Tension-adjustable drying device for packaging film processing

A drying device and packaging film technology, which is applied to heating devices, drying, drying machines, etc., can solve the problems of moisture in the packaging film, a lot of time and human resources, and the drying effect of the packaging film is not very good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

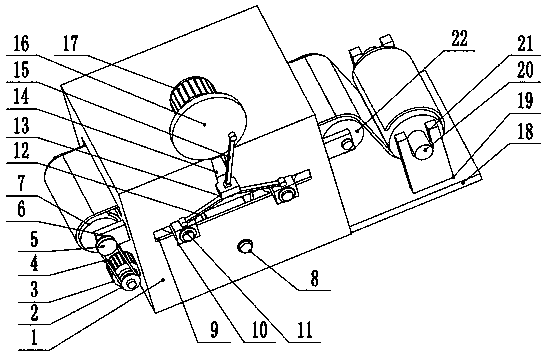

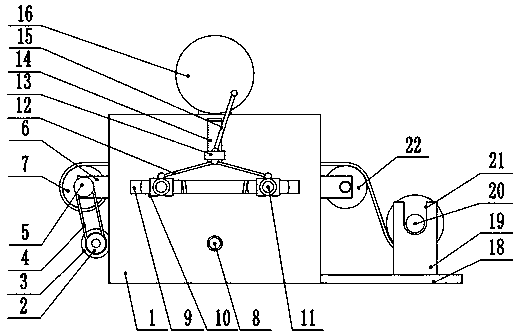

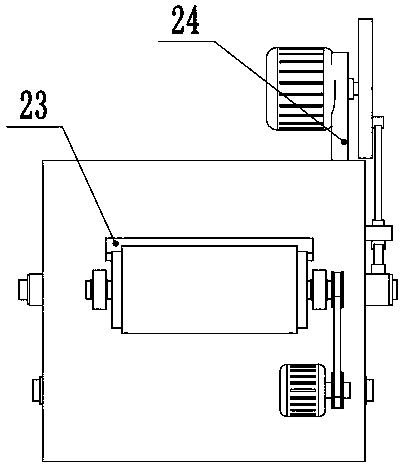

[0026] see Figure 1-4 , a tension-adjustable drying device for packaging film processing, comprising a drying box 1, the left and right side walls of the drying box 1 are provided with a first bearing seat 6, and the first bearing seat 6 on the left side is rotatably connected to a winding roller 7. The lower part of the left side wall of the drying box 1 is provided with a first drive motor 3, the output shaft of the first drive motor 3 is fixedly connected to the first pulley 2, and the first pulley 2 is connected to the second pulley 5 through a belt 4, The second pulley 5 is fixedly connected to the front end of the winding roller 7, and the middle part of the first bearing seat 6 on the right side is connected to the guide roller 22 in rotation, and the left and right side walls of the drying box 1 are provided with a relief groove 23, and the winding roller 7 is flush with the top of the guide roller 22, and the height of the top of the winding roller 7 and the guide ro...

Embodiment 2

[0029] see figure 1 The other content of this embodiment is the same as that of Embodiment 1, except that: the upper part of the support plate 19 is provided with a third chute 21 , and the third chute 21 slidably connects the front and rear sides of the storage roller 20 . By arranging the third chute 21, the storage roller 20 can be directly placed on the upper part of the chute. When the packaging film in the storage roller 20 is exhausted, the storage roller 20 can be directly taken out and replaced with a new storage roller 20, so that The disassembly and assembly of the whole device is more convenient, and the production efficiency is improved.

[0030]In the implementation process of the present invention, firstly, the free end of the packaging film that needs to be dried is extracted, inserted into the right side relief groove 23, and passed through the upper part of the second tension roller 11 on the right side, the first tension roller 8 The lower part and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com