Clamping-plate support of hub-type joint net rack

A splint type, node technology, applied in the direction of architecture, building structure, etc., can solve the problem that the anti-risk ability needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

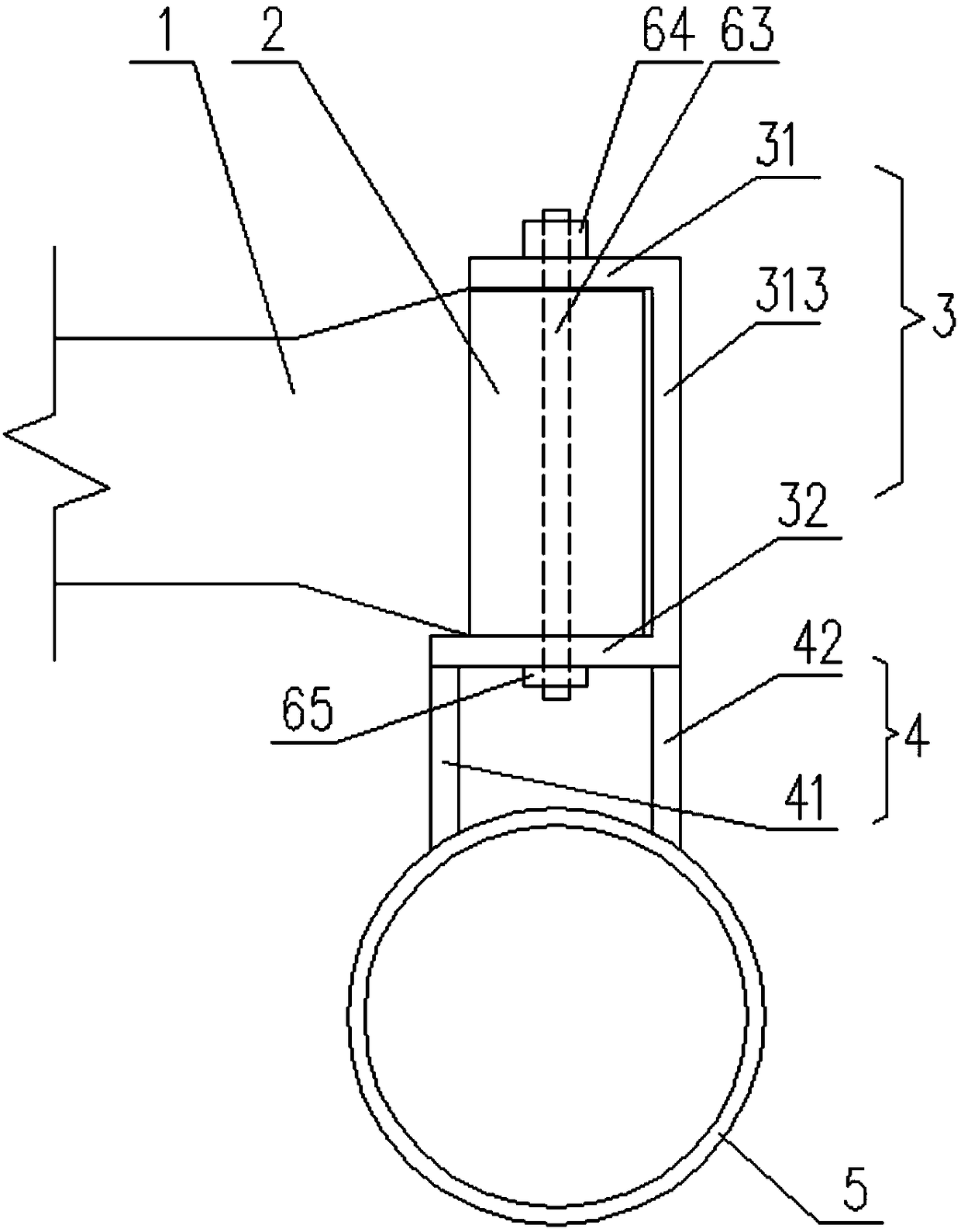

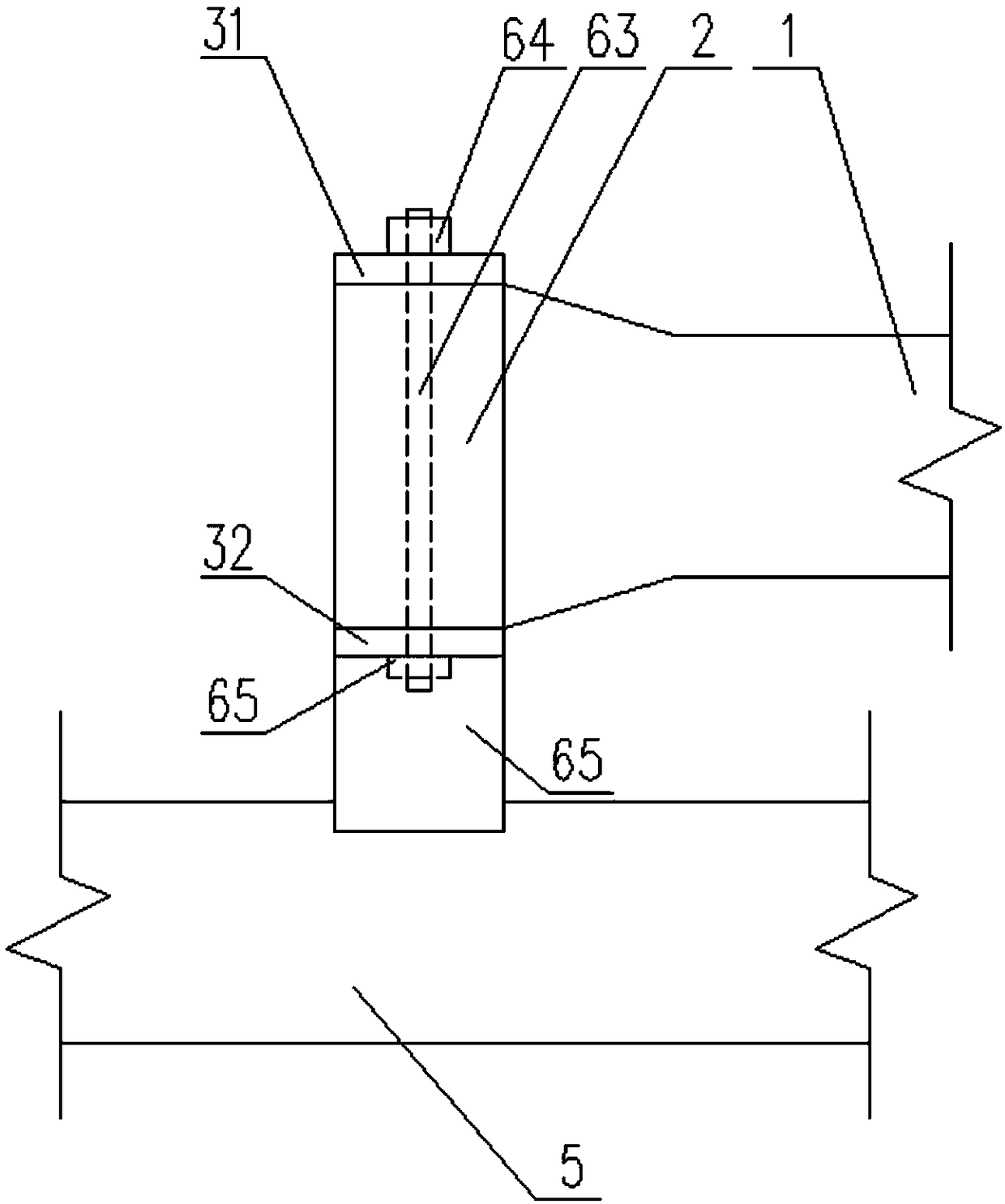

[0038] Such as Figure 1-2 As shown, the present embodiment provides a splint-type support of a hub-type node network frame, including: a holding part 3 having a fixed end plate and a first blocking end plate 31 arranged in parallel on one side of the fixed end plate 313 and The second blocking end plate 32, a positioning groove suitable for inserting the hub node 2 is enclosed between the two blocking end plates and the fixed end plate, and the hub node 2 is inserted into the positioning groove to the limit position, and the two blocking end plates form a blocking and clamping structure at both ends of the hub node 2 in the axial direction; the locking assembly includes sequentially passing through the first The blocking end plate 31, the hub node 2, the penetrating piece of the second blocking end plate 32, and the two ends of the penetrating piece are adapted to limit the axis of the penetrating piece along the hub node 2. A locking member to be displaced; a connecting mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com