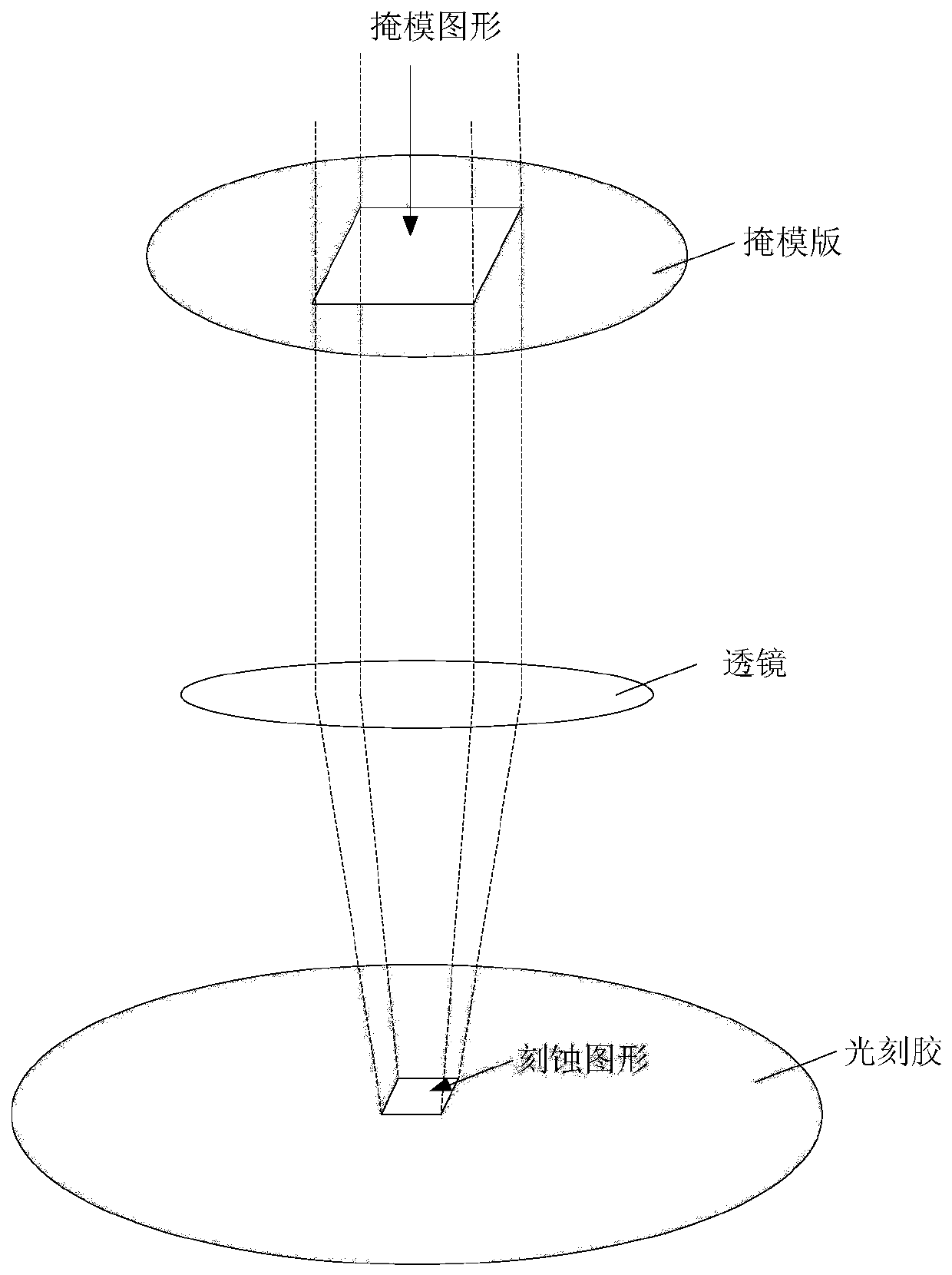

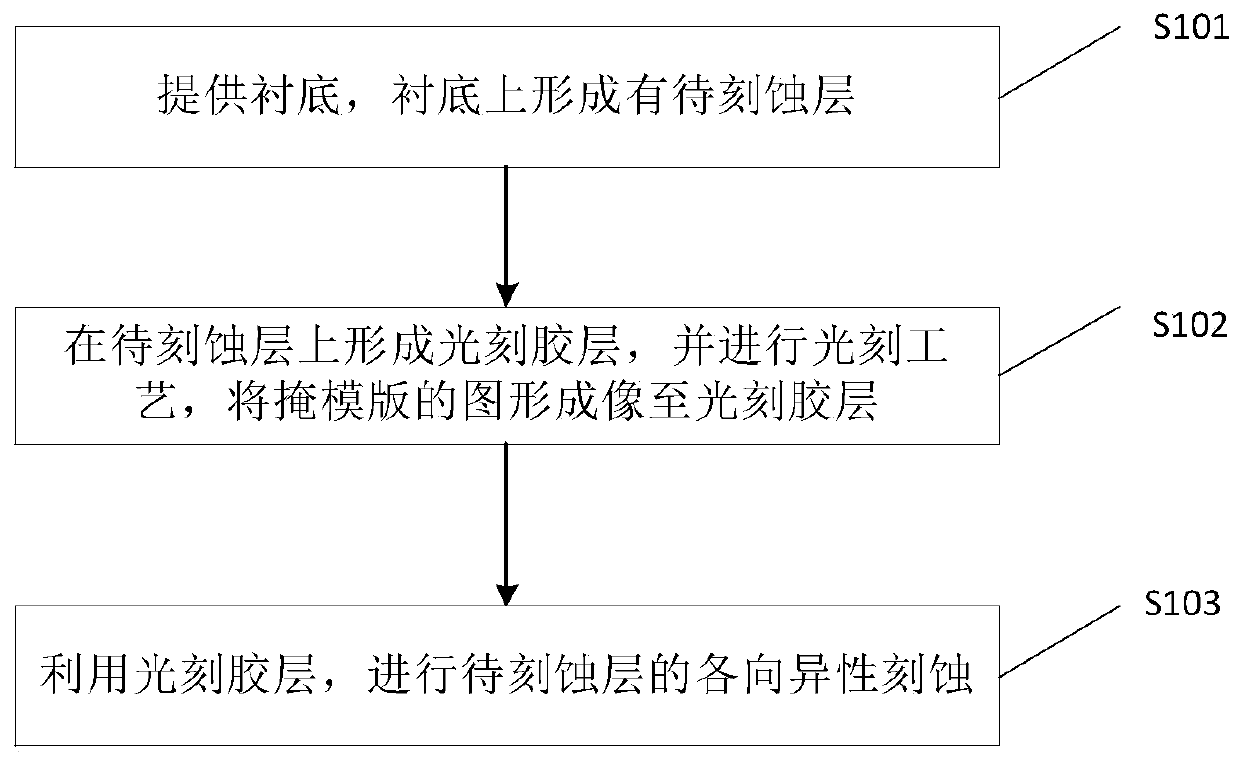

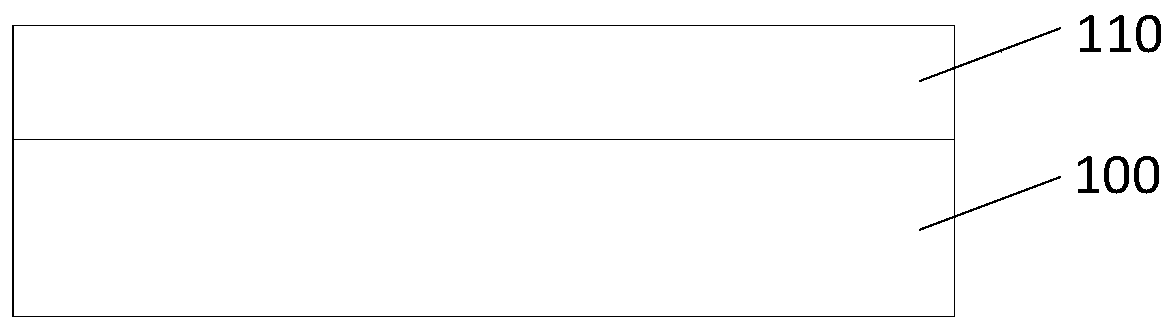

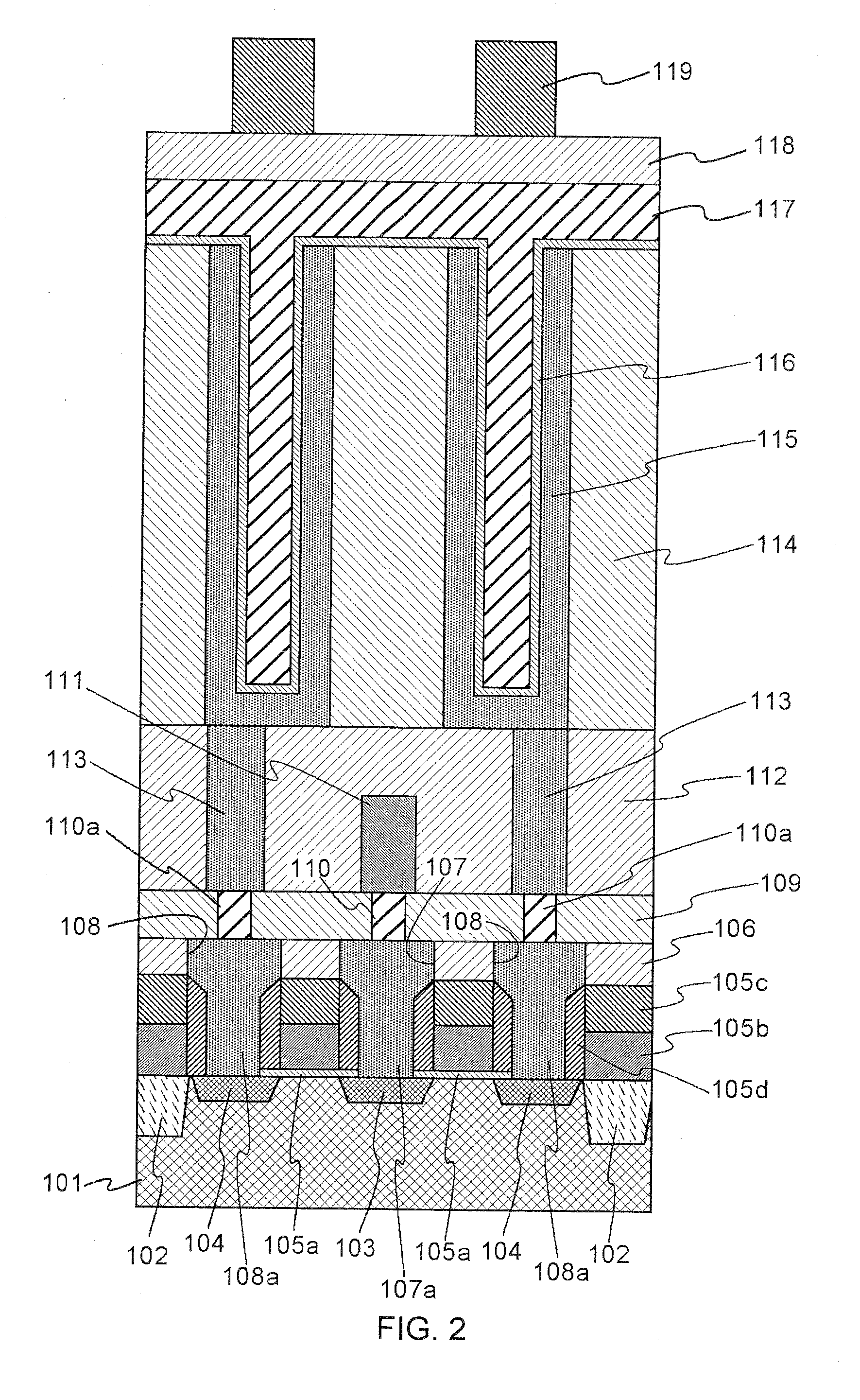

Mask plate and manufacturing method of semiconductor device

InactiveCN110491776APrevent heat deformationImprove etching precisionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistPower semiconductor device

The invention provides a mask plate and a manufacturing method of a semiconductor device. Patterns of the mask plate comprise a first pattern capable of being exposed and a second pattern which is a sub-resolution auxiliary pattern, the ratio of the area of the first pattern to the total area of the mask plate is smaller than or equal to a preset ratio, and the ratio of the sum of the area of thesecond pattern and the area of the first pattern to the total area of the mask plate is within a preset range. Since the second graph is a sub-resolution auxiliary graph, the photoresist layer cannotbe imaged, so that etching of the to-be-etched layer cannot be affected; meanwhile, due to the existence of the second pattern, the density of the pattern in the mask plate is increased, the problem that the mask plate is heated and deformed due to the fact that light intensity is excessively concentrated when photoresist is patterned is solved, and the etching precision of the to-be-etched layerin the semiconductor device is improved.

Owner:YANGTZE MEMORY TECH CO LTD

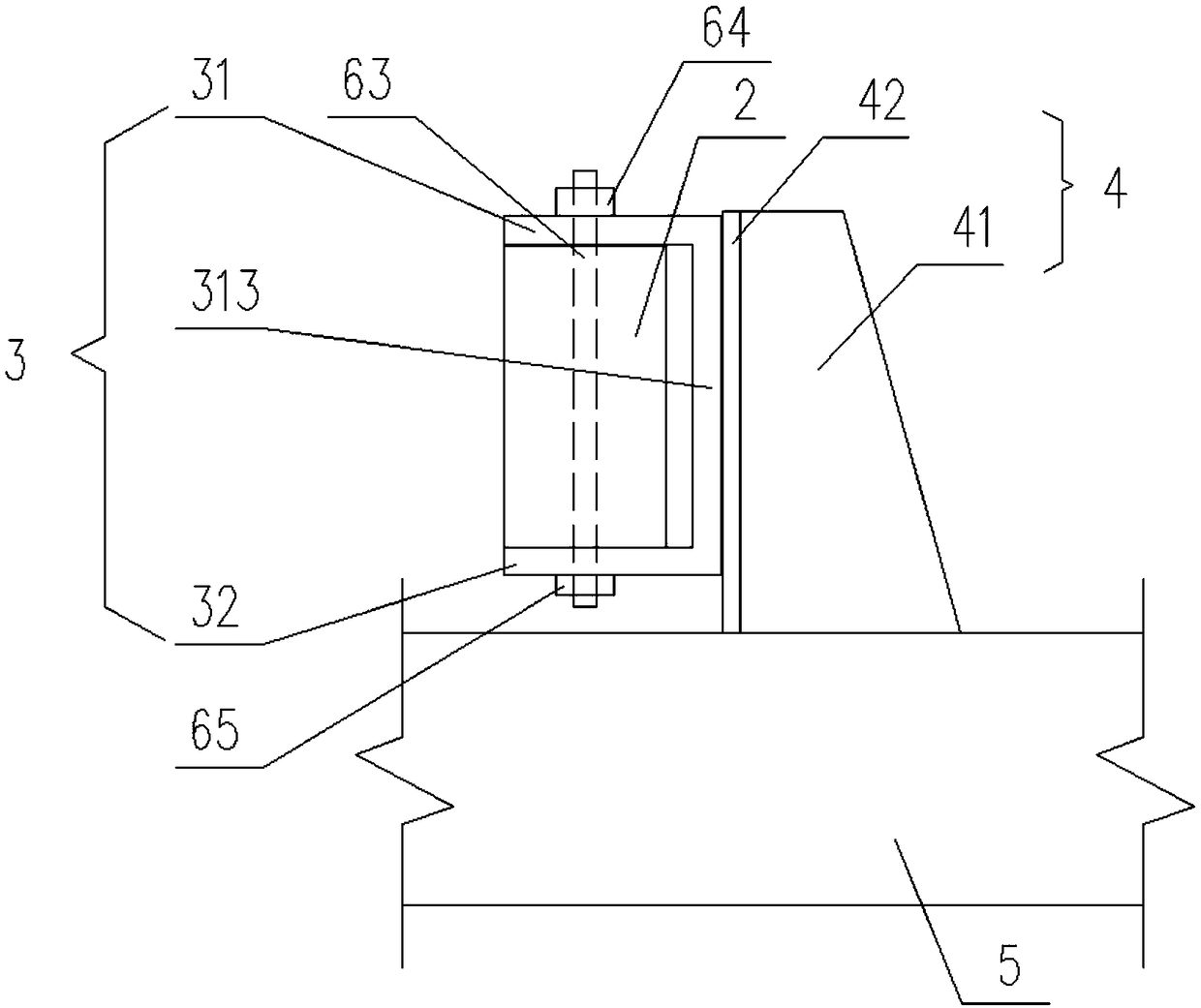

Clamping plate type support of aluminum alloy hub-type joint net frame

PendingCN109138164ASimple structureSave steelExtraordinary structuresEngineeringUltimate tensile strength

The invention provides a clamping plate type support of an aluminum alloy hub-type joint net frame. The technical problem that a screw rod is not subjected to shearing force is solved. According to the adopted technical scheme, the splint type support comprises a maintaining part, a locking assembly, and a connecting part, wherein the maintaining part is provided with a fixing end plate and further provided with a first sealing end plate and a second sealing end plate which are arranged on one side face of the fixing end plate in parallel, and a positioning groove suitable for placing a hub joint is enclosed among the two sealing end plates and the fixing end plate; the locking assembly includes a perforating part passing through the first sealing end plate, the hub joint and the second sealing end plate in sequence in the axial direction of the hub joint, and locking parts arranged at the two ends of the perforating part; and the connecting part is suitable for connecting the maintaining part to a to-be-connected object. Cover plate seals in the prior art is replaced by adopting a clamping type sealing structure, seals are in rigid connection, the overall structural strength of the support is enhanced, thus the perforating part can withstand a certain degree of shearing resistance, and the structural strength of the support is greatly enhanced.

Owner:HUADIAN HEAVY IND CO LTD

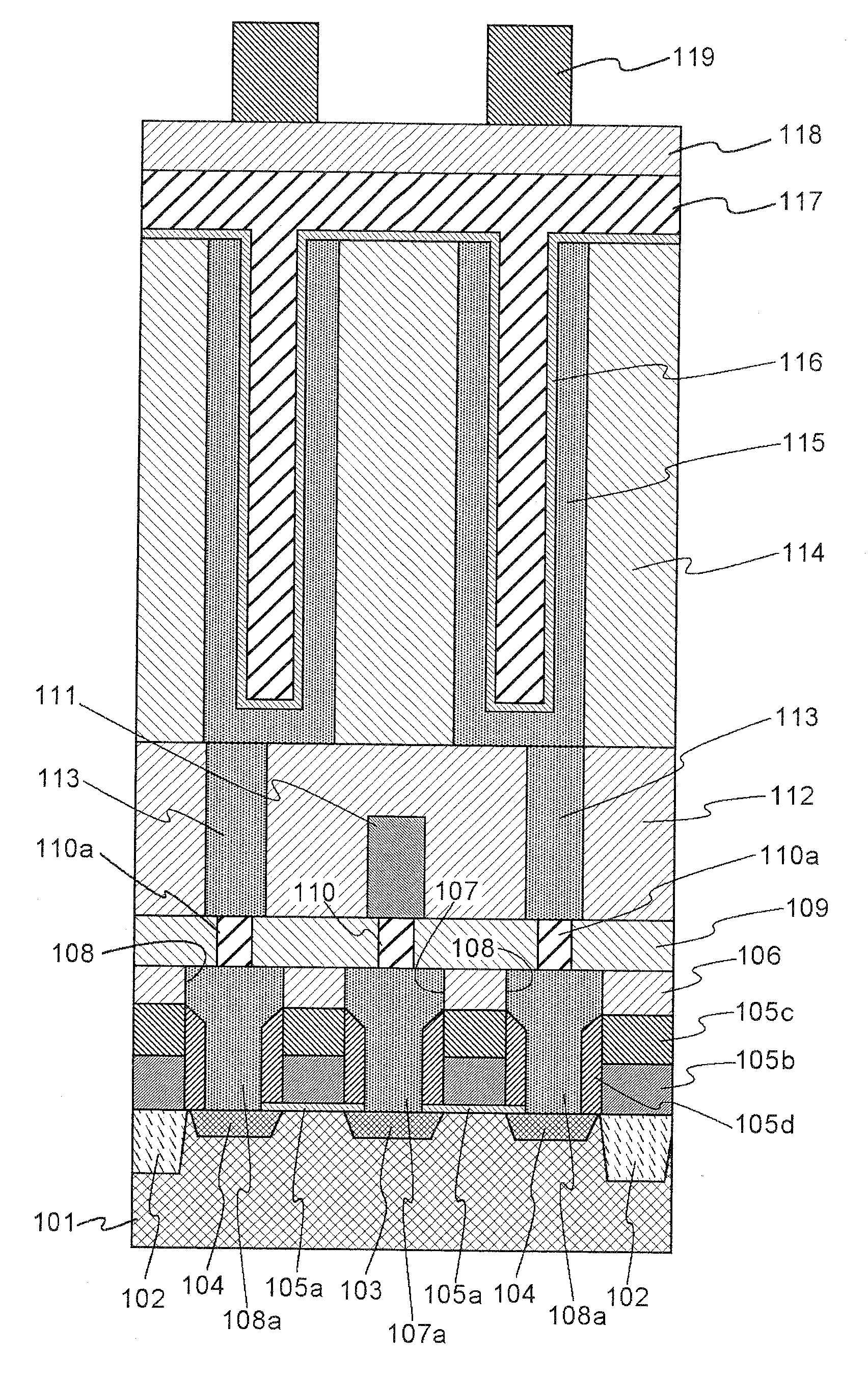

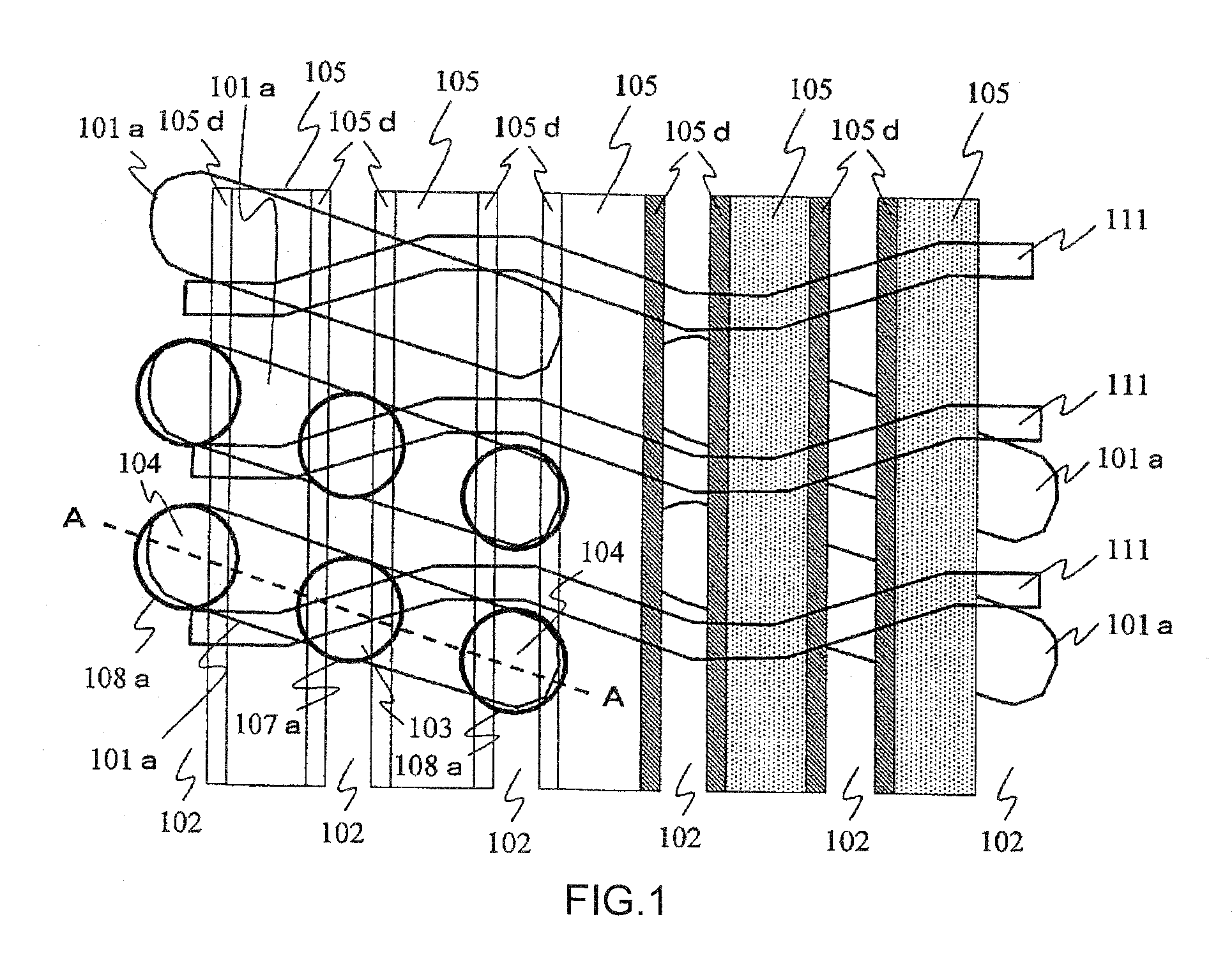

Method for manufacturing a semiconductor device

ActiveUS20080299760A1Improve surface roughnessPrevent thermal deformationSemiconductor/solid-state device detailsSolid-state devicesBit lineDevice material

A highly reliable method for forming contact plugs is provided. The method can prevent short circuiting from occurring between self aligned contact plugs and word lines or between self aligned contact plugs and bit lines by applying a material, whose etching speed ratio relative to that of the silicon-based insulating film is 100 or more, to an interlayer film for forming the contact plugs therein. The method comprises forming wiring lines each of which is covered with silicon oxide films at its top surface and lateral sides, forming a sacrificial interlayer film overall, which is made up of an organic coating film without containing silicon, so as to cover the wiring lines, forming contact holes by sequentially etching the sacrificial interlayer film and a lower-layer insulating film, and forming contact plugs. The method further comprises forming columns of the contact plugs by removing the sacrificial interlayer film, forming an interlayer insulating film overall, and partially removing the interlayer insulating film from above the surface thereof to expose the surfaces of the capacitor contact plugs.

