Bio-particle fuel burner

A technology of biological particles and burners, which is applied to the combustion, combustion and ignition of solid fuels, combustion methods, etc., can solve the problems of difficulty in improving the automation level of feeding, expanding the source of granular materials, and inability to directly input sawdust, etc., so as to improve the utilization rate of energy. , The effect of improving fuel utilization and rapid ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

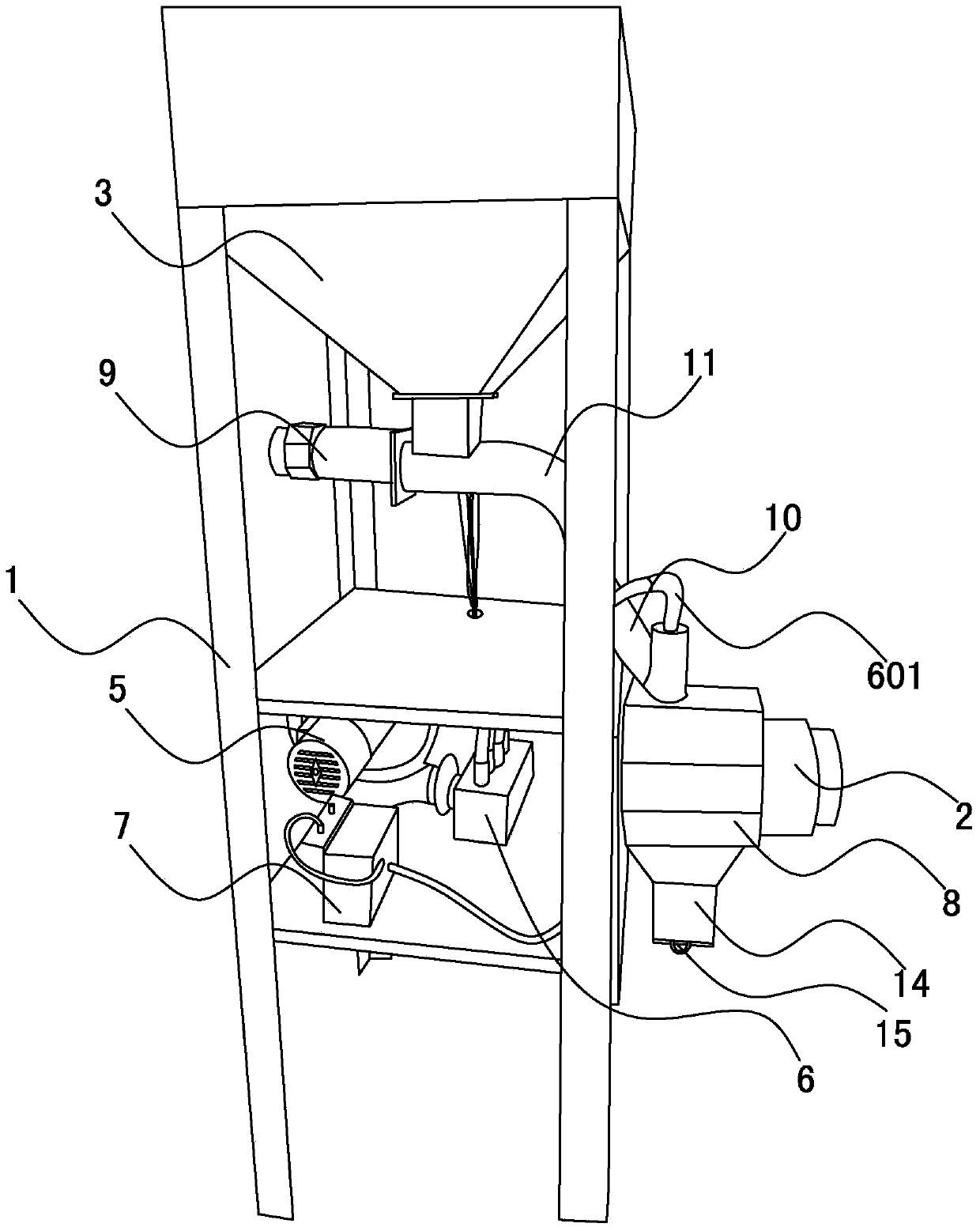

