Etching method

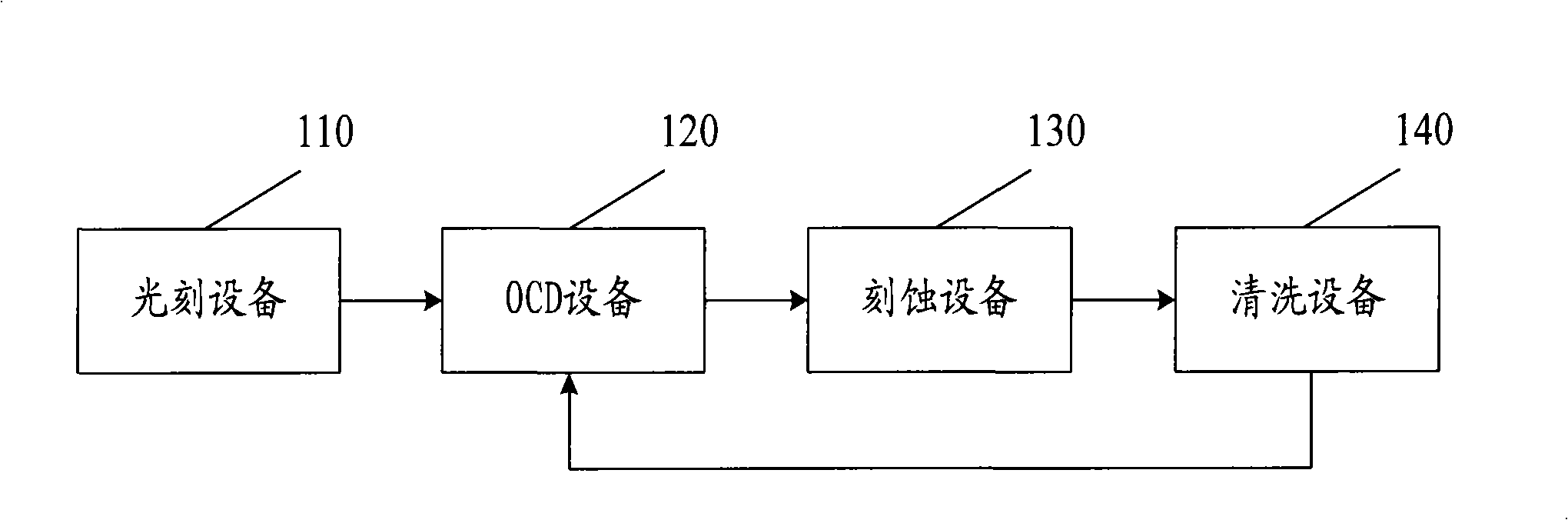

A technology for etching masks and etching equipment, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing product yield, etching rate changes, and different etching results, saving work. time, avoid the deviation of etching results, improve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