Owner:HEFEI RELIANCE MEMORY LTD

Clamping-plate support of hub-type joint net rack

PendingCN109267655AReduce the difficulty of on-site constructionReduce intensityBuilding constructionsEngineeringUltimate tensile strength

The invention provides a clamping-plate support of hub-type joint net rack. The technical problem that a threaded rod is not subjected to shearing force is solved. The clamping-plate support in the technical scheme comprises a keeping part, a locking assembly and a connecting piece, wherein the keeping part is provided with a fixing end plate, a first blocking end plate and a second blocking end plate, the first blocking end plate and the second blocking end plate are arranged on one side face of the fixing end plate in parallel, and a positioning groove suitable for imbedding into a hub jointis defined by the portion between the two blocking end plates and the fixing end plate; the locking assembly comprises a penetrating piece sequentially penetrating the first blocking end plate, the hub joint and the second blocking end plate in the axis direction of the hub joint and locking pieces arranged at the two ends of the penetrating piece; the connecting piece is suitable for connectingthe keeping part on a to-be-connected object. Clamping-plate blocking in the prior art is replaced with a clamping-type blocking structure, rigid connection is carried out between blocking, the wholestructural strength of the support is enhanced, the penetrating piece can bear the shearing resistance of the certain degree, and the structural strength of the support is greatly enhanced.

Owner:HUADIAN HEAVY IND CO LTD

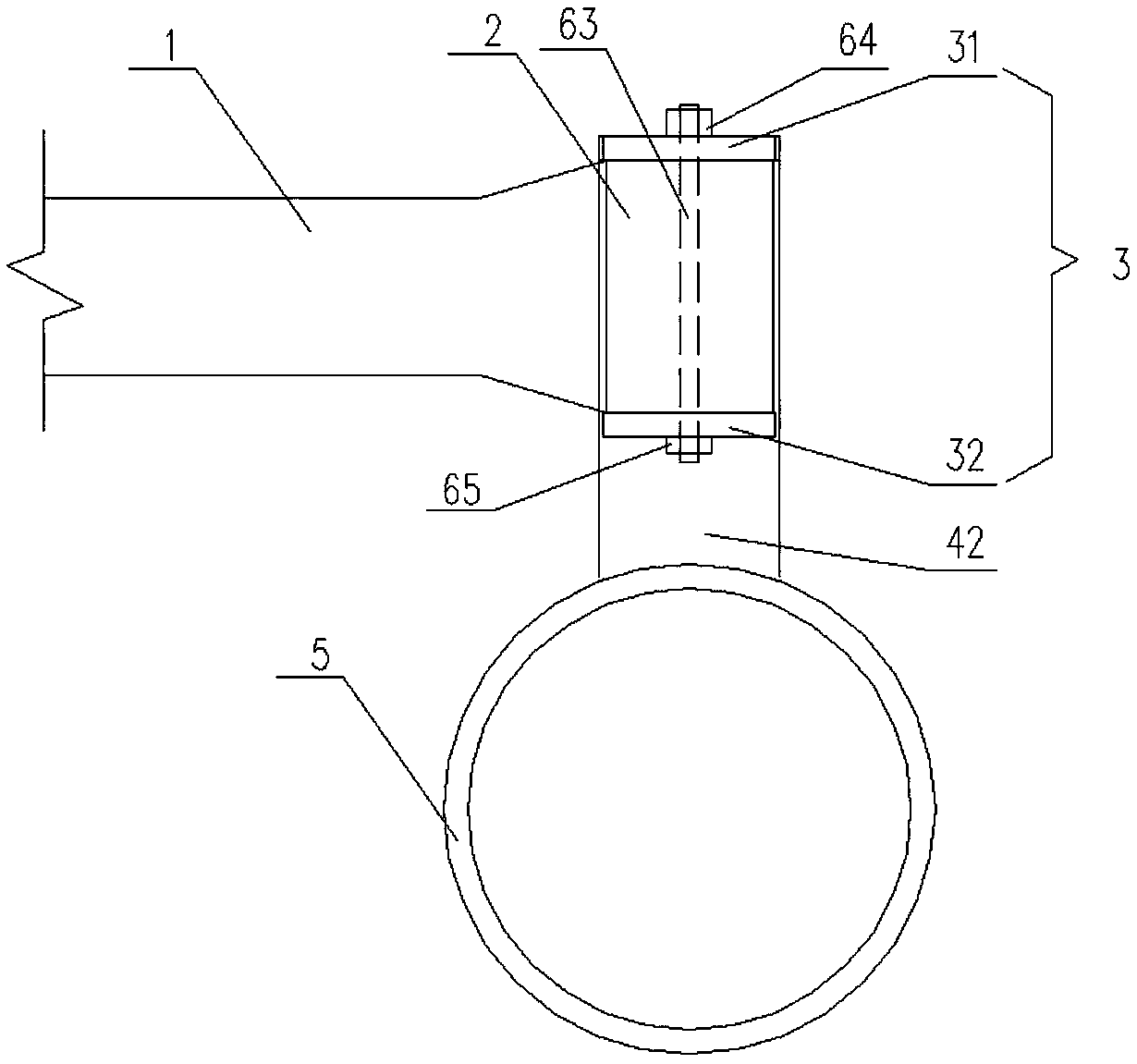

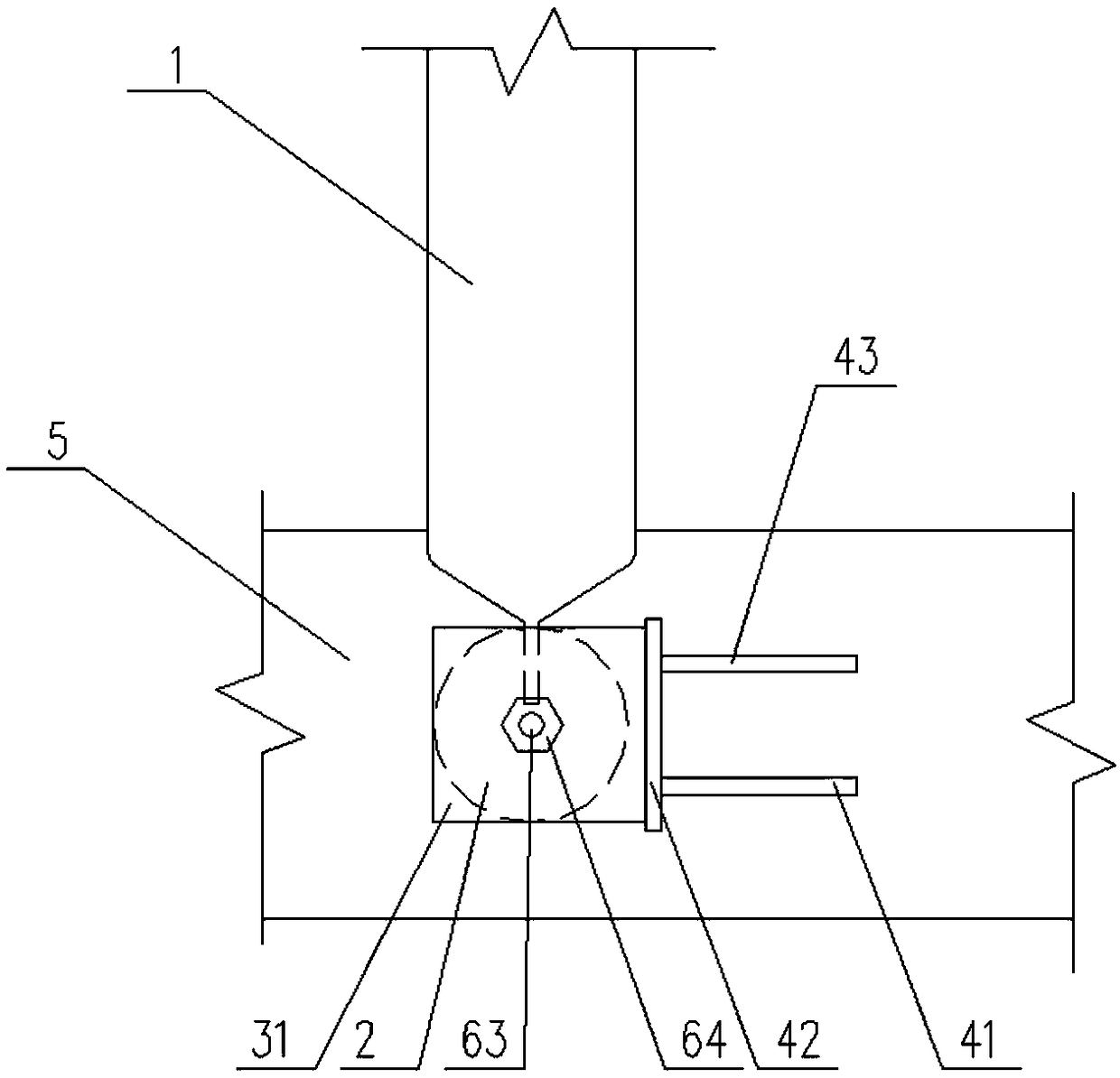

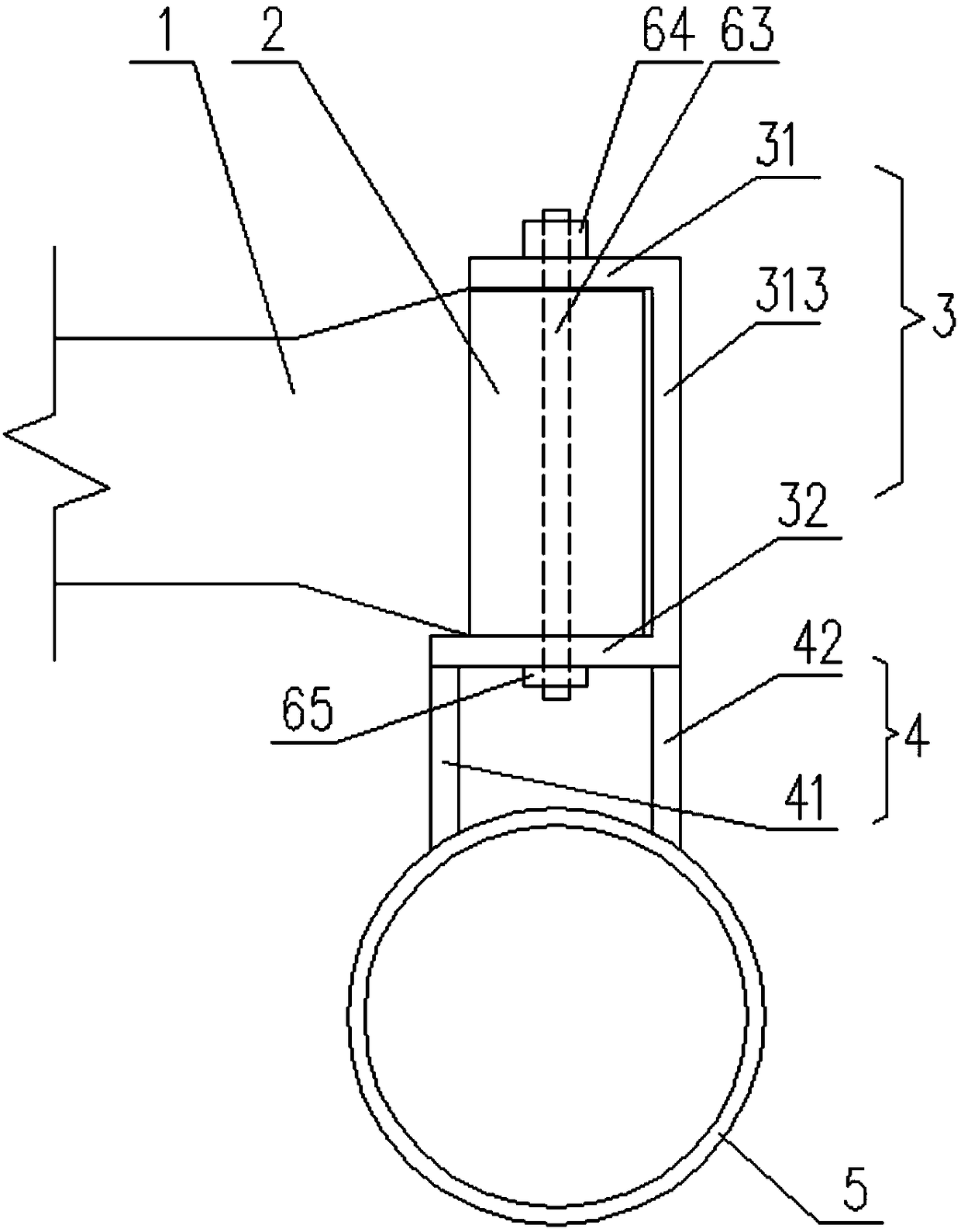

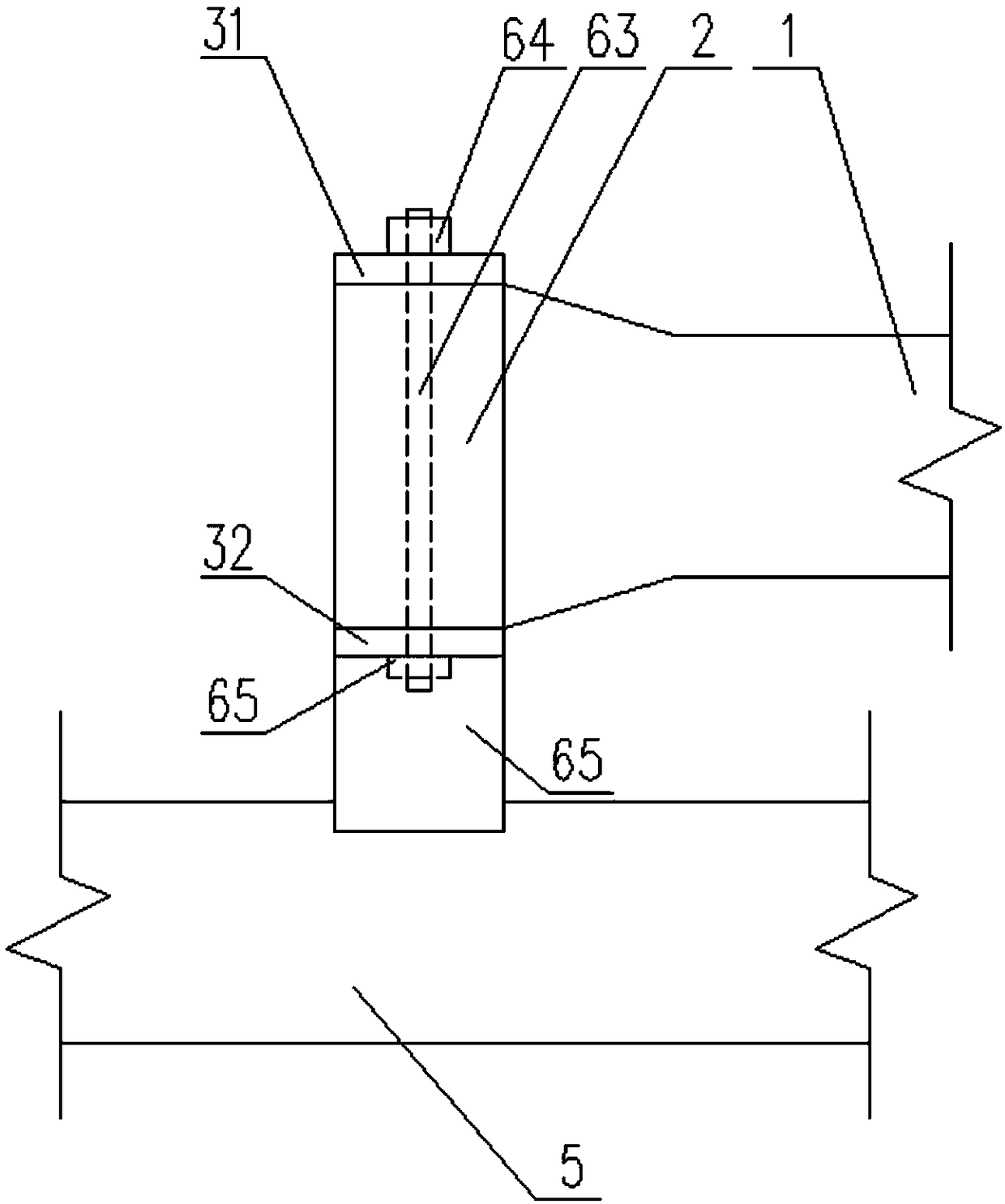

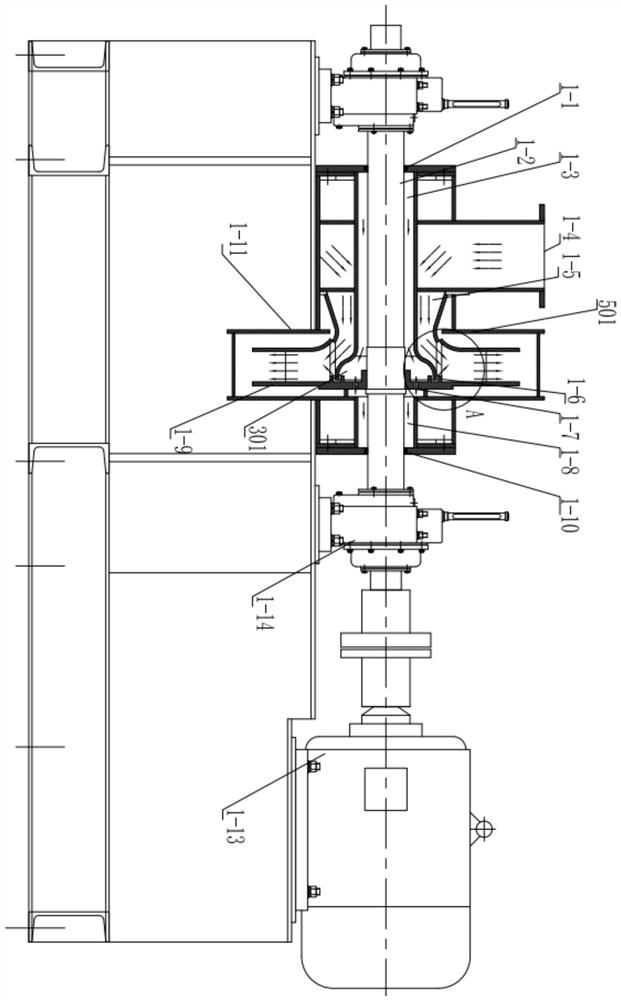

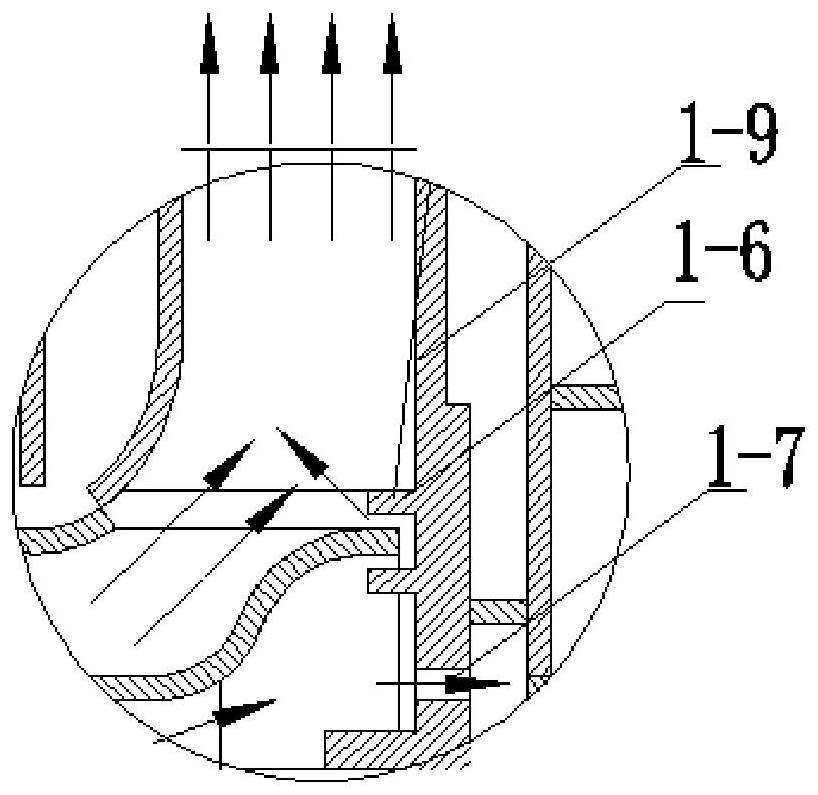

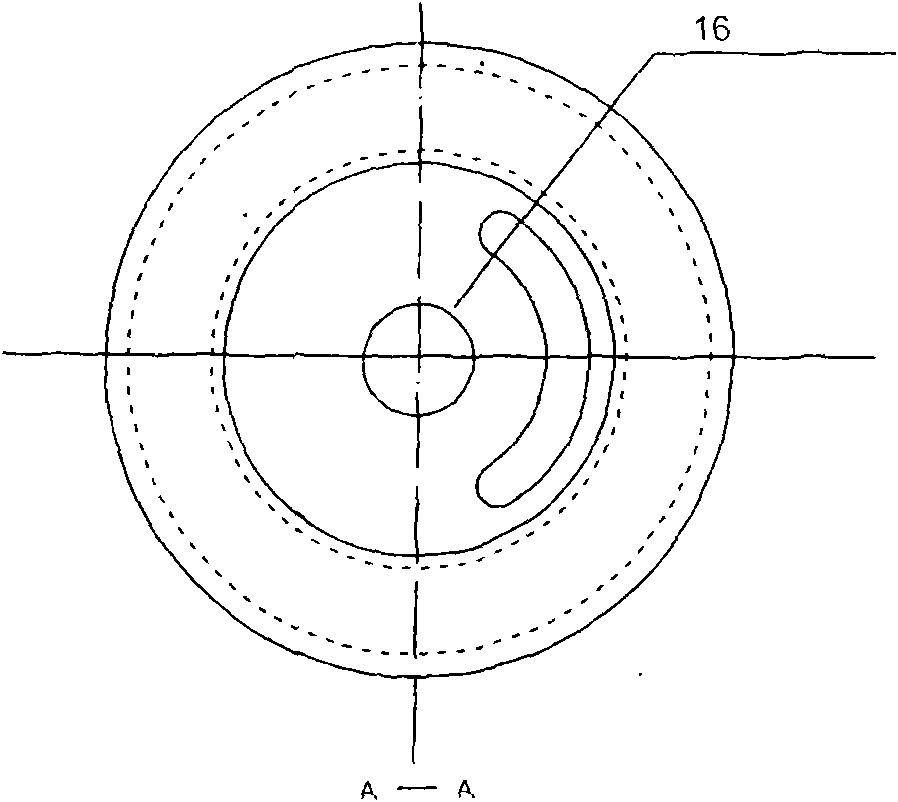

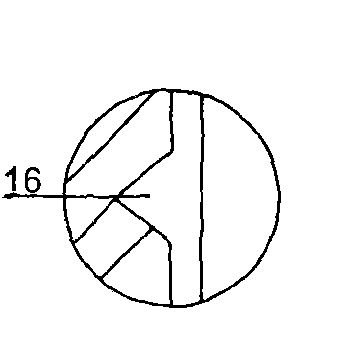

General centrifugal fan capable of being rapidly arranged

PendingCN114135516AOperation impactPrevent heat deformationPump componentsPumpsClassical mechanicsCentrifugal fan

When the universal centrifugal fan capable of being rapidly arranged moves, a universal centrifugal fan body is hoisted away from the ground through a jack or a top hoisting machine, then a sliding rail is laid below the universal centrifugal fan body, and a pulley is connected to the sliding rail in a sliding mode; the universal centrifugal fan body is pulled to a designated installation position through the cable-stayed hoist; high-temperature-resistant connecting hoses are arranged on an air inlet and an air outlet of the universal centrifugal fan body, and hoops used for fixing the hoses to a system pipeline are arranged at the ends of the connecting hoses. The universal centrifugal fan capable of being rapidly arranged can be conveniently and rapidly moved to a proper position, an inlet and an outlet are connected through hoses and hoops, direct disassembly can be achieved, and the disassembly time is shortened.

