Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

A technology of proton exchange membrane and water electrolysis, which is applied in the direction of battery electrodes, solid electrolyte fuel cells, fuel cells, etc., can solve the problems of high cost and high load capacity, avoid hot pressing deformation, improve utilization rate, and protect the diffusion layer Substrate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

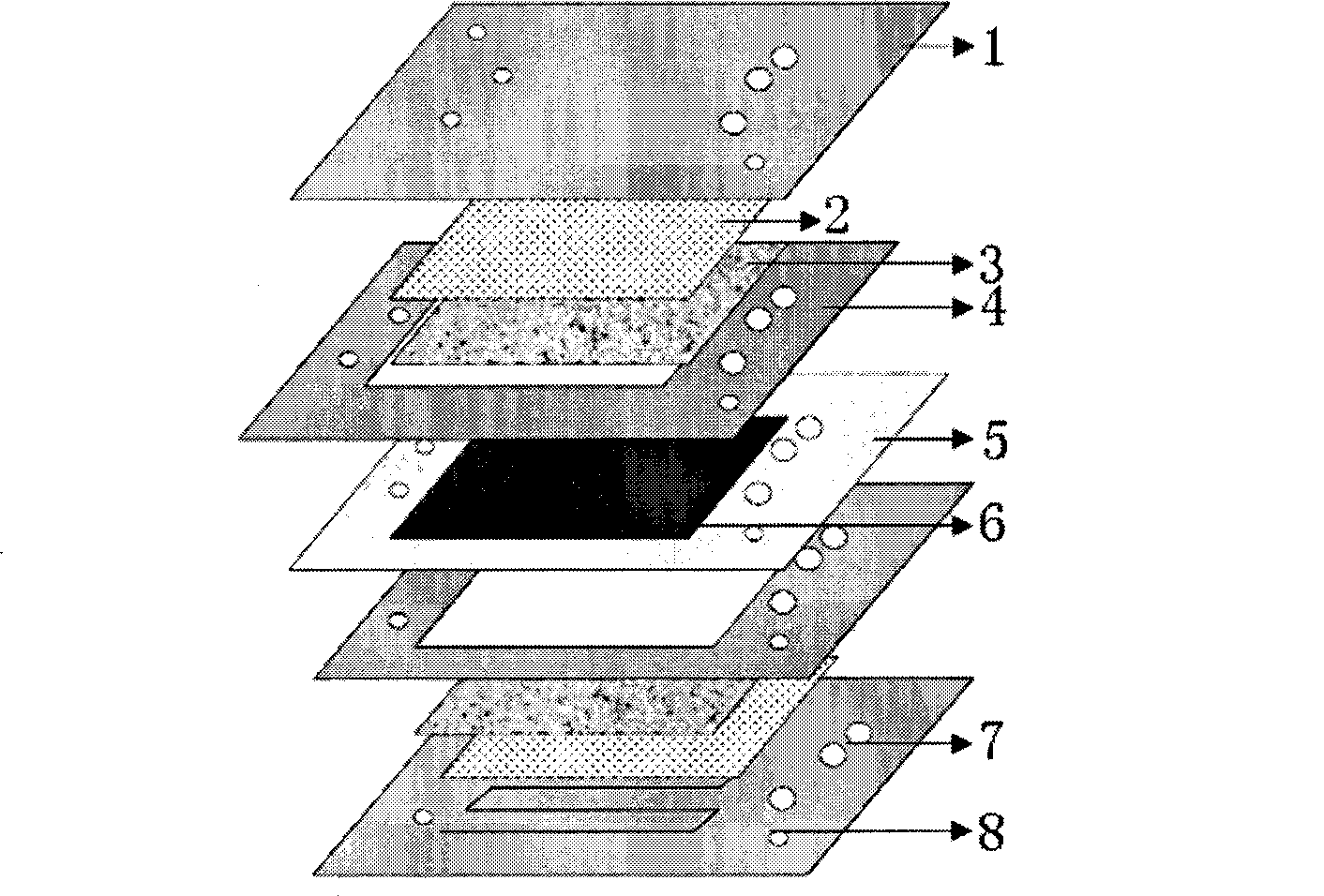

[0044] Such as figure 1 As shown, the membrane electrode of the proton exchange membrane water electrolysis battery involved in this embodiment includes a flow field plate 1, a support layer 2, a diffusion layer 3, and a hydrophilic thin layer structure 5, wherein:

[0045] The hydrophilic thin-layer structure 5 is formed by coating the anode (oxygen electrode) catalytic layer and the cathode (hydrogen electrode) catalytic layer on both sides of the polymer electrolyte membrane respectively.

