Reflow method, pattern generating method, and fabrication method for TFT element for LCD

A technology for patterning and resist film, which is applied in the field of manufacturing TFT elements for liquid crystal display devices, can solve the problems of increased manufacturing cost, complicated manufacturing process of semiconductor devices, etc., achieves fast flow, omits and reduces the number of processes, and shortens processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Next, preferred embodiments of the present invention will be described with reference to the drawings.

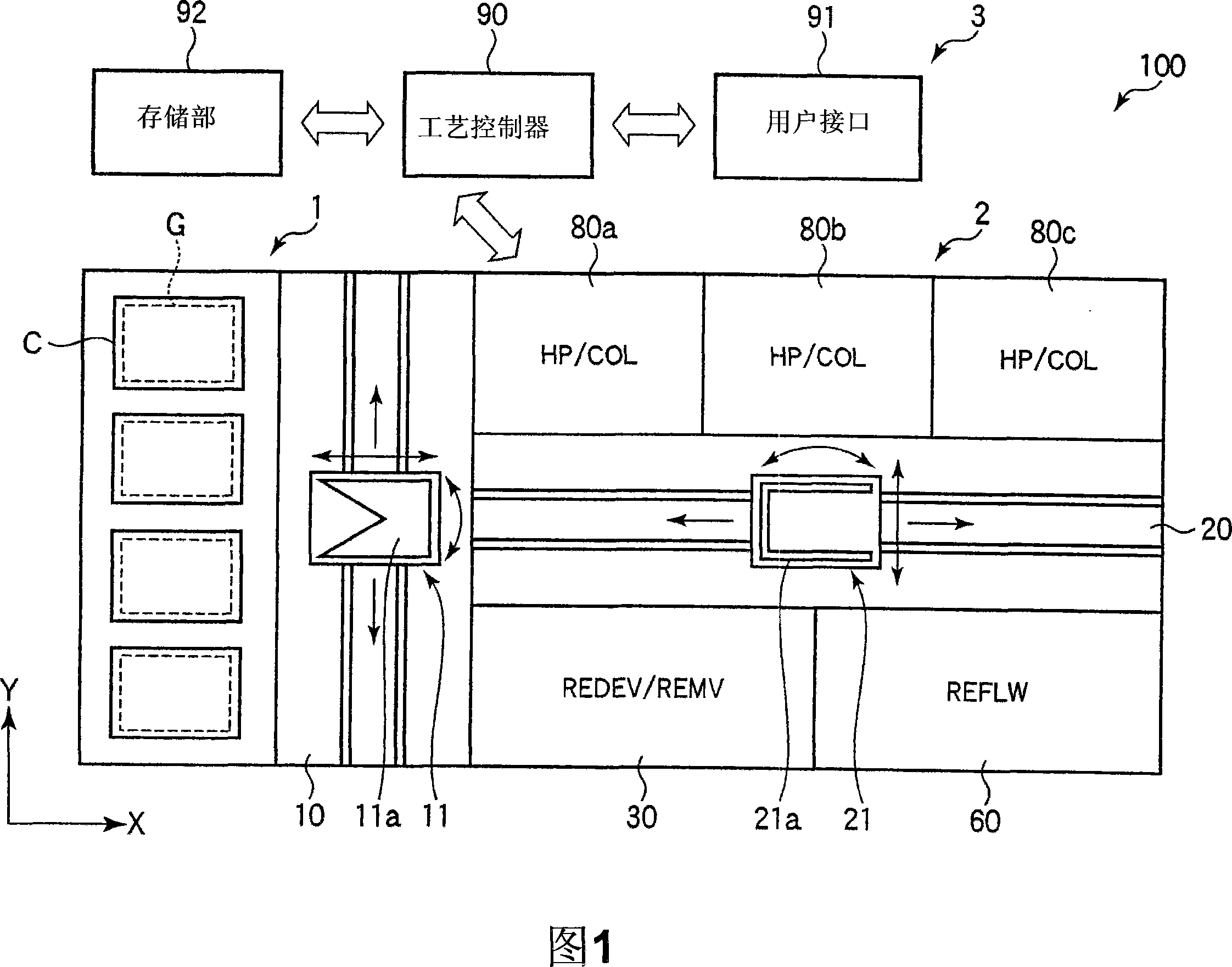

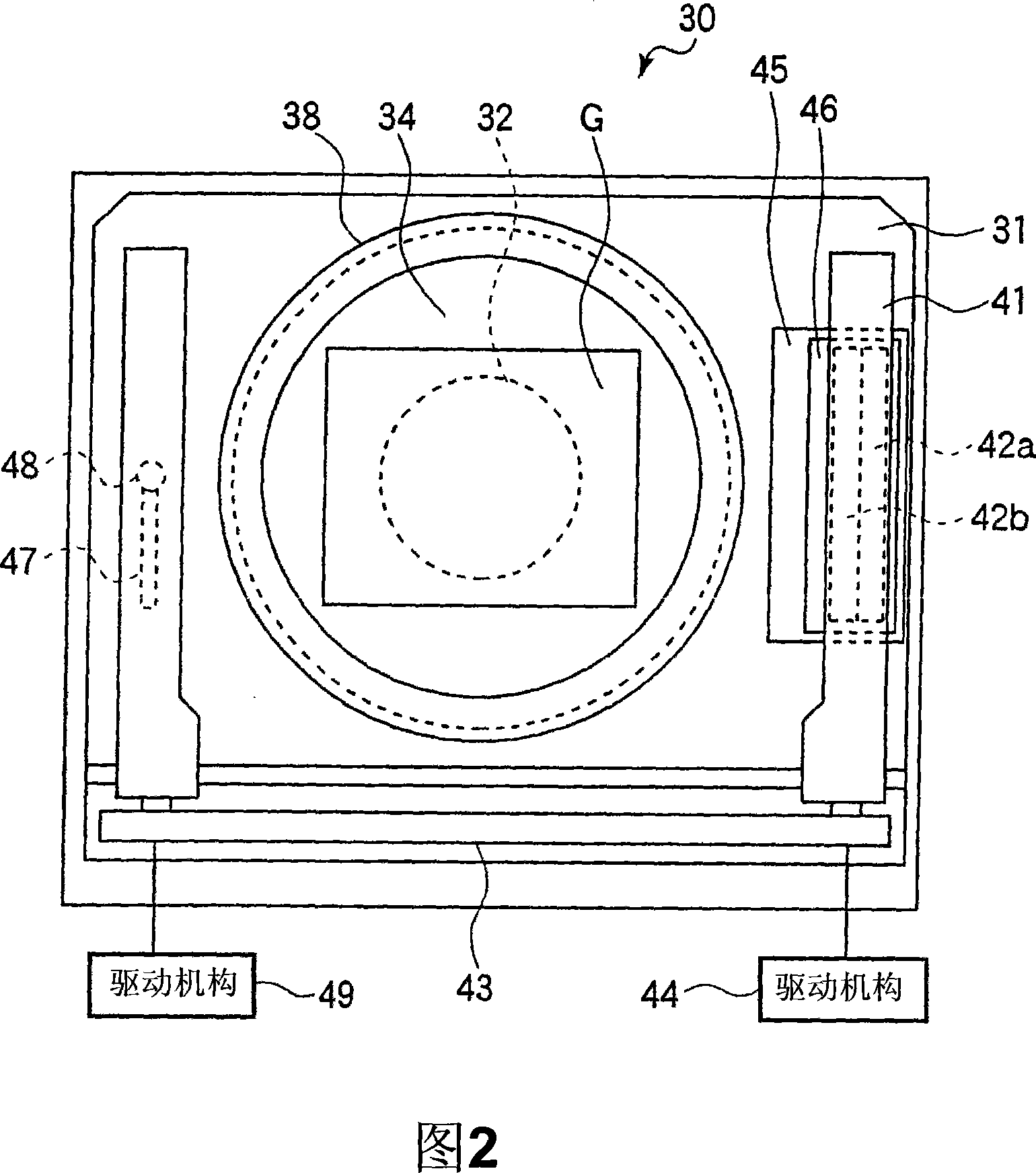

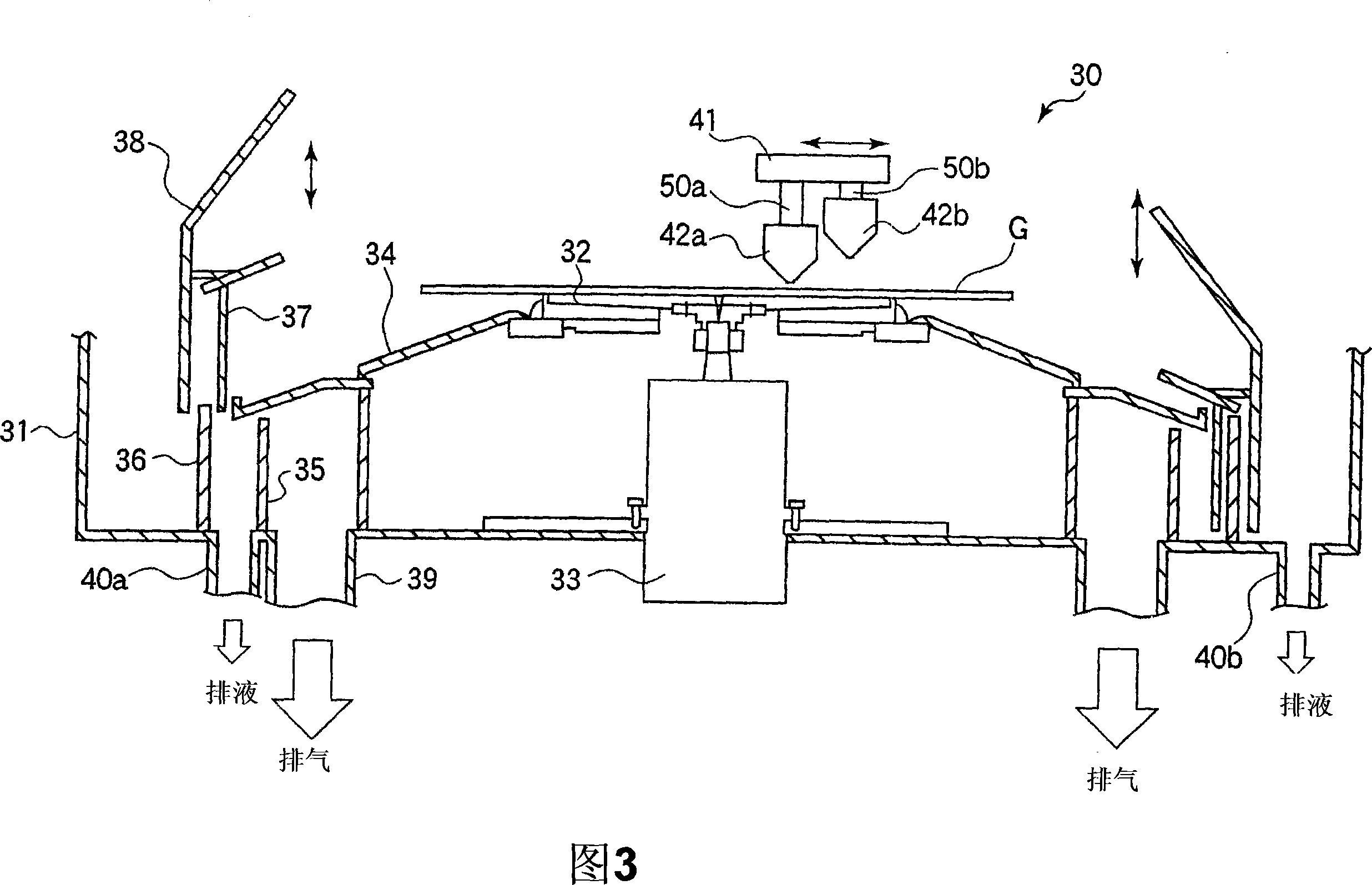

[0091] Fig. 1 is an overall schematic plan view of a releveling treatment system suitable for the releveling method of the present invention. In this embodiment, the resist film formed on the surface of the glass substrate for LCD (hereinafter abbreviated as "substrate") G is softened and deformed after the development treatment, and re-leveling treatment is carried out for re-covering. The re-leveling treatment unit and the re-leveling treatment system of the re-development treatment / release agent unit (REDEV / REMV) for performing the re-development treatment and pre-treatment performed before the re-leveling treatment will be described as an example. This reflow processing system 100 includes a cassette loading and unloading station (loading and unloading section) 1 on which a cassette C accommodating a plurality of substrates G is mounted, and is used to perform re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com