Owner:华能重庆两江燃机发电有限责任公司

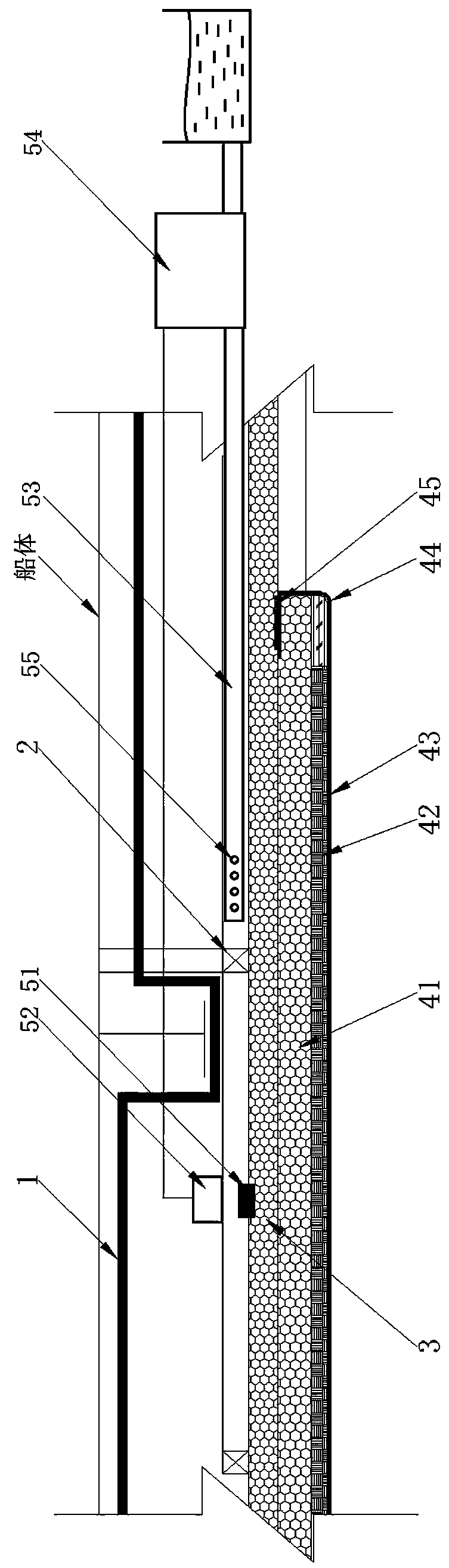

Marine fire-proof soft package structure

PendingCN109665069ASmall impact on structureReduce the temperatureFire rescueCabinsEngineeringAluminum honeycomb

The invention aims to provide a marine fire-proof soft package structure with good fire-proof performance. The marine fire-proof soft package structure comprises fire-proof cotton fixed on the cabin wall of a ship, a square tube frame fixedly connected with the cabin wall of the ship, an aluminum bottom plate of which the interior is honeycomb and a detachable soft package; the aluminum bottom plate is fixedly connected with the square tube frame; the detachable soft package comprises an aluminum honeycomb plate; the lower surface of the aluminum honeycomb plate is provided with a sponge layer; the lower surface of the sponge layer is coated with a leather layer; four side faces of the aluminum honeycomb plate are provided with edge-closing strips; two adjacent edge-closing strips are fixedly connected; the aluminum honeycomb plate, the sponge layer and the leather layer are clamped and fixed in the edge-closing strips; the edge-closing strips and the aluminum bottom plate are providedwith connecting structures; and the detachable soft package is fixedly cooperated with the aluminum bottom plate through the connecting structures. The marine fire-proof soft package structure provided by the invention is applied to the technical field of ship structures.

Owner:JIANGLONG BOAT TECH

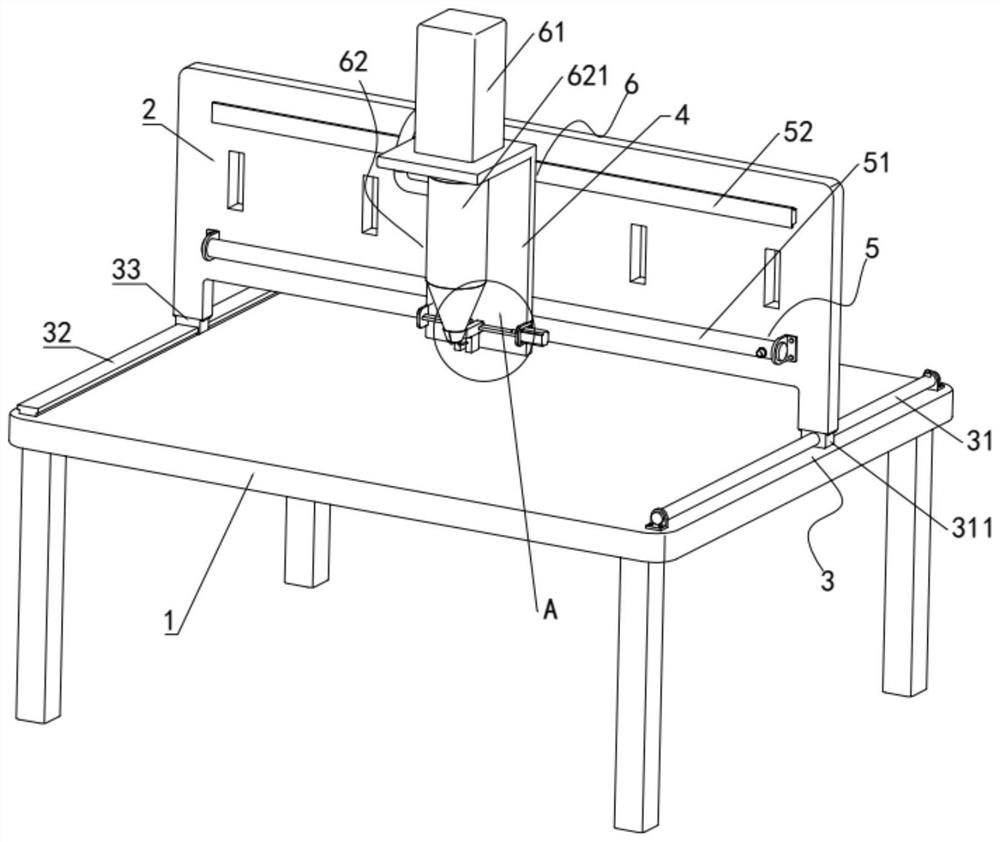

Glue spraying mechanism for electronic communication product

PendingCN114713446AEasy to removeAvoid spillingLiquid surface applicatorsShaking/oscillating/vibrating mixersElectronic communicationAdhesive glue

The invention discloses a glue spraying mechanism for electronic communication products, which relates to the technical field of gluing devices and comprises a worktable, a mounting frame, a gluing mechanism and a cleaning mechanism. Under the condition that the gluing head is not damaged, glue left on the outer side and in the gluing head can be cleaned, and the conditions that the gluing head is blocked and dust is doped in the glue when the gluing head is used again are avoided.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

