Single-stage blade pump for dimethyl ether vehicle

A technology of dimethyl ether and vane pumps, which is applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of the application and popularization of clean energy, reduce the use time, increase maintenance costs, etc., and achieve the solution of shaft holding and The effect of short service life of skeleton seal, prolonging service life and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

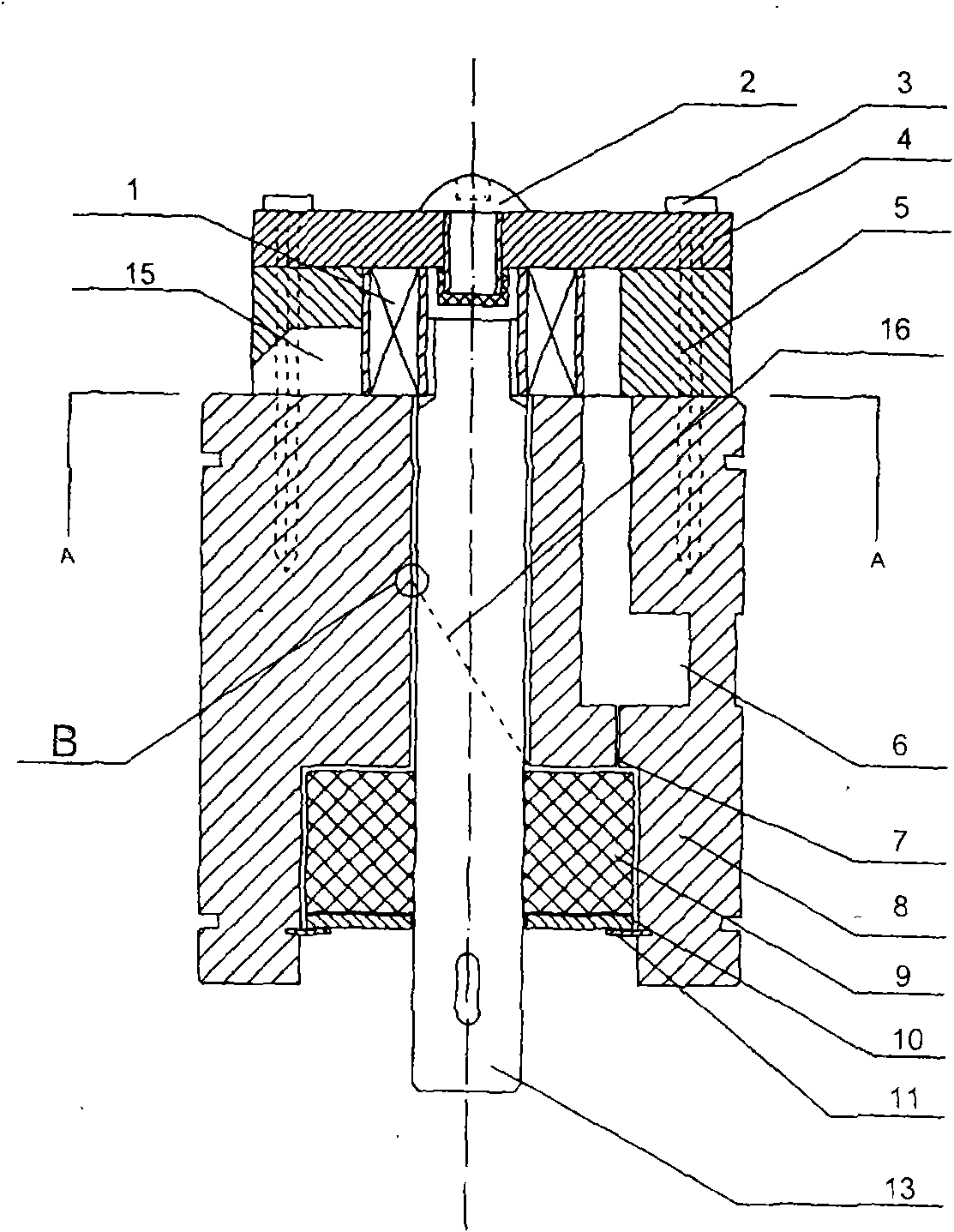

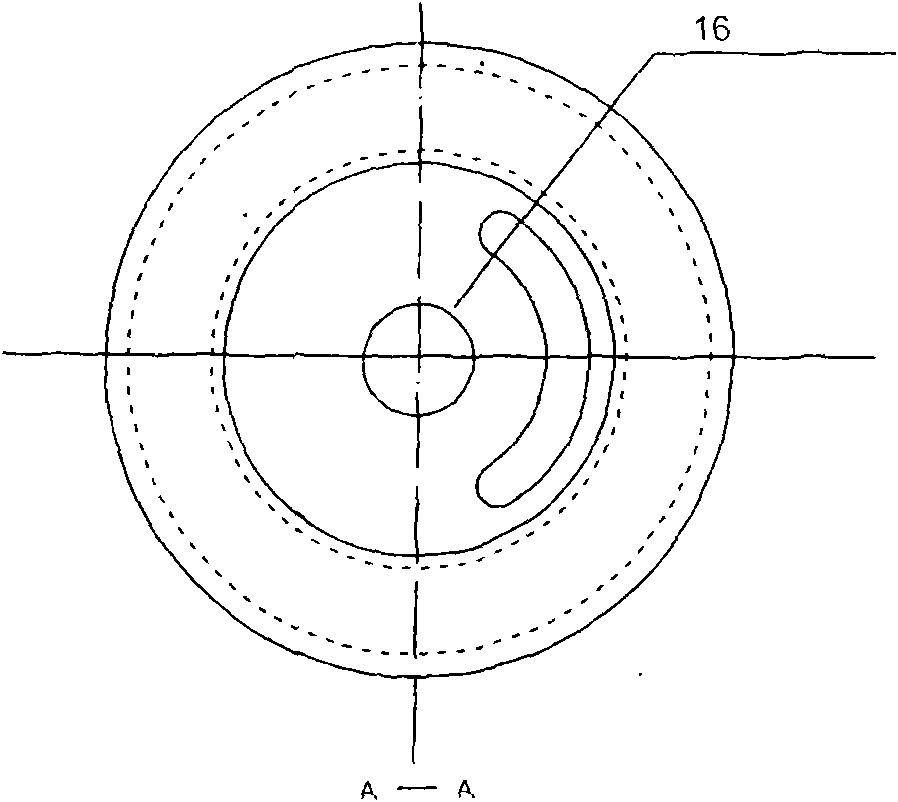

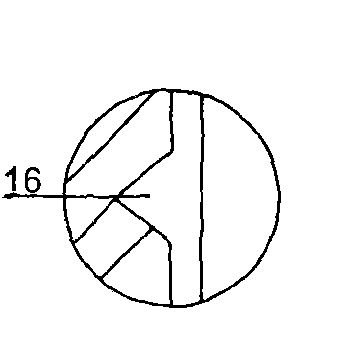

[0018] In the figure 1. blade, 2. shaft pin screw, 3. screw, 4. end cover, 5. pump cavity (stator), 6. oil inlet ring, 7. small oil passage, 8. pump body bushing, 9. Skeleton seal, 10. Retaining ring, 11. Circlip, 13. Shaft, 15. Oil outlet cavity, 16. Spiral oil line.

[0019] figure 1 On the inner surface of the pump body bushing 8 and along the axial direction, a helical oil line 16 is installed, the shaft 13 is put into the inside of the pump body bushing 8, the upper end of the shaft 13 is equipped with the blade 1, and the lower end of the shaft 13 is equipped with the skeleton seal 9. Install retaining ring 10, install circlip 11, install pump cavity 5 and end cover 4 on the upper part of pump body bushing 8, and screw 3 to fasten pump body bushing 8, pump cavity 5 and end cover 4 on Together, finally install the shaft pin screw 2; the oil inlet ring 6, the small oil passage 7, the helical oil line 16, and the oil outlet chamber 15 form an oil return path to communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com