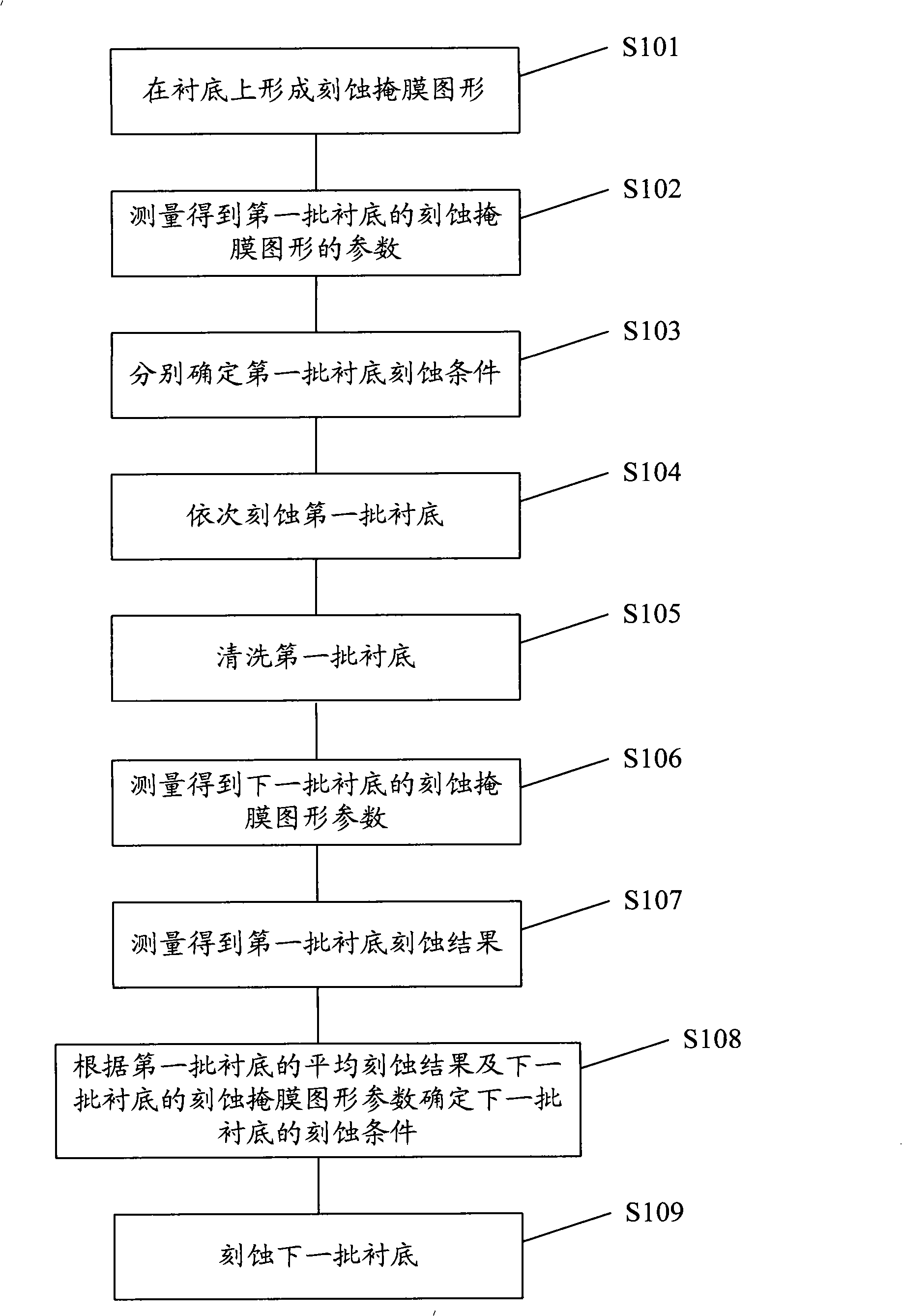

no. 1 example

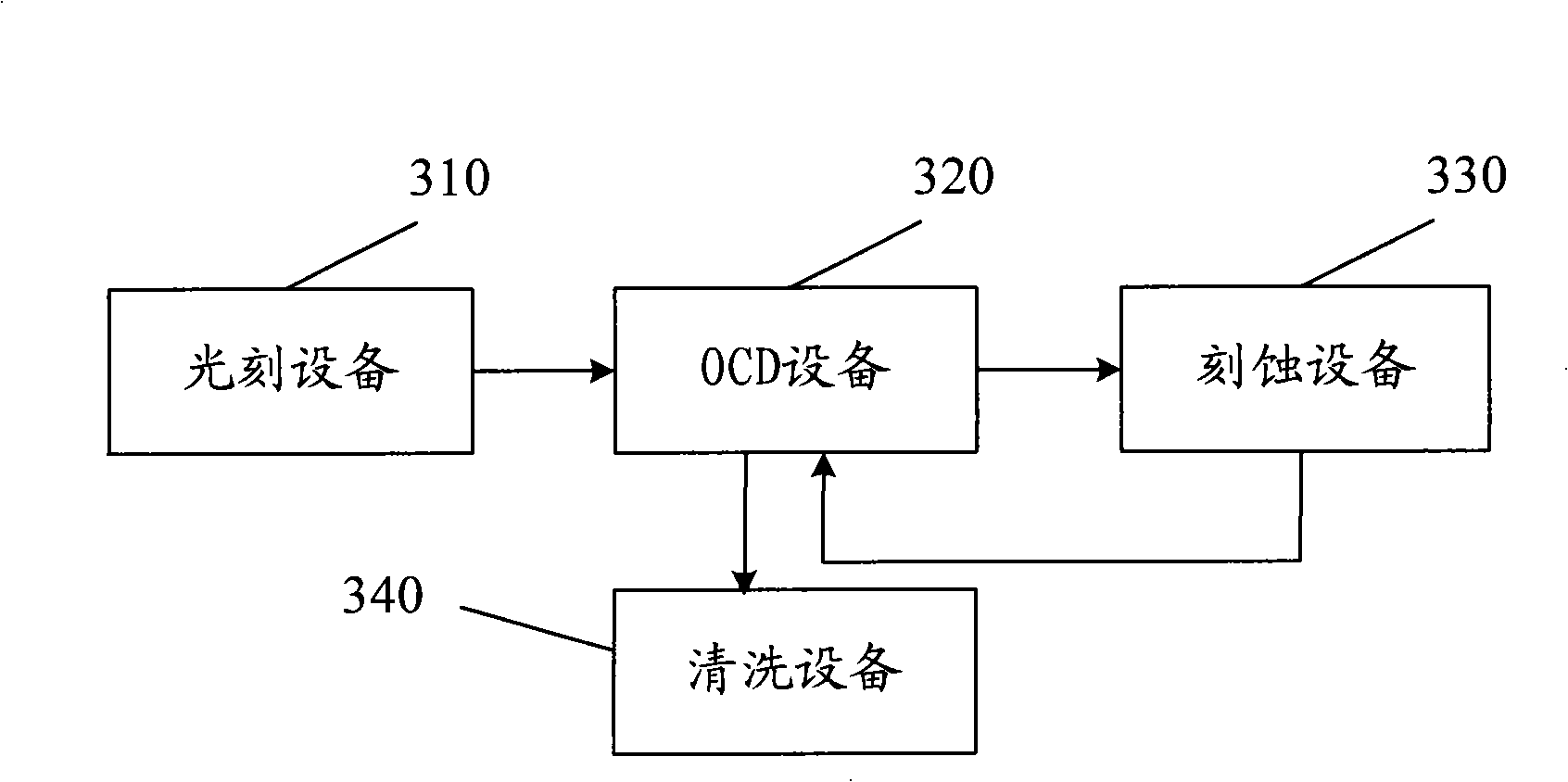

[0075] In actual production, each substrate is processed one by one during the photolithography, detection and etching process steps, and in cleaning, in order to save cost and time, it is usually cleaned in batches. For this reason, in the first embodiment of the present invention, each substrate is measured for the etched pattern CD before cleaning, and after a batch of substrates are etched, they are then uniformly sent to the cleaning device 340 for cleaning, which is the same as The traditional etching method is different (it measures the etched pattern CD after cleaning).

[0076] For this reason, it is necessary to verify that the measurement of the etched pattern CD performed before cleaning can also correctly reflect the state of the etching equipment. Figure 5 It is a comparison diagram of etching depth before / after cleaning in the first embodiment of the present invention, wherein the abscissa is the etching depth measured after cleaning, and the ordinate is the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com