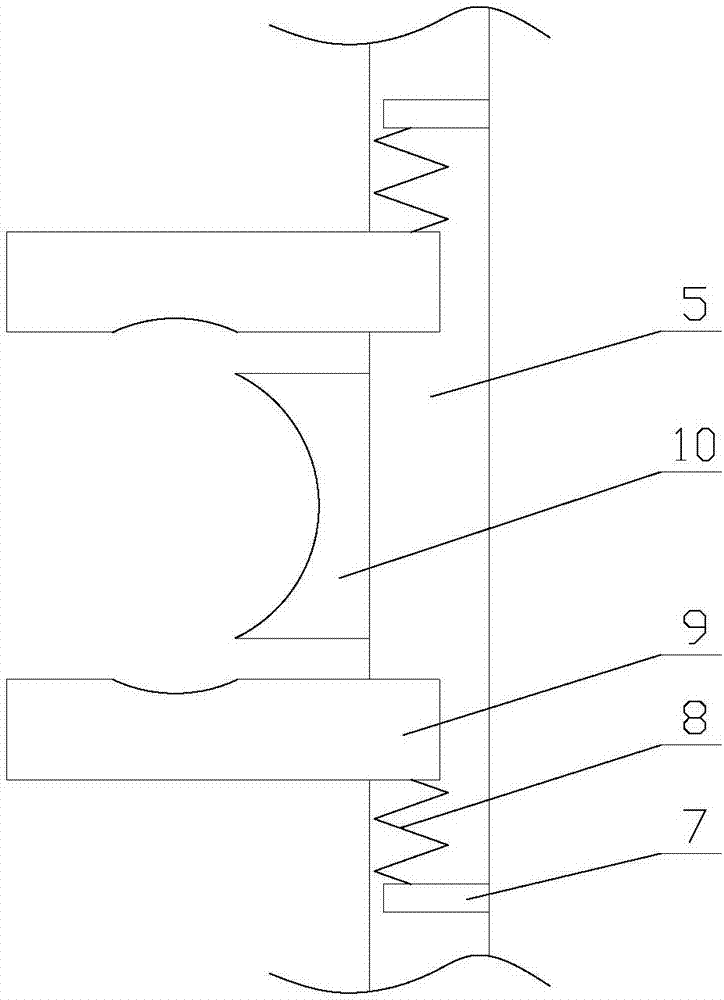

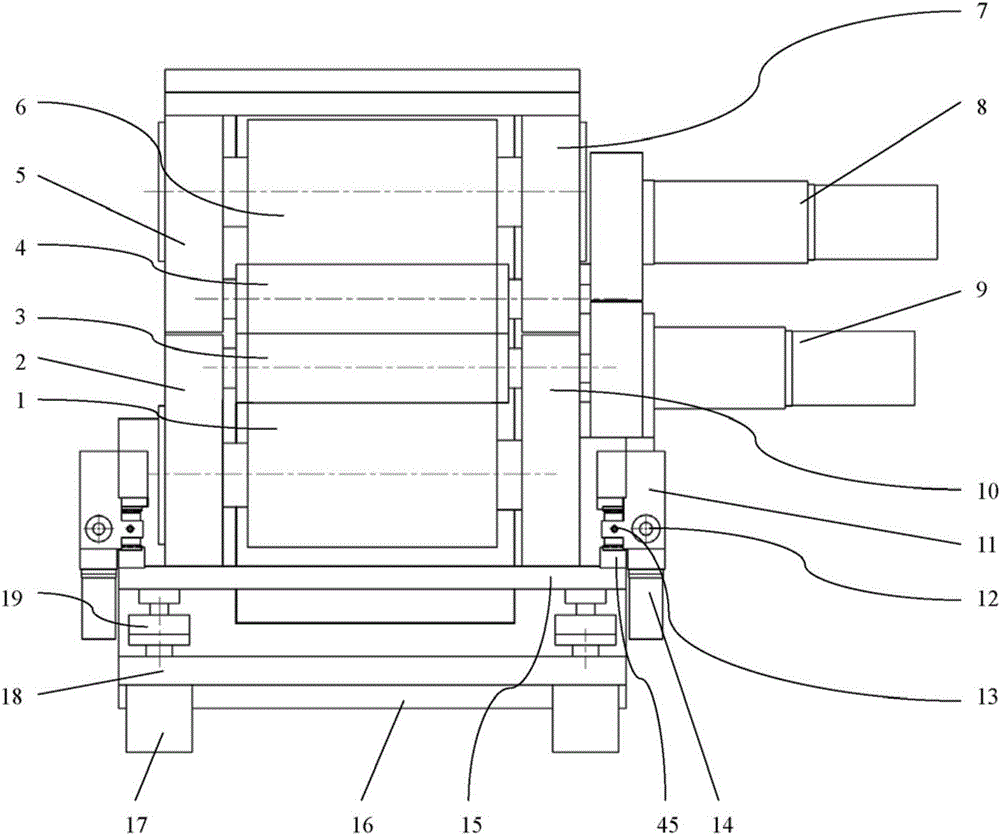

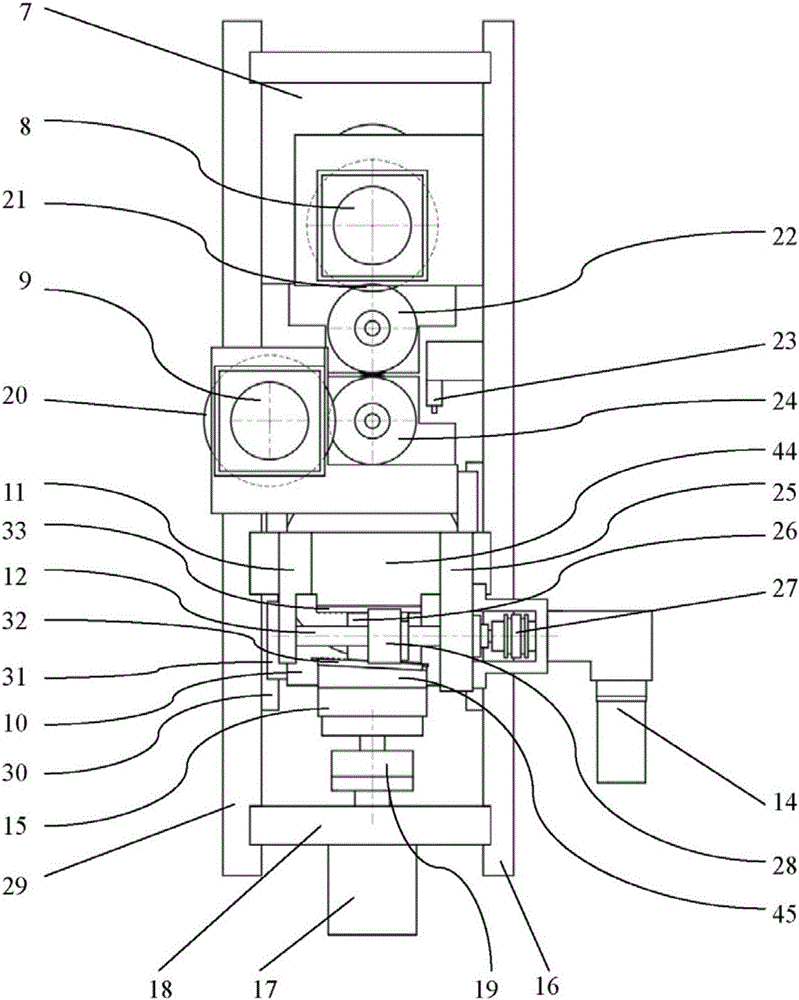

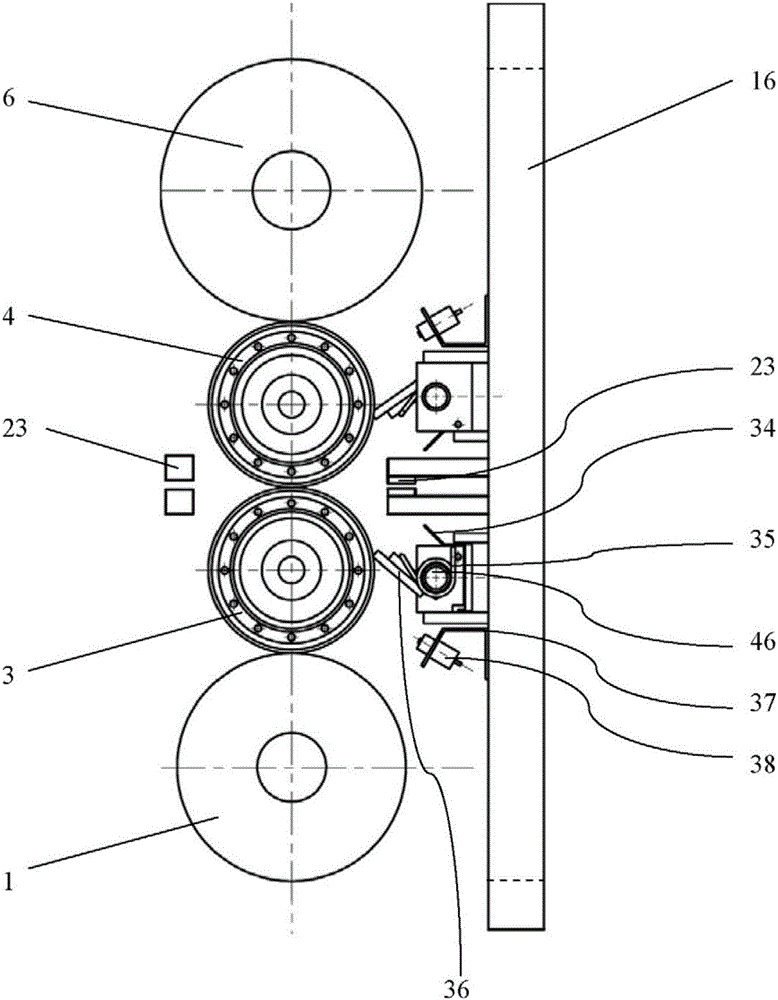

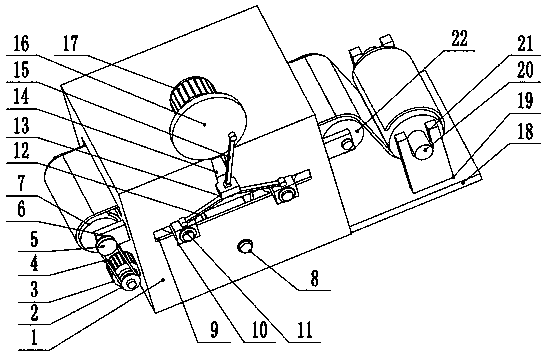

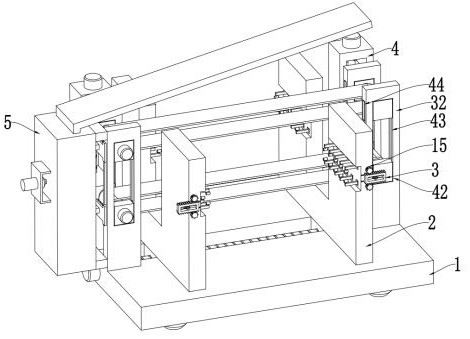

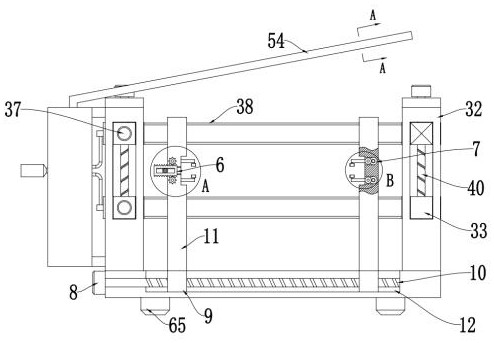

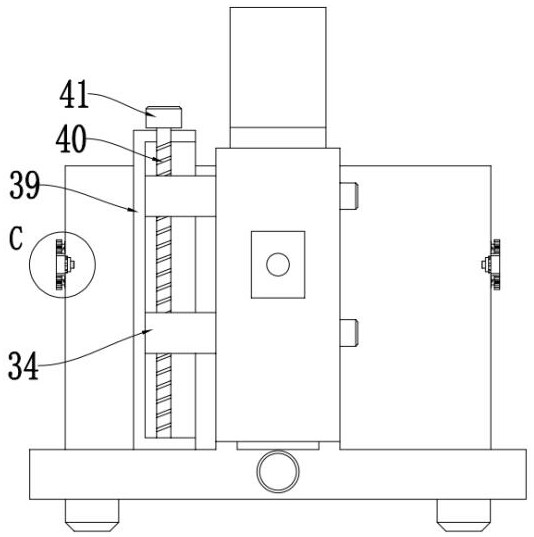

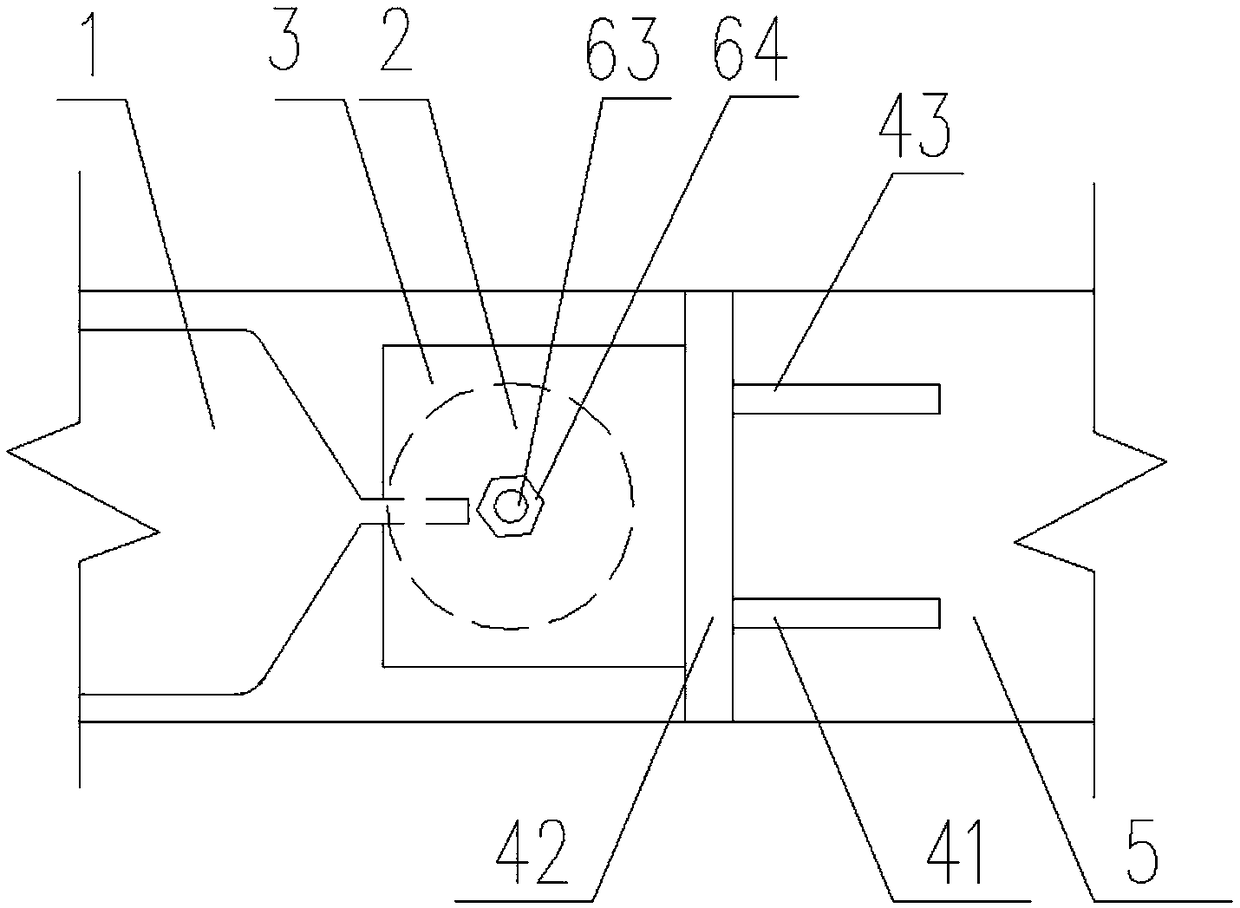

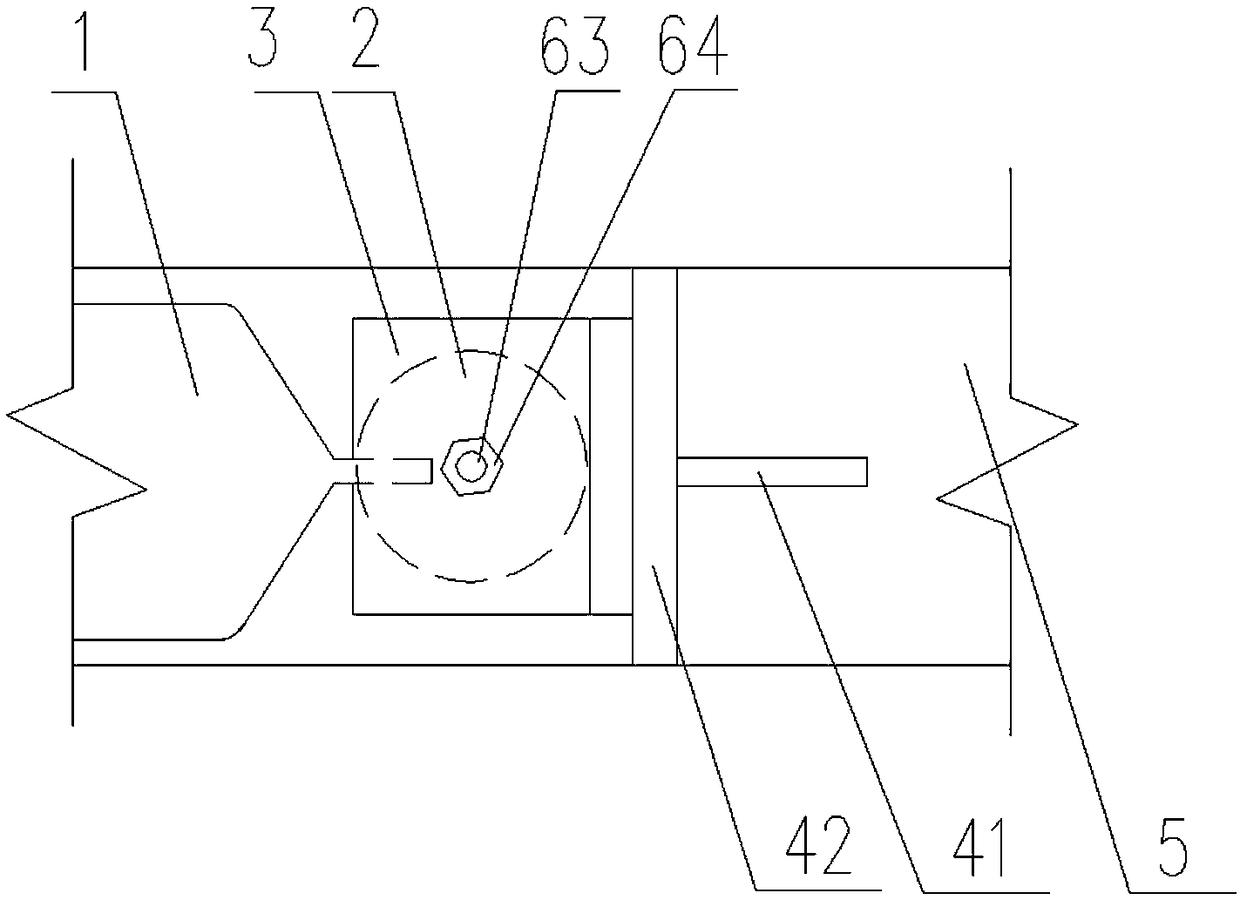

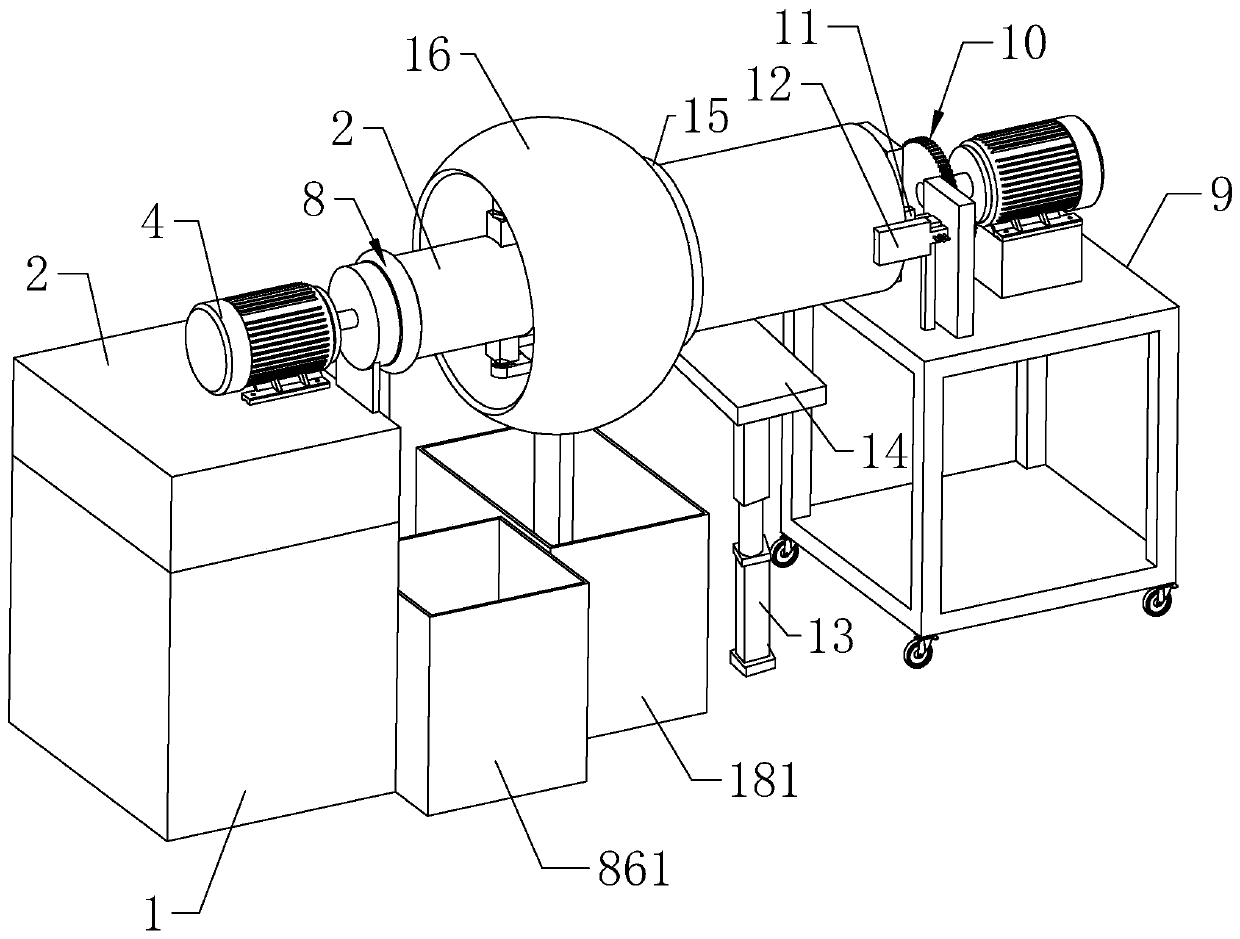

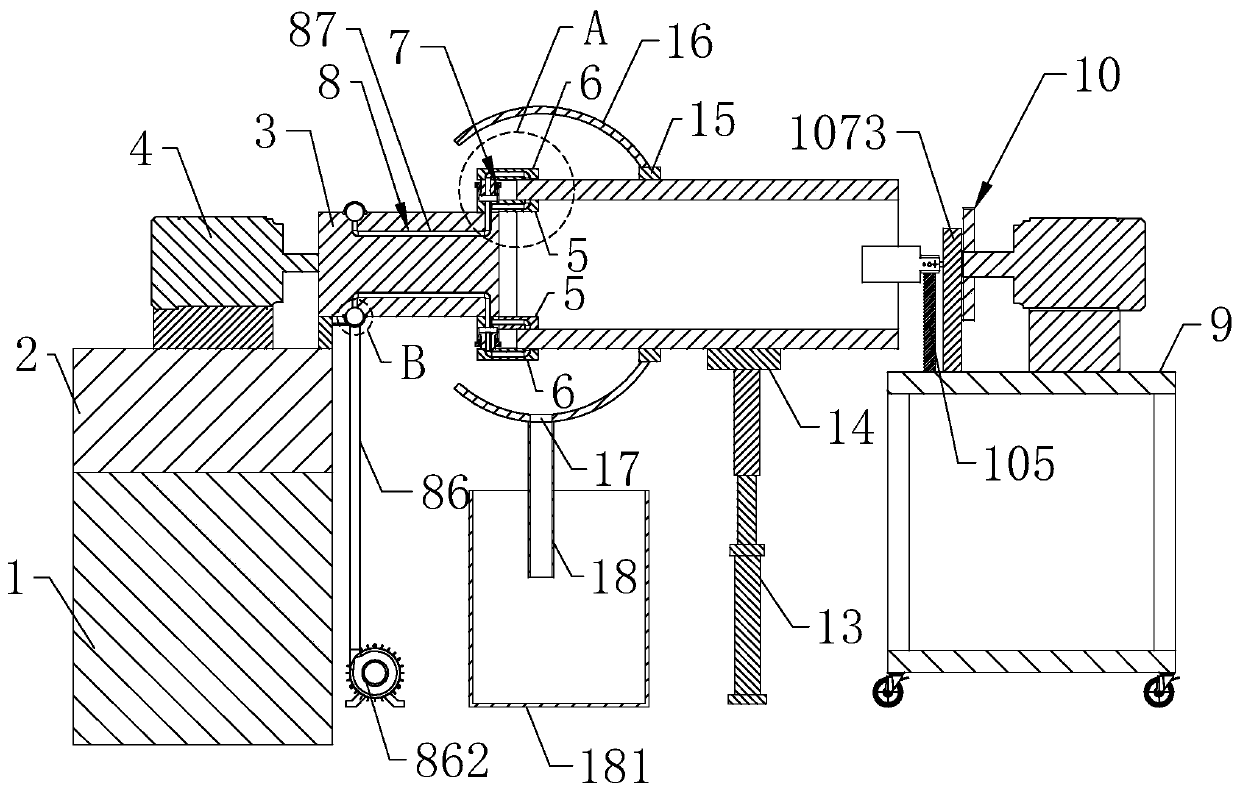

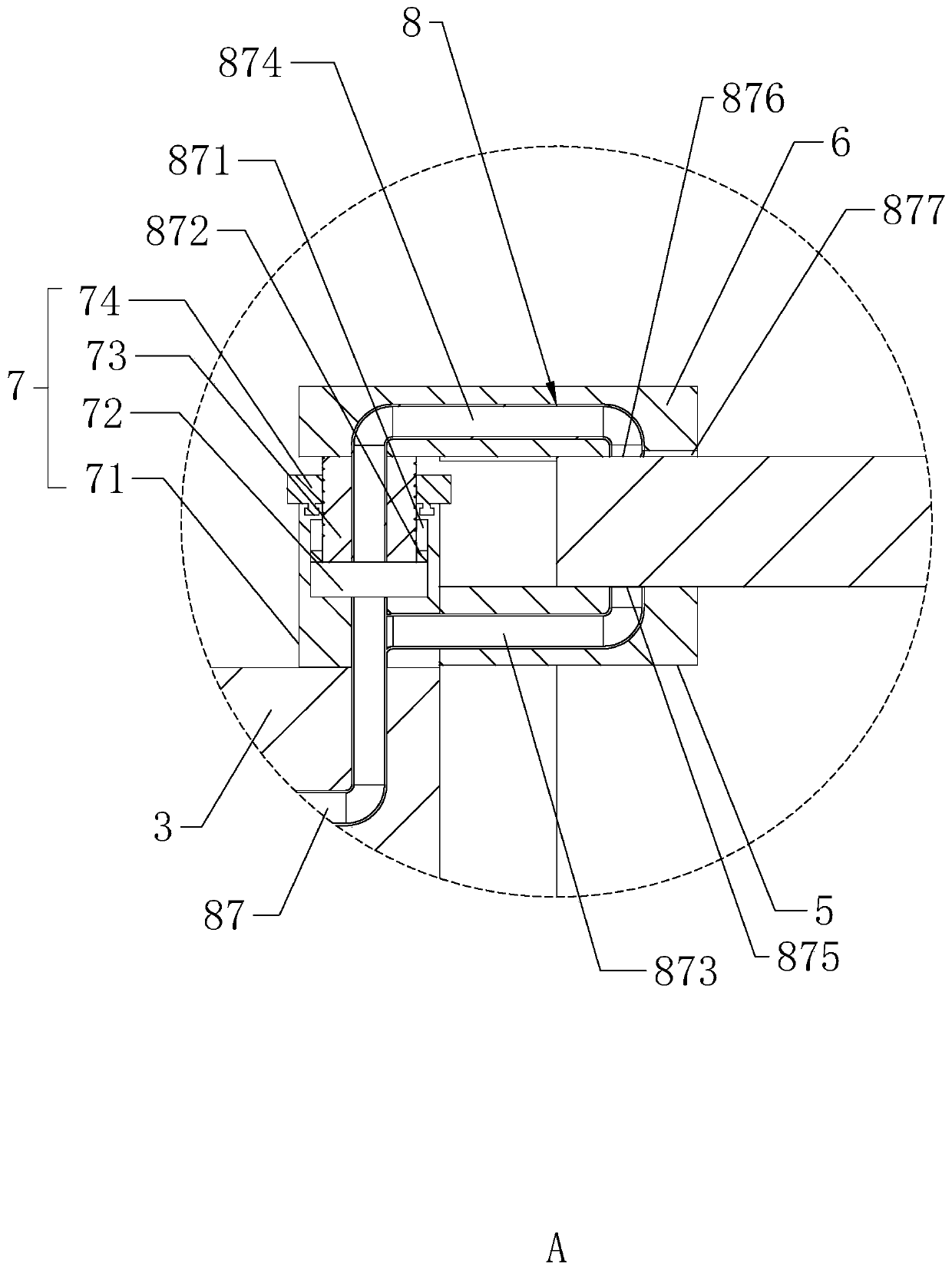

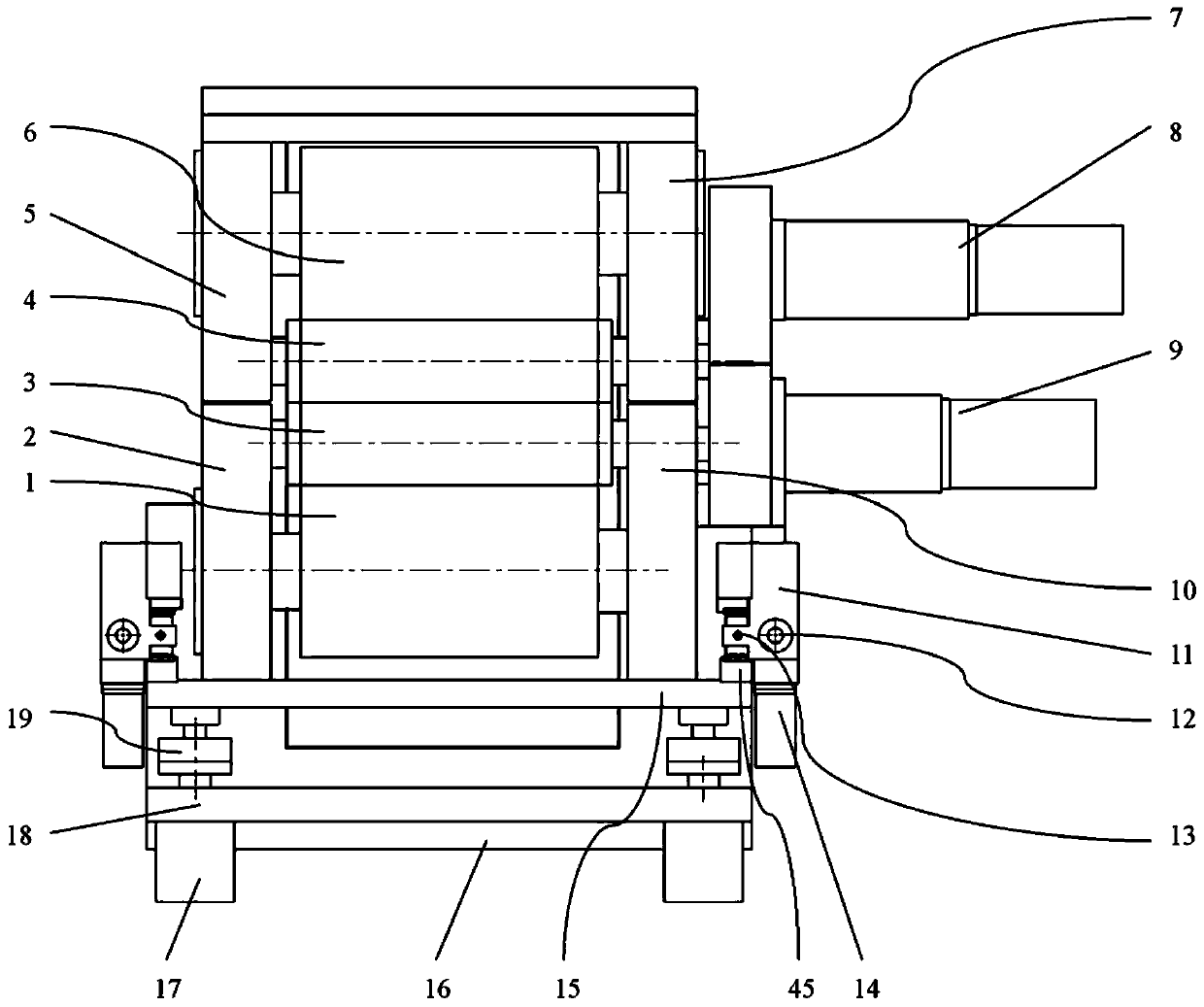

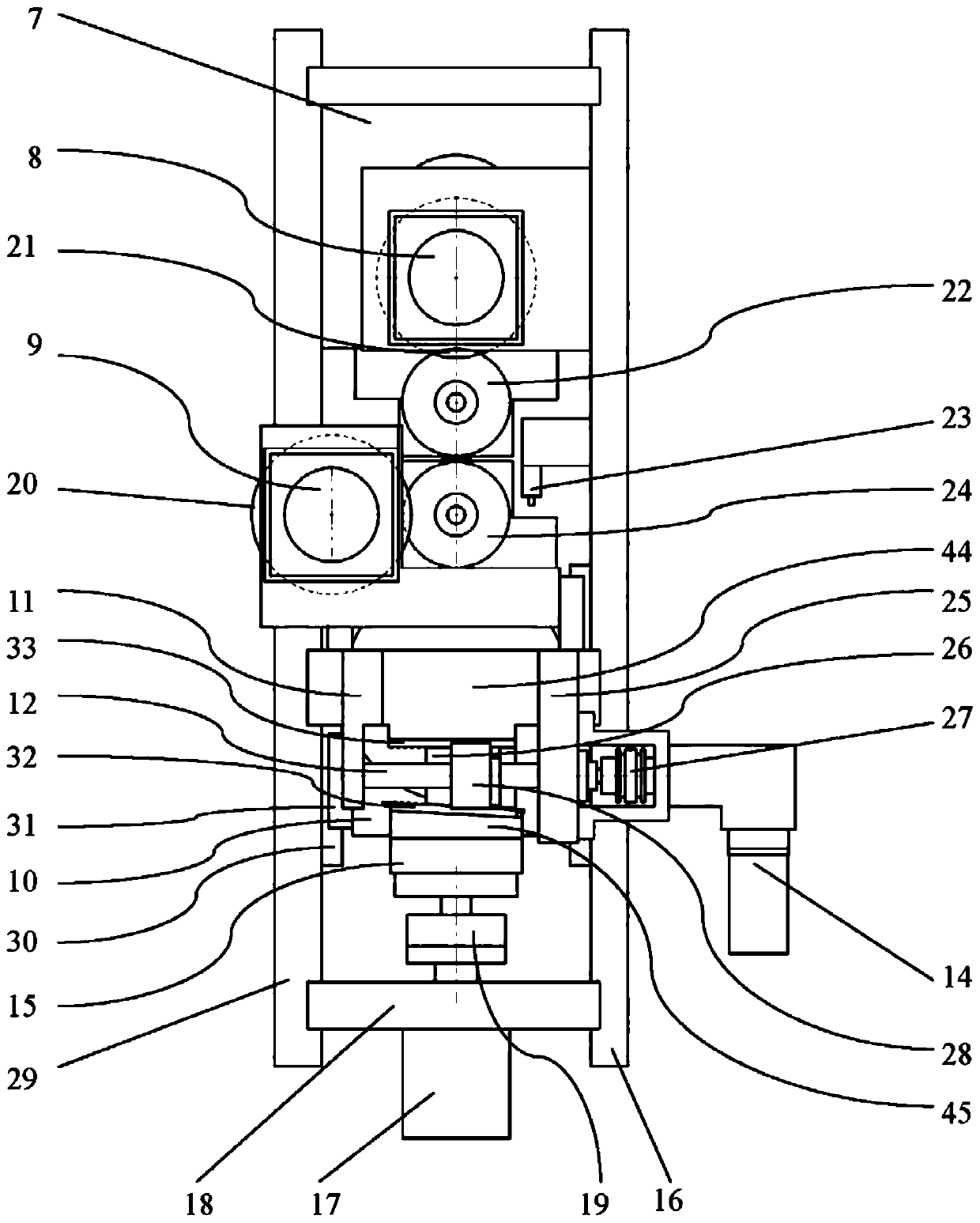

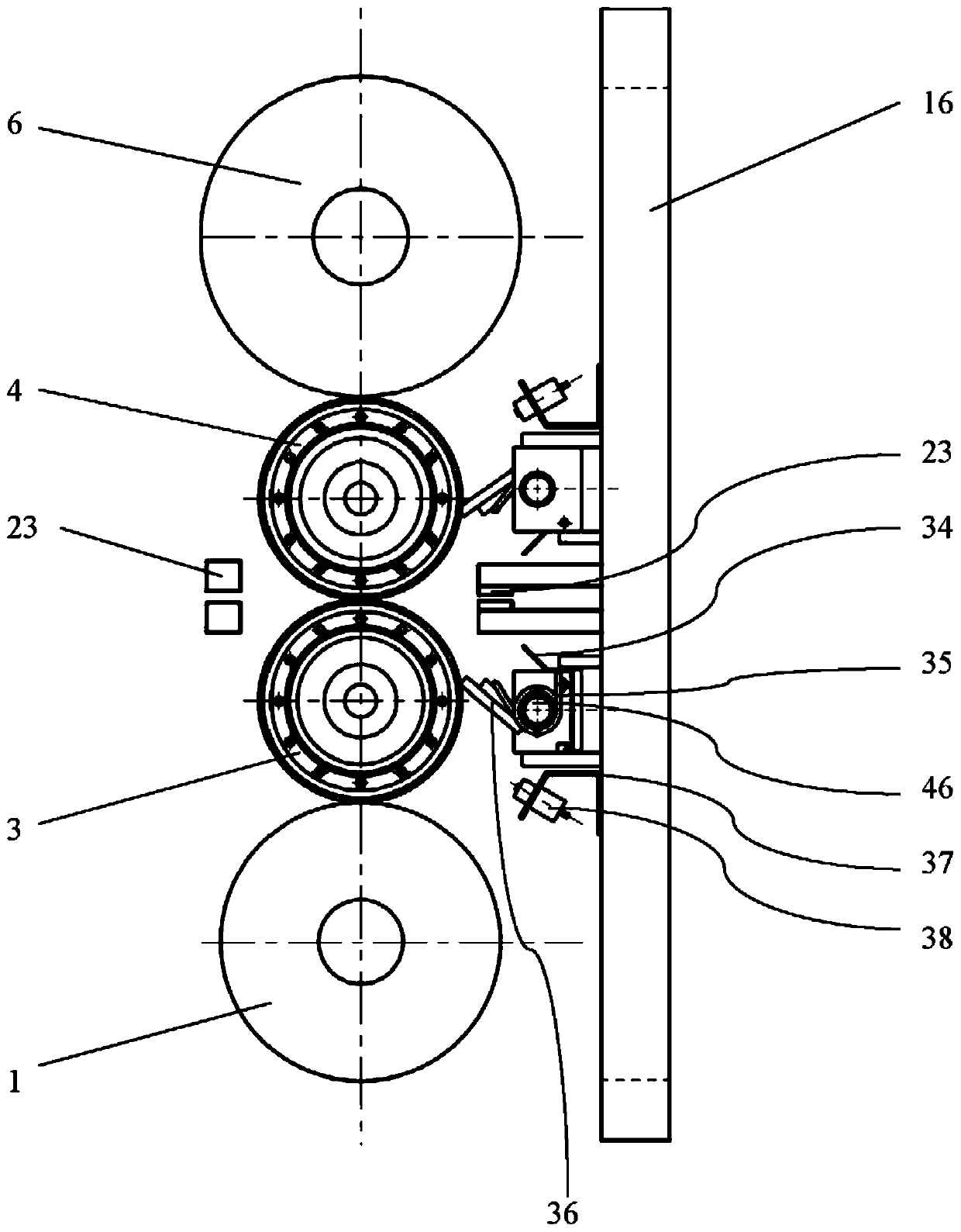

Four-roll lithium strip calendering mechanism

ActiveCN106252606ALimit shaft runoutReduce distortionElectrode rolling/calenderingLithiumPulp and paper industry