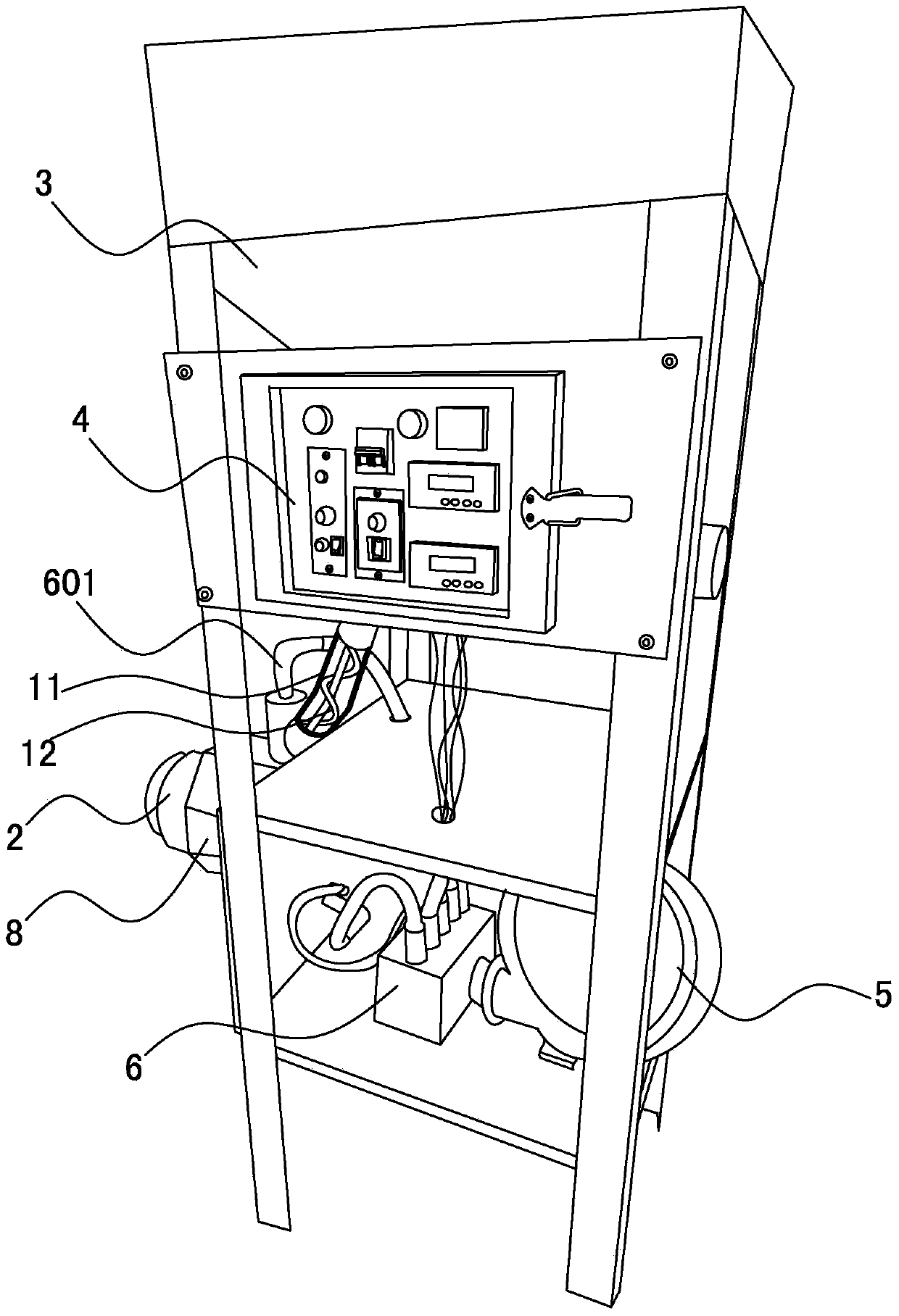

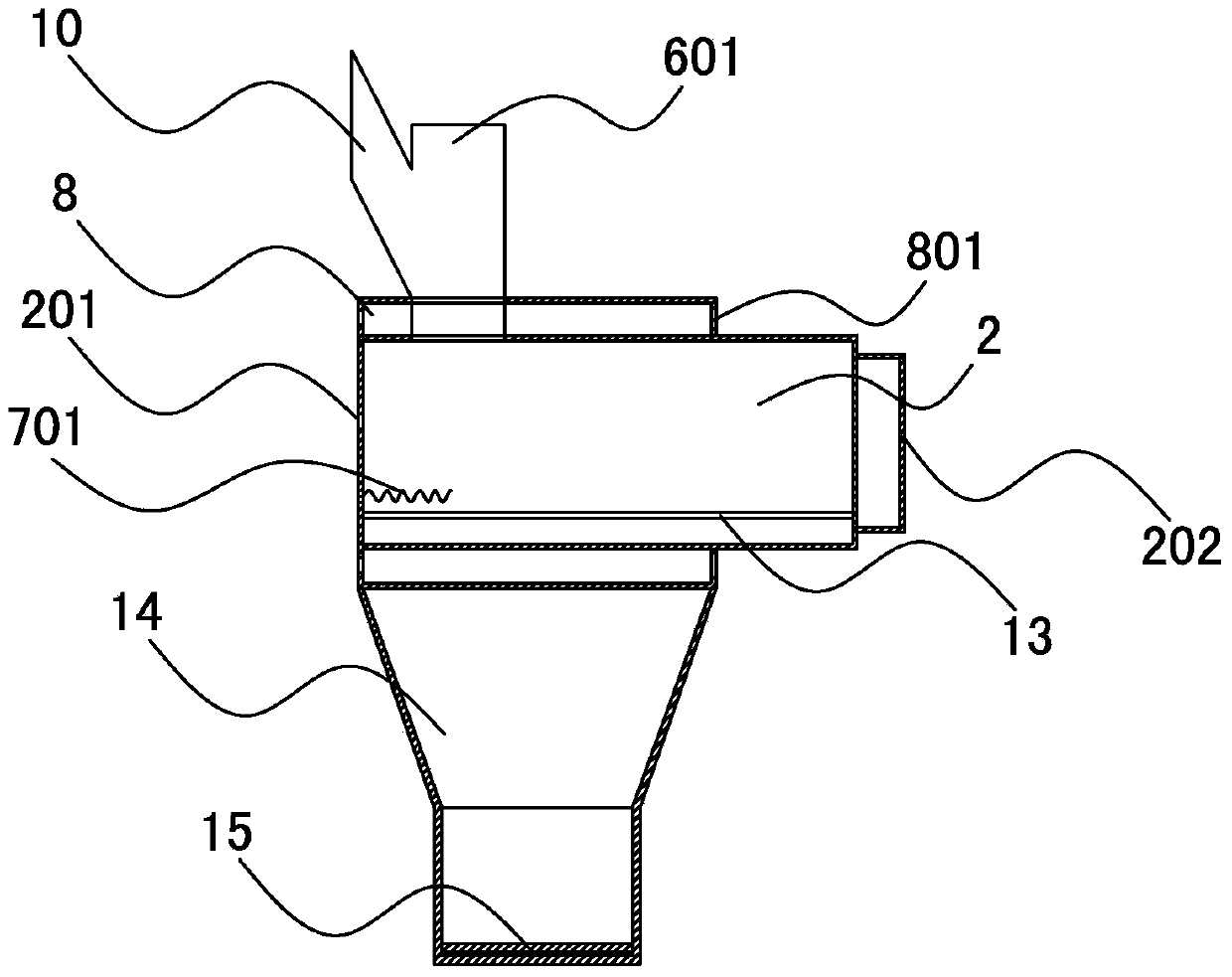

[0016] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0017] refer to figure 1 , figure 2 , image 3 , the biomass pellet fuel burner of the present invention comprises a frame 1 and a combustion chamber 2, a feed bin 3, a PLC controller 4, a temperature sensor, a blower 5, an air adjustable splitter device 6, and an ignition device arranged on the frame 1 7. Waste heat recovery device 8, alarm and material detector, the silo 3 is provided with a discharge device 9, the combustion chamber 2 is provided with a feed pipe 10 communicated with the discharge device of the silo 3, the The temperature sensor is located in the combustion chamber 2, and the air blower 5 is connected with the air inlet 201 of the combustion chamber 2 through the air adjustable splitter 6 to adjust the firepower of the combustion chamber 2 fire outlet 202, and the air adjustable splitter 6 The gas outlet 601 of the shunt outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com