[0046] The diffusion layer 3 includes an anode (oxygen electrode) diffusion layer and a cathode (hydrogen electrode) diffusion layer.

[0047] On both sides of the hydrophilic thin-layer structure 5, the anode (oxygen electrode) diffusion layer or cathode (hydrogen electrode) diffusion layer, support layer 3, and flow field plate 1 with a microporous structure are stacked in sequence. Tightly, a water electrolysis cell is formed, in which the hydrophilic thin-layer structure 5 and the d...

Embodiment 2

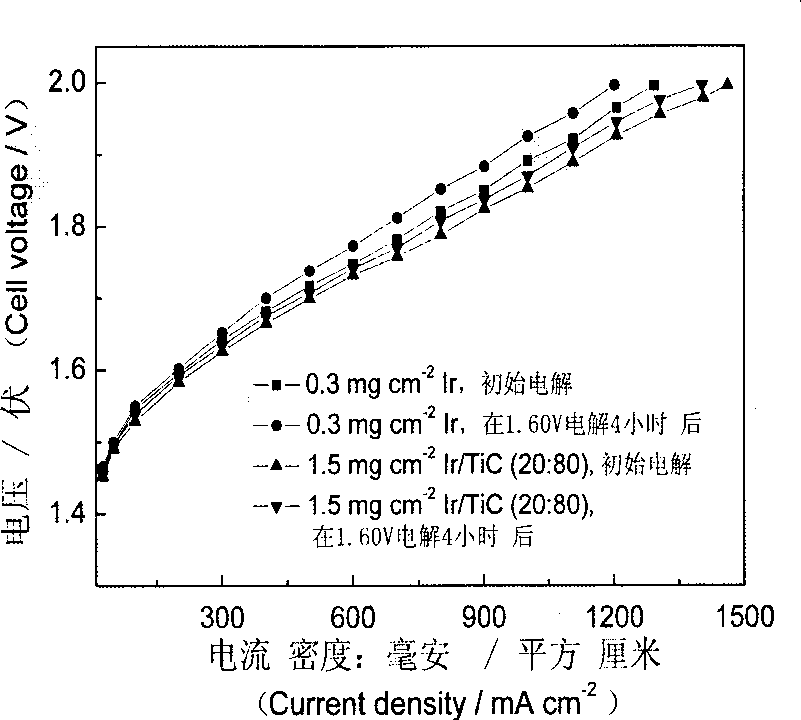

[0066] 1. Weigh 0.2086 g of TiC powder, add a small amount of isopropanol and an appropriate amount of double distilled water, ultrasonically disperse to make a suspension, add 0.1162 g (NH 4 ) 2 IrCl 6 , ultrasonically dispersed and heated to 80°C, and kept at a constant temperature for 40 minutes. The reducing agent solution (HCHO:NH 3 :H 2 O≈2:1:21, weight percent), constant temperature ultrasonic reaction for 1 hour, cooled to room temperature. Suction filter and wash the slurry until the Cl in the filtrate - The content is lower than 40ppm. In a flowing Ar atmosphere, dry at 80°C for 1 hour, then heat-treat at 500°C for 30 minutes, and then get the Ir / TiC supported catalyst (weight ratio 20:80) after cooling.

[0067] 2. Weigh 31 mg of Ir / TiC catalyst (weight ratio 20:80), add 435 mg of isopropanol and mix evenly, add 270 mg of 5% Nafion solution (perfluorosulfonic acid resin solution produced by U.S. DuPont) and 45 Milligrams of deionized water, mixed evenly, spra...

Embodiment 3

[0074] 1. Weigh 0.2086 g of TiC powder, add a small amount of isopropanol and an appropriate amount of double distilled water, ultrasonically disperse to make a suspension, add 0.1162 g (NH 4 ) 2 IrCl 6 , ultrasonically dispersed and heated to 80°C, and kept at a constant temperature for 40 minutes. The reducing agent solution (HCHO:NH 3 :H 2 O≈2:1:21, weight percent), constant temperature ultrasonic reaction for 1 hour, cooled to room temperature. Suction filter and wash the slurry until the Cl in the filtrate -The content is lower than 40ppm. In a flowing Ar atmosphere, dry at 80°C for 1 hour, then heat-treat at 500°C for 30 minutes, and then get the Ir / TiC supported catalyst (weight ratio 20:80) after cooling.

[0075] 2. Weigh 31 mg of Ir / TiC catalyst (weight ratio 20:80), add 435 mg of isopropanol and mix evenly, add 270 mg of 5% Nafion solution (perfluorosulfonic acid resin solution produced by U.S. DuPont) and 45 Milligrams of deionized water, mixed evenly, spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com