Tilting pad thrust bearing of tail gas expansion machine

An exhaust gas expander and thrust bearing technology, applied in the field of thrust bearings, can solve the problems of old-fashioned design that cannot meet long-term stable operation and carbon deposition, and achieve the effects of reducing carbon deposition, avoiding carbon deposition and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

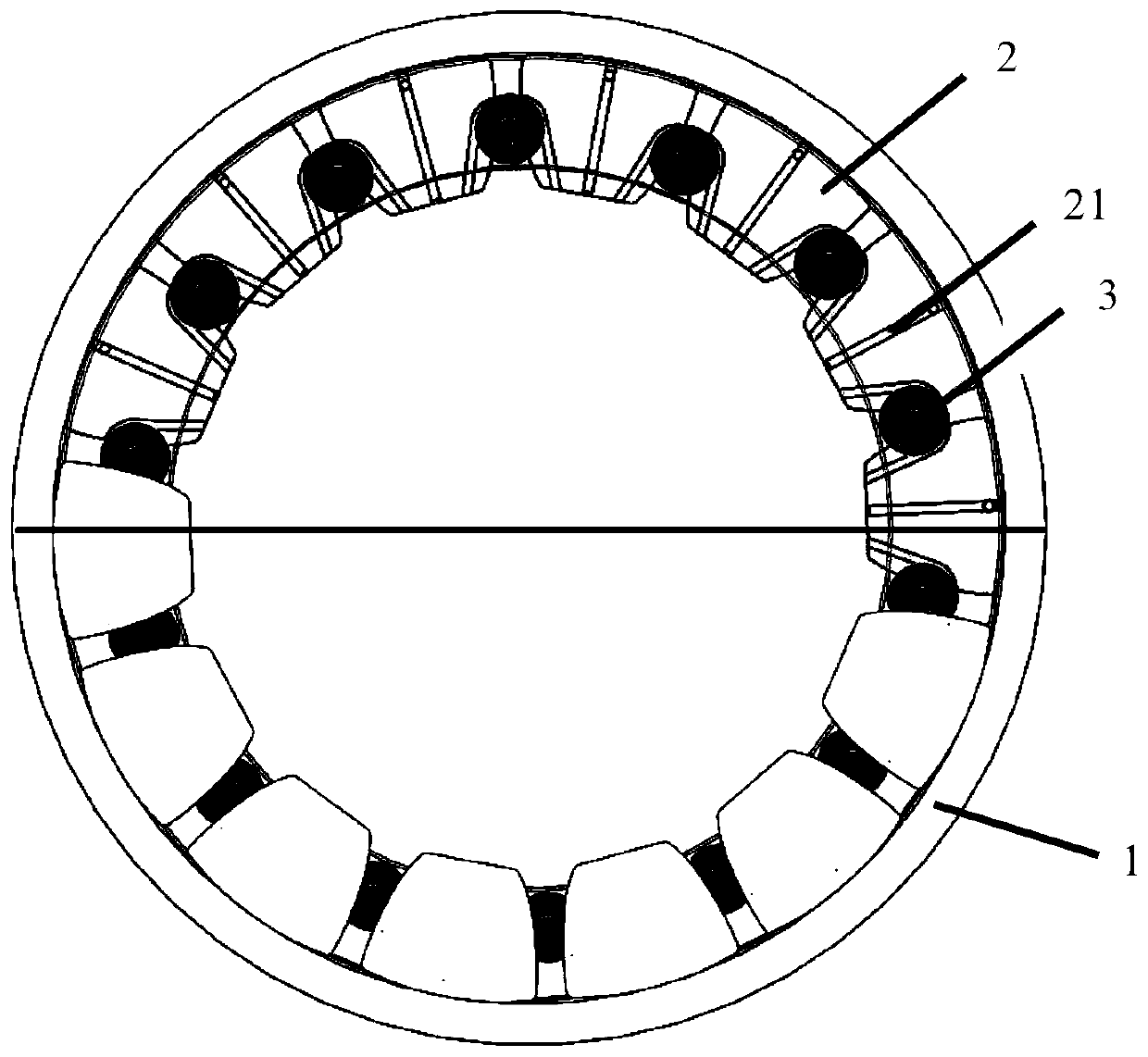

[0030] Such as figure 1 and figure 2 The basic structure of the old-fashioned bearing shown has a symmetrical center support rib on the back of the pad. Under the action of oil pressure, the pad swings and tilts around the support rib, thereby forming a wedge-shaped gap between the thrust plate and the thrust pad. When the rotor rotates At the same time, the oil is continuously brought into the wedge-shaped gap to form a dynamic pressure oil film with pressure resistance to withstand the axial thrust of the exhaust gas expander and transmit the thrust to the bearing seat.