The invention relates to a four-roll lithium strip calendering mechanism. The four-roll lithium strip calendering mechanism is characterized by comprising a dynamic compression roller and a compression roller of which the interval between roller surfaces is adjustable, wherein an auxiliary dynamic compression roller and an auxiliary compression roller are respectively arranged at the outer sides of the dynamic compression roller and the compression roller, the auxiliary dynamic compression roller is tightly attached to the roller surface of the dynamic compression roller, and the auxiliary compression roller is tightly attached to the roller surface of the compression roller; the two shaft ends of the dynamic compression roller and the auxiliary dynamic compression roller are respectively rotationally installed on a dynamic compression roller seat, two shaft ends of the compression roller and the auxiliary compression roller are respectively rotationally installed on a compression roller seat, and the shaft ends of the dynamic compression roller and the compression roller are respectively connected with a power source which drives the dynamic compression roller and the compression roller to rotate; the compression roller seat is fixedly mounted on a mounting bottom plate and the dynamic compression roller is mounted on the mounting bottom plate in a sliding way; oil channels are machined in the dynamic compression roller and the compression roller, the two ends of each oil channel are respectively connected with an oil input pipeline and an oil output pipeline. According to the four-roll lithium strip calendering mechanism, lithium ions are transferred to the surface of a thin film through calendering so as to obtain continuous, uniform and quantitative ultrathin lithium thin film, thus making preparation for the subsequent procedure of lithium supplementing and film coating for the pole piece.

Owner:CONTEMPORARY AMPEREX TECH CO

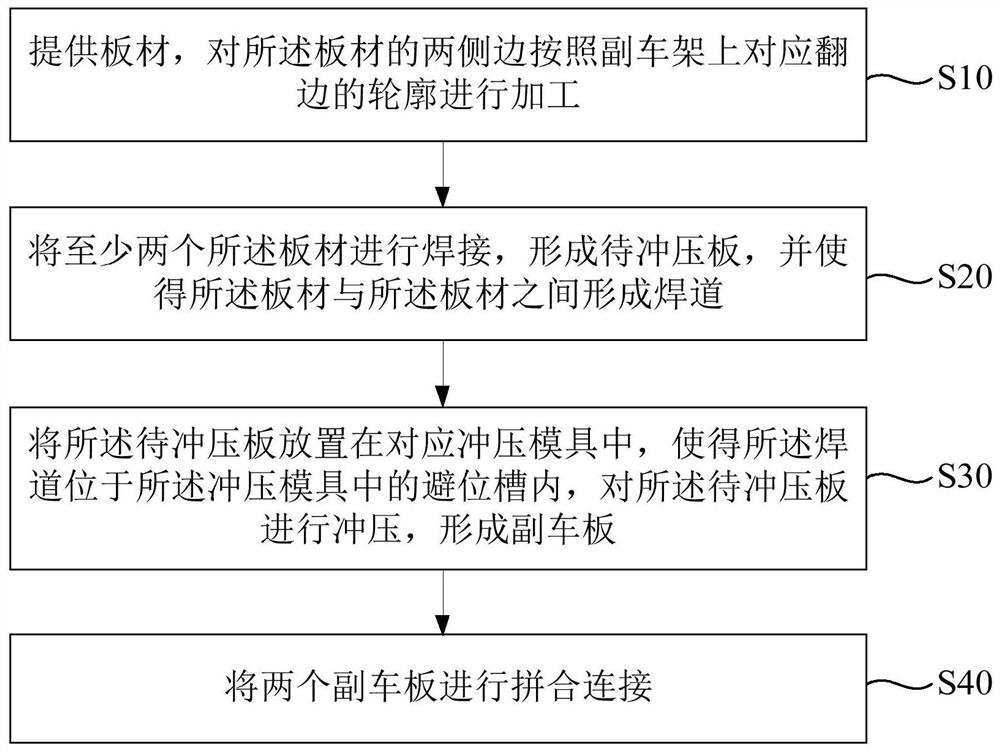

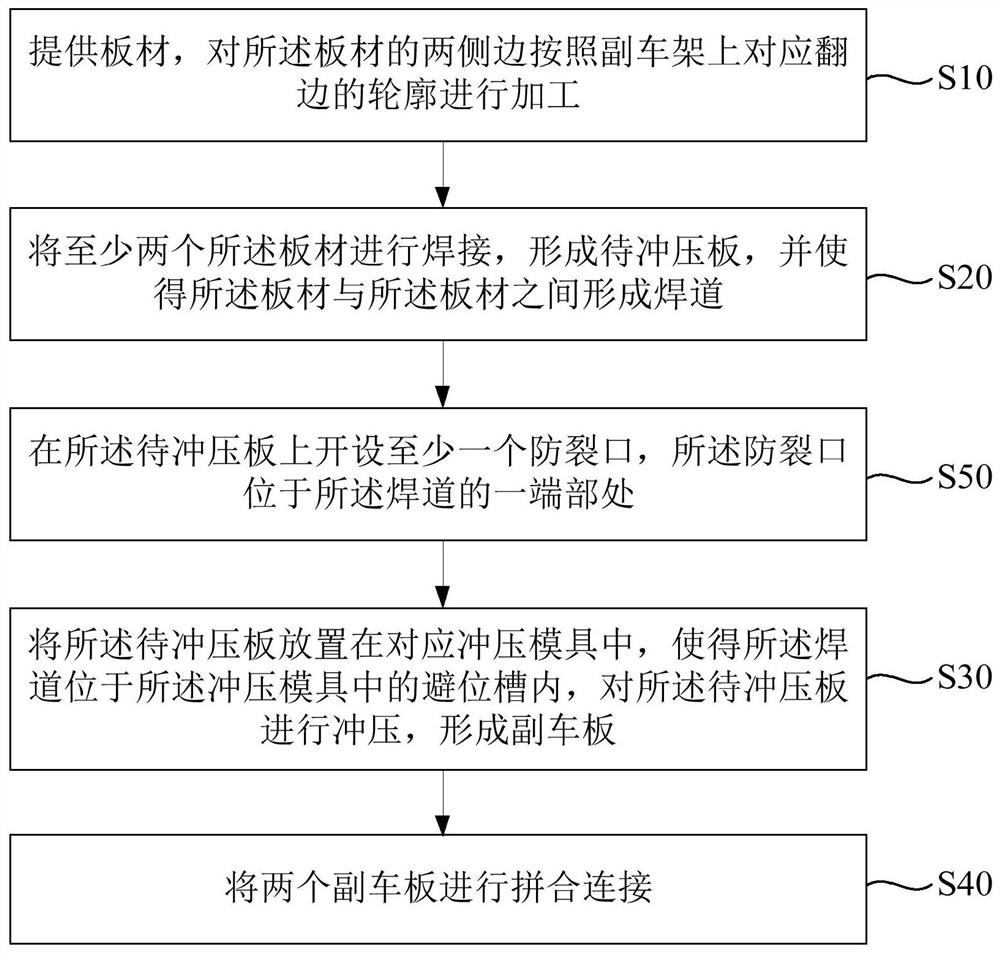

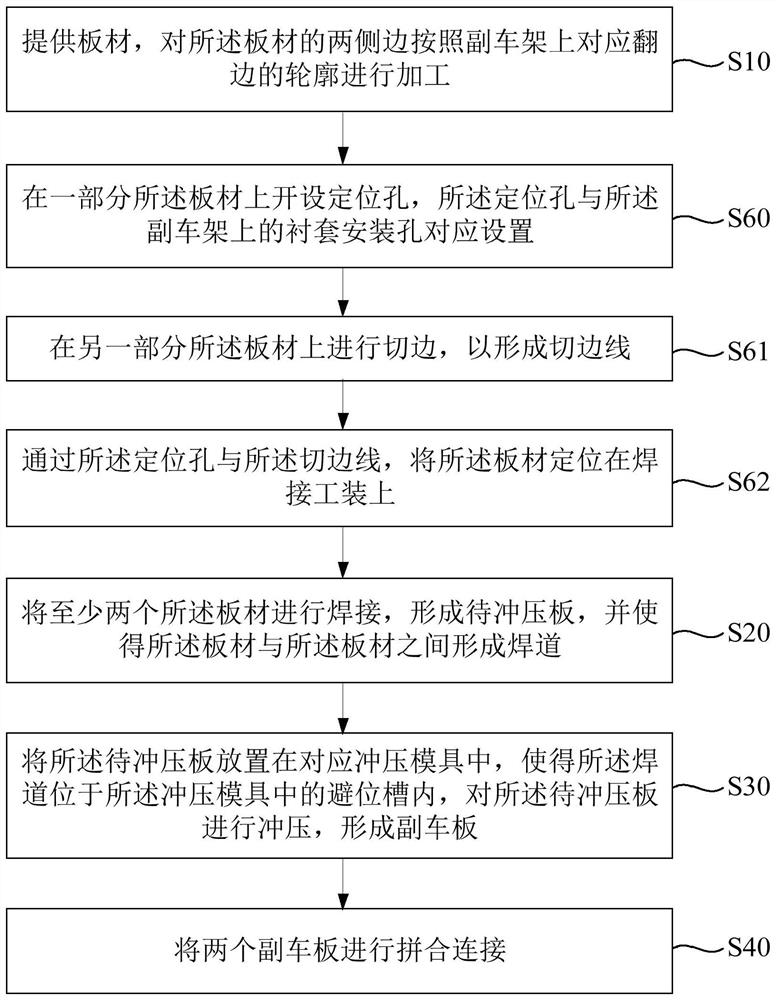

Auxiliary sweeping board manufacturing process, auxiliary frame manufacturing process, and auxiliary frame

ActiveCN111716067AImprove flatnessStable structureWelding/cutting auxillary devicesAuxillary welding devicesStamping processWelding deformation

The invention relates to an auxiliary sweeping board manufacturing process, an auxiliary frame manufacturing process, and an auxiliary frame. In the manufacturing process, side edges of boards are processed according to corresponding flanging outlines on an auxiliary frame, so that an auxiliary frame outline formed by follow-up stamping is ensured to meet the actual product appearance requirement;secondly, the multiple boards are welded, so that a weld pass is formed between each two adjacent boards, and boards to be stamped are formed; then, the boards to be stamped are placed into corresponding stamping dies so as to be stamped, so that auxiliary sweeping boards are formed; and finally, the two auxiliary sweeping boards are fastened mutually so as to be welded, so that the manufacturingof the auxiliary frame is completed. According to the manufacturing processes, a way of welding firstly and stamping secondly is adopted, so that the occurrence of the phenomenon that the auxiliary sweeping boards formed by stamping are heated so as to be deformed due to welding is effectively avoided, and the planeness of the auxiliary sweeping boards is favorably improved. Meanwhile, the stamping step is set after the welding step, so that the stamping process has a certain shaping function on the welded planes, the welding deformation of the boards to be stamped is reduced, and the overallplaneness of the auxiliary frame is further improved.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

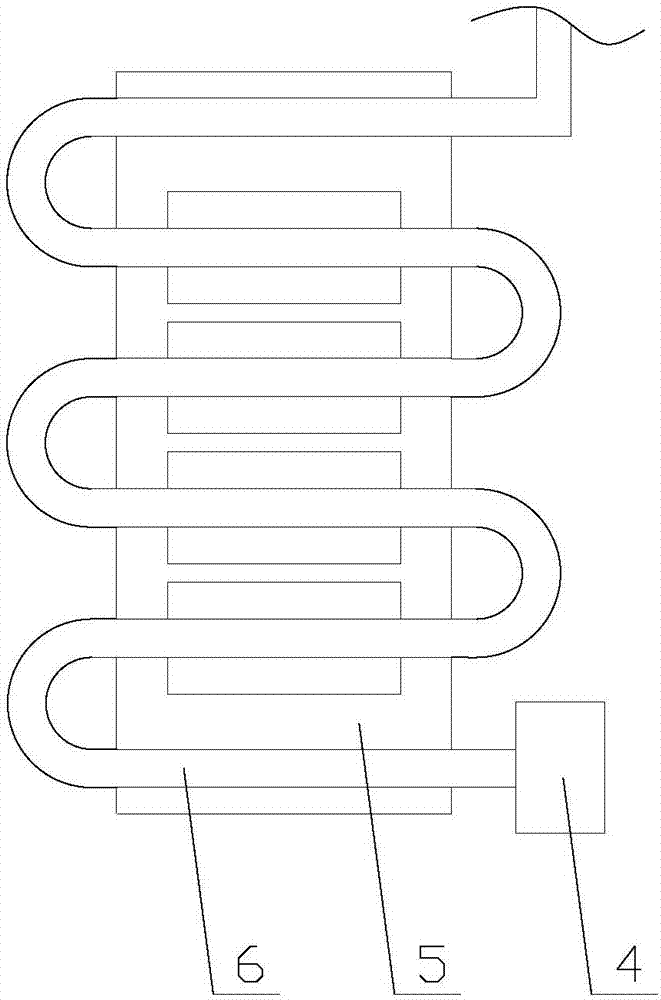

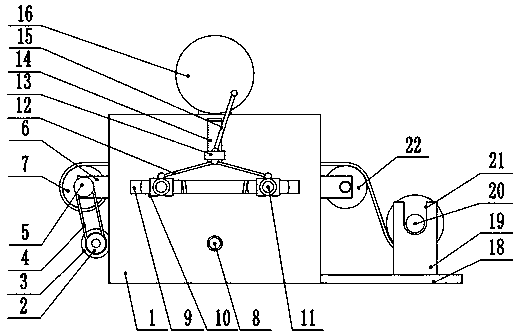

Tension-adjustable drying device for packaging film processing

InactiveCN110926177APrevent heat deformationDrying machines with progressive movementsDrying solid materialsElectric machineryEngineering

The invention relates to the technical field of packaging film drying, and discloses a tension-adjustable drying device for packaging film processing. The device comprises a drying box, first bearingblocks are arranged on the left side wall and right side wall of the drying box, a winding roller is rotationally connected to the first bearing block on the left side, a second bearing block is arranged at the top of the drying box, a second driving motor is fixedly connected to the upper portion of the second bearing block, an output shaft of the second driving motor is fixedly connected with adriving disc, the front side of the driving disc is rotationally connected with the upper end of a second supporting rod, and the lower end of the second supporting rod is rotationally connected withthe middle of the upper surface of a second sliding block. According to the tension-adjustable drying device for packaging film processing, a first tension roller and a second tension roller are arranged in the drying box, so that packaging film can be expanded in the drying box; and the second tension roller is driven to continuously move through the second driving motor, and the tension of the packaging film is continuously adjusted, so that local heating deformation of the packaging film is avoided.

Owner:SHANDONG ZHONGSU TAIFU TECH

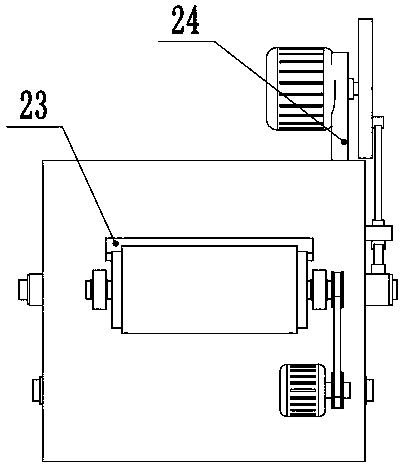

Device for detecting thermal insulation performance of thermal insulation material

PendingCN111707707AEfficient detectionHigh precisionMaterial heat developmentFiberThermal insulation

The invention discloses a device for detecting the heat preservation and insulation performance of a heat preservation and insulation material. The device structurally comprises an insertion pipe column block, an exhaust rotating cylinder, a trapezoidal table cover, a detection square box, a power distribution control cabinet, an observation window and a microwave armature tray. According to the invention, the cooperation of the detection square box and the microwave armature tray is realized; a thermal insulation material containing silicon-aluminum fibers is placed on an outer frame ring tray in a detection square box, so that the aluminum fibers are electromagnetically dragged by the armature block to form a composite board slot material electromagnetic field erecting and protecting effect that the fibers pull the silicon fibers; microwaves are released by electrifying the micro-wave bent frame rods to penetrate through the heat preservation and insulation material containing the silicon-aluminum fibers, and the detection of the molecular gap heat resistance and the material plastic surface is achieved, so the accuracy of the overall heat preservation and insulation performanceis improved, the material is effectively protected, loss in the detection process is avoided, the aluminothermic deformation quantity in the specific heat capacity is stabilized, and the effect of controlling the overall disc surface lifting heat drying fine adjustment coefficient is improved.

