General centrifugal fan capable of being rapidly arranged

A centrifugal fan, fast technology, applied in parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., to achieve the effects of shortening disassembly time, reducing processing costs, and reducing switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

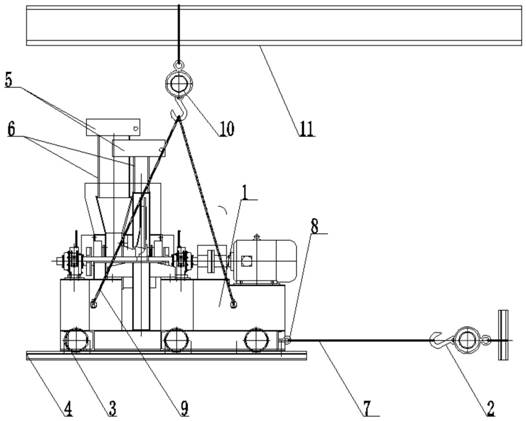

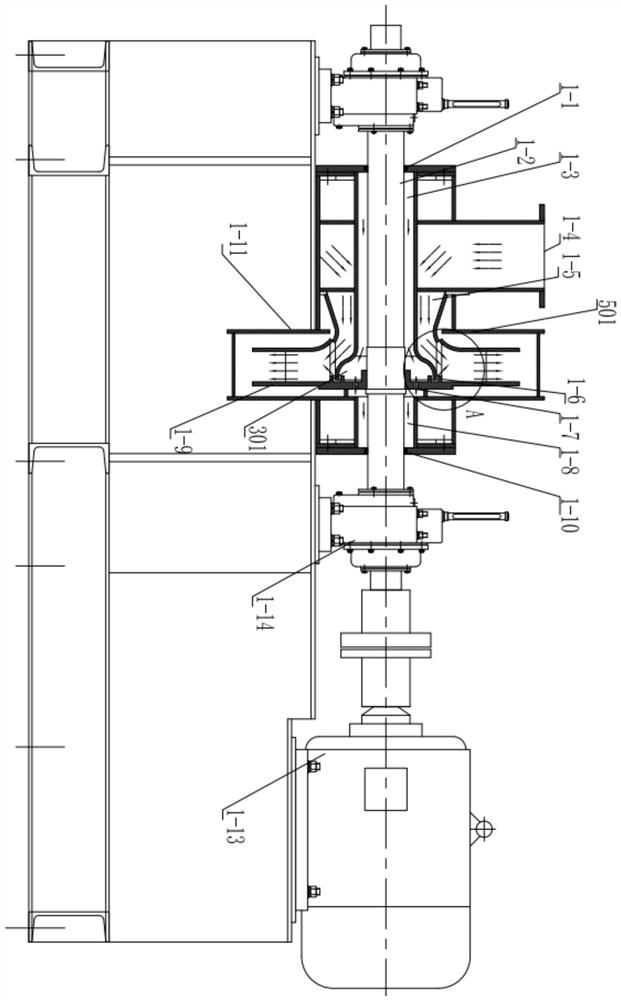

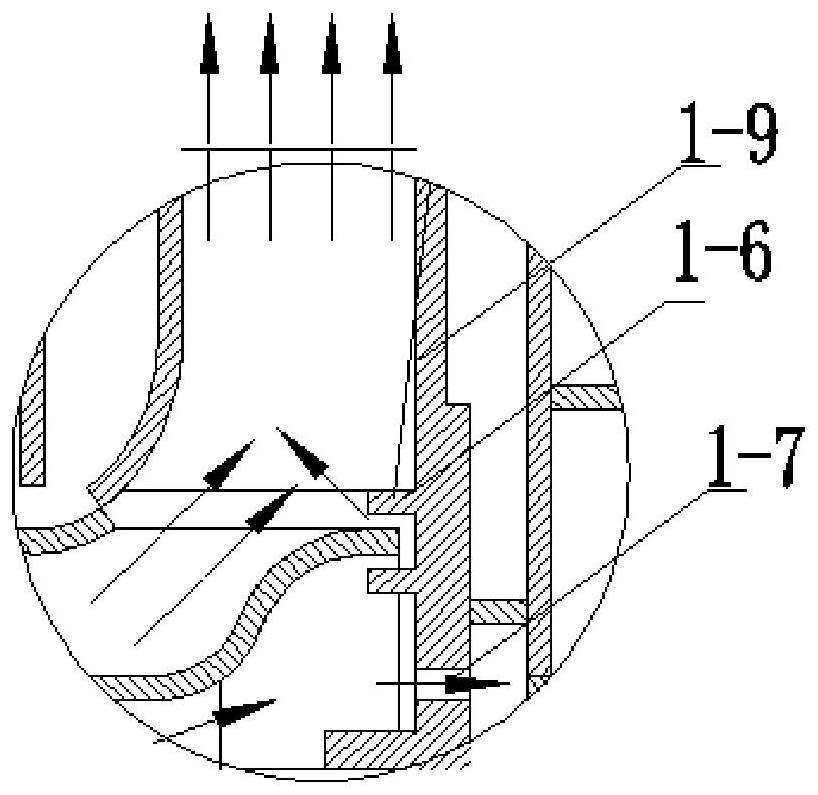

[0022] like Figure 1-3 As shown, the general-purpose centrifugal fan that can be quickly arranged includes a general-purpose centrifugal fan body 1. The general-purpose centrifugal fan body 1 is provided with an air inlet and an air outlet. It is characterized in that: the top of the general-purpose centrifugal fan body is equipped with a 1. The top hoisting machine 10 lifted off the ground. The body of the universal centrifugal fan is provided with connecting lugs for connecting with the hoisting rope 9 of the top hoisting machine. The hoisting rope 9 is connected to the top hoisting machine 10, and the top hoisting machine 10 is installed on the top On the hoisting mechanical beam 11. The front side of the general centrifugal fan body is provided with a pull hook 8, which is connected with a steel wire rope 7, and the steel wire rope 7 is connected with the cable hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com