Photoresist composition and preparation method and composition method thereof

A technology of photoresist and composition, which is applied in the field of photolithography, can solve the problems of photoresist peeling and low adhesion of photoresist, and achieve the effect of improving etching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

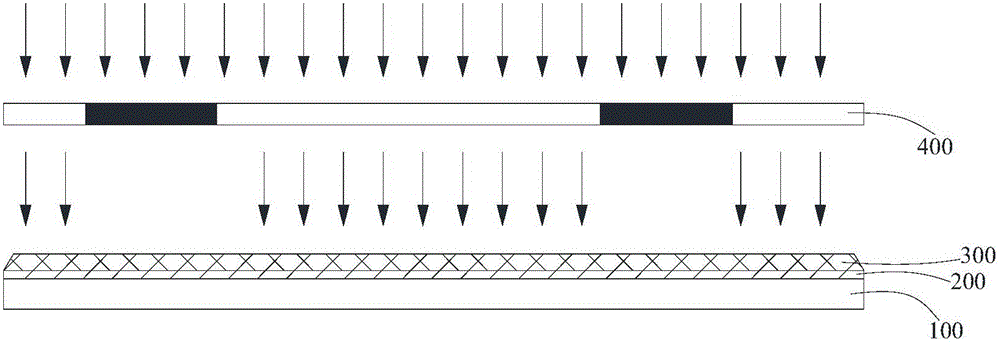

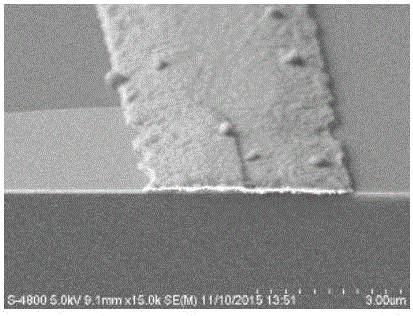

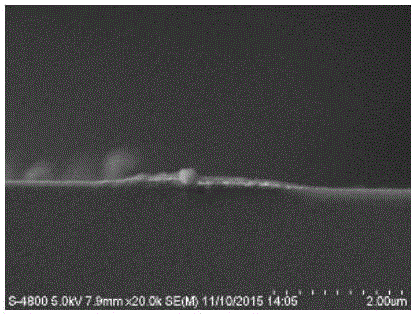

Image

Examples

Embodiment approach

[0077] As a preferred embodiment of the present invention, the first photosensitive resin includes a naphthoquinone-based diazo type photosensitive resin, and the number average molecular weight of the first photosensitive resin is 400-2000. The polymer molecule of the naphthoquinone diazo photosensitive resin contains an ortho-diazonaphthoquinone structure, and the solubility changes from oil-soluble to alkali water-soluble after absorbing light energy.

[0078] As a preferred embodiment of the present invention, the naphthoquinone-based diazo photosensitive resin is esterified with polyhydroxybenzophenone and 2,1-diazonaphthoquinone-5-sulfonyl chloride and / or 2,1- The photosensitive compound is obtained by esterification of naphthoquinone diazonium-4-sulfonyl chloride. Specifically, the general structural formula of the naphthoquinone-based diazo photosensitive resin is:

[0079]

[0080] where R 1 is 2,1-diazonaphthoquinone-5-sulfonyl ester group, R 2 is 2,1-diazonaph...

preparation example

[0164] The second photosensitive resin prepared by the synthesis of formaldehyde N-ethyl 2-nitrodiphenylamine 4-diazo (ENDDS) resin specifically includes the following steps:

[0165] S1, 300g (1.49mol) 2,4-dinitrochlorobenzene was added to 1485mL absolute ethanol, heated to dissolve, and then 173g (1.63mol) anhydrous Na was added 2 CO 3 . Heating to reflux, dripping N-ethylaniline 196.9g (1.63mol), dropping the reaction for 6h, cooling overnight to obtain a large amount of dark red prismatic single crystal A, yield 299g, yield 70%;

[0166] S2, 180g (0.63mol) A was dissolved in 1000mL 95% ethanol, 66.5g (0.63mol) anhydrous Na2CO3 was added, heated to reflux, and 301g (1.25mol) Na was slowly added dropwise 2 S·9H 2 A solution of O dissolved in 500 mL of water was dropped for about 2 hours, then refluxed for 4 hours, and cooled. Pour the reaction mixture into 2000 mL of water, let it stand for a period of time, separate layers, pour the water from the upper layer, and then ...

Embodiment 1

[0173] Weigh 0.4g of Victoria pure blue, 300g of ethylene glycol monoethyl ether, 1g of the second photosensitive resin, 5g of the first photosensitive resin, 10g of polyvinyl formal maleate, and prepare the photoresist composition as follows:

[0174] S10. Dissolve Victoria pure blue in ethylene glycol monoethyl ether;

[0175] S20, successively add the second photosensitive resin, the first photosensitive resin, and polyvinyl formal maleate, and stir until completely dissolved;

[0176] S30, filtering out impurities with filter paper to obtain a photoresist composition.

[0177] Wherein, the first photosensitive resin is PAC-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com