Owner:GUIZHOU BUILDING MATERIAL QUALITY SUPERVISION TESTING INST

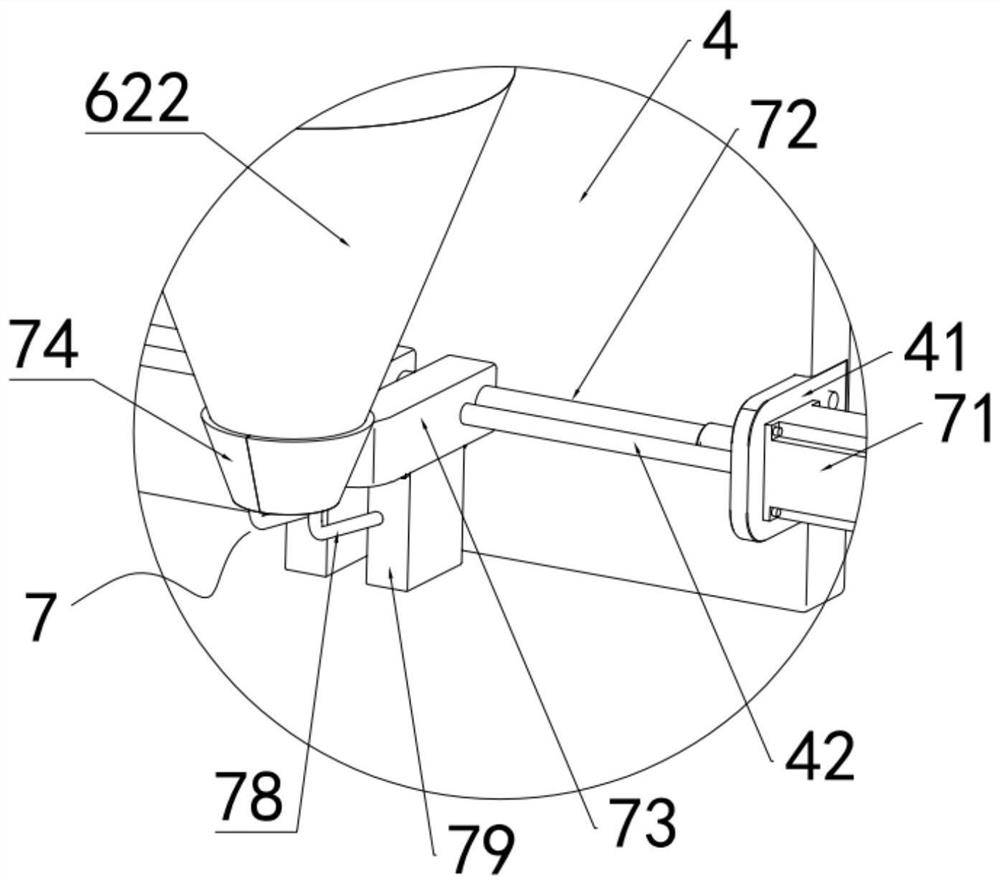

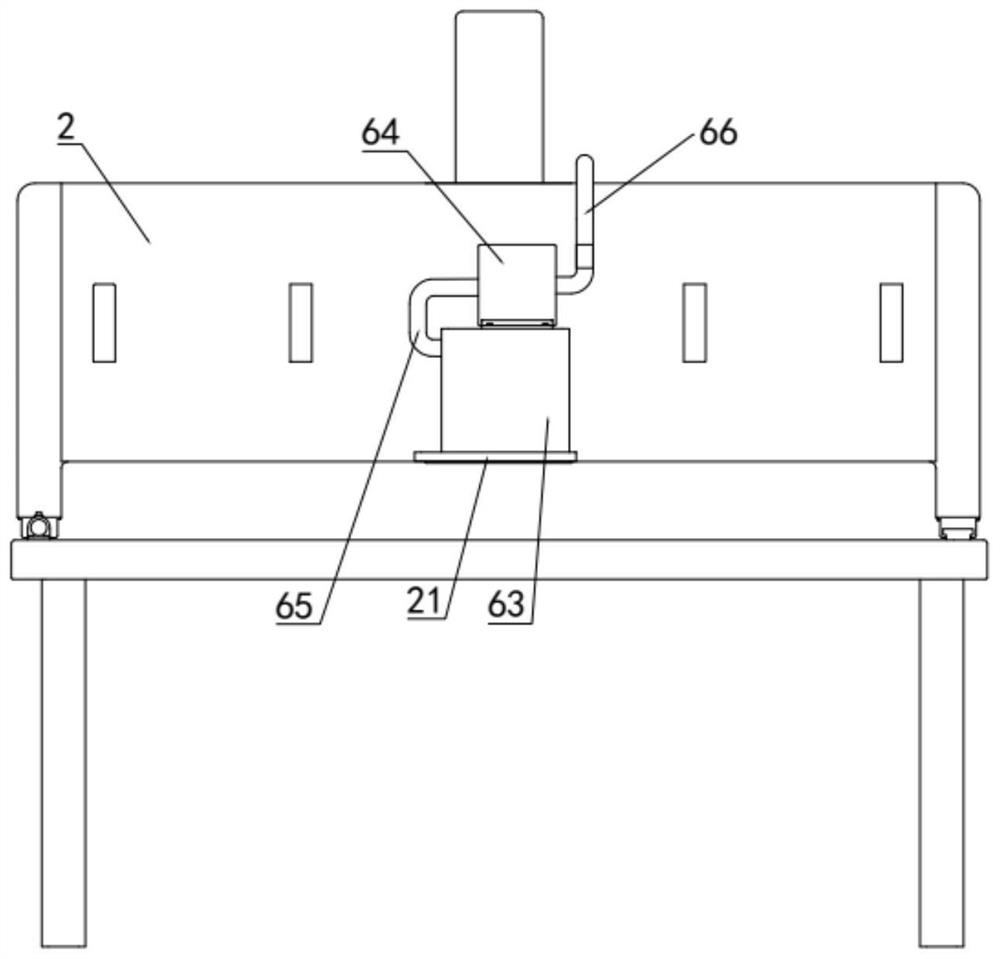

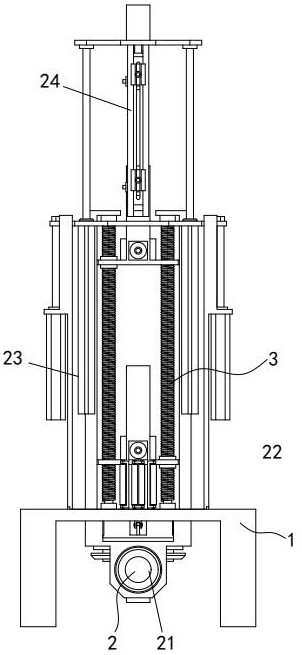

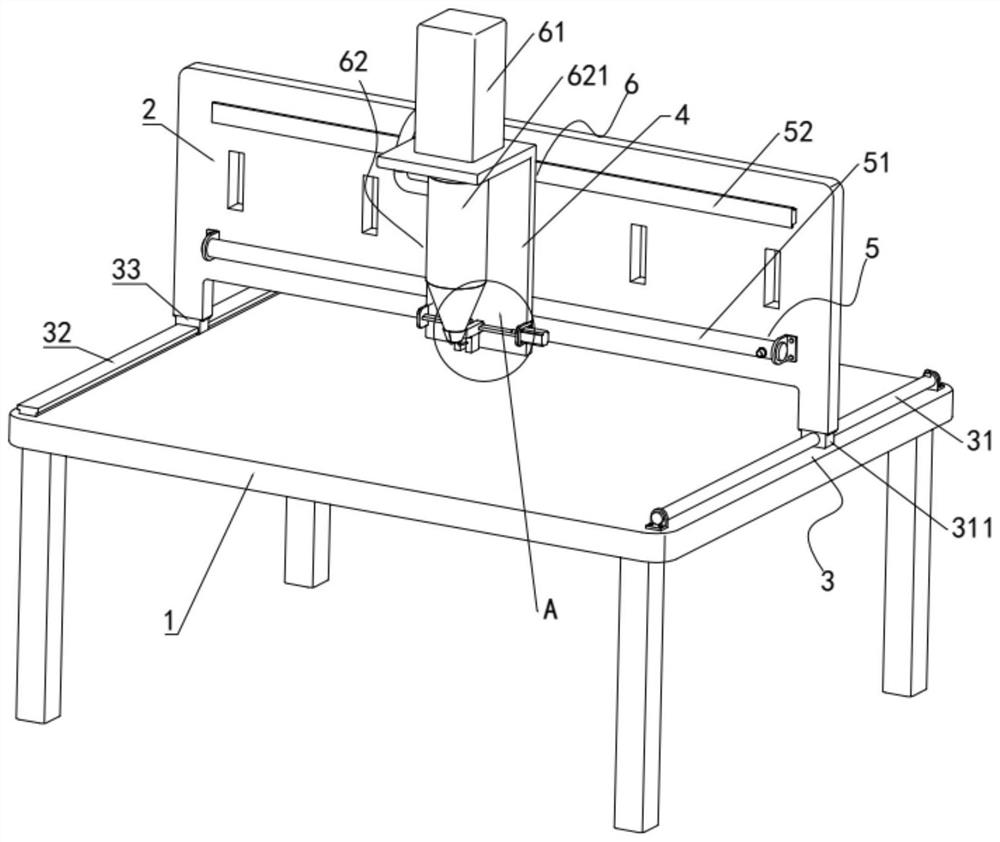

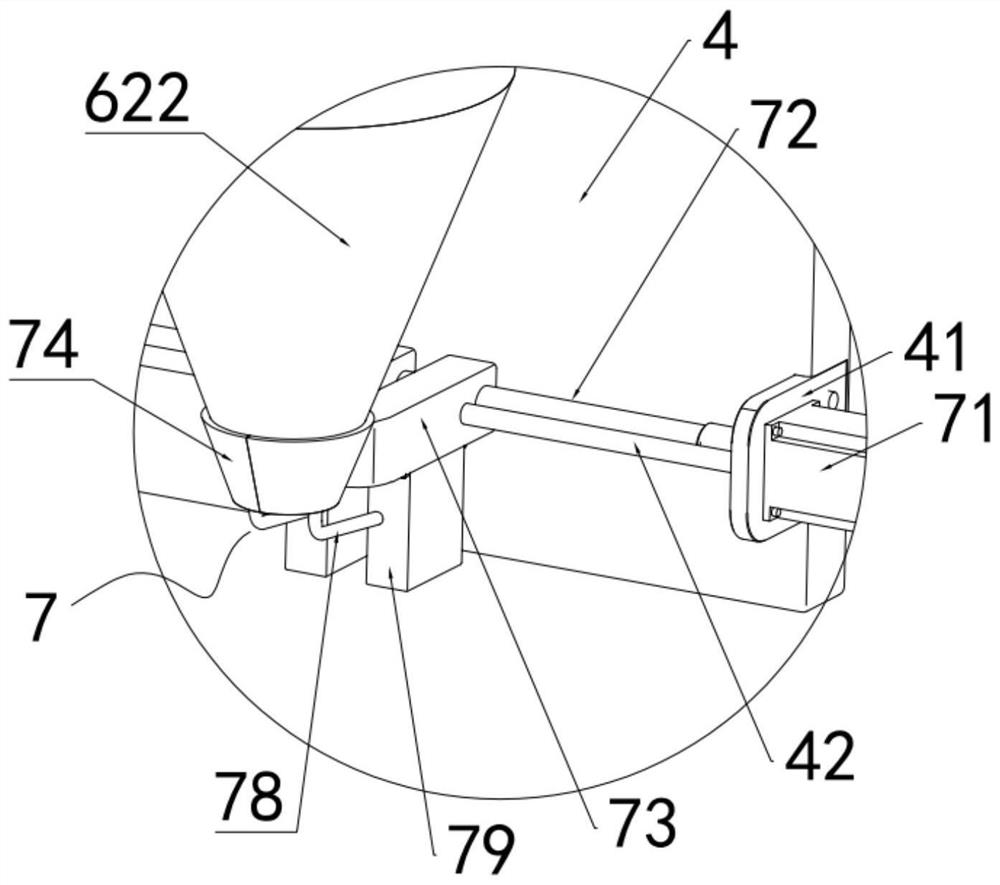

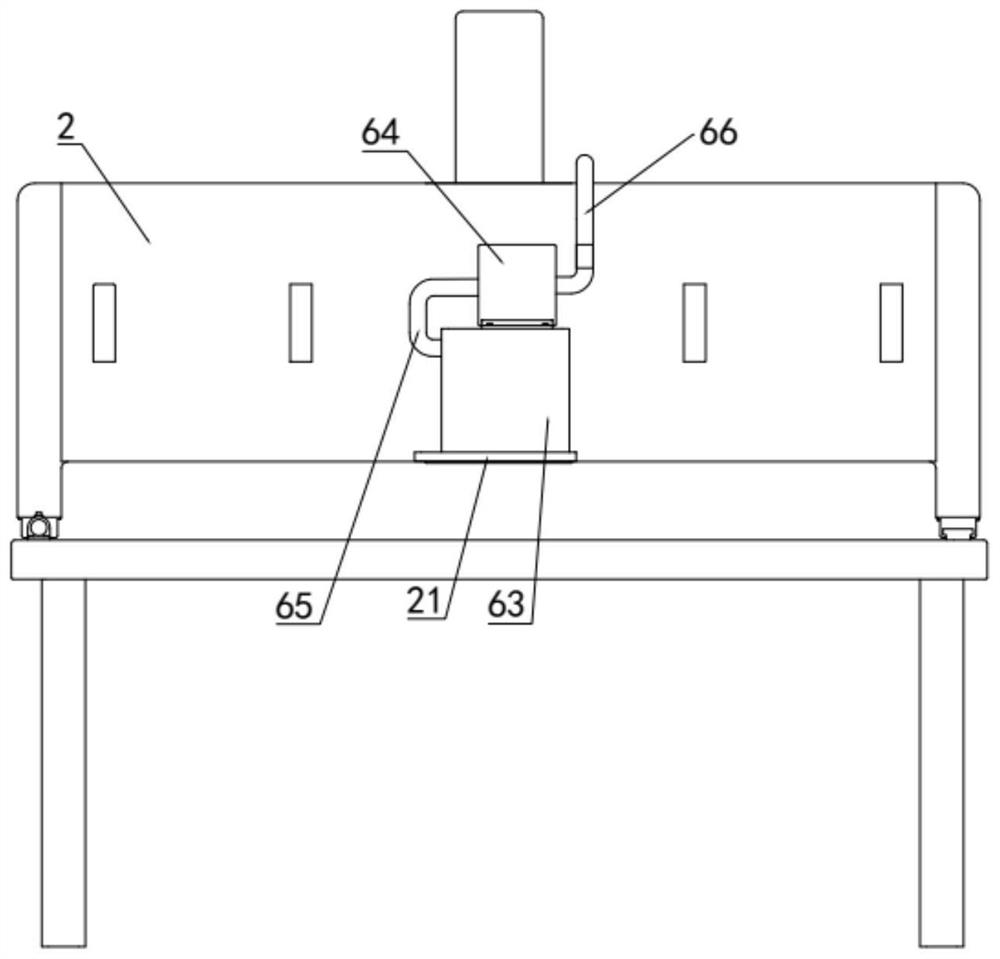

Hydraulic oil cylinder outer pipe cylinder barrel clamping tool clamp

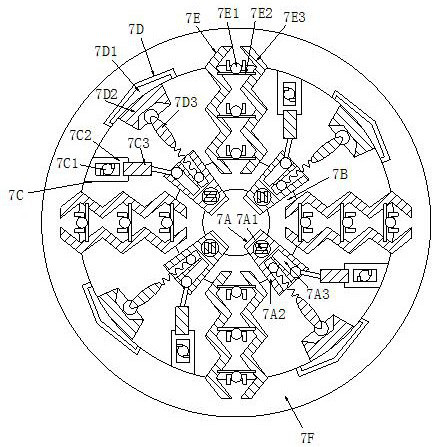

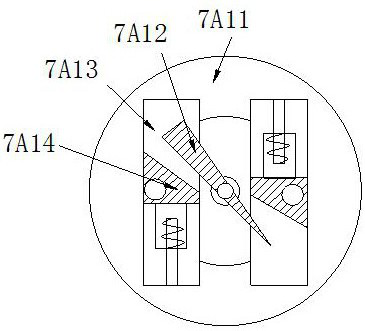

ActiveCN114273848APrevent heat deformationFast realization of automatic coincidence alignmentWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention relates to the technical field of welding tool clamps, in particular to a hydraulic oil cylinder outer pipe cylinder barrel clamping tool clamp which comprises a workbench, a rotary clamp table assembled on the workbench and a pipe opening positioning clamp assembled on the workbench. The rotary clamp table comprises a rotary table mechanism assembled on the working table, the rotary table mechanism comprises a rotary platform which is vertically and rotatably installed, and a synchronous positioning clamp used for axially aligning a cylinder part of a cylinder barrel with a flange plate is arranged on the rotary platform. A pressing mechanism used for pressing the cylinder part of the cylinder barrel and the flange plate is arranged on the upper end face of the rotary platform. The tool clamp provided by the invention can be used as a hydraulic cylinder barrel welding positioning clamp, can replace manual work to realize rapid and automatic alignment of a welding part, and solves the problems of trouble of manual adjustment and uncontrollable error and unreliable precision in the manual adjustment process.

Owner:XUZHOU NAIKEDUN MACHINERY MFG

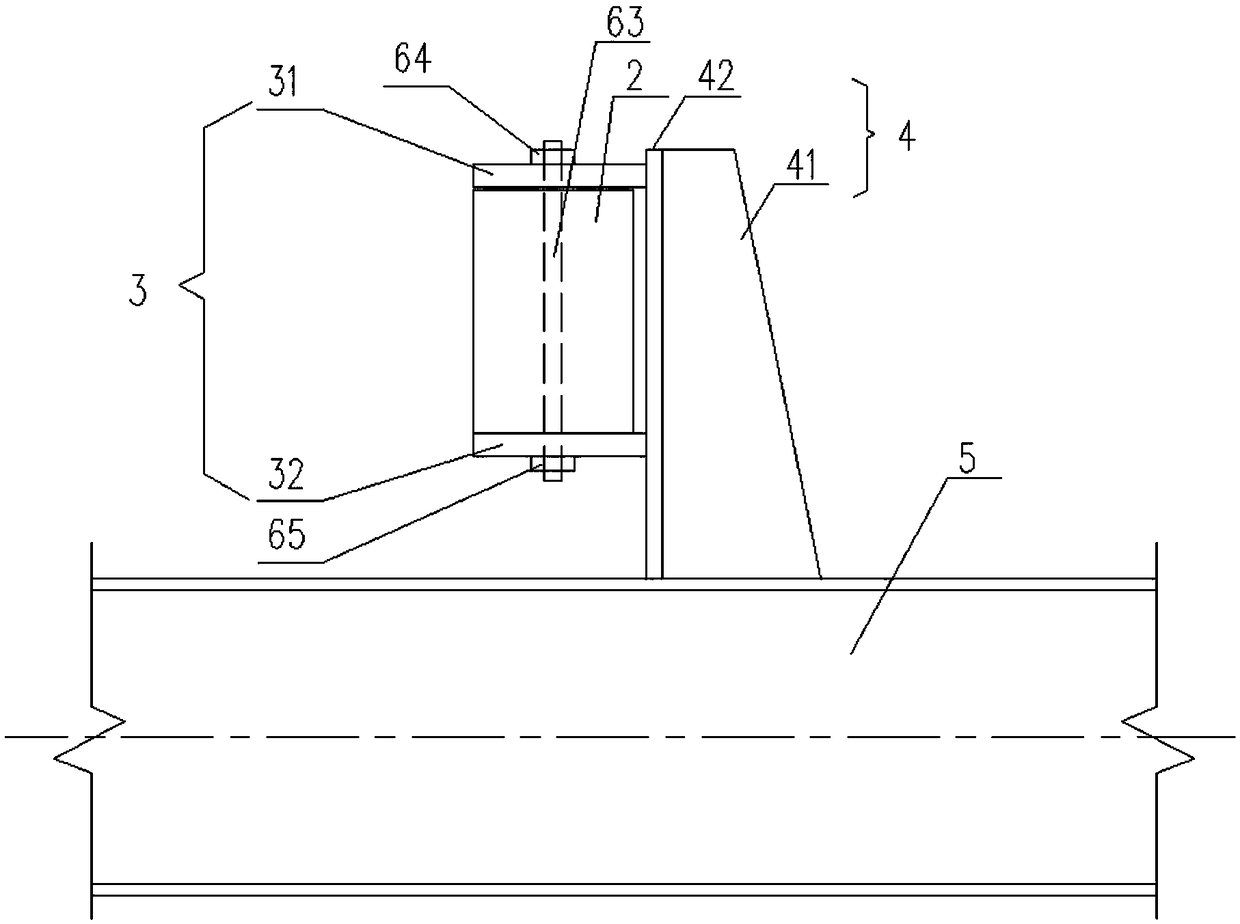

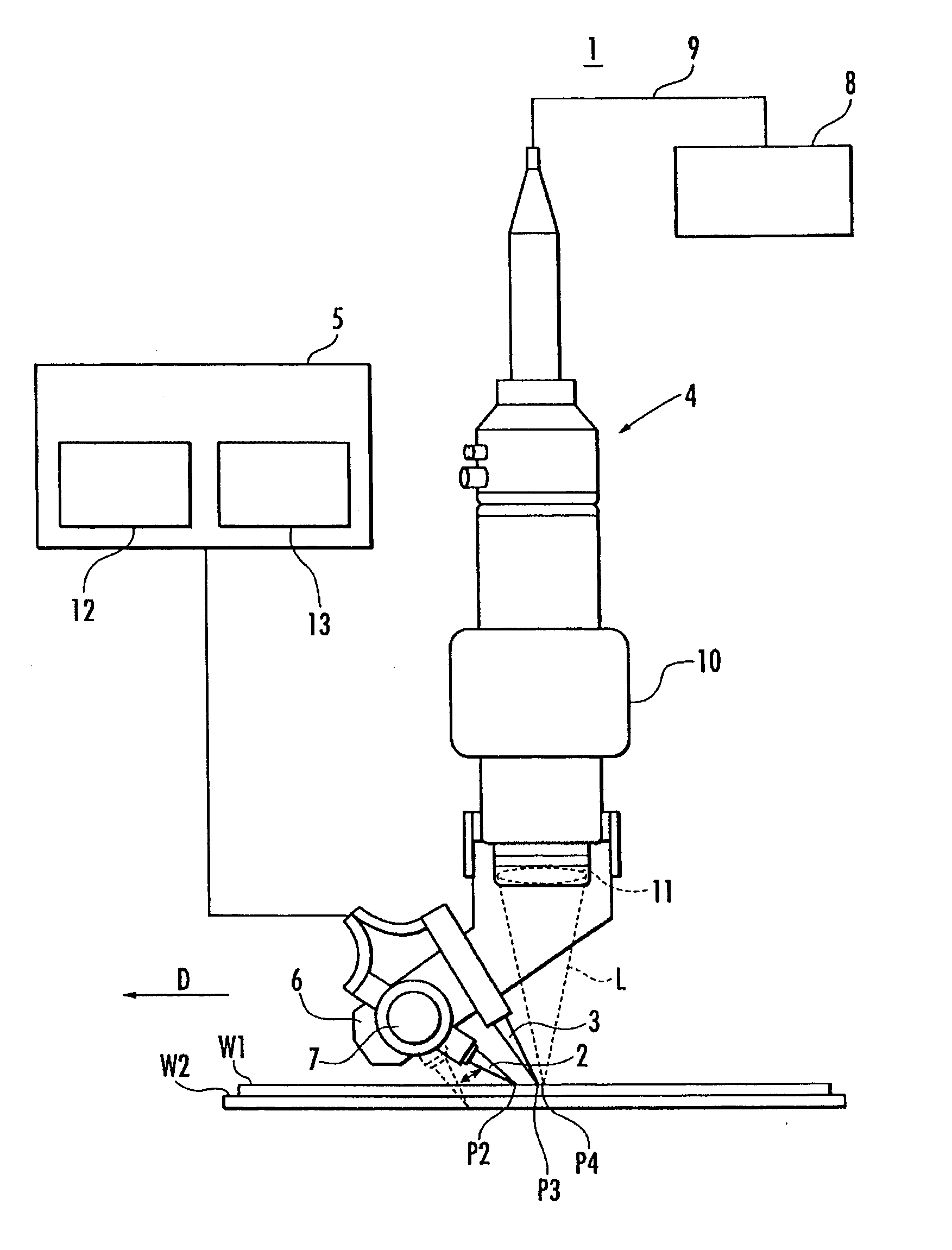

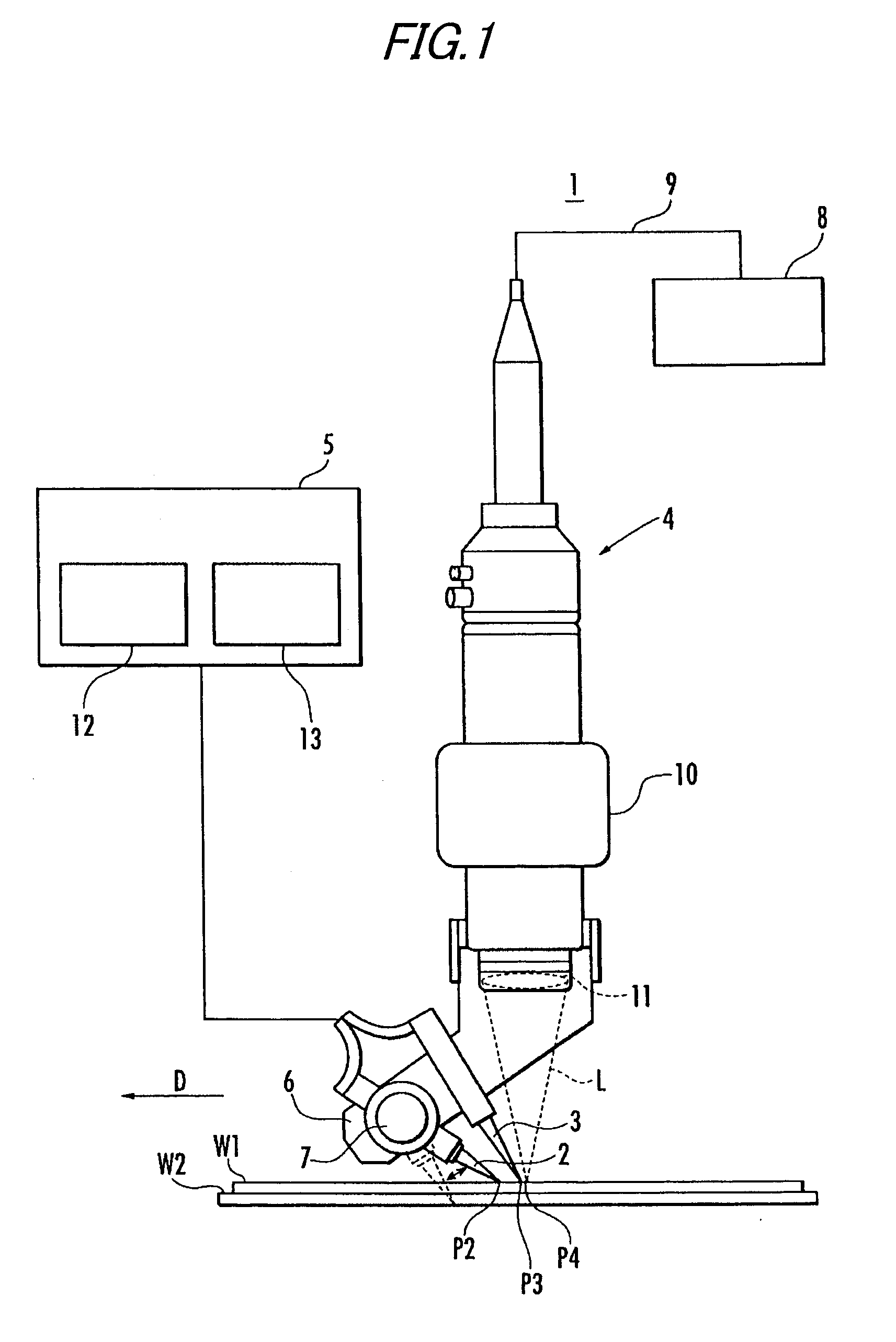

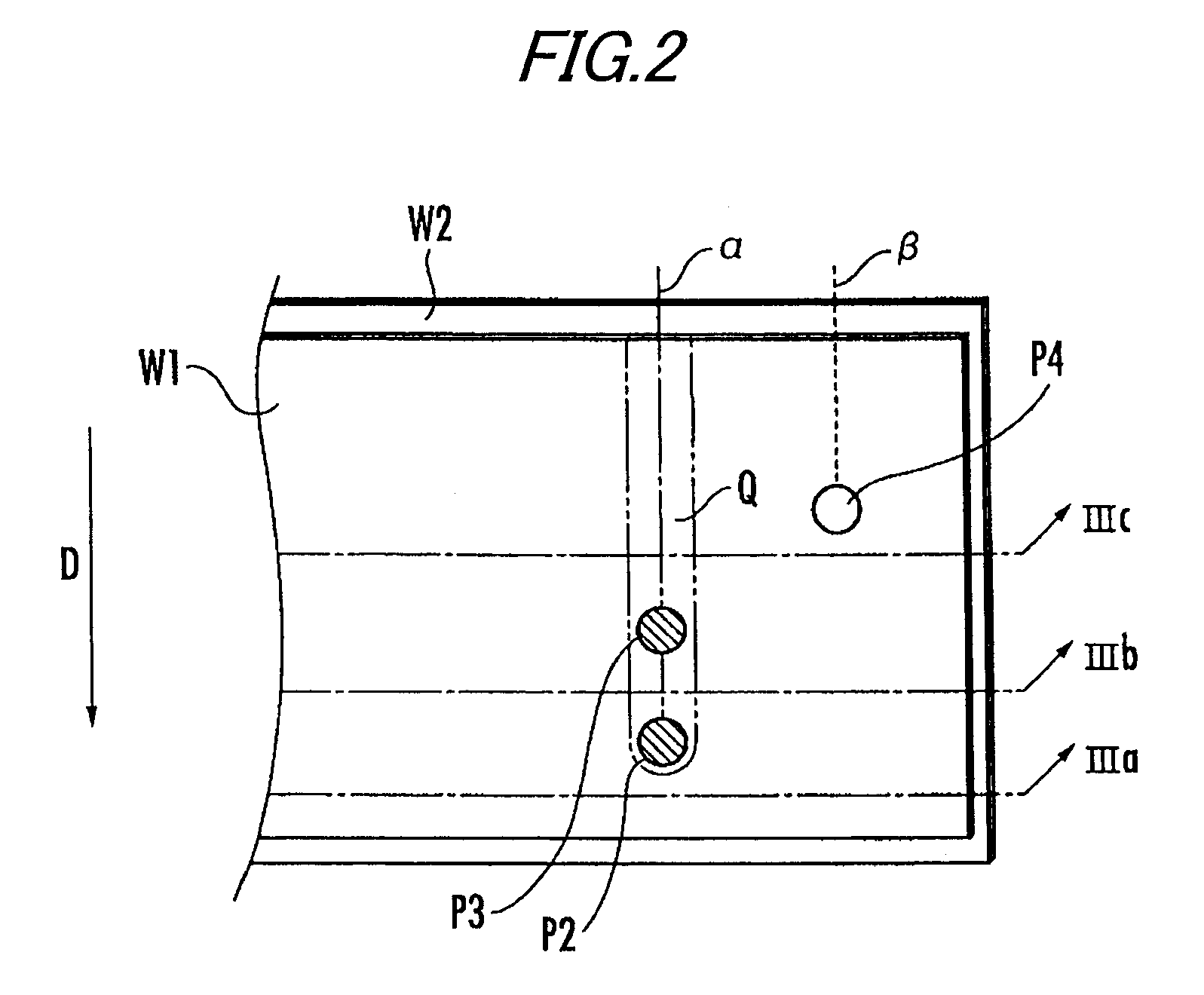

Laser welding method and device

InactiveUS20070029293A1Prevent heat deformationNot to damageElectrode supporting devicesWelding/soldering/cutting articlesEngineeringElectrical and Electronics engineering

Electrodes 2, 3 are contact with an uppermost work W1 and energized with electricity so as to thermally expand an electrode contact portion of the work W1 or alternatively so as to thermally expand the electrode contact portion of the work W1 and a heat transfer portion of an adjoining work W2 to which heat is transferred from the electrode contact portion, and then the portions are contracted so as to form a deformed portion Q and the deformed portion Q is separated from the adjoining works W1, W2 and a gap H is formed between the works W1, W2 which are overlapped, and a laser beam L is irradiated at a position where the gap H is large enough to spread the vapor generated by the vaporization of the coating heated.

