Prefabricated subway shield segment and detection and installation method thereof

A technology of shield segment and installation method, which is applied in the direction of measuring devices, underground chambers, shaft equipment, etc., and can solve problems such as uneven quality of shield segments, uncompact splicing, and poor waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

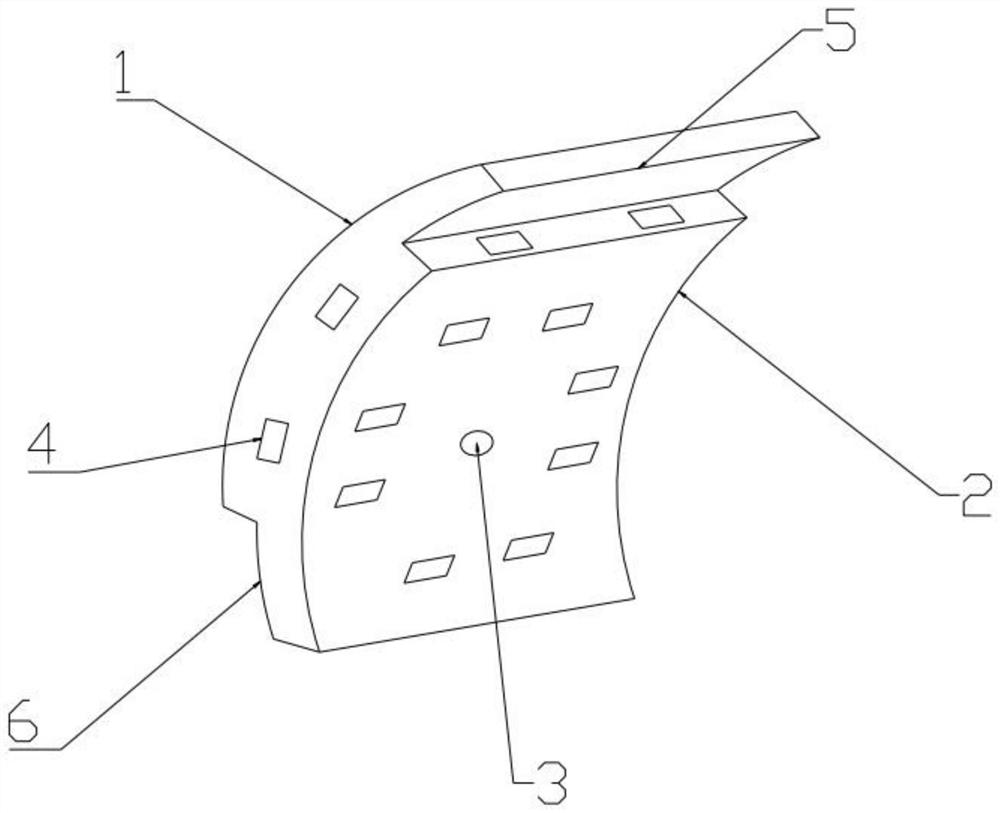

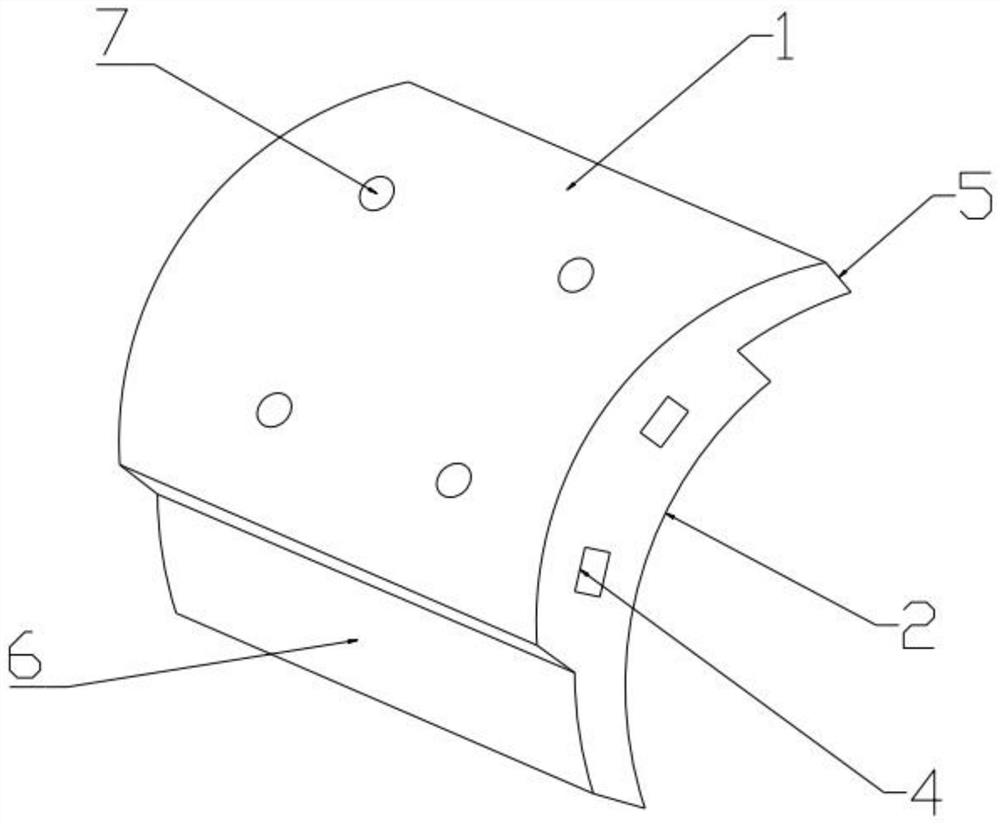

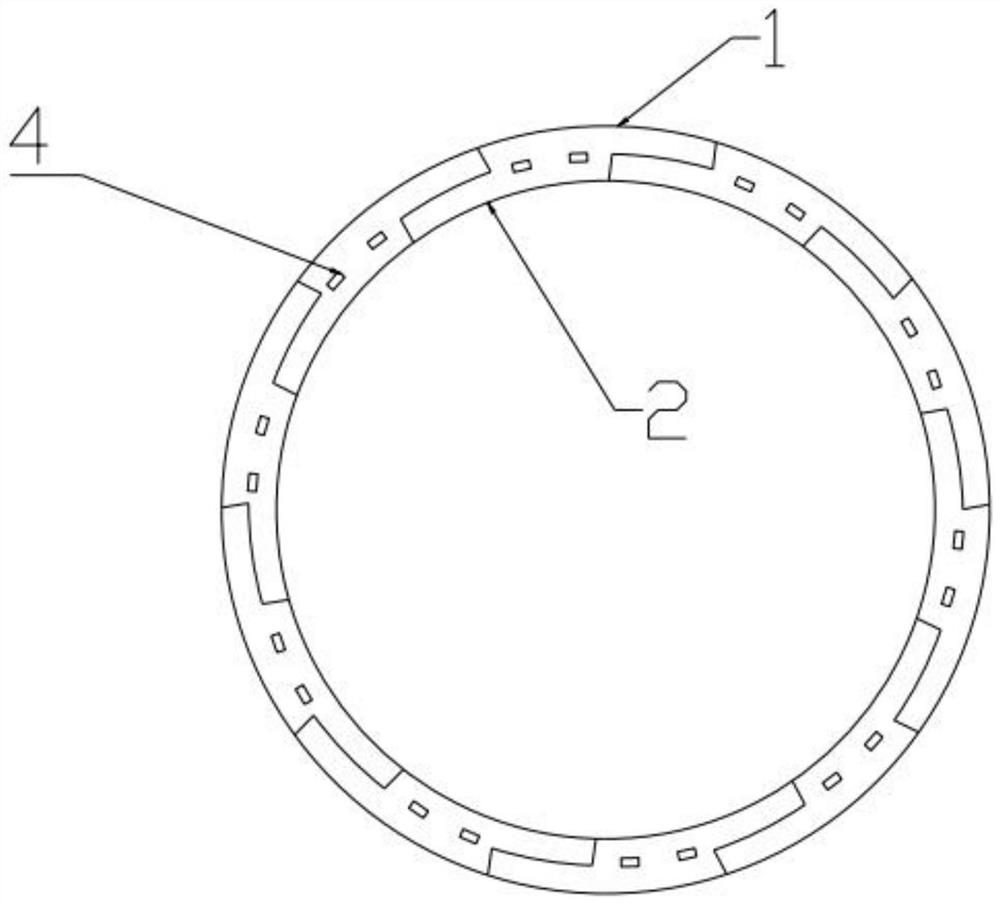

[0032] Specific implementation plan one: combine Figure 1 to Figure 4 As shown, the present invention provides a prefabricated subway shield segment, the shield segment is an arc-shaped body, one end of the shield segment is a first stepped structure 5, and the other end of the shield segment For the second stepped structure 6 matching the first stepped structure 5, the first stepped structure 5 for the shield segment is connected to the second stepped structure 6 of the adjacent shield segment, and the shield segment The inner arc surface 2 of the shield segment is provided with a first grouting hole 3, and the outer arc surface 1 of the shield segment is provided with at least three second grouting holes 7, and the first grouting hole 3 and the second injection hole The grout hole 7 forms a connecting pipe inside the shield segment, which is used for the secondary grouting process to allow the grout to quickly fill the gap between the shield segment and the soil body. Both ...

specific Embodiment approach 2

[0034] Specific implementation plan two: combine Figure 1 to Figure 4 As shown, the radian threshold of the shield segment is π / 8-π / 5, that is, the 10-16 ring shield segment structure is used for staggered annular splicing, which can be adjusted accordingly according to the construction environment. The other combinations and connections of this embodiment are the same as those of Embodiment 1.

specific Embodiment approach 3

[0035] Specific implementation plan three: combination Figure 1 to Figure 4 As shown, the arc length of the connecting part of the first stepped structure 5 and the second stepped structure 6 accounts for 1 / 3-1 / 2 of the arc length of the outer arc surface 1 of the shield segment. The setting of the arc length of the connecting part of the first stepped structure 5 and the second stepped structure 6 can ensure the stability of the connecting part and facilitate the installation of positioning bolts. The other combinations and connections of this embodiment are the same as those of Embodiment 1.

[0036] Specific implementation plan four: combination Figure 1 to Figure 4As shown, at least two bolt holes 4 are provided on both sides of the shield segment, and at least six bolt holes 4 are arranged on the inner arc surface 2 of the shield segment in a circular shape. The first stepped structure 5 At least two bolt holes 4 are provided on the end face of the joint with the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com