High-sensitivity frequency domain filtering baffle plate Z-scan method for measuring material nonlinearity

A frequency-domain filtering and high-sensitivity technology, applied in the field of optical nonlinearity of measurement materials, can solve the problems of reducing the measurement signal-to-noise ratio, limiting sensitivity, edge light intensity, etc., reducing measurement costs, solving damage, and measuring sensitivity improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

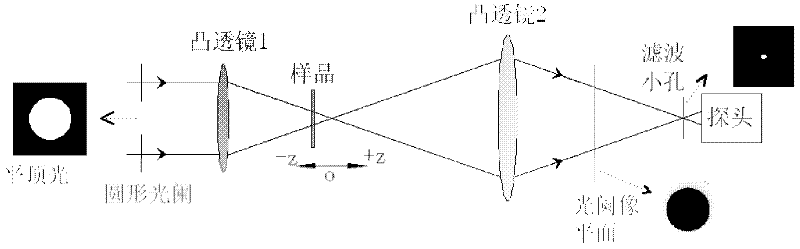

[0024] see figure 1 As shown, a high-sensitivity frequency-domain filter baffle Z-scanning method for measuring material nonlinearity, the optical path is composed of beam splitter, convex lens, small hole, opaque baffle, energy detector, etc.; the pulsed laser is focused on the On sample 9.

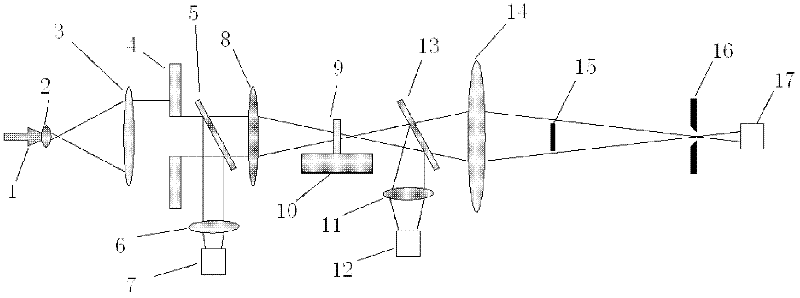

[0025] attached figure 2 It is an experimental device diagram of a method for measuring material nonlinearity by Z-scanning of a high-sensitivity frequency-domain filter baffle in the present invention. The experimental setup can be divided into three parts: beam expander system, measurement system and reference system. The beam expander system consists of a beam expander convex lens 2 and a collimating convex lens 3; the measurement system consists of a circular diaphragm 4, a convex lens 8, a sample one-dimensional translation platform 10, a semi-transparent and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com