Owner:HONDA MOTOR CO LTD

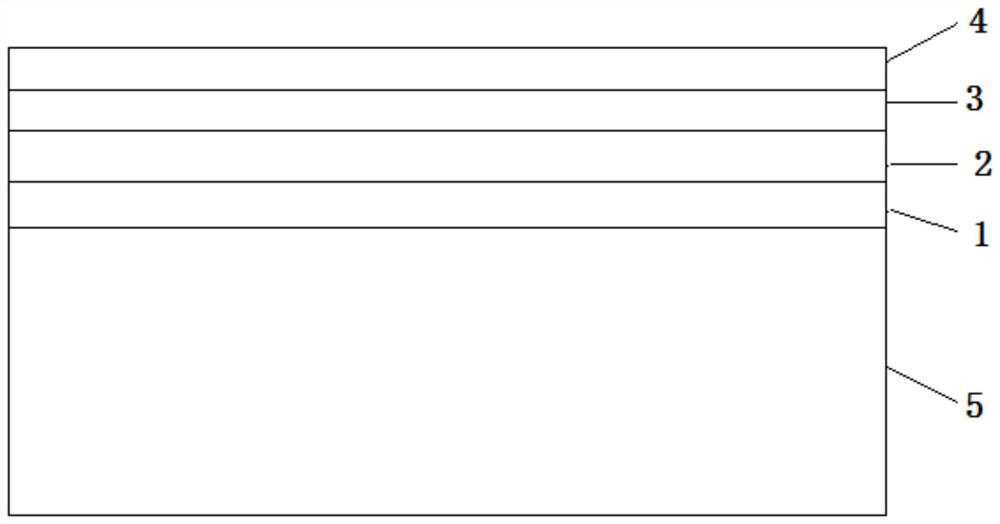

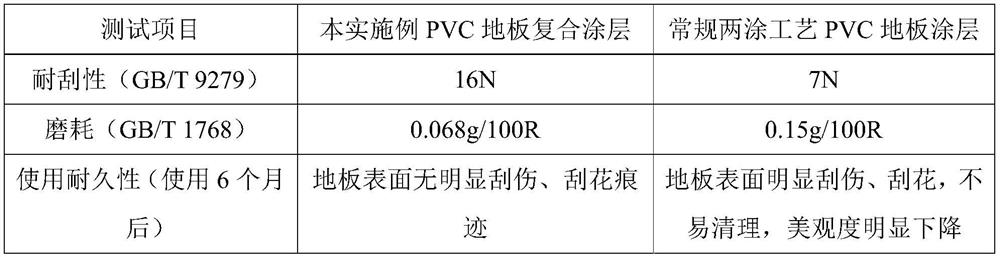

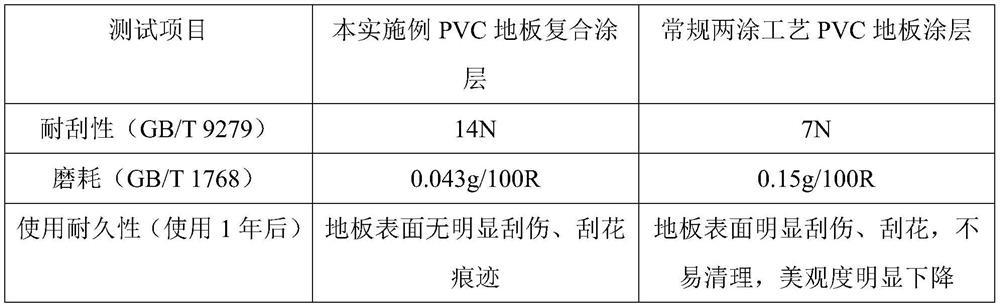

A kind of pvc floor composite coating and preparation method thereof

ActiveCN109821715BReduce heat buildupPrevent heat deformationPretreated surfacesPolyurea/polyurethane coatingsHigh intensityHigh intensity light

The invention discloses a PVC floor composite coating, the composite coating is located on the surface of a substrate, and the composite coating sequentially includes a first primer layer, a second primer layer, a third primer layer and a topcoat layer from bottom to top . The preparation method of the present invention comprises the following steps: firstly treating the substrate, then coating the first primer layer on the substrate, and curing; then coating the second primer layer on the surface of the first primer layer, and curing; The surface of the second primer layer is coated with the third primer layer and cured; finally, the top coat is applied and cured, that is, a composite coating is formed on the substrate. The present invention combines the formula design of the PVC floor composite coating with the curing method of the high-intensity LED light source, making it possible to apply multi-coat coating to the PVC floor. The cured coating has low shrinkage, excellent toughness, high hardness, and Wear and scratch resistance, which can solve the industry common problem that PVC floor is easy to scratch.

Owner:HUNAN BANFERT NEW MATERIALS TECH

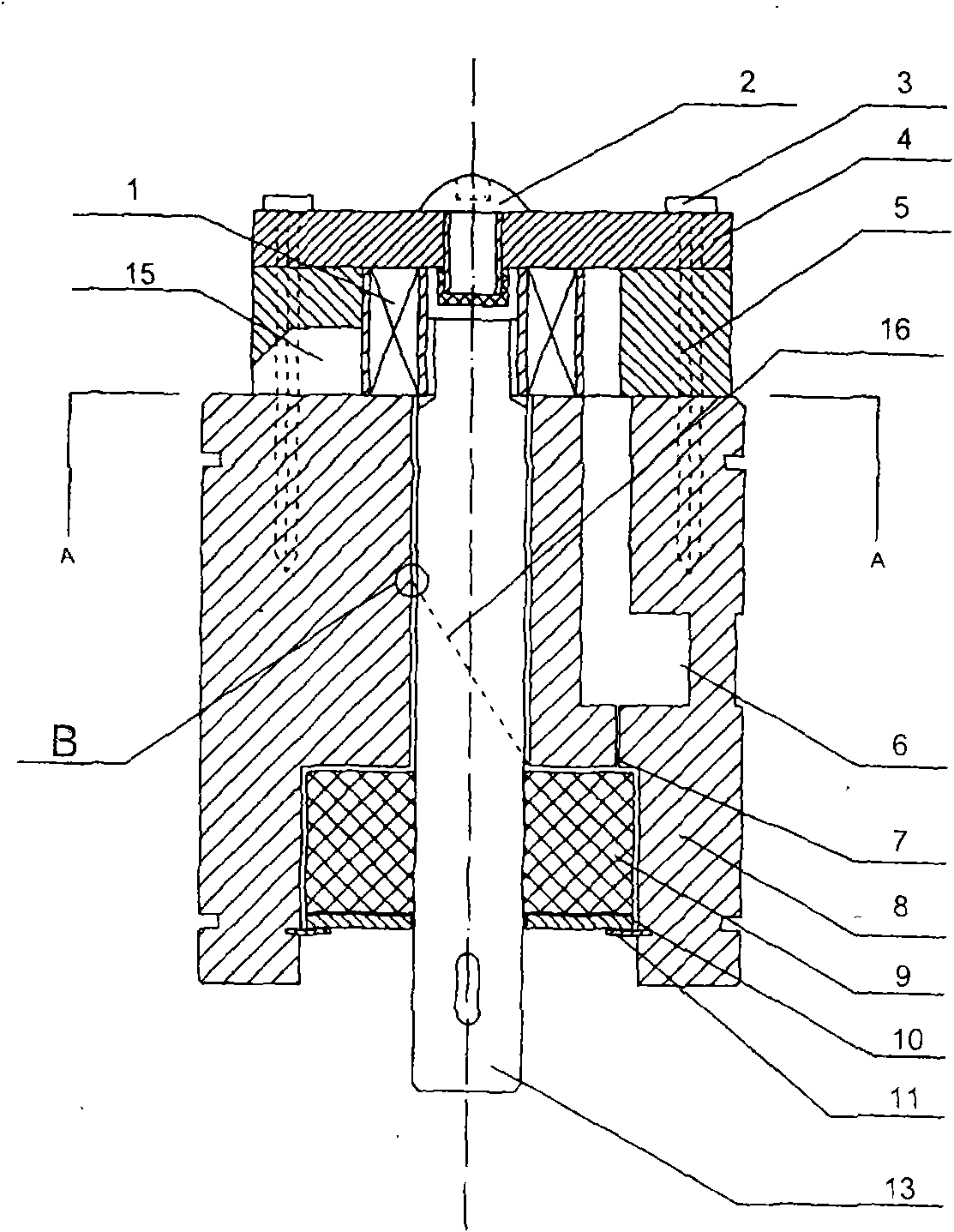

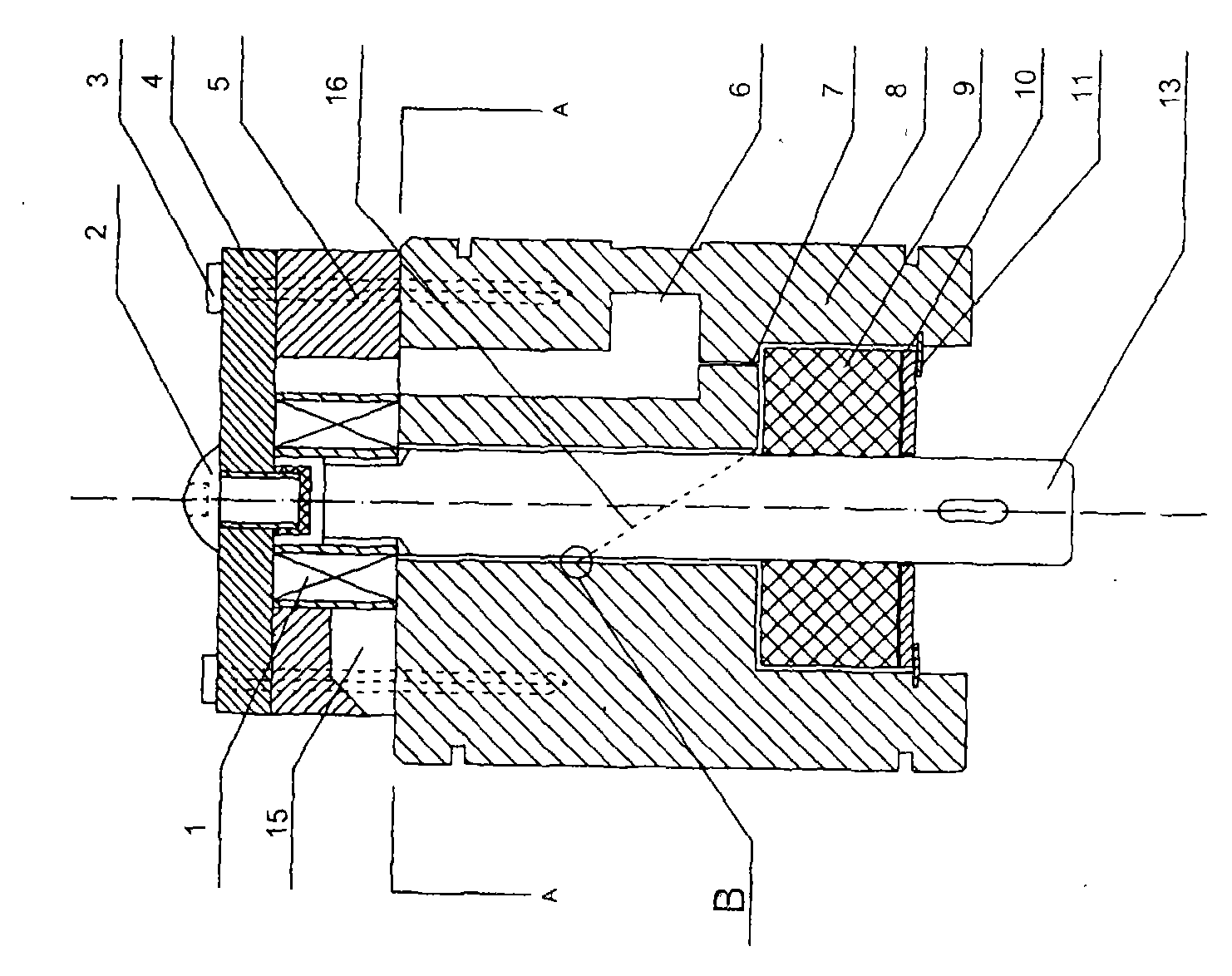

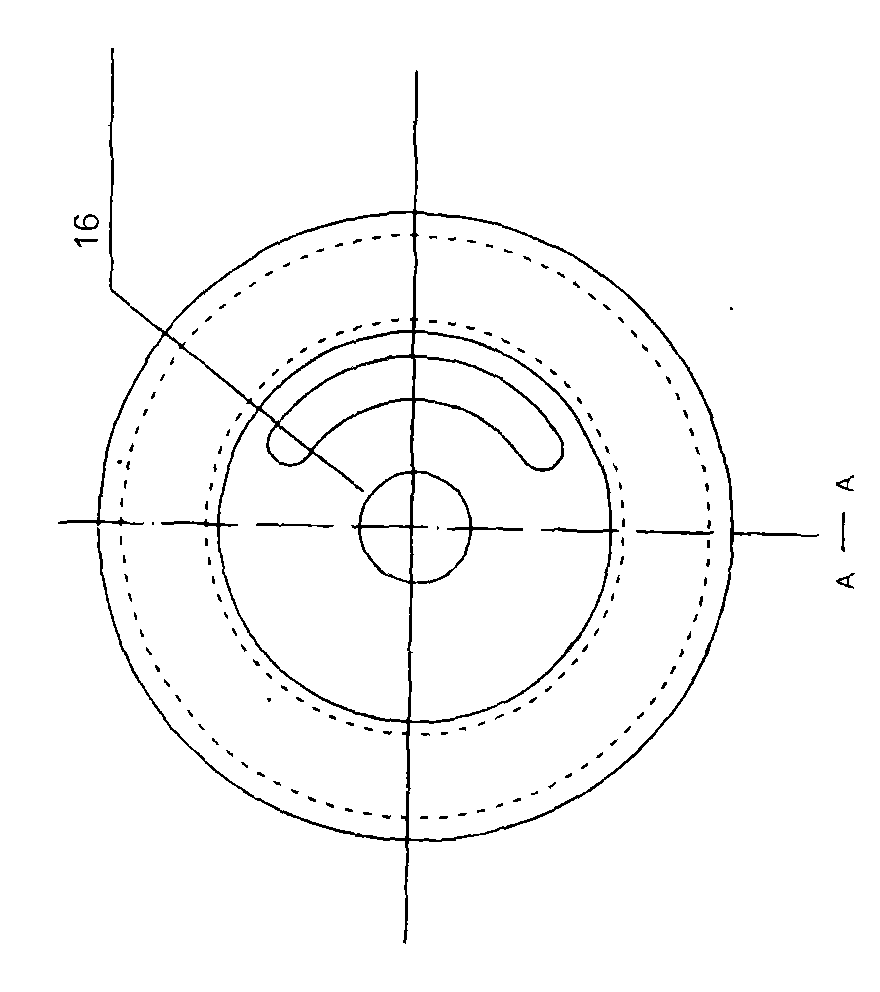

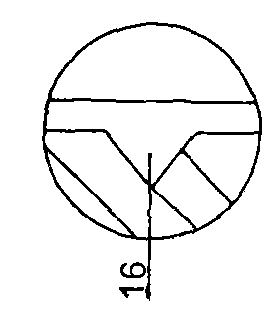

Single-stage blade pump for dimethyl ether vehicle

ActiveCN101672279BIncrease the amount of lubricating oilImprove the lubrication effectRotary piston pumpsRotary piston liquid enginesSingle stageEngineering

The invention discloses a single-stage blade pump for dimethyl ether vehicles, comprising a blade, a shaft pin screw, a screw, an end cover, a pump cavity, an oil-taking ring, a small oil passage, a pump body shaft sleeve, a framework seal, a retainer ring, a snap spring, a shaft, an oil-outlet cavity. A swirl oil line is arranged on the inner surface of the pump body shaft sleeve axially; and bythe swirl oil line, the quantity of lubrication oil between the shaft and the pump body shaft sleeve is improved, the problems of easy occurrence of shaft clasping of the single-stage blade pump and short service life of the framework seal are solved, and reliable equipment guarantee for taking dimethyl ether as the fuel for vehicles to replace diesel is provided.

Owner:河北裕泰实业集团有限公司

Gluing device for electronic communication product

PendingCN114713447APrevent glue from settingAvoid being heated and deformedLiquid surface applicatorsShaking/oscillating/vibrating mixersElectronic communicationAdhesive glue

The invention discloses a gluing device for electronic communication products, and relates to the technical field of gluing devices.The gluing device comprises a workbench, a mounting frame, a gluing mechanism and a cleaning mechanism, the mounting frame is arranged on the upper end face of the workbench and is driven by a first driving mechanism to move front and back, and a moving frame is arranged on the front side of the mounting frame; the moving frame is driven by the second driving mechanism to move left and right, the gluing mechanism is arranged on the moving frame and used for gluing products on the workbench, and the cleaning mechanism is arranged below the gluing mechanism and used for cleaning and collecting overflowing glue. Under the condition that the gluing head is not damaged, glue left on the outer side and in the gluing head can be cleaned, and the conditions that blocking occurs when the gluing head is used again and dust is doped in the glue are avoided.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

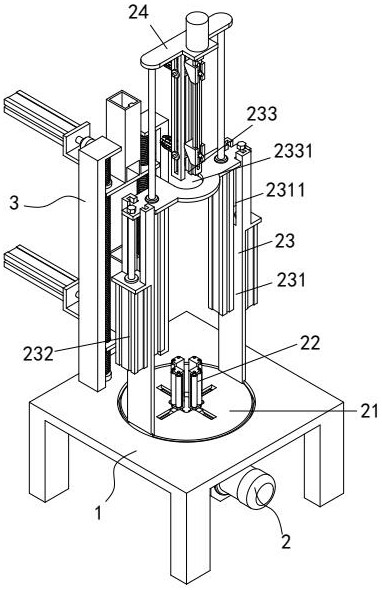

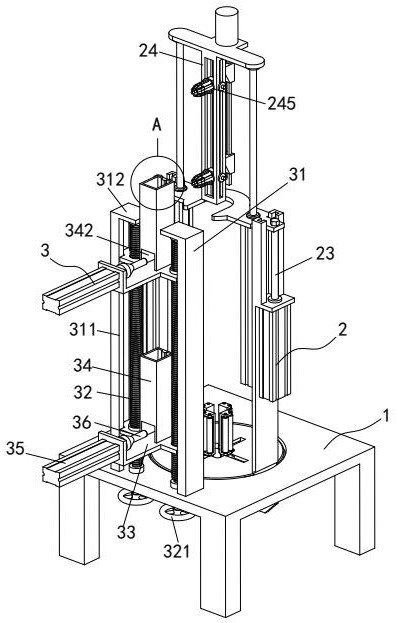

Phase change type building decorative plate surface leveling device based on Venturi effect

ActiveCN114131473APrevent heat deformationReduce the temperatureGrinding carriagesBelt grinding machinesClassical mechanicsDust control

The invention discloses a venturi effect-based phase change type building decorative plate surface leveling device, which comprises a base, an adjustable movable clamping mechanism, a self-adaptive centering clamping rolling supporting mechanism, a symmetric missing-free comprehensive polishing leveling mechanism and a venturi phase change type cooling dust removal mechanism, and is characterized in that the adjustable movable clamping mechanism is arranged on the base; the self-adaptive clamping rolling supporting mechanism is arranged on the adjustable movable clamping mechanism, and the symmetrical missing-free comprehensive grinding and leveling mechanisms are symmetrically arranged on the base and symmetrically arranged on the two sides of the adjustable movable clamping mechanism. The venturi phase change type cooling and dust removing mechanism is arranged on one side of the symmetrical omission-free comprehensive grinding and leveling mechanism, and the self-adaptive centering, clamping, rolling and supporting mechanism comprises a centering, clamping and transmission assembly and a self-adaptive clamping, rolling and supporting assembly. The invention belongs to the field of building decoration processing, and particularly relates to a venturi effect-based phase change type building decoration plate surface leveling device which is compact in structure and can be used for cooling and dedusting.

Owner:江苏金狮堂视觉科技有限公司

Single-stage blade pump for dimethyl ether vehicle

ActiveCN101672279AIncrease the amount of lubricating oilImprove the lubrication effectRotary piston pumpsRotary piston liquid enginesSingle stageLubrication

The invention discloses a single-stage blade pump for dimethyl ether vehicles, comprising a blade, a shaft pin screw, a screw, an end cover, a pump cavity, an oil-taking ring, a small oil passage, a pump body shaft sleeve, a framework seal, a retainer ring, a snap spring, a shaft, an oil-outlet cavity. A swirl oil line is arranged on the inner surface of the pump body shaft sleeve axially; and bythe swirl oil line, the quantity of lubrication oil between the shaft and the pump body shaft sleeve is improved, the problems of easy occurrence of shaft clasping of the single-stage blade pump and short service life of the framework seal are solved, and reliable equipment guarantee for taking dimethyl ether as the fuel for vehicles to replace diesel is provided.

