Pump

A technology of pump cavity and outlet flow channel, applied in the direction of pump, pump control, pump components, etc., can solve the problems of pressure drop, operation failure, inability to achieve miniaturization, high efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

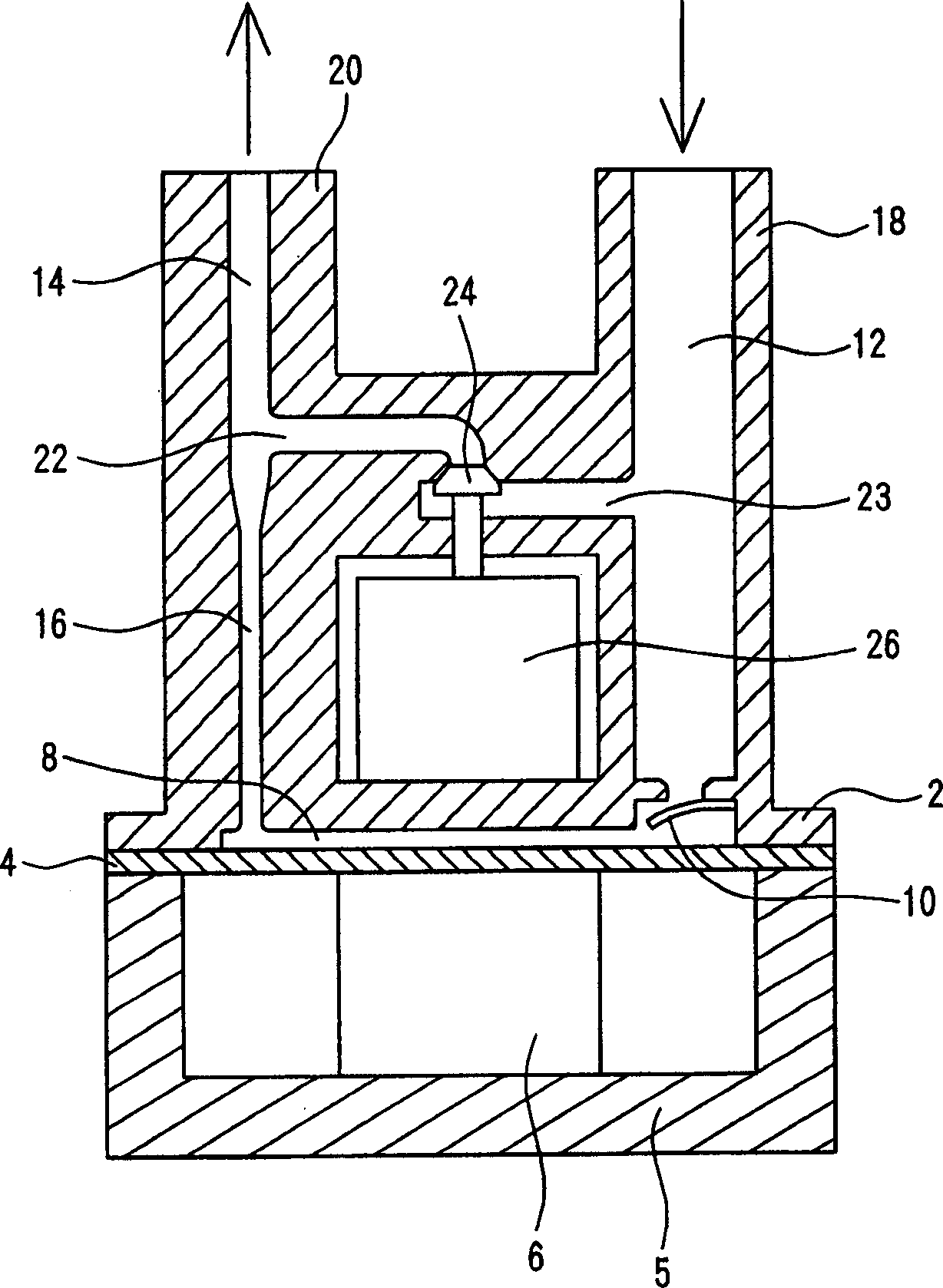

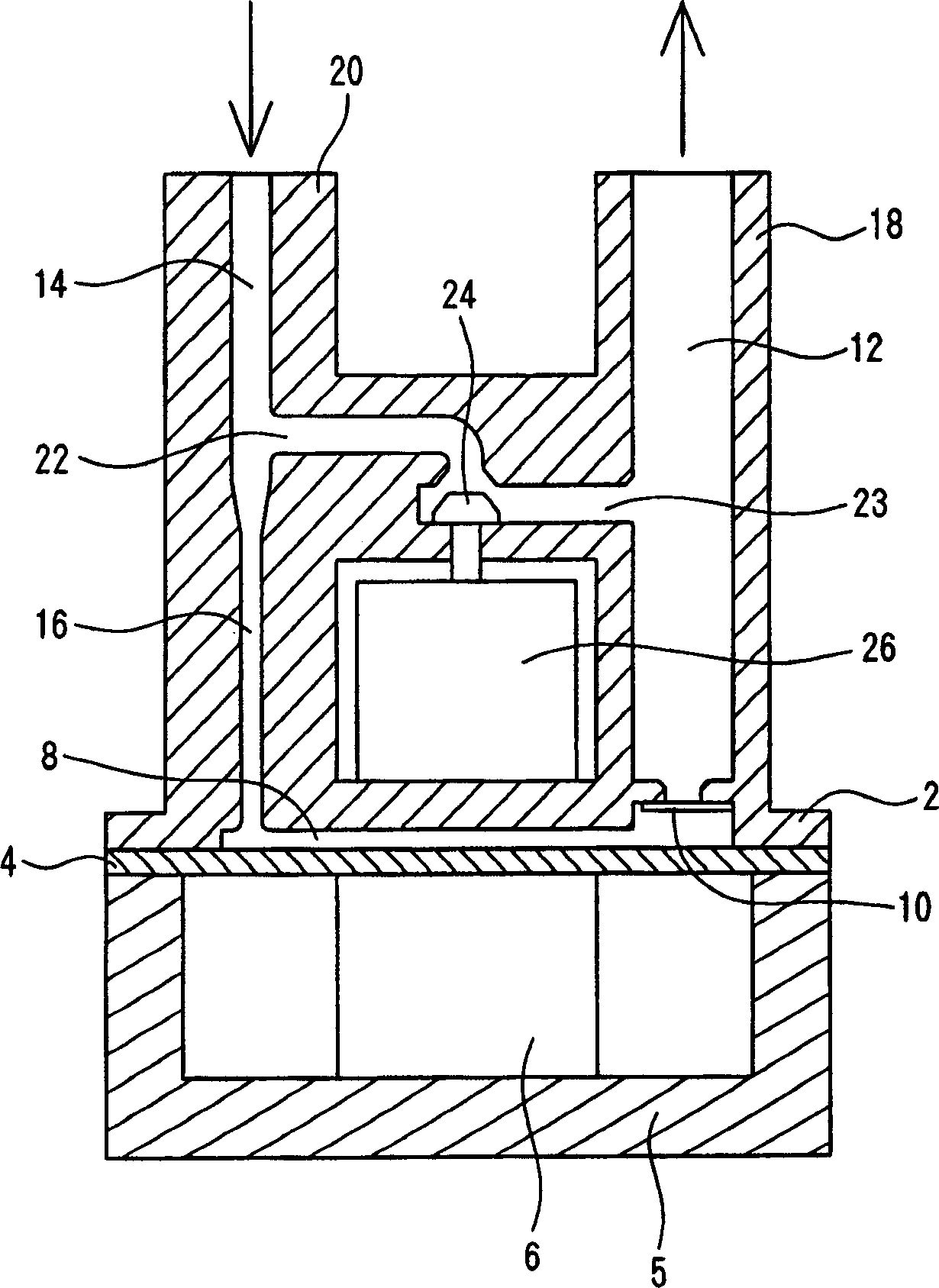

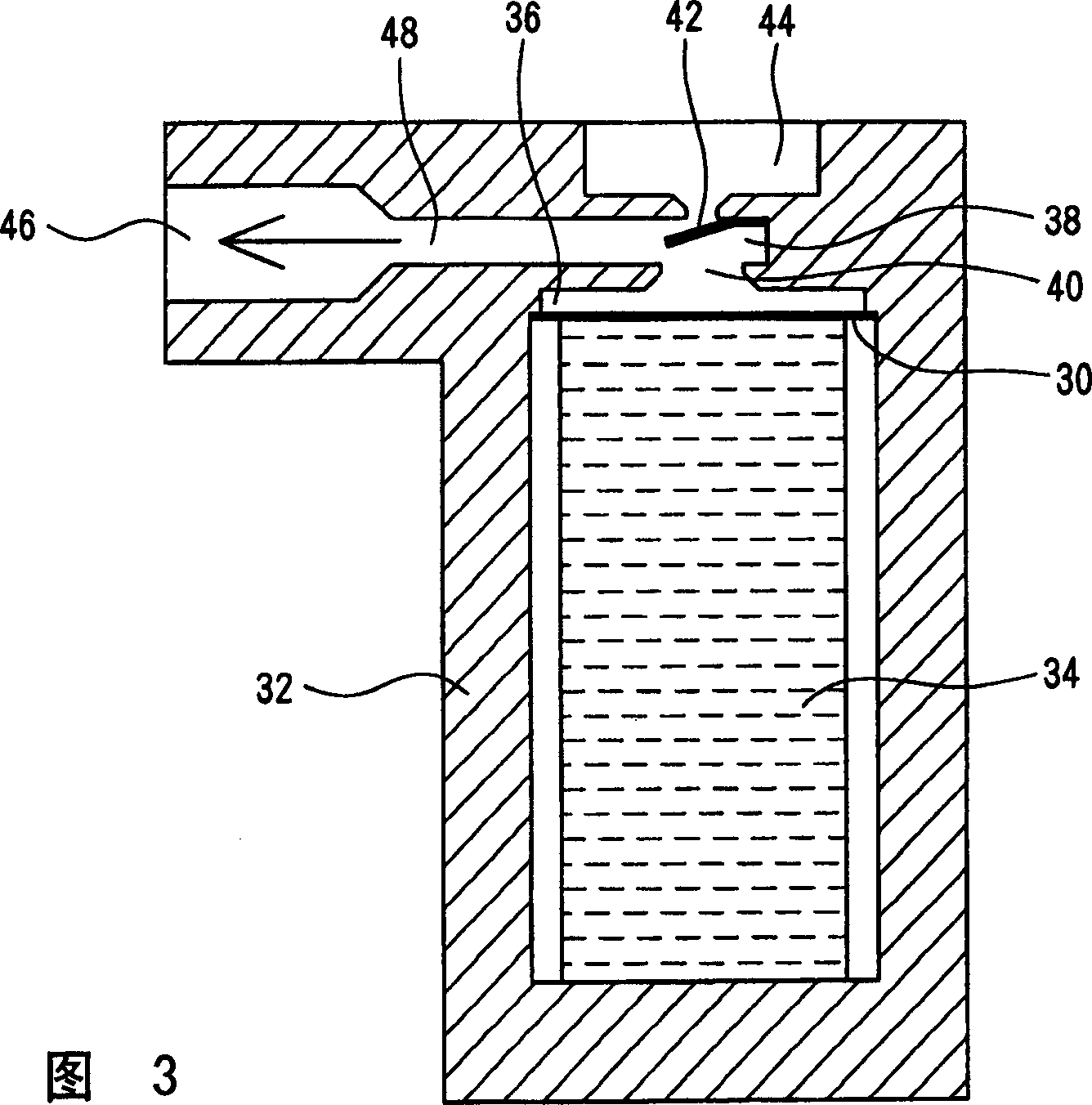

[0035] Embodiments of the pump according to the present invention will be described in detail below with reference to the accompanying drawings.

[0036] (1) The first embodiment

[0037] figure 1 is a longitudinal sectional view of the pump according to the first embodiment of the present invention. exist figure 1 Among them, a circular diaphragm 4 is set at the bottom of the cylindrical housing 2 . The diaphragm 4 is free to deform elastically, while its edges are rigidly supported by the housing 2 . Underneath the diaphragm 4 , a piezoelectric member 6 that expands and contracts in the vertical direction in the figure is installed in its own housing 5 as an actuator for moving the diaphragm 4 .

[0038] The elongated space between the diaphragm 4 and the top wall of the housing 2 forms a pump chamber 8 . An inlet flow channel 12 and an outlet flow channel 14 lead to the pump chamber 8 , wherein a check valve 10 serving as a fluid resistance is installed in the inlet fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com