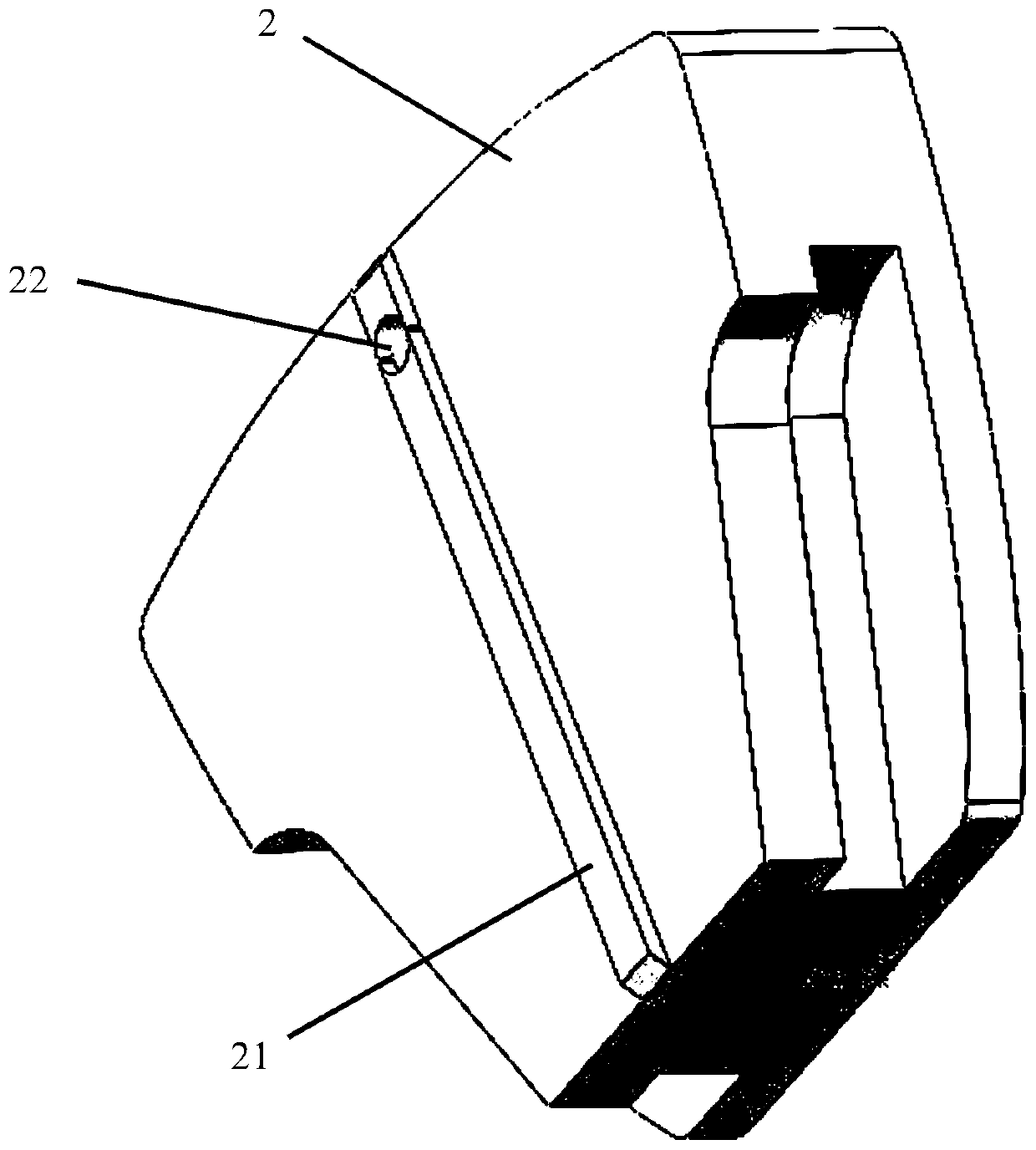

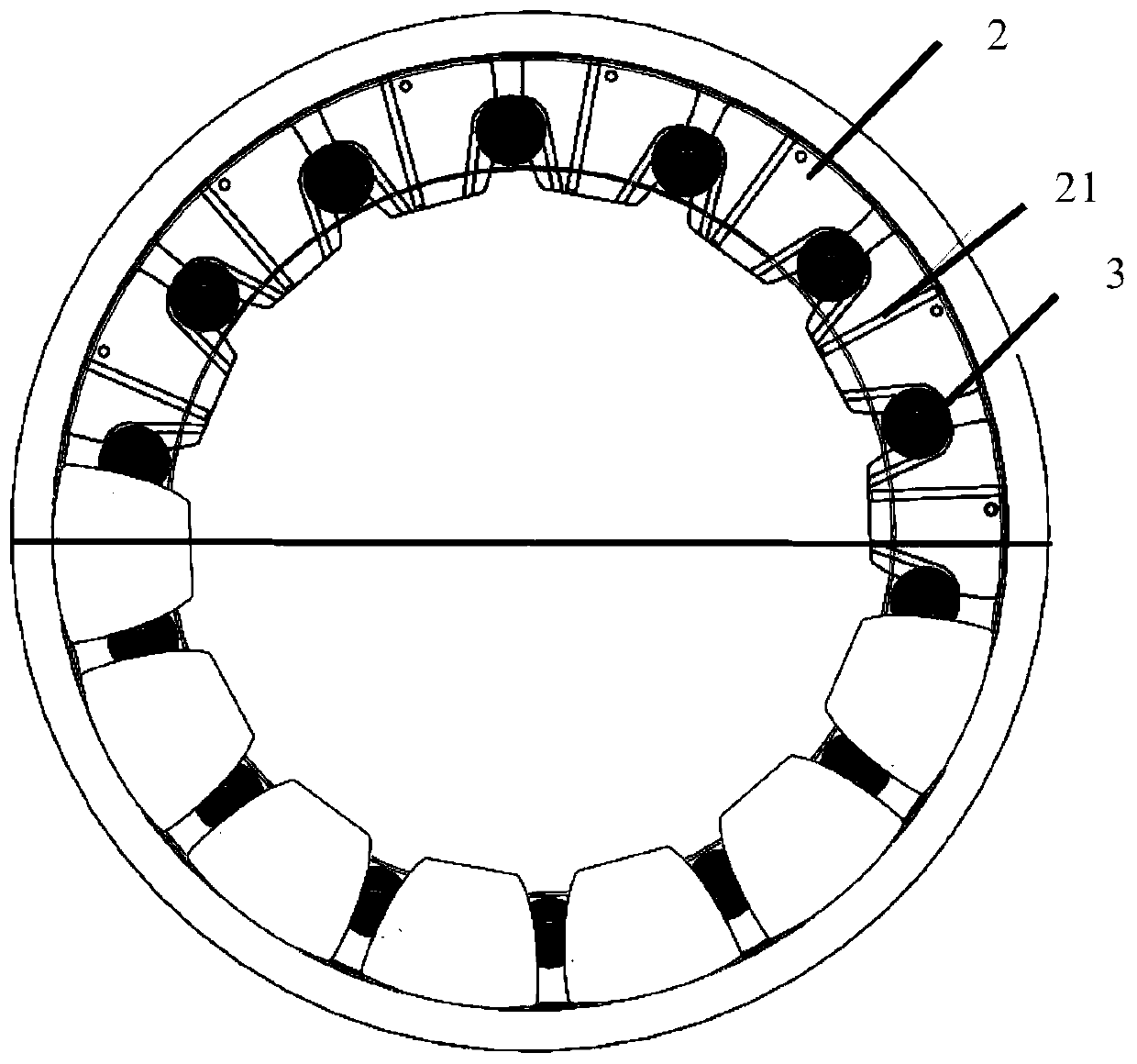

[0031] Such as image 3 and Figure 4 As shown, the present invention provides a tiltable pad thrust bearing of an exhaust gas expander. The extension direction of the support ribs of the pads is all extended in the radial direction with the geometric center of the thrust bearing as the center point; the support ribs are divided according to the golden section from the middle position The line deviates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com