Owner:河北裕泰实业集团有限公司

Aluminum alloy hub-type joint net frame clamping plate type support based on groove steel

PendingCN109138163ALower the elevationReduce steel consumptionExtraordinary structuresShear forceAluminium alloy

The invention provides an aluminum alloy hub-type joint net frame clamping plate type support based on groove steel. The technical problem that a screw rod is not subjected to shearing force is solved. According to the adopted technical scheme, the aluminum alloy hub-type nodal grid frame splint type support comprises a maintaining part, a locking assembly, and a connecting part, wherein the maintaining part is provided with a fixing end plate and further provided with a first sealing end plate and a second sealing end plate which are arranged on one side face of the fixing end plate in parallel, and a positioning groove suitable for placing a hub joint is enclosed among the two sealing end plates and the fixing end plate; the locking assembly includes a perforating part passing through the first sealing end plate, the hub joint, and the second sealing end plate in sequence in the axial direction of the hub joint, and locking parts arranged at the two ends of the perforating part; andthe connecting part is suitable for connecting the maintaining part to a to-be-connected object. Cover plate seals in the prior art is replaced by adopting a clamping type sealing structure, seals arein rigid connection, the overall structural strength of the support is enhanced, thus the perforating part can withstand a certain degree of shearing resistance, and the structural strength of the support is greatly enhanced.

Owner:HUADIAN HEAVY IND CO LTD

A sizing agent for cigarette paper of heat-not-burn tobacco products and its preparation and sizing method

ActiveCN109797601BImprove protectionNo pollution in the processWater-repelling agents additionCigar manufactureEngineeringProcess engineering

The invention provides a sizing agent for heat-not-burn tobacco product cigarette paper and a preparation and sizing method thereof. The sizing agent is to place the AKD glue in a reaction vessel, stir and heat it to 60-90° C., add the treated expanded graphite, conditioner and tobacco flavor, stir evenly, and then use a high-pressure homogenizer to homogenize the sizing agent. Obtained; the expanded graphite is obtained by placing expanded graphite particles with a particle size of 10 to 100 μm in an atomizing agent solution, stirring under negative pressure to fully absorb the atomizing machine solution, and then drying at a low temperature of 70 to 100 ° C to obtain. of expanded graphite particles. The AKD glue solution is obtained by adding starch and AKD wax into hot water at 60-90° C. for 30-60 minutes under heat preservation and stirring. The above sizing agent is transported into the feeding trough, and then sent to the surface sizing machine to be applied to the inner surface of the cigarette paper; it can not only protect the cigarette paper from high temperature baking, but also prevent the cigarettes from being overheated, Affect the consumer's sensory experience and increase the amount of smoke when puffing.

Owner:HUBEI CHINA TOBACCO IND

A kind of production method of composite steel pipe

ActiveCN110682179BImprove quality pass rateImprove pass rateEdge grinding machinesGrinding carriagesPolishingPipe

Owner:上海奉贤钢管厂有限公司

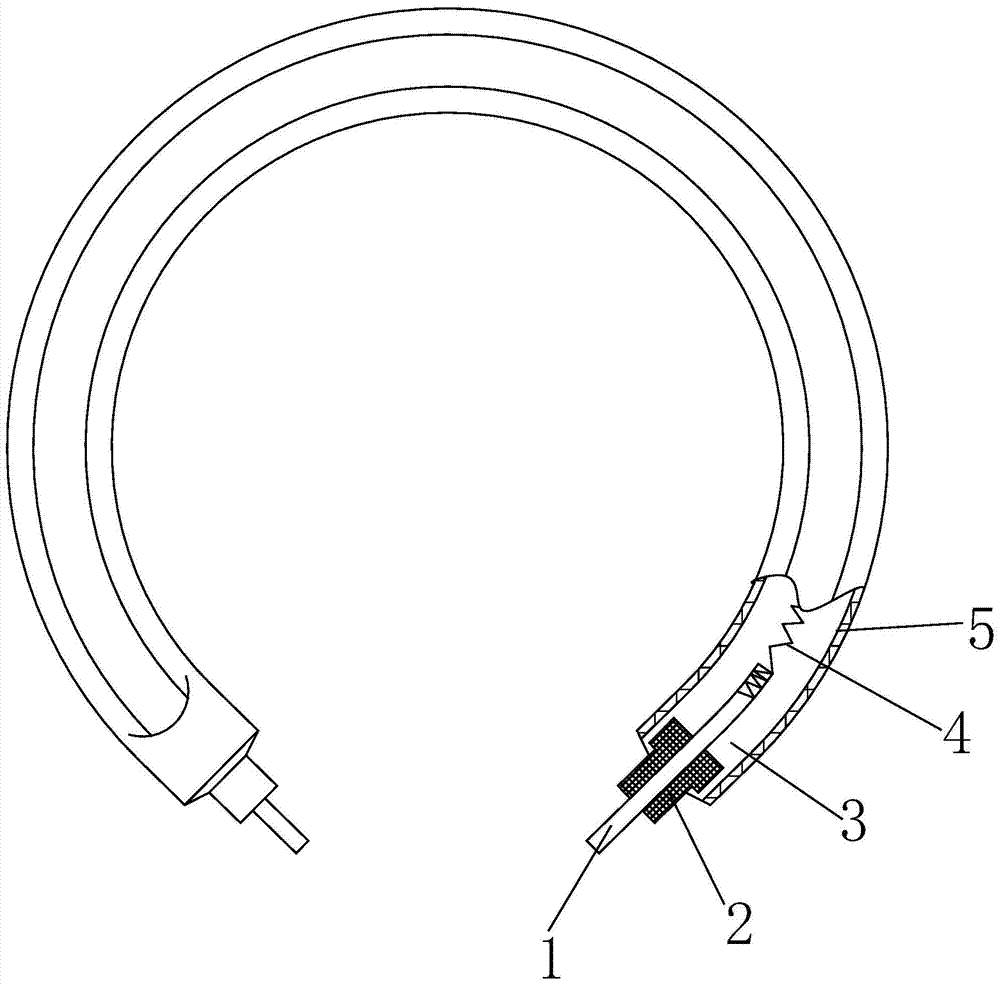

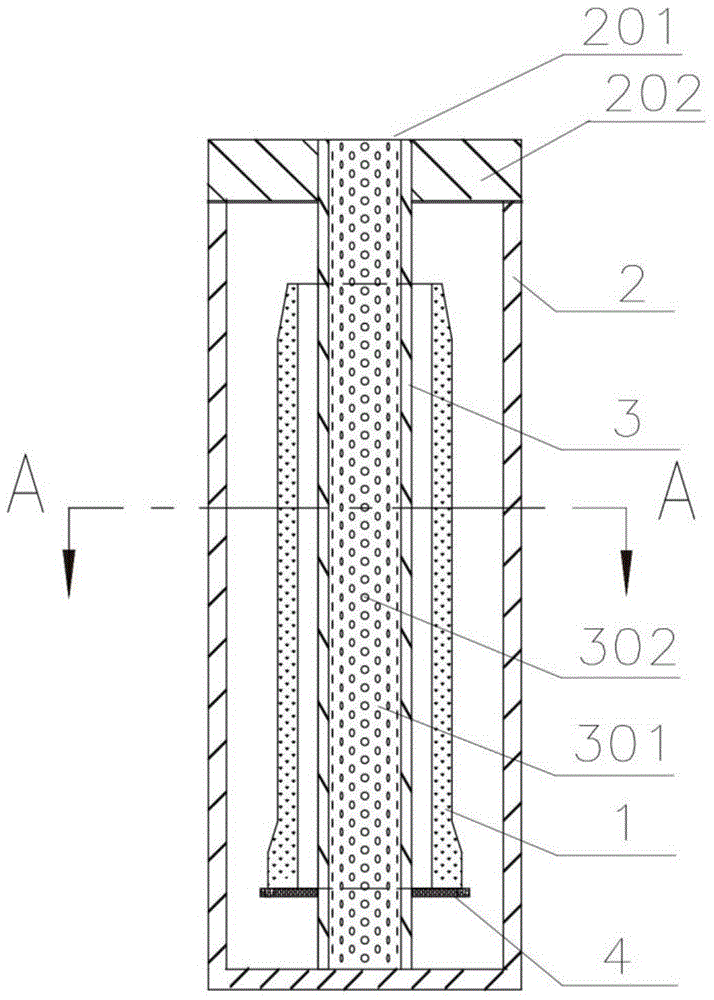

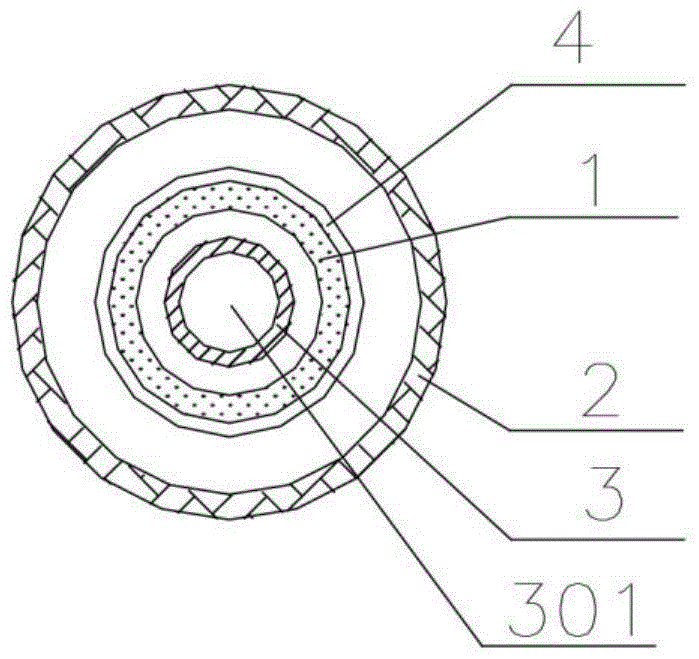

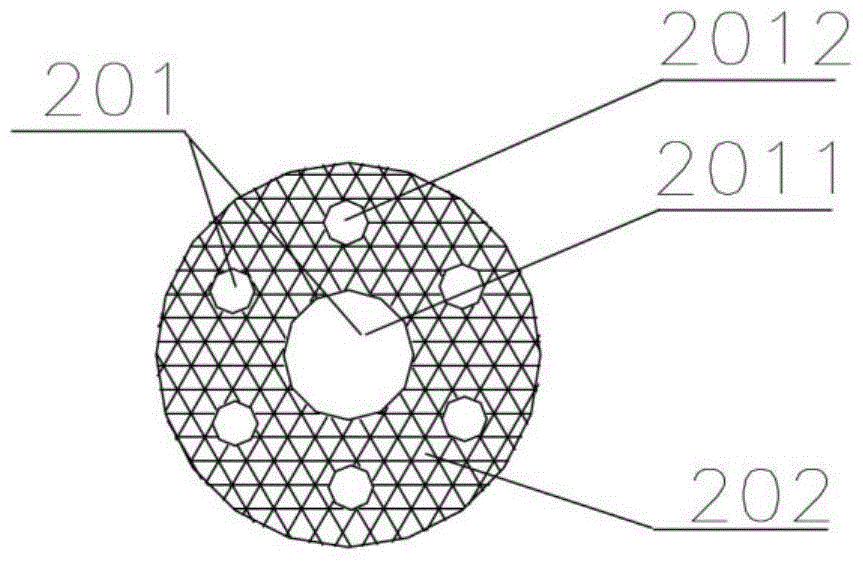

Heating aluminum tube

InactiveCN104333925APrevent heat deformationEasy to useHeating element shapesThermal deformationHot Temperature

The invention relates to a heating aluminum tube which comprises a tube body which is in the shape of a C-shaped ring. A filling material is wrapped at the center of the tube body. Two ends of the tube body sleeve ceramic materials. Lead columns are wrapped at the centers of the ceramic materials. The inner end parts of the lead columns are provided with heating wires which are encircled structures. The heating wires are in the filling material and are correspondingly connected between the inner end parts of the lead columns. Both the filling material and the ceramic materials have good heat insulation effect, and the thermal deformation of the tube body due to the transfer of high temperature on the heating wires and the lead columns to the tube body is avoided. The filing material is magnesium oxide powder. The core of the invention is that through the good heat insulation effect of the filling material and the ceramic materials, the transfer of high temperature to cause the thermal deformation of the tube body is greatly prevented. The heating aluminum tube has the advantages of compact structure, good use effect and long service life.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

Integrated exhaust gas sintering method and tooling for implementing the method

An exhausting and sintering integration method comprises the steps that a rough piece to be sintered is placed in a sintering boat to be sintered, the sintering boat is provided with an exhaust port, an exhaust conduction structure is arranged in the sintering boat, the outer wall outline is arranged to adapt to the inner cavity outline of the rough piece, an exhaust cavity is formed in the exhaust conduction structure and communicated with the outside world, exhaust holes which are formed in the surface of the exhaust conduction structure are communicated with the exhaust cavity, positioning is conducted on the exhaust conduction structure and the rough piece, sintering sand is laid on and filled into the sintering boat to exceed the top of the rough piece, and heating sintering and cooling are conducted. The invention provides an exhausting and sintering integration tool which implements the exhausting and sintering integration method. The tool comprises the sintering boat, the exhaust conduction structure, and the exhaust port is formed in the sintering boat; the exhaust conduction structure is installed in the sintering boat and comprises the exhaust cavity which is communicated with the outside world, the surface of the exhaust conduction structure is provided with exhaust through holes, and the outer wall outline of the exhaust conduction structure adapts to the inner cavity outline of the rough piece.

Owner:CHENGDU INTERMENT TECH

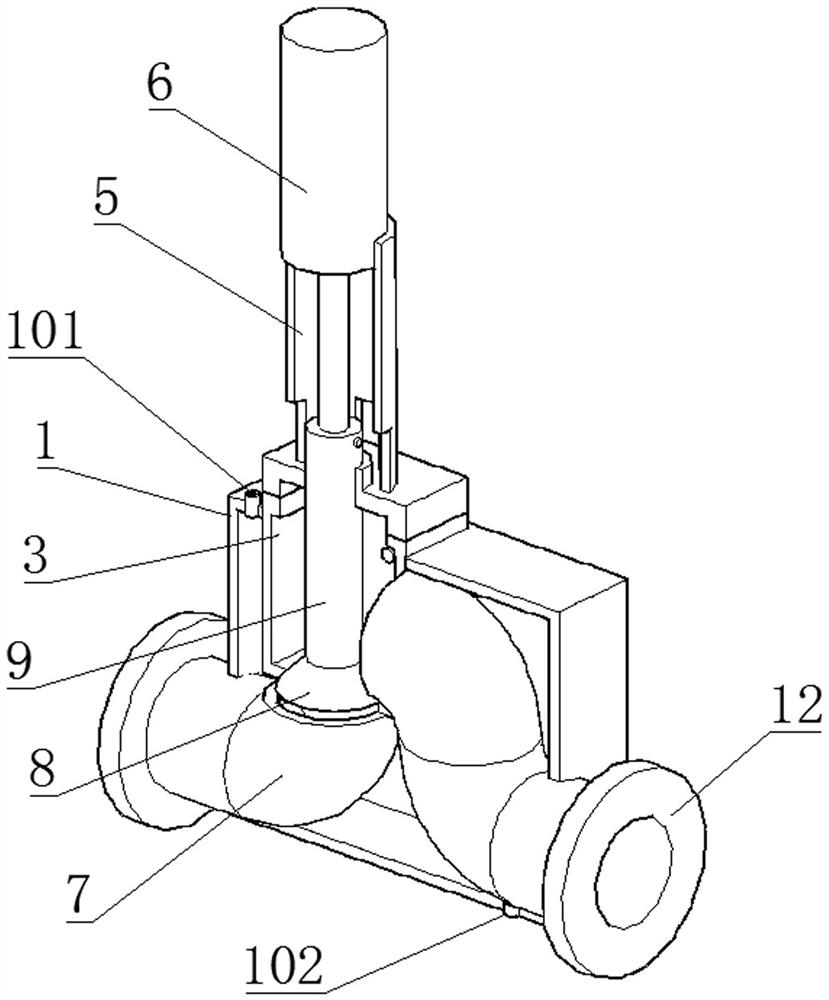

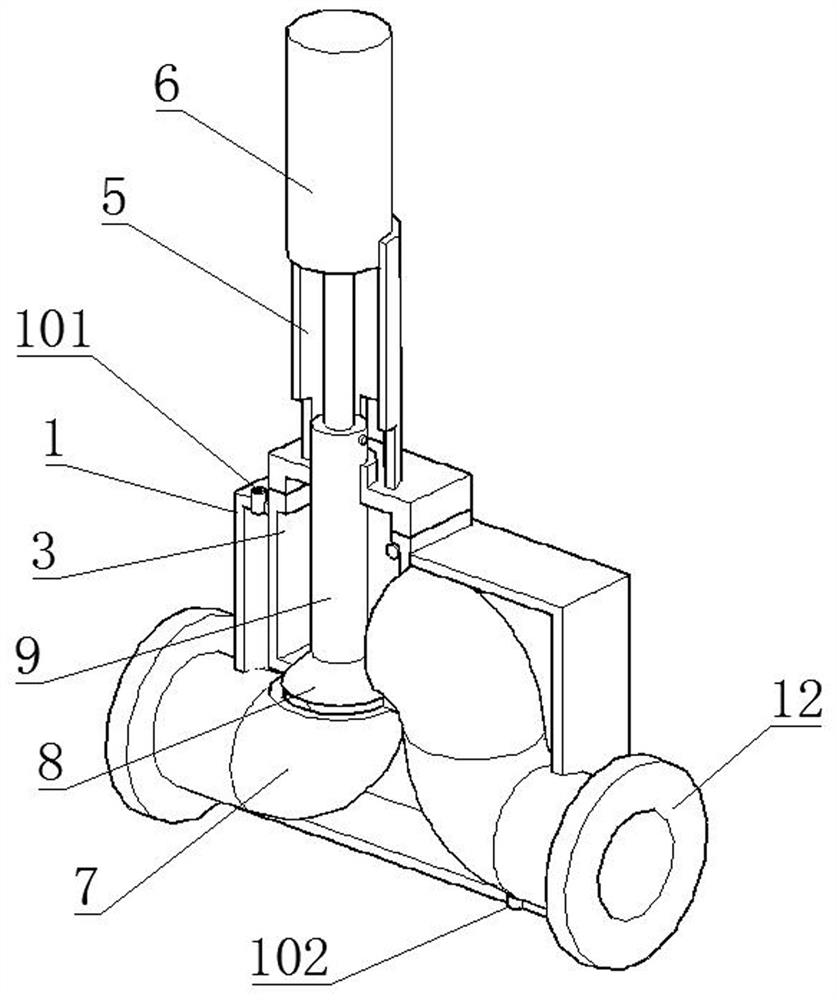

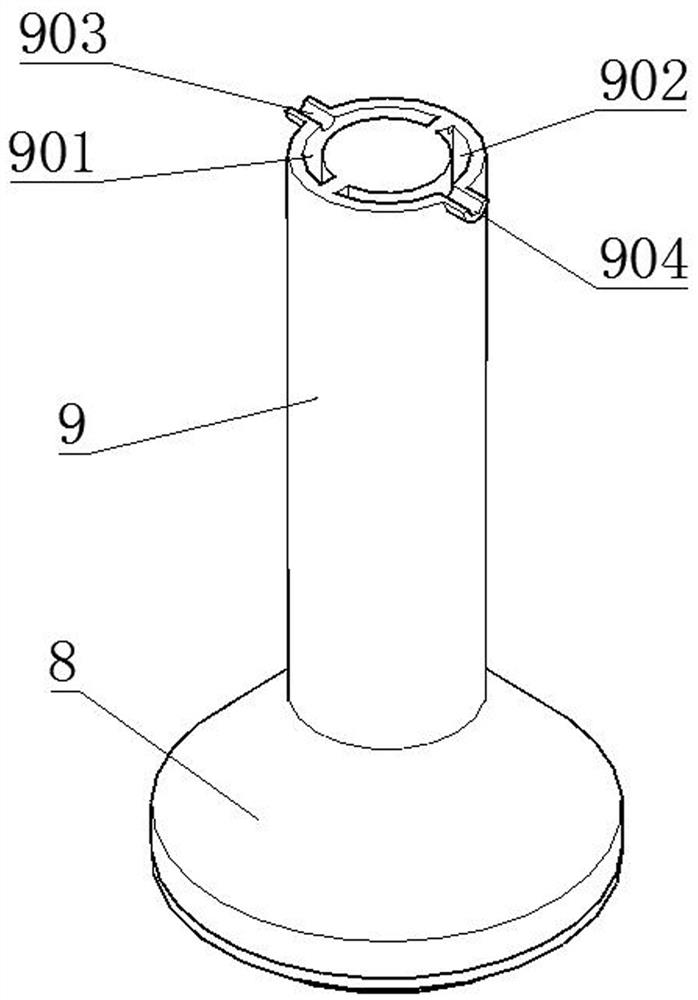

A self-control valve for anti-failure high-temperature dusty gas

ActiveCN111457153BReduce the temperaturePrevent heat deformationValve members for heating/coolingValve members for absorbing fluid energyAutomatic controlEngineering

The invention provides a self-control valve for preventing failure of high-temperature dust-containing gas, which relates to the field of fluid transportation, and includes a cylinder, the cylinder is fixed on the valve cover through a bracket, and the piston rod of the cylinder is fixed to the valve rod of the valve cover passing through the valve cover. connected, the valve cover is fixedly connected with the valve body, one end of the valve stem located in the valve body is fixedly connected with the valve core, the valve stem and the valve core are provided with a through flow channel, and the outside of the valve body is fixedly connected with a water tank, In the present invention, the cooling method of circulating water is adopted to reduce the temperature of the valve stem, and a water tank is installed outside the valve body to cool the valve body, so as to prevent the valve body from being heated and deformed by high-temperature gas, thereby ensuring normal operation and prolonging the life of the valve body. A rotary plate connected to the valve body is installed inside, and the rotary plate is slidingly connected with the valve core, and the rotary plate is driven by the movement of the valve core to rotate. When the valve is opened, the rotary plate fits with the upper side of the valve body to avoid dust The high temperature gas directly flushes the valve core to protect the valve core.

Owner:SUZHOU BORUI AUTOMATIC CONTROL VALVE CO LTD

Four-roll lithium belt calendering mechanism

ActiveCN106252606BLimit shaft runoutReduce distortionElectrode rolling/calenderingLithiumPulp and paper industry

The invention relates to a four-roll lithium strip calendering mechanism. The four-roll lithium strip calendering mechanism is characterized by comprising a dynamic compression roller and a compression roller of which the interval between roller surfaces is adjustable, wherein an auxiliary dynamic compression roller and an auxiliary compression roller are respectively arranged at the outer sides of the dynamic compression roller and the compression roller, the auxiliary dynamic compression roller is tightly attached to the roller surface of the dynamic compression roller, and the auxiliary compression roller is tightly attached to the roller surface of the compression roller; the two shaft ends of the dynamic compression roller and the auxiliary dynamic compression roller are respectively rotationally installed on a dynamic compression roller seat, two shaft ends of the compression roller and the auxiliary compression roller are respectively rotationally installed on a compression roller seat, and the shaft ends of the dynamic compression roller and the compression roller are respectively connected with a power source which drives the dynamic compression roller and the compression roller to rotate; the compression roller seat is fixedly mounted on a mounting bottom plate and the dynamic compression roller is mounted on the mounting bottom plate in a sliding way; oil channels are machined in the dynamic compression roller and the compression roller, the two ends of each oil channel are respectively connected with an oil input pipeline and an oil output pipeline. According to the four-roll lithium strip calendering mechanism, lithium ions are transferred to the surface of a thin film through calendering so as to obtain continuous, uniform and quantitative ultrathin lithium thin film, thus making preparation for the subsequent procedure of lithium supplementing and film coating for the pole piece.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com