Coating liquid for heating incombustible tobacco product cigarette paper and preparation method and application of coating liquid

A heat-not-burn and tobacco product technology, applied in paper coating, textile and papermaking, coating, etc., to achieve the effect of light weight, fast heat dissipation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

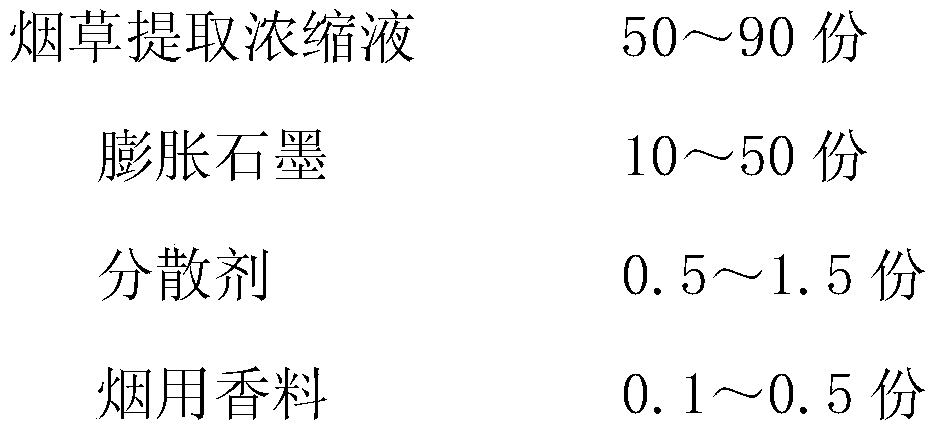

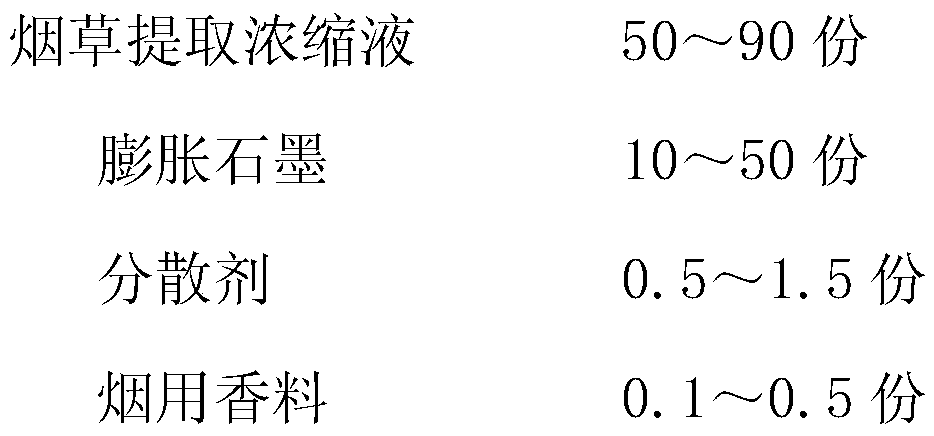

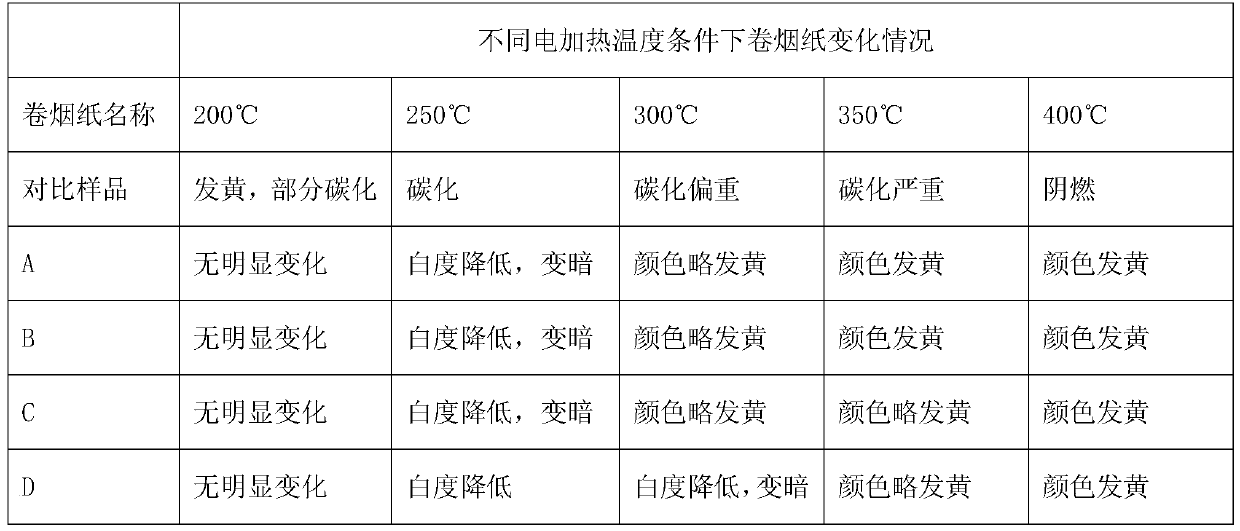

[0042] Example 1 provides a coating solution for heat-not-burn tobacco product cigarette paper, the specific preparation method is as follows: take 50 parts by weight of tobacco extract concentrate, 10 parts by weight of expanded graphite particles treated by the above method, 0.5 3% sodium alginate aqueous solution and 0.1 weight part damascenone were mixed evenly in parts by weight and dispersed by ultrasonic wave for 10 minutes to obtain the coating solution A for cigarette paper of heat-not-burn tobacco products.

[0043] Coating solution A for cigarette paper of heat-not-burn tobacco products prepared in Example 1 is uniformly coated on one side of the base paper of the above-mentioned cigarette paper, and the coated base paper is dried at 50°C , slice to get cigarette paper A.

Embodiment 2

[0044] Example 2 provides a coating solution for heat-not-burn tobacco product cigarette paper, the specific preparation method is as follows: take 60 parts by weight of tobacco extract concentrate, 15 parts by weight of expanded graphite particles treated by the above method, 0.8 The 3% sodium alginate aqueous solution and 0.15 weight part of Turkone were mixed uniformly and ultrasonically dispersed for 10 minutes to obtain the coating liquid B for cigarette paper of heat-not-burn tobacco products.

[0045] Coating liquid B prepared in Example 2 for cigarette paper of heat-not-burn tobacco products is evenly coated on one side of the base paper of the above-mentioned cigarette paper, and the coated base paper is dried at 55°C , slice to get cigarette paper A.

Embodiment 3

[0046] Example 3 provides a coating solution for heat-not-burn tobacco product cigarette paper, the specific preparation method is as follows: take 80 parts by weight of tobacco extract concentrate, 30 parts by weight of expanded graphite particles treated by the above method, 1.0 2% carboxymethyl cellulose aqueous solution by weight and 0.25 weight part Yunyan extract were mixed evenly, and ultrasonically dispersed for 13 minutes to obtain the coating liquid C for cigarette paper of heat-not-burn tobacco products.

[0047] Coating solution C for heat-not-burn tobacco product cigarette paper prepared in Example 3 is evenly coated on one side of the above-mentioned cigarette paper substrate paper, and the coated substrate paper is dried at 55°C , sliced to get cigarette paper C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com