Device for detecting thermal insulation performance of thermal insulation material

A thermal insulation performance, thermal insulation technology, applied in the field of material testing, can solve problems such as deformation refraction, instability, aluminum fiber damage, etc., to achieve the effect of stabilizing the thermal deformation of aluminum, improving accuracy, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

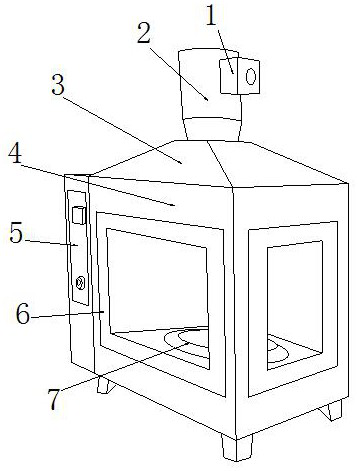

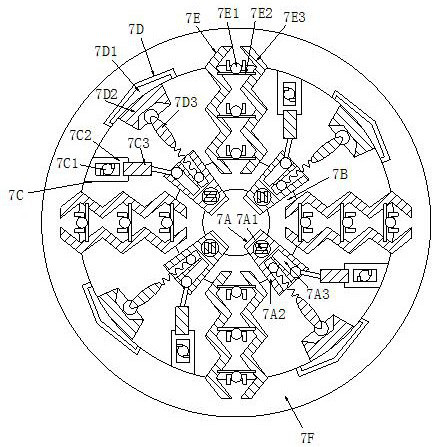

[0033] see Figure 1-Figure 6, the present invention provides a device for detecting the thermal insulation performance of thermal insulation materials, and its structure includes: an intubation column block 1, an exhaust drum 2, a trapezoidal table cover 3, a detection square box 4, and a power distribution control Cabinet 5, observation window 6, and microwave armature tray 7. The microwave armature tray 7 is installed inside the detection square box 4. The observation window 6 and the detection square box 4 are inserted into one body and are on the same vertical plane. The control cabinet 5 is closely attached to the left side of the detection square box 4, the trapezoidal platform cover 3 is nested on the top of the detection square box 4 and penetrates each other, and the exhaust drum 2 is inserted into the trapezoidal platform cover 3 and the axes are collinear, the intubation column block 1 is nested on the right side of the exhaust drum 2, and the microwave armature tr...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a device for detecting the thermal insulation performance of thermal insulation materials, the other aspects are the same as in Embodiment 1, the difference is that:

[0041] see figure 2 , the spark scraper frame 7D is composed of a folding frame scraper 7D1, a trapezoidal column block 7D2, and a spring wire balloon frame 7D3. 7D2 is mechanically connected with the spring wire balloon holder 7D3 and is on the same vertical plane, and the spring wire balloon holder 7D3 elastically presses the trapezoidal column block 7D2 to form an effect of supporting and brushing the middle section of the protective material.

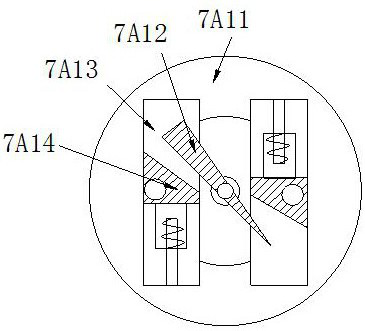

[0042] see Figure 5 , the folding frame scraper 7D1 is composed of a reinforcing rib bar 7D11, a needle frame block 7D12, a curved buckle plate 7D13, and a spring push pad frame 7D14, and the needle frame block 7D12 is inserted in the upper right corner of the reinforcing rib bar 